Quality and Innovation at CIA Printed Circuit Boards Ltd: A Deep Dive

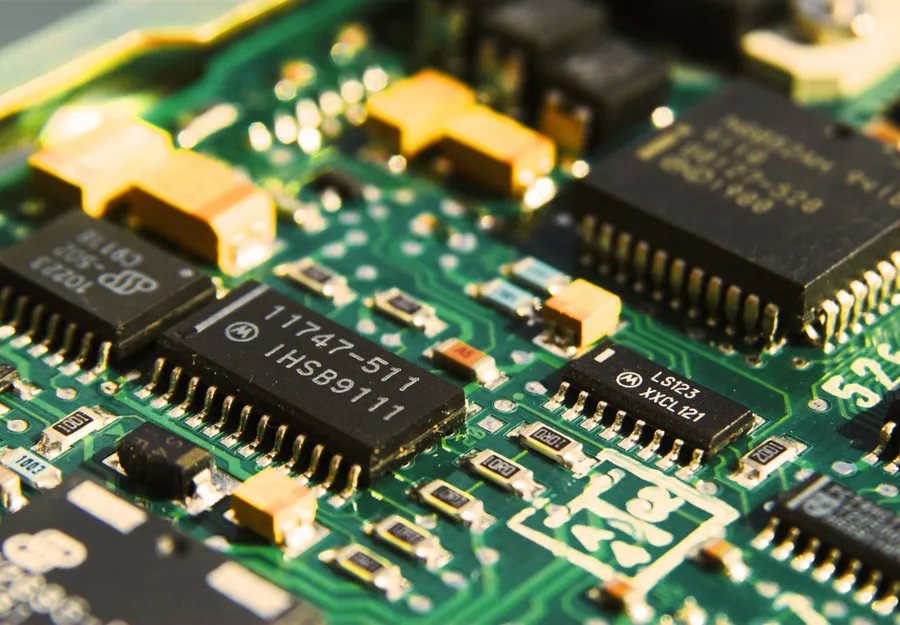

In the ever-evolving world of technology, printed circuit boards (PCBs) remain at the core of countless innovations. CIA Printed Circuit Boards Ltd sets the industry standard with an unwavering dedication to both quality and innovation. This article dives deep into their processes and methodologies to demonstrate how they combine quality with innovation to consistently exceed client expectations.

CIA Printed Circuit Boards Ltd: A Commitment to Quality

CIA Printed Circuit Boards Ltd. operates with a foundational philosophy centered on an unwavering commitment to quality in every facet of printed circuit board (PCB) manufacturing. This dedication is not merely a stated goal but is deeply embedded within their operational procedures, from initial design to final product delivery. Their approach ensures that each PCB meets the high standards required for reliable and consistent performance in diverse applications.

Innovation as a Driving Force in PCB Design

CIA Printed Circuit Boards Ltd distinguishes itself through a relentless pursuit of innovation in PCB design, positioning itself as a leader in the industry. This commitment extends beyond mere adoption of new technologies; it encompasses a culture of continuous improvement and creative problem-solving within their design processes.

CIA's approach to innovation can be categorized into several key areas:

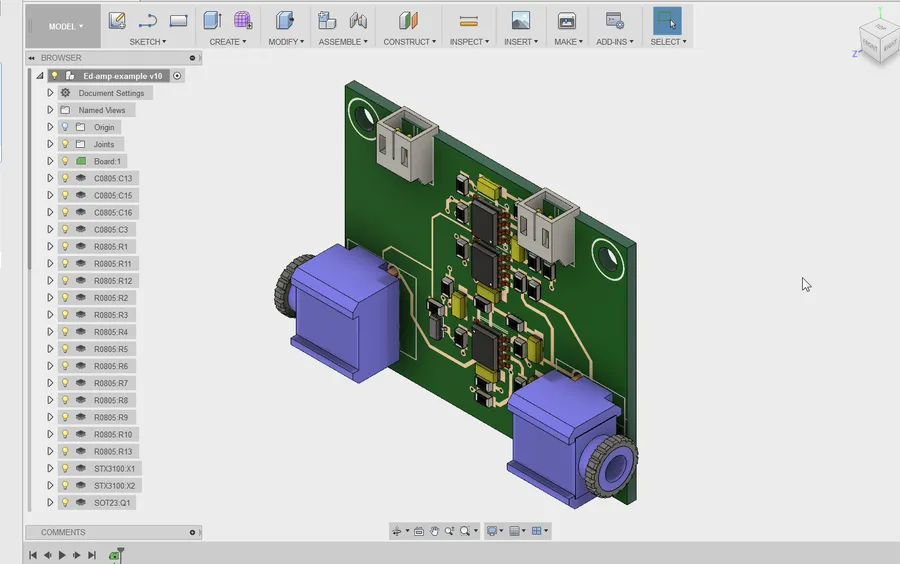

- Advanced Design Software Utilization

CIA employs cutting-edge design software, enabling complex layouts and simulations. This includes tools for signal integrity analysis and thermal management, ensuring designs meet stringent performance criteria. - Materials Research and Development

Continuous research into new materials for PCBs allows CIA to offer solutions that are both high-performing and reliable. This includes exploration of substrates with improved thermal properties and high-frequency performance characteristics. - Design for Manufacturability (DFM)

Innovation at CIA extends to DFM practices, where design processes are streamlined to optimize manufacturing efficiency and reduce production costs, without compromising quality. - Proactive Problem Solving

CIA proactively addresses complex design challenges by utilizing cross-functional teams, ensuring that innovative solutions are developed collaboratively and effectively.

By integrating these innovative strategies into their design processes, CIA Printed Circuit Boards Ltd not only meets but exceeds industry standards, providing clients with state-of-the-art PCB solutions tailored to their specific needs. This focus on innovation ensures that CIA remains at the forefront of PCB design and manufacturing.

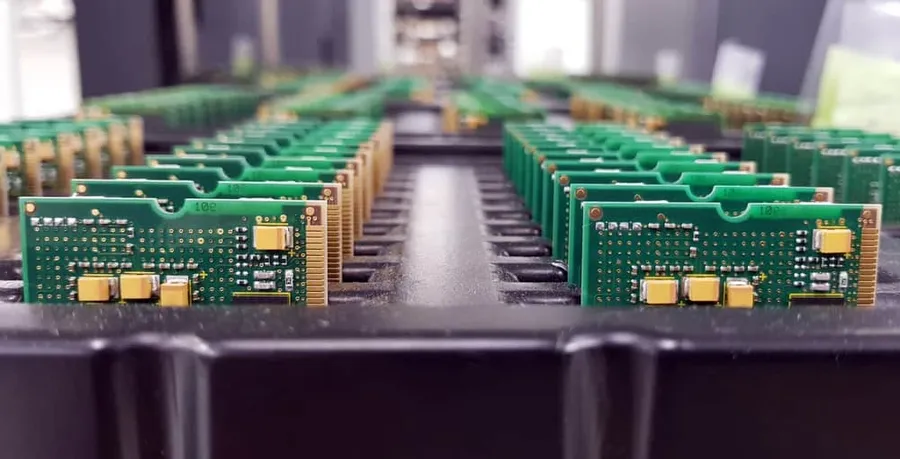

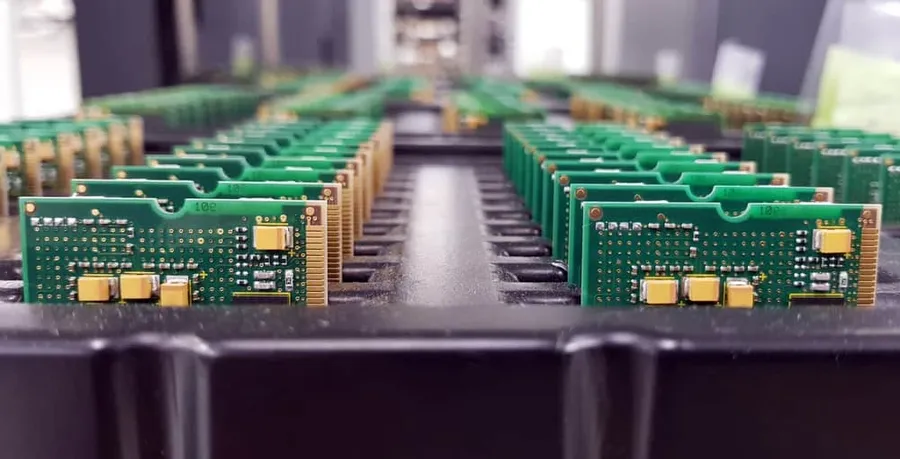

Cutting-Edge Technology for Manufacturing

CIA Printed Circuit Boards Ltd leverages state-of-the-art manufacturing technologies to ensure the highest levels of precision and performance in their PCB production. These technologies are critical in meeting the stringent demands of modern electronics, from high-density interconnects to advanced materials processing.

| Technology | Description | Benefits |

|---|---|---|

| Automated Optical Inspection (AOI) | High-resolution cameras and software to automatically inspect PCBs for defects. | Ensures consistent quality, identifies errors early, reduces manual inspection time, and improves yield. |

| Direct Imaging (DI) | Laser-based technology to expose PCB patterns directly from CAD data. | Enhances precision, reduces processing steps, and improves registration accuracy, crucial for fine-line PCBs. |

| Laser Drilling | High-speed laser systems used to create microvias and precision holes. | Enables high-density interconnects, better thermal management, and reduces production time. |

| Automated Solder Paste Printing | High-precision machines for consistent solder paste application. | Ensures uniform solder distribution, minimizing soldering defects. |

| Multi-Layer Pressing | Advanced presses with controlled temperature and pressure for lamination | Produces strong and reliable multi-layer boards with consistent layer alignment. |

| Surface Mount Technology (SMT) | Automated machines for precise placement of surface mount components | Enables efficient and accurate assembly of complex boards. |

Advanced Prototyping Processes for Faster Development

CIA Printed Circuit Boards Ltd employs advanced prototyping methodologies to significantly accelerate the development and testing phases of new PCB products. These processes are designed to rapidly iterate designs, identify potential issues early, and ensure that the final product meets the required specifications, ultimately reducing time to market and development costs.

The core of CIA Printed Circuit Boards Ltd's rapid prototyping approach involves several key elements:

- Digital Twins

Utilizing digital simulations and virtual models, CIA can assess the performance and reliability of new designs before physical production, allowing for adjustments and optimizations in the virtual realm. - Rapid Fabrication Technologies

CIA Printed Circuit Boards leverages state-of-the-art fabrication technologies including direct imaging, laser drilling, and high-speed milling, to swiftly produce prototype boards with superior precision and reduced turnaround times. - Design For Manufacturing (DFM) Analysis

Proactively evaluates design specifications and ensures that the design is not only functionally sound, but also manufacturable at scale, eliminating potential production hiccups and enhancing efficiency. - Iterative Design and Testing

CIA's development pipeline emphasizes quick feedback loops, where prototypes are rapidly fabricated, rigorously tested, and then refined, ensuring continuous improvement and rapid problem-solving.

The benefits of CIA's advanced prototyping processes include:

- Reduced Time-to-Market

The accelerated pace of prototyping significantly shortens the development cycle, allowing new products to reach the market sooner. - Lower Development Costs

Identifying and resolving design flaws during the prototyping phase, rather than in mass production, drastically cuts down development expenses. - Enhanced Product Quality

Thorough prototyping and testing ensure a higher-quality end product that meets all performance and reliability standards. - Optimized Designs

The rapid iteration process enables fine-tuning of designs based on real-world feedback and testing results, leading to optimized solutions.

Stringent Quality Control at Each Production Stage

CIA Printed Circuit Boards Ltd implements a rigorous, multi-stage quality control system to ensure the consistent delivery of high-quality PCBs, from the initial design phase through to final product delivery. This approach minimizes defects, maximizes reliability, and ultimately ensures customer satisfaction.

- Design Verification

Prior to manufacturing, all PCB designs undergo a comprehensive verification process. This includes checks for design rule compliance, signal integrity analysis, and thermal performance evaluation, ensuring the design meets all specifications and performance criteria before production begins. - Incoming Material Inspection

All raw materials received by CIA Printed Circuit Boards Ltd undergo thorough inspection to ensure they meet the required specifications. This meticulous approach prevents substandard materials from entering the production process, which in turn ensures the final product is of the highest possible standard. - In-Process Quality Checks

Throughout the manufacturing process, CIA Printed Circuit Boards Ltd implements numerous in-process quality checks. These checks include automated optical inspection (AOI) to detect any issues during the etching, plating, and assembly phases. These checks ensure that each manufacturing step is executed correctly. - Automated Optical Inspection (AOI)

CIA Printed Circuit Boards Ltd utilizes AOI systems to rapidly and accurately identify defects in PCB manufacturing. These automated systems enhance consistency, improve the overall efficiency of the production line, and reduce the risk of human error. - Electrical Testing

Every finished PCB undergoes electrical testing to verify its functionality and performance according to the design specifications. This testing process checks for shorts, opens, and resistance values to ensure reliable operation. - Final Visual Inspection

Prior to packaging and shipment, each PCB undergoes a final detailed visual inspection for any cosmetic flaws or defects that might affect overall product quality. This extra layer of quality assurance is critical for maintaining customer confidence in CIA Printed Circuit Boards Ltd. - Statistical Process Control (SPC)

CIA Printed Circuit Boards Ltd uses SPC to monitor and control the manufacturing process. By analyzing production data, adjustments are made to production parameters as needed to prevent deviations from the target performance parameters and guarantee stable product quality.

The Integration of Innovation and Reliability

CIA Printed Circuit Boards Ltd distinguishes itself by seamlessly integrating innovative design practices with stringent reliability protocols, ensuring that each product not only meets but exceeds client expectations for performance and durability. This fusion is not merely a process but a core philosophy driving their manufacturing excellence.

This integration is achieved through several key strategies:

- Concurrent Engineering:

Design and reliability teams collaborate from the initial stages of product development, ensuring that innovative designs are feasible and reliable under specified operational conditions. - Advanced Simulation Tools:

CIA Printed Circuit Boards Ltd uses sophisticated simulation software to model PCB performance under various scenarios, identifying potential reliability risks before production begins. This proactive approach significantly reduces the chances of field failures. - Rigorous Testing Protocols:

Each board is subjected to comprehensive testing including thermal, electrical, and mechanical stress tests. This ensures that every PCB can perform reliably over extended periods of time in real-world conditions. - Data-Driven Process Optimization:

CIA Printed Circuit Boards Ltd utilizes manufacturing data to identify areas where both innovation and reliability can be improved. This constant feedback loop leads to more robust and better performing PCB designs. - Materials Selection:

The choice of materials is carefully considered, balancing the need for innovation with known reliability requirements. This involves staying current with the latest advancements in substrate and component technologies, ensuring that innovative materials are selected only if they meet high reliability standards.

Through these strategies, CIA Printed Circuit Boards Ltd creates a synergy between innovation and reliability, offering clients products that are not only cutting-edge but also dependable. This approach reduces risks, lowers long-term costs, and reinforces customer confidence.

Global Standards and Certifications

CIA Printed Circuit Boards Ltd demonstrates a strong commitment to internationally recognized quality and environmental standards, holding various certifications that underscore their dedication to delivering reliable and high-performance PCBs globally. These certifications are not just badges of honor but represent rigorous processes and consistent quality adherence.

| Standard/Certification | Description | Relevance to CIA PCBs Ltd |

|---|---|---|

| ISO 9001:2015 | International standard for quality management systems, demonstrating consistent product quality and customer satisfaction. | CIA PCBs Ltd implements ISO 9001 standards to ensure that their manufacturing processes, from design to delivery, meet the highest quality benchmarks. |

| ISO 14001:2015 | Specifies requirements for an environmental management system to enhance environmental performance and reduce ecological impact. | CIA PCBs Ltd actively reduces waste, optimizes resource use and minimizes their ecological footprint through the implementation of ISO 14001. |

| IPC Standards | Industry-specific standards covering various aspects of PCB manufacturing, design, and assembly. | CIA PCBs Ltd follows IPC standards rigorously to ensure that their PCB products meet industry-wide benchmarks for performance and reliability. |

| RoHS Compliance | Restriction of Hazardous Substances directive, which restricts the use of certain toxic substances in electrical and electronic equipment. | CIA PCBs Ltd adheres to RoHS directive to ensure that their products are safe for use and compliant with global regulations. |

| UL Certification | Safety standard for components and products, demonstrating rigorous testing for fire and electrical safety. | Specific product certifications may vary; however, adherence to UL safety standards demonstrates commitment to safety and product reliability. |

Frequently Asked Questions About CIA Printed Circuit Boards Ltd's Quality and Innovation

This section addresses common questions regarding CIA Printed Circuit Boards Ltd, focusing on their design processes, quality control measures, and the resulting high-quality products. We also clarify their client consultation process and support services.

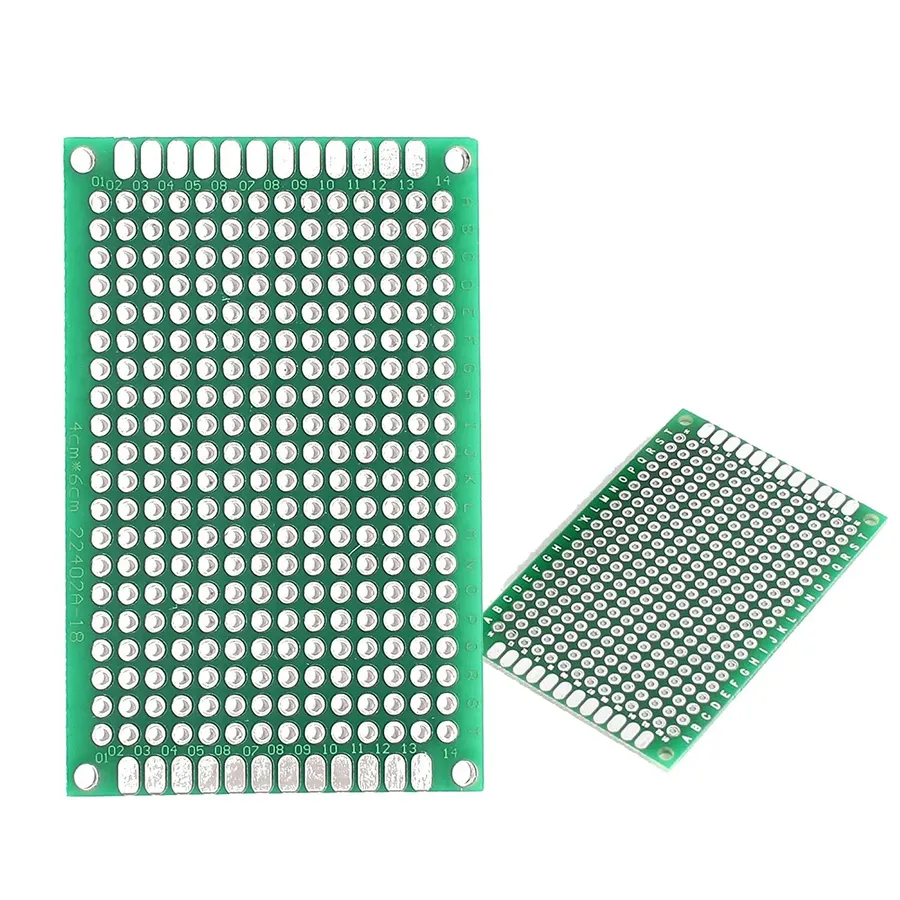

- What types of printed circuit boards does CIA Printed Circuit Boards Ltd manufacture?

CIA Printed Circuit Boards Ltd produces a diverse range of PCBs, including single-layer, double-layer, multilayer, flexible, and rigid-flex boards. They also specialize in PCBs with specific material requirements and high-density interconnect (HDI) designs to meet various industry needs. - How does CIA Printed Circuit Boards Ltd ensure the high quality of its PCBs?

CIA Printed Circuit Boards Ltd maintains rigorous quality control at every stage of production, from initial design to final product. They use advanced inspection tools, including automated optical inspection (AOI) and electrical testing, to guarantee adherence to precise specifications. Further, they are certified to global standards, underscoring their consistent quality management system. - Can CIA Printed Circuit Boards Ltd handle complex PCB designs?

Yes, CIA Printed Circuit Boards Ltd has extensive experience with complex PCB designs, including high-density layouts, impedance-controlled designs, and RF applications. Their skilled design engineers utilize advanced software and techniques to manage design complexities efficiently, ensuring optimal performance and reliability. - What is the typical turnaround time for PCB prototyping at CIA Printed Circuit Boards Ltd?

CIA Printed Circuit Boards Ltd offers accelerated prototyping services with expedited turnaround times. The specific time frame is project dependent, typically ranging from a few days for simple designs to several weeks for highly intricate boards. They prioritize quick turnaround without compromising quality, aiding faster product development cycles. - What client support services does CIA Printed Circuit Boards Ltd provide?

CIA Printed Circuit Boards Ltd offers comprehensive client support, including design for manufacturability (DFM) reviews, technical consultation, and after-sales support. Their dedicated support teams ensure clients are well-guided throughout the entire production process, from initial design concept to final product delivery and continued use. - Does CIA Printed Circuit Boards Ltd adhere to international quality and environmental standards?

Yes, CIA Printed Circuit Boards Ltd adheres to several internationally recognized standards such as ISO 9001 for quality management, and ISO 14001 for environmental management. They are committed to maintaining these high standards, demonstrating their dedication to both product quality and environmental sustainability. - How does CIA Printed Circuit Boards Ltd integrate the latest technology into PCB manufacturing?

CIA Printed Circuit Boards Ltd continuously invests in the most cutting-edge technologies and equipment, like laser direct imaging (LDI), automated assembly lines, and advanced testing methods. By consistently upgrading their production capabilities, they achieve high levels of precision, efficiency, and reliability in their manufacturing processes.

CIA Printed Circuit Boards Ltd exemplifies how quality and innovation can converge to deliver exceptional results. Their constant dedication to improving processes and outcomes make them an ideal partner for any project, ensuring that you get the best in reliability, performance, and advanced technology. By choosing CIA Printed Circuit Boards Ltd, you are selecting a forward-thinking partner committed to achieving excellence.

AnyPCBA

AnyPCBA