Revolutionizing Electronics: Choosing the Right PCB Board Printer

From the complex circuitry of smartphones to the intricate systems in modern vehicles, Printed Circuit Boards (PCBs) are the backbone of modern electronics. A PCB board printer enables rapid prototyping and small-scale production, empowering engineers and hobbyists alike. This article will delve into the various types of PCB board printers, their applications, and what to consider when choosing the right one for your needs, connecting this technology directly to its impact on our daily lives and the advancement of tech.

Understanding PCB Board Printer Technology

PCB board printers utilize a variety of technologies to transfer circuit patterns onto a substrate, each impacting precision, cost, and scalability. These core technologies include inkjet printing, laser etching, and milling, each catering to different prototyping and production needs.

| Technology | Mechanism | Precision | Cost | Scalability | Typical Use Cases |

|---|---|---|---|---|---|

| Inkjet Printing | Deposits conductive ink onto the substrate using printhead nozzles. | Moderate | Relatively Low | Moderate | Rapid prototyping, low-volume production |

| Laser Etching | Uses a laser to selectively remove material from a copper-clad board. | High | Moderate | Moderate | Prototyping, fine-detail circuits |

| Milling | Cuts away unwanted copper using a mechanical router. | Moderate to High | Moderate | Low | Prototyping, educational settings |

Desktop PCB Printers: A Detailed Overview

Desktop PCB printers represent a significant shift in electronics prototyping, enabling engineers and hobbyists to create circuit boards in-house. These devices, exemplified by models like the Voltera V-One and Squink, offer a compact, accessible alternative to traditional fabrication methods for low-volume production and rapid design iteration. They utilize various technologies, often involving inkjet deposition or specialized dispensing, to deposit conductive inks or materials directly onto substrate.

| Feature | Voltera V-One | Squink | Other Desktop Options |

|---|---|---|---|

| Printing Technology | Inkjet deposition | Material extrusion | Varies |

| Max Board Size | 110 x 85 mm | 150 x 150 mm | Varies (typically A4 or smaller) |

| Resolution | ~150 μm trace width | ~200 μm trace width | Dependent on model |

| Material Compatibility | Conductive ink, solder paste | Conductive ink, solder paste, dielectric | Dependent on model |

| Layer Capability | Single or double-sided | Single or double-sided | Typically Single or double-sided |

| Cost | ~$4000 | ~$3500 | ~$2000-5000 |

| Typical Use Cases | Rapid Prototyping, Educational purposes | Prototyping, small batch production | Hobbyist, simple prototype creation |

| Advantages | Ease of use, compact size | Versatile material handling, compact | Low cost, easy to maintain |

| Limitations | Limited board size, slower print speed | Limited resolution, relatively lower print accuracy | Low resolution, material limitation |

DIY PCB Printing Methods: Using Your Inkjet Printer

Creating printed circuit boards (PCBs) at home using an inkjet printer offers a cost-effective alternative to professional fabrication, though it demands careful execution and an understanding of its inherent limitations. This approach leverages readily available technology to enable prototyping and small-scale production of PCBs, making electronics projects more accessible.

This section details the materials, process, safety precautions, and quality considerations when using an inkjet printer for PCB fabrication. While not suitable for high-precision or complex multilayer boards, the method serves as a valuable introduction to PCB design and manufacturing.

- Required Materials:

Essential materials include an inkjet printer, specialized transfer paper (such as glossy photo paper or transparency film), etching solution (ferric chloride or ammonium persulfate), copper-clad board, and appropriate protective gear. - Process Overview:

The process involves designing the PCB layout using CAD software, printing the design onto transfer paper, transferring the toner to the copper board via heat and pressure, etching away the exposed copper, and then cleaning the final board. Each stage needs precision and control to avoid defects. - Safety Precautions:

It is imperative to use protective equipment (gloves, goggles) when handling chemicals and to work in a well-ventilated area. Proper disposal of chemical waste must also be followed to avoid environmental damage. - Quality and Limitations:

Home-printed PCBs have limitations in resolution and layer count compared to professionally manufactured boards. This method is best for simple circuits and prototypes, where high precision isn't critical. The consistency and reliability is dependent on user's experience and the quality of materials used.

