Self-Service Smart Vending Machine Solution

In today's fast-paced world, convenience and automation are no longer luxuries but expectations. From quick coffee runs to essential product pickups, self-service solutions are reshaping consumer interactions. The heart of this transformation lies in sophisticated technology, particularly the robust and reliable electronics that power these systems. Zero One Solution Limited, a leader in rapid prototyping and one-stop PCB solutions, is at the forefront of enabling this evolution. We provide the foundational PCB design, manufacturing, and assembly services crucial for developing cutting-edge self-service smart vending machine solutions that meet the demands of modern retail and consumer needs.

The Rise of Self-Service: Why Smart Vending Matters

The self-service industry is experiencing a significant upswing, largely fueled by increasing consumer demand for convenience and automation. Smart vending machines are at the forefront of this transformation, offering a compelling solution to meet these evolving market needs. This shift isn't just about convenience; it's driven by tangible economic benefits for operators and enhanced user experiences for consumers.

Several factors contribute to the rising importance of smart vending:

- Consumer Demand for Convenience:

Today's consumers expect instant access to products and services. Smart vending machines provide 24/7 availability, eliminating the constraints of traditional retail hours. - Labor Cost Savings:

Automated vending reduces the need for human staff, lowering operational costs and improving profitability for businesses. - Enhanced Product Accessibility:

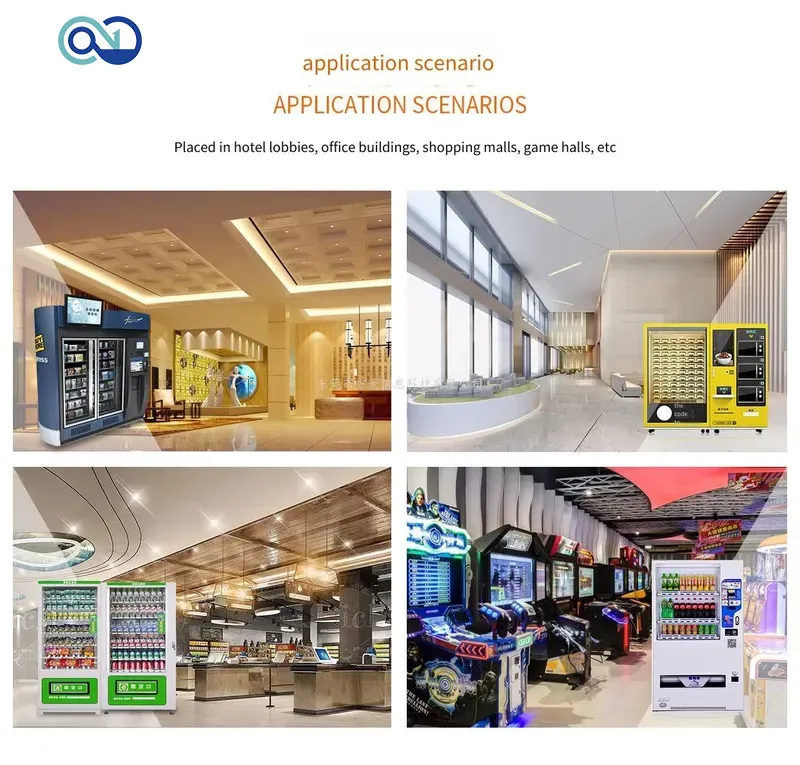

Smart vending machines can be placed in diverse locations, from offices and hospitals to transportation hubs, making products readily available to consumers where they need them most. - Data-Driven Insights:

Smart vending solutions offer valuable data on consumer preferences, purchasing patterns, and inventory levels, enabling operators to optimize product selection and placement for maximum revenue. - Technological Advancements:

The integration of IoT, advanced sensors, and secure payment systems has made smart vending machines more reliable, efficient, and user-friendly.

Core Components of a Smart Vending Machine Solution

A sophisticated smart vending machine solution integrates a variety of hardware and software components to deliver a seamless self-service experience. These core elements work in concert to manage inventory, process payments, ensure secure transactions, and provide valuable data insights through IoT connectivity.

- Embedded Systems

The brain of the vending machine, managing all operations from product selection to dispensing. This includes microcontrollers and processors that execute the vending machine's software. - Payment Modules

Enable cashless transactions, supporting credit/debit cards, mobile payments (NFC, QR codes), and potentially even cryptocurrency. Security is paramount, requiring PCI DSS compliance. - Connectivity (IoT)

Facilitates remote monitoring, inventory management, and data collection. This often involves cellular, Wi-Fi, or Ethernet connections, allowing operators to track sales, restock efficiently, and diagnose issues remotely. - Touchscreen Display

Provides a user-friendly interface for product selection, displaying nutritional information, and running promotions. These screens are often ruggedized for public use and can support interactive advertising. - Dispensing Mechanism

Reliably delivers products to the customer. Designs vary based on product type (e.g., spirals for snacks, robotic arms for delicate items) and must be robust to prevent jams or failures. - Sensors

Monitor various aspects of the machine's operation, such as temperature, humidity, and product levels. They can also detect malfunctions and alert operators to potential problems. - Power Supply

Provides stable and reliable power to all components. Often includes battery backup to ensure operation during power outages.

