Seamless PCB Order Online: A Comprehensive Guide for Every Need

In today’s fast-paced electronics industry, ordering printed circuit boards (PCBs) online has become a vital part of product development and manufacturing. Whether you're an engineer designing the next groundbreaking gadget, or a hobbyist working on a DIY project, the ability to quickly and easily order PCBs online is essential. This article explores the landscape of online PCB ordering, providing you with a comprehensive guide to navigate the process and ensure you get the best quality for your printed circuit board order online.

Understanding Your PCB Needs

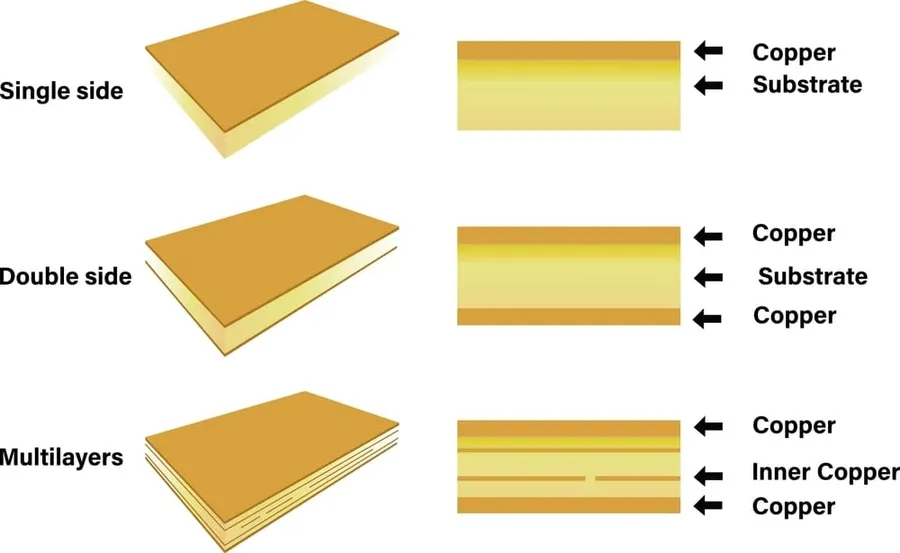

Before initiating a printed circuit board order online, a thorough understanding of your specific requirements is paramount; this directly influences cost, lead time, and the suitability of the final product. Key considerations involve the PCB type (single-layer, multi-layer, flexible), material selection, physical dimensions, board thickness, and the required production quantity.

| Consideration | Description | Impact |

|---|---|---|

| PCB Type | Single-layer, multi-layer, flexible, rigid-flex, etc. | Complexity, cost, application suitability |

| Material | FR-4, aluminum, polyimide, etc. | Performance (e.g., thermal, electrical), cost |

| Size | Length, width, area | Cost, panelization, manufacturing process |

| Thickness | Standard (1.6mm) or custom | Impedance control, mechanical stability, application |

| Quantity | Number of boards | Unit price, production efficiency |

Choosing the Right PCB Manufacturer Online

Selecting the appropriate PCB manufacturer is crucial for ensuring the success of your project. The online landscape offers numerous options, each with varying capabilities, pricing structures, lead times, and customer feedback. A thorough evaluation process is essential to secure a manufacturer that meets your specific requirements and delivers high-quality printed circuit boards.

The process of choosing the right manufacturer for your printed circuit board order online involves several key considerations. By focusing on a manufacturer's specific capabilities, cost-effectiveness, production timelines, user experience, and quality control measures, you can mitigate risks and create a more streamlined manufacturing process.

| Factor | Description | Considerations |

|---|---|---|

| Capabilities | Technical expertise and manufacturing capabilities | Review the specific board requirements (single-layer, multi-layer, impedance control, etc.), material capabilities (FR-4, Aluminum, etc.), and tolerances. |

| Pricing | Cost of PCB production and any additional charges | Compare quotes from multiple suppliers and assess the price relative to quality. Pay attention to tooling costs, expedite fees and quantity discounts. Be wary of unusually low prices, which can indicate lower quality. |

| Lead Time | Time required to manufacture and deliver the PCBs | Align the manufacturer's lead time with your project timeline. Check for expedited production options if faster turnaround is needed. |

| User Experience | Ease of use of the manufacturer's online platform | The platform should allow easy uploading of Gerber files, provide accurate and clear specifications selection, instant quoting, and secure checkout. |

| Customer Reviews | Feedback from previous customers regarding their experience with the manufacturer | Look for unbiased reviews on third-party sites. Check for consistent positive comments and ratings in areas like quality, communication, and reliability. |

| Quality Control | The processes that the manufacturer follows to ensure quality and standards | Look for a manufacturer with well documented quality control processes, including testing procedures such as electrical testing, visual inspections, and impedance measurements. |

Preparing Your PCB Design Files (Gerber Files)

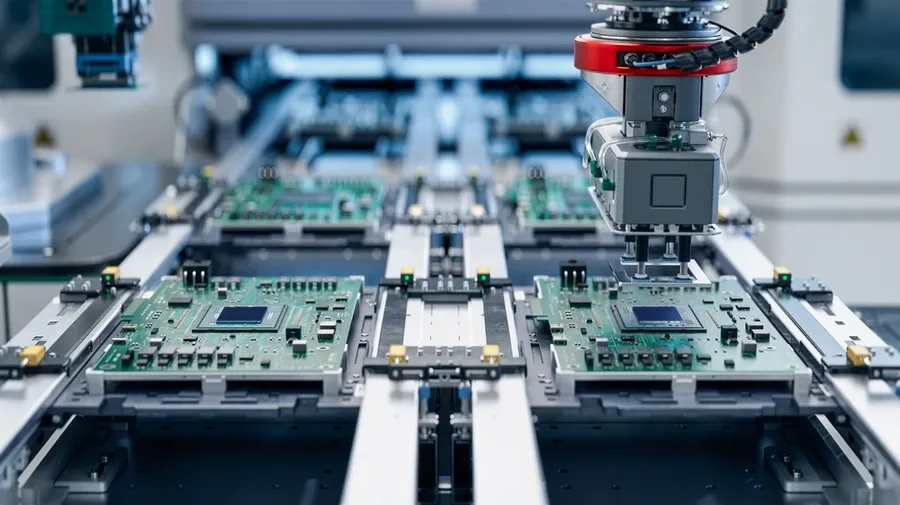

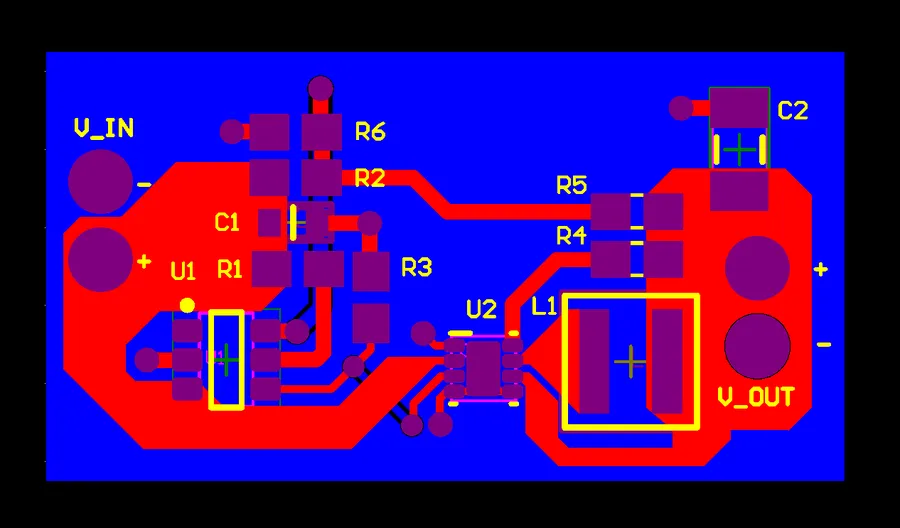

Gerber files are the industry-standard format for communicating PCB design data to manufacturers. These files are essential for accurate fabrication, encompassing all necessary information for each layer of your board, including copper traces, solder mask, silkscreen, drill locations, and board outlines. Generating and verifying the accuracy of these files is a critical step in ensuring a smooth and successful printed circuit board order online.

- Essential Gerber Files for PCB Manufacturing

A complete set of Gerber files typically includes: Copper layers (top and bottom, and any internal layers), Solder mask layers (top and bottom), Silkscreen layers (top and bottom), Drill files (NC drill file), and Board outline file. Each layer is crucial for specific fabrication processes. - Ensuring Accuracy in Gerber File Generation

Carefully verify that the files are generated correctly from your PCB design software. Make sure that all design elements are included and accurately represented, without any errors or omissions. Incorrectly generated files are a common cause of delays and errors in PCB manufacturing. - Common Pitfalls in Gerber File Preparation

Failing to include all necessary layers, inaccurately defined drill holes, incorrect scaling, and overlapping features can lead to significant issues during manufacturing. Proper file verification, ideally by both the designer and the online manufacturer's automated system, is essential to prevent these problems.

| Gerber File Type | Description | File Extension |

|---|---|---|

| Copper Layer | Defines the conductive traces and pads on each layer of the board. | *.GTL (Top), *.GBL (Bottom), *.G1, *.G2, etc. (Internal layers) |

| Solder Mask Layer | Defines the areas where solder mask is applied, preventing solder bridging. | *.GTS (Top), *.GBS (Bottom) |

| Silkscreen Layer | Defines the text and component outlines printed on the board. | *.GTO (Top), *.GBO (Bottom) |

| Drill File | Defines the locations and sizes of all drilled holes. | *.DRL, *.TXT |

| Board Outline | Defines the physical shape and dimensions of the board. | *.GKO or sometimes included in a copper layer file |

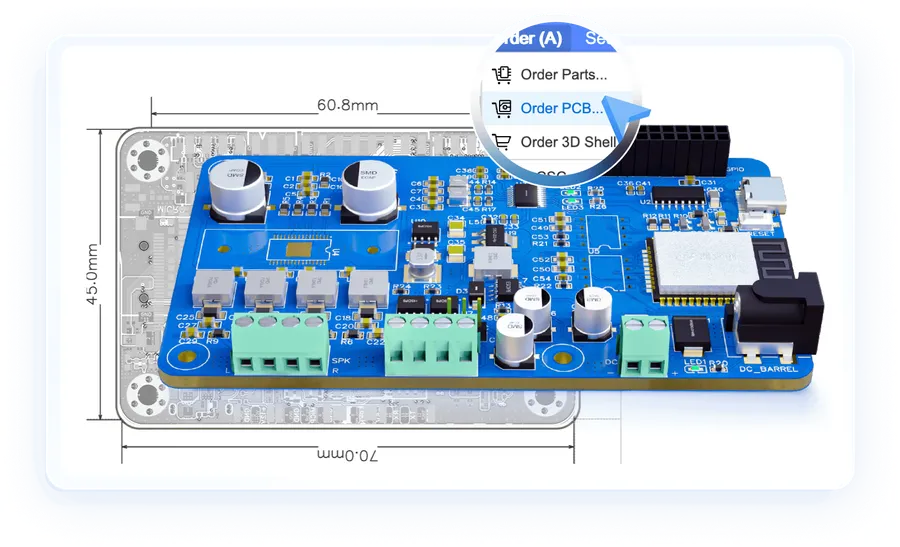

Navigating Online PCB Ordering Platforms

Successfully navigating online PCB ordering platforms is crucial for a smooth and efficient manufacturing process. These platforms are designed to streamline the process of converting your design files into physical printed circuit boards. The core interaction involves uploading your Gerber files, specifying your required board parameters, and finalizing your order with appropriate shipping and payment selections. Many platforms offer instant quoting features, enabling real-time price comparisons and adjustments to specifications to meet both budget and design needs. Additionally, ensuring secure transactions during payment is a critical step in the online ordering process.

- Gerber File Upload

The primary step involves uploading your Gerber files, which are standard PCB design files, to the platform. These files contain all the necessary information to manufacture your board. - Specification Selection

You will be prompted to select various board specifications. This includes dimensions, layers, materials, thickness, solder mask color, silkscreen options, and copper weight. Precise selection will directly affect cost and quality. - Instant Online Quoting

Many online platforms offer instant quoting features. This allows you to see a price estimate based on the specifications you've chosen. You can adjust specs to see how costs change in real-time. - Shipping and Payment

After confirming your order, the platform will prompt you to select your preferred shipping method and process the payment. Make sure the website uses secure payment processing to protect your financial information.

| Feature | Description |

|---|---|

| File Upload | Uploading Gerber files (RS-274X format) for manufacturing. |

| Specification Selection | Selecting materials, dimensions, layers, thickness, and finishes. |

| Instant Quote | Real-time price calculation based on specs. |

| Secure Checkout | Safe and protected payment processing. |

| Order Tracking | Monitoring the production and delivery status. |

Cost Factors in Online PCB Orders

The cost of a printed circuit board order online is a multifaceted issue, influenced by a range of variables. Understanding these factors is crucial for budgeting and making informed decisions. Primary drivers include the physical dimensions of the board, its design complexity, the volume of boards required, the materials used, and the turnaround time requested.

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Board Size | The physical dimensions of the PCB. | Larger boards generally cost more due to increased material usage. |

| Complexity | The number of layers, trace density, and intricate design elements. | More complex designs, particularly multi-layer boards, increase manufacturing costs. |

| Quantity | The number of PCBs in the order. | Larger quantities often benefit from economies of scale, reducing the cost per unit. |

| Materials | The specific materials used in PCB construction, such as FR-4, aluminum, or flexible substrates. | Specialized materials may significantly increase costs. |

| Turnaround Time | The time required to manufacture and deliver the boards. | Faster turnaround times (expedited service) come at a premium. |

| Surface Finish | The type of surface finish applied (e.g., HASL, ENIG). | Some finishes like ENIG are more expensive due to their enhanced performance and durability. |

| Copper Thickness | The thickness of the copper layers. | Thicker copper can increase the cost but may be required for high-current applications. |

| Solder Mask and Silkscreen Colors | The colors of the solder mask and silkscreen. | Non-standard or multiple colors may result in additional charges. |

When comparing pricing across different manufacturers, it’s important to be cautious of extremely low quotes. These may suggest compromises in material quality, production processes, or testing procedures. A balance must be found between cost and reliability, as the long-term performance and durability of the boards directly affect the final product’s quality and lifespan.

Turnaround Time and Delivery

The lead time for printed circuit board (PCB) fabrication is a critical factor that directly influences project timelines. Turnaround times can significantly vary, ranging from a few hours to several weeks, depending on a combination of factors including the manufacturer's operational capacity, the complexity of the PCB design, and the type of service chosen (standard or expedited).

It's imperative to carefully assess your project's timeline and align it with the anticipated lead time to prevent any scheduling conflicts. A thorough examination of the delivery and shipping options offered is also necessary before finalizing your printed circuit board order online.

| Factor | Impact on Turnaround Time | Considerations |

|---|---|---|

| Manufacturer's Processes | Varies widely depending on production capacity and efficiency. | Research manufacturer's typical lead times and production schedules. |

| PCB Complexity | More complex designs (multi-layer, high density) require longer fabrication times. | Factor in additional time for intricate designs and special features. |

| Service Type | Expedited services prioritize production, reducing lead times at a higher cost. | Weigh the cost of expedited service against project timeline constraints. |

| Order Quantity | Larger orders may require more time to produce | Consider how volume affects lead time in your project |

| Shipping Options | Different shipping methods have varying delivery speeds. | Select a shipping method that fits your timeframe |

- Standard vs. Expedited Service

Standard service offers a cost-effective solution with longer lead times, while expedited services prioritize your order for faster turnaround at a premium. - Shipping Timeframes

Different shipping carriers and methods (e.g., express, standard) will have varied delivery times. Select the method that suits your project timeline requirements. - Tracking and Communication

Reputable manufacturers offer tracking information and timely communication updates regarding the status of your order, allowing for better planning.

Quality Assurance and Testing

Ensuring the quality of printed circuit boards (PCBs) is paramount, especially when ordering online. Reputable manufacturers implement rigorous testing and inspection processes to guarantee that the final products meet stringent industry standards and the customer's specific requirements. These processes are crucial in avoiding costly issues and project delays down the line.

- Electrical Testing

Electrical tests are fundamental to verifying the functionality of PCBs. These tests typically include continuity tests, which confirm that circuits are complete, and isolation tests, which ensure that separate circuits are not shorted. Advanced testing may also involve signal integrity analysis to ensure proper signal transmission through the board. This is very crucial in ensuring proper signal transmission and overall reliability of the PCB. - Visual Inspection

Visual inspection is a critical step in identifying manufacturing defects such as scratches, misalignments, or solder issues. This process typically involves both manual inspections by trained personnel and automated optical inspection (AOI) systems that utilize high-resolution cameras to scan for anomalies. The combination of manual and automated processes ensures that all boards are thoroughly checked. - Impedance Measurement

For high-speed circuits, impedance control is essential to maintain signal integrity. Impedance measurements verify that the board’s impedance characteristics meet the design specifications. This is often done with Time Domain Reflectometry (TDR) equipment, which is used to measure impedance at specific points. Incorrect impedance can cause signal reflections, which degrade performance. - Microsection Analysis

Microsection analysis is a more destructive testing method used to evaluate the internal structure of the PCB, such as plating thickness, layer registration, and via quality. It involves cutting the board and examining it under a microscope. While not performed on every board, it’s a vital quality check for manufacturers, especially when setting up new processes or validating new designs. - Functional Testing

Functional testing, performed on sample boards, involves running the PCB through its intended operational environment. This ensures that the PCB performs to the specifications of the design before it is released for mass production. Functional testing is often the final stage of the quality assurance and includes testing all aspects of the intended functionality of the PCB and allows engineers to catch errors not caught in earlier tests.

Frequently Asked Questions About Ordering PCBs Online

Ordering printed circuit boards online often raises several questions. This section addresses the most common inquiries to ensure a smooth and informed ordering process.

- How do I order a PCB using Gerber files?

Most online PCB manufacturers utilize a streamlined process where you upload your Gerber files directly through their platform. These files are the industry standard for PCB design, encompassing all necessary layers like copper, solder mask, and silkscreen, along with drill and outline data. Ensure that your files adhere to the specific requirements and formats stated by the manufacturer to prevent delays and inaccuracies. - What factors influence the cost of a printed circuit board?

The cost of a PCB is influenced by multiple parameters, including the board's size and complexity, the materials used (such as FR-4, aluminum, or polyimide), the number of layers, the required quantity, and the chosen manufacturing and delivery timeline. Added complexities like impedance control, blind and buried vias, or specific surface finishes will also increase the cost. Always clarify the cost breakdown with the manufacturer to avoid unexpected expenses. - Which PCB company is the best for my specific needs?

Determining the 'best' PCB company is highly subjective and depends heavily on your specific project requirements. Some manufacturers excel in rapid prototyping with quick turnaround times, while others may be better suited for large volume orders. Some specialize in specific materials or technologies, like RF or high-frequency PCBs. Conduct thorough research and check customer reviews, technical capabilities, and pricing to find the manufacturer that fits your project's unique constraints. - Is it cost-effective to replace a PCB or should I attempt repairs?

The decision to replace or repair a PCB hinges on the extent of the damage, the cost of repairs versus the cost of a new board, and the technical complexity involved. Simple fixes like soldering a loose connection can be attempted if you have sufficient technical expertise. However, for complex damages involving internal layers or critical components, replacement might be more cost-effective and reliable in the long run. Always evaluate the cost of repair, including time and materials, against the cost of replacement. - What is the typical turnaround time for an online PCB order?

Turnaround times can vary greatly depending on the complexity of the PCB design, the manufacturing capacity of the selected provider, and the type of service chosen (standard or expedited). Simple, single-layer designs may only take a few days, while more complex multi-layer designs with specific requirements may take several weeks. Always check the manufacturer's quoted turnaround time and delivery estimates and factor this into your project's overall timeline. - How can I ensure the quality of the PCBs I order online?

To ensure quality, select a reputable manufacturer with a well-documented quality assurance process. Check for certifications, customer testimonials, and ask about their testing methodologies. Request samples or a prototype run if possible, especially for larger orders. Look for manufacturers that offer electrical testing, visual inspections, and impedance checks, and always verify that they comply with industry standards. A thorough review of their documentation and process will offer the needed level of quality assurance. - What should I do if I have questions or concerns during the ordering process?

If you encounter any issues, questions, or concerns during the ordering process, it is best to reach out directly to the manufacturer's customer support team. Many companies provide support via email, phone, or live chat. Being proactive and clarifying any confusion will result in a successful order. Be clear and concise in your communication and keep relevant information, such as order numbers and design specifications handy.

Tips for a Smooth Online PCB Ordering Process

Ensuring a seamless online PCB ordering experience involves meticulous preparation, clear communication, and strategic decision-making. By focusing on key areas, from file verification to manufacturer selection, you can significantly reduce the likelihood of errors and delays, leading to a more efficient and cost-effective process.

- Thorough Design File Review

Prior to uploading, meticulously check all Gerber files for accuracy, including layer alignment, drill hole sizes, and trace widths, to avoid production errors. Use a Gerber viewer to visually inspect your design. - Clear Specification Communication

Precisely define your PCB requirements, such as material type (e.g., FR-4, aluminum), board thickness, copper weight, solder mask color, and surface finish. When communicating with the manufacturer, clarity is key to preventing any misunderstandings. - Utilization of Instant Quoting Tools

Employ online quoting tools to obtain cost estimates based on varying specifications, allowing you to optimize your design for cost-effectiveness while maintaining the desired quality. Explore all the options to make an informed decision. - Customer Support Engagement

Don't hesitate to reach out to the manufacturer's customer support for any questions or concerns throughout the entire process, from the initial quote request to the final delivery of your PCBs. Good communication can prevent common issues. - Manufacturer Reliability Assessment

Choose established and reliable PCB manufacturers that have a proven track record of delivering high-quality boards consistently. Consider reviews, certifications, and client testimonials to find a dependable partner. - Complete Understanding of the Order Process

Ensure all steps involved in the online ordering procedure are clearly understood, including the submission of gerber files, order confirmation, production status, and delivery options, before the final confirmation of your printed circuit board order online.

Ordering PCBs online offers immense convenience and efficiency for designers and engineers. By thoroughly understanding your requirements, carefully selecting the right manufacturer, and adhering to the best practices outlined in this article, you can ensure that you get high-quality boards that meet your specifications. Remember to compare pricing, lead times, and customer reviews to make an informed decision when it comes to your printed circuit board order online. With the right approach, the process can be a seamless and crucial part of your electronic projects' success.

AnyPCBA

AnyPCBA