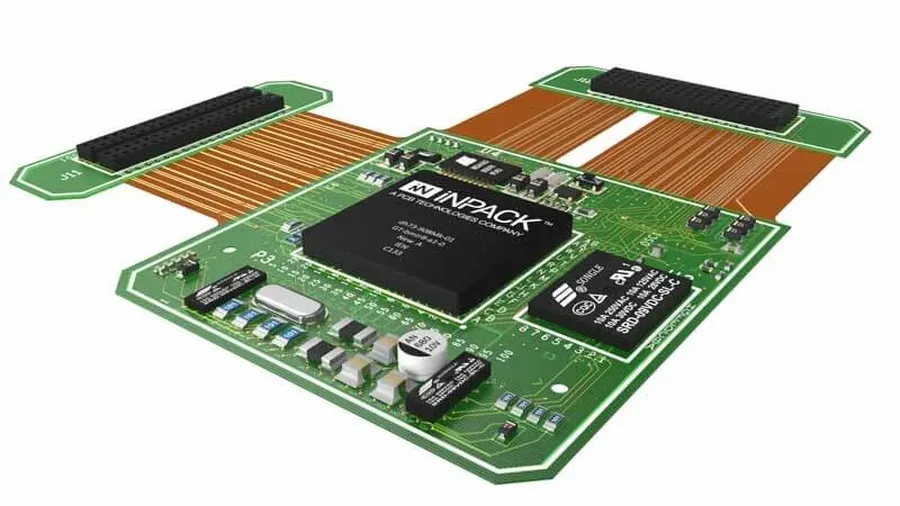

Industrial PCB Printers: Scaling Up Production

Industrial PCB printers represent the pinnacle of printed circuit board manufacturing technology, designed for high-volume, high-precision production. These advanced systems offer significant advantages in speed, accuracy, and automation, making them indispensable for large-scale electronics manufacturing and significantly reducing production costs per unit through economies of scale.

These printers utilize sophisticated technologies like advanced inkjet systems, laser direct imaging (LDI), and high-precision milling, all integrated into automated workflows that facilitate continuous operation. The substantial investment in industrial PCB printers is justified by the need for mass production, enabling businesses to meet the demands of a high-output manufacturing environment.

| Feature | Industrial PCB Printers | Desktop PCB Printers |

|---|---|---|

| Production Volume | High, suitable for mass production | Low to medium, suitable for prototyping and small batches |

| Precision | Very high, capable of fine-line and multi-layer designs | Moderate, may not achieve the same level of detail |

| Speed | Fast, designed for continuous operation | Slower, not designed for high-volume outputs |

| Automation | High, typically features automated material handling and alignment | Lower, often requiring manual setup and intervention |

| Cost | High initial investment, lower per-unit cost at scale | Lower initial cost, but higher per-unit cost for large quantities |

| Footprint | Large, requires dedicated space and infrastructure | Compact, can fit on a workbench or desktop |

| Materials | Supports a wide range of advanced materials and substrates | Limited range of materials |

The operational advantages extend beyond speed, encompassing automated material handling, precise alignment systems, and integrated quality control mechanisms. These features reduce the need for manual intervention, minimize errors, and ensure consistency across large production runs. By significantly reducing production time and increasing accuracy, industrial PCB printers optimize manufacturing workflows for businesses focused on large scale operations.

In summary, industrial PCB printers are indispensable for companies that need mass production capabilities while maintaining high standards of quality and efficiency. The ability to quickly produce complex, multi-layer boards with minimal human involvement positions these printers as a key element of modern electronics manufacturing.

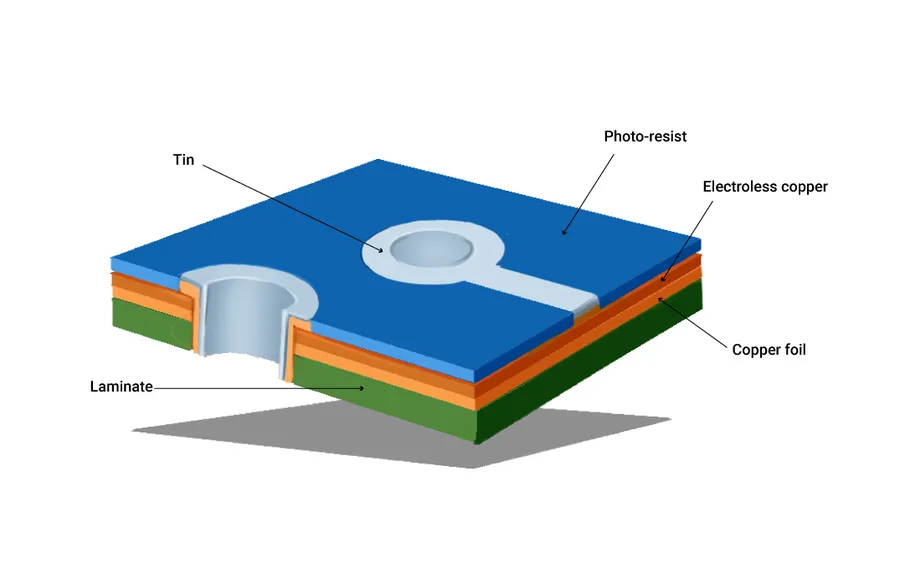

PCB Printer vs. Traditional PCB Manufacturing: A Comparison

Choosing between a PCB printer and traditional PCB manufacturing hinges on project needs, volume, and budget. PCB printers offer rapid prototyping and in-house customization, while traditional methods excel in mass production and complex designs. This section provides a detailed comparison to guide your decision-making process.

| Feature | PCB Printer | Traditional PCB Manufacturing |

|---|---|---|

| Cost | Lower initial investment for small-scale prototyping; higher per-board cost for large volumes | Higher initial setup costs; lower per-board cost for mass production |

| Turnaround Time | Very fast; boards can be produced in hours or days | Longer lead times; often requires weeks |

| Flexibility & Customization | High flexibility for design changes and customization | Less flexible; design changes often lead to delays and increased costs |

| Complexity | Suitable for simple to moderately complex designs; limited by printer capabilities | Capable of handling complex, multi-layered designs and specialized materials |

| Precision | Dependent on printer's resolution; may not match photolithography precision | High precision and accuracy through photolithography and etching |

| Material Compatibility | Limited to compatible inks and substrates; may not support advanced materials | Wider range of material choices, including FR4, flexible substrates, and high-performance laminates |

| Scalability | Less efficient for large-scale production; best for prototyping and small batches | Optimized for mass production; cost-effective for large volumes |

| In-House vs. Outsourcing | Provides in-house control over the production process | Typically requires outsourcing, which can impact project timelines and security |

| Environmental Impact | Reduced waste and chemical usage compared to traditional processes | Potentially high environmental impact from chemical etching and processing |

Choosing the Right PCB Board Printer: Key Considerations

Selecting the appropriate PCB board printer requires careful evaluation of several critical factors to ensure the chosen device aligns with specific project requirements and budgetary constraints. This section provides a structured approach to navigate the decision-making process, acting as a practical buyer's guide.

- Budgetary Constraints

Establish a clear budget range. PCB printers vary significantly in price, from entry-level desktop models to high-end industrial systems. Consider not only the initial investment but also the ongoing costs for consumables (inks, substrates, etc.) and maintenance. - Project Complexity

Evaluate the complexity of the circuits you intend to produce. Single-layer boards with large traces might be well-suited for simpler printers, while multilayer PCBs with fine pitch components will necessitate more advanced equipment capable of higher resolution and registration accuracy. - Material Compatibility

Confirm that the printer supports the specific substrate materials required for your applications. Considerations include the material's thickness, flexibility, and thermal properties. Some printers may be limited to certain types of conductive inks or substrates, affecting the final performance of the printed boards. - Precision and Resolution

Assess the required precision and resolution needed for your PCBs. The printer's resolution determines the smallest feature size it can reliably produce. Applications requiring fine lines and high-density components demand higher resolution capabilities, which often correlate with higher equipment costs. - Learning Curve and Ease of Use

Consider the operational complexity of the printer. Some PCB printers are more user-friendly with intuitive software and straightforward setup procedures, while others may require specialized technical expertise. Evaluate the learning curve associated with the device to ensure your team can effectively operate and maintain it. - Throughput and Speed

Determine the required production speed and throughput. Desktop printers are suitable for prototyping and small batch production, while industrial-grade machines are designed for high-volume manufacturing. The printer's speed directly impacts how efficiently your production needs can be met, with faster printers often incurring higher operating costs. - Maintenance and Support

Investigate the manufacturer's reputation for reliability, availability of support, and ease of acquiring replacement parts or consumables. This will reduce downtime and ensure sustained productivity. Comprehensive support services and readily available parts reduce long-term operational costs.

Frequently Asked Questions About PCB Board Printers

This section addresses common questions regarding PCB board printers, offering concise and authoritative answers to help clarify user doubts and provide expert insights into the technology.

- What is the role of PCB in a printer?

The term 'PCB' in the context of a printer generally refers to the Printed Circuit Board within the printer itself, not the output material. This board houses the electronic components, facilitating control and operation of the printer. This differs from the target of a 'PCB Board Printer' which is a machine designed to create circuit boards. - How does a PCB board printer work?

PCB board printers utilize various technologies such as inkjet printing, laser etching, or milling to create circuit patterns on a substrate. These methods involve depositing conductive materials or removing substrate to form the desired circuitry. - Can a standard 3D printer be used to print a PCB board?

While some 3D printers are adapted to create PCBs, it's not their primary purpose. Standard 3D printers typically lack the precision and material handling needed for complex circuitry. Specialized conductive materials and precise layering are needed to make a PCB, which are usually not supported in common 3D printers. - Why are PCBs generally expensive?

The cost of PCBs can be attributed to several factors, including the need for precision manufacturing, specialized materials (such as copper clad laminates), and the often complex and multi-layered designs. High-end PCBs also undergo rigorous testing and quality control, further contributing to their price. - What are the typical costs associated with owning a PCB printer?

The cost of PCB printers can vary widely based on their capabilities. Desktop models can range from a few thousand dollars to upwards of ten thousand, while industrial-grade printers can cost hundreds of thousands of dollars. Additionally, operational costs, like inks, substrates, and maintenance should also be factored in. - Can I use my home inkjet printer to print PCBs?

Yes, it is possible to create basic PCBs using a modified home inkjet printer and special transfer paper. However, this method has significant limitations in terms of accuracy and durability. It's mostly suitable for single-layer boards, and the resulting PCBs are not as reliable as professionally made ones. - What level of accuracy can I expect from a desktop PCB printer?

Desktop PCB printers vary, however, the best can produce resolution of a 100um, it is vital to check the individual specifications to understand the precision. However, this may not be suitable for complex multi-layered designs that would benefit from a professional solution.

Future Trends in PCB Printing Technology

The landscape of PCB printing is poised for significant transformation, driven by emerging technologies like additive manufacturing, advancements in conductive inks, and the integration of novel materials. These innovations are not only enhancing the capabilities of PCB printers but also paving the way for more efficient, sustainable, and customized electronics manufacturing processes.

- Additive Manufacturing Integration

The integration of additive manufacturing, also known as 3D printing, is revolutionizing PCB production. This technology enables the creation of complex three-dimensional circuit structures, moving beyond the limitations of traditional 2D printing. Additive manufacturing offers rapid prototyping capabilities, reduced material waste, and the potential for customized PCB designs, significantly reducing time-to-market. - Advanced Conductive Inks

New conductive inks with enhanced electrical properties and improved adhesion are being developed. These inks, often based on nanomaterials, allow for finer and more precise printing, enabling higher-density circuits. This advancement is particularly important for miniaturized electronics and high-frequency applications. Furthermore, research into flexible and stretchable inks is opening doors for wearable and flexible electronics. - Novel Material Utilization

Beyond traditional substrate materials, there is a growing interest in using advanced polymers, ceramics, and composites. These materials offer tailored properties, such as high temperature resistance, mechanical flexibility, and improved electrical insulation, allowing for PCBs to operate in more extreme environments. This expansion of material options provides designers more flexibility. - AI-Driven Design and Optimization

Artificial intelligence (AI) is increasingly being used to optimize PCB designs for enhanced performance and manufacturability. AI algorithms can automate the design process, predict potential manufacturing issues, and optimize routing for better electrical performance. This leads to faster design cycles and higher-quality, more efficient PCBs. - Sustainable Manufacturing Practices

Sustainability is becoming a critical focus, with the development of eco-friendly printing processes and materials. Researchers are exploring biodegradable and recyclable substrates, as well as low-energy printing methods. These advancements are aimed at reducing the environmental impact of PCB manufacturing.

These future trends are poised to disrupt traditional PCB manufacturing, enabling a new era of rapid prototyping, customized designs, and more sustainable production methods. This will lead to innovative solutions across numerous industries, from consumer electronics to aerospace and medical devices, reducing cost, and empowering innovation.

The evolution of the PCB board printer is significantly reshaping how we approach electronics design and production, offering everything from rapid prototyping capabilities to streamlined manufacturing. Whether you are an engineer, hobbyist, or a company seeking efficient solutions, understanding the various types, applications, and trends in PCB printing is crucial. As technology advances, so too will the accessibility and affordability of PCB board printers, making them an indispensable tool in the electronics field. Choosing the right PCB board printer is essential for the success of your projects, providing efficiency and precision from start to finish.

AnyPCBA

AnyPCBA