The Critical Role of PCBs in Smart Vending

Printed Circuit Boards (PCBs) are the central nervous system of any smart vending machine, underpinning their functionality and reliability. Without PCBs, the advanced features that define smart vending—touchscreen interfaces, sensor integration, secure payment processing, and IoT connectivity—simply wouldn't be possible. They are the crucial link between software commands and hardware actions, enabling seamless operation and enhanced user experiences in self-service vending.

- What makes PCBs essential for touchscreens in vending machines?

PCBs provide the necessary circuitry to translate touch inputs into actionable commands, manage display graphics, and ensure responsive user interactions. They handle the complex communication between the touchscreen, the machine's central processing unit, and other components, ensuring a seamless user experience. - How do PCBs support sensor integration in smart vending?

PCBs act as the interface for various sensors, such as those detecting product levels, temperature, or even user presence. They manage the data collected by these sensors, relaying information to the central control system for inventory management, environmental control, or security purposes. - What role do PCBs play in secure payment processing?

PCBs are fundamental in enabling secure transactions by integrating payment modules that adhere to industry security standards. They manage the encryption and transmission of payment data, ensuring compliance with PCI DSS and protecting against fraud. - How do custom PCB solutions enhance the functionality of smart vending machines?

Custom PCBs allow for tailored integration of specific features and components, optimizing performance and efficiency. They enable designers to create compact, reliable, and highly functional vending systems that meet unique requirements, such as specific product dispensing mechanisms or environmental conditions. - Why is PCB material selection important for vending machine reliability?

The choice of PCB materials directly impacts the board's durability and resistance to environmental factors like temperature and humidity. Selecting appropriate materials ensures long-term reliability and prevents failures that could lead to downtime and lost revenue. - Can PCBs improve the energy efficiency of smart vending machines?

Yes, optimized PCB design can significantly reduce energy consumption by minimizing power losses and improving thermal management. Efficient power distribution and component placement contribute to lower energy bills and a reduced environmental footprint. - How do PCBs enable IoT connectivity in vending machines?

PCBs incorporate communication modules that allow vending machines to connect to the internet, enabling remote monitoring, data collection, and software updates. This connectivity is crucial for real-time inventory management, dynamic pricing, and predictive maintenance.

Zero One Solution Limited's Expertise in Vending Machine PCB Solutions

At Zero One Solution Limited, we specialize in providing comprehensive PCB solutions tailored for the self-service smart vending machine industry. Our expertise spans the entire process, from initial PCB design and rapid prototyping to efficient manufacturing and assembly, ensuring a seamless, one-stop service for our clients. We understand the critical role PCBs play in enabling the advanced functionalities of smart vending machines, and we are committed to delivering high-quality, reliable solutions.

- PCB Design

Our experienced engineers utilize cutting-edge design tools to create custom PCB layouts that meet the specific requirements of smart vending applications. We optimize for factors such as component density, signal integrity, and thermal management to ensure optimal performance and reliability. - Rapid Prototyping

We offer rapid prototyping services to quickly validate designs and identify potential issues early in the development process. Our agile approach allows for faster iteration and reduced time-to-market. - Manufacturing

Our state-of-the-art manufacturing facilities are equipped to handle both small and large production runs. We adhere to strict quality control standards throughout the manufacturing process to ensure consistent product quality. - Assembly

We provide comprehensive PCB assembly services, including SMT (Surface Mount Technology) and through-hole assembly. Our skilled technicians ensure accurate component placement and soldering for reliable performance. - One-Stop Service

We offer a complete one-stop service, managing the entire PCB development process from design to assembly. This streamlined approach simplifies project management and reduces the risk of errors or delays. - Quality Assurance

Quality is at the heart of everything we do. We implement rigorous testing and inspection procedures at every stage of the process to ensure that our PCBs meet the highest standards of performance and reliability.

Key Features and Benefits of Our Self-Service Smart Vending Machine Solutions

Zero One Solution Limited's PCB solutions for smart vending machines are engineered to deliver a suite of key features and benefits that directly address the needs of both vending operators and end-users. Our focus is on enhancing reliability, bolstering security, enabling efficient remote management, and providing extensive customization options to create a superior vending experience.

- Enhanced Reliability:

Our PCBs are designed for durability and longevity, ensuring consistent performance in demanding vending environments. We use high-quality components and rigorous testing protocols to minimize downtime and maintenance costs. - Robust Security:

Security is paramount in self-service transactions. Our PCB solutions incorporate advanced security features to protect against fraud and unauthorized access, safeguarding both operator revenue and customer data. - Remote Management Capabilities:

Our PCBs facilitate seamless integration with remote management systems, allowing operators to monitor inventory, track sales, and troubleshoot issues in real-time. This leads to improved efficiency and reduced operational costs. - Customization Options:

We offer a wide range of customization options to meet the specific needs of different vending applications. From custom form factors to specialized functionalities, we can tailor our PCB solutions to your exact requirements. - Seamless Integration:

Our PCB solutions are designed for easy integration with other vending machine components, minimizing development time and ensuring a smooth and efficient manufacturing process. - Improved User Experience:

By enabling advanced features such as touchscreens, cashless payments, and personalized recommendations, our PCB solutions contribute to a more engaging and satisfying user experience, driving increased sales and customer loyalty.

Future Trends in Self-Service Smart Vending Technology

The self-service smart vending machine industry is poised for significant advancements, driven by innovations in artificial intelligence (AI), predictive maintenance, and personalized consumer experiences. Zero One Solution Limited is committed to providing PCB solutions that not only meet today's demands but also pave the way for these future technological integrations. Our forward-thinking designs ensure that vending machines can evolve to offer more intelligent, efficient, and customer-centric services.

Here's a look at some of the key trends shaping the future of smart vending:

- AI-Powered Vending

AI is set to revolutionize vending machines by enabling features like facial recognition for personalized recommendations, voice-activated interactions, and intelligent inventory management. These advancements will make vending machines more intuitive and responsive to consumer needs. Zero One Solution Limited's PCBs support the integration of AI modules and sensors, allowing for seamless implementation of these advanced capabilities. - Predictive Maintenance

By leveraging IoT sensors and data analytics, vending machines can predict potential maintenance issues before they occur. This reduces downtime, optimizes maintenance schedules, and extends the lifespan of the machines. Our PCB solutions facilitate the collection and transmission of critical performance data, enabling proactive maintenance strategies. - Personalized Consumer Experiences

Future vending machines will offer highly personalized experiences based on individual preferences, purchase history, and real-time data. This includes customized product recommendations, targeted promotions, and loyalty programs. Zero One Solution Limited's flexible PCB designs allow for the integration of advanced display technologies and communication modules, creating engaging and personalized interactions. - Cashless and Contactless Payments

The trend towards cashless and contactless payments will continue to accelerate, with vending machines supporting a wide range of payment options, including mobile wallets, NFC, and QR codes. Our PCB solutions ensure secure and reliable payment processing, complying with the latest industry standards and regulations. - Sustainability and Energy Efficiency

As environmental concerns grow, vending machines will become more energy-efficient and sustainable. This includes features like energy-saving lighting, eco-friendly refrigerants, and optimized cooling systems. Zero One Solution Limited is committed to developing PCB solutions that minimize energy consumption and support sustainable practices. - Remote Management and Monitoring

Cloud-based platforms will enable vending operators to remotely manage and monitor their machines in real-time. This includes tracking inventory levels, monitoring performance metrics, and updating software. Our PCB solutions provide seamless connectivity and data transmission, empowering operators with greater control and visibility.

Partnering with Zero One Solution Limited for Your Vending Machine Project

Embarking on a self-service smart vending machine project requires a partner that understands the intricacies of PCB design, manufacturing, and assembly. Zero One Solution Limited offers a streamlined, collaborative process, guiding you from initial concept to mass production. Our expertise ensures your vending machine project benefits from cutting-edge technology, efficient production, and a reliable global supply chain.

- What is the collaborative process like when working with Zero One Solution Limited?

Our collaborative process begins with understanding your specific project requirements and goals. We then move into PCB design and prototyping, offering rapid iteration and feedback. Once the design is finalized, we handle manufacturing, assembly, and quality control, ensuring a seamless transition to mass production. Throughout the process, you'll have a dedicated project manager as your single point of contact. - How does Zero One Solution Limited ensure quality throughout the vending machine project?

Quality is paramount at Zero One Solution Limited. We adhere to strict quality control procedures at every stage, from component selection to final assembly. Our facilities are equipped with advanced testing equipment, and our team is trained to identify and address any potential issues proactively. We are committed to delivering PCB solutions that meet the highest standards of reliability and performance. - What are the advantages of Zero One Solution Limited's strategic location in Shenzhen and Dubai?

Our headquarters in Shenzhen, China's electronic manufacturing hub, provides unparalleled access to a vast network of suppliers and resources. This allows us to source components efficiently and cost-effectively. Our branch office in Dubai extends our reach into the Middle East and beyond, providing localized support and access to a global customer base. This strategic presence enables us to offer a truly global PCBA supply chain. - Can Zero One Solution Limited handle both small prototype runs and large-scale production for vending machine PCBs?

Yes, we are equipped to handle projects of any size, from small prototype runs for R&D to large-scale mass production. Our flexible manufacturing capabilities allow us to scale our production to meet your specific needs. Whether you need a few prototypes for testing or thousands of units for deployment, we have the capacity and expertise to deliver. - What kind of support does Zero One Solution Limited offer after the vending machine PCBs are manufactured?

Our commitment to customer satisfaction extends beyond manufacturing. We offer comprehensive after-sales support, including technical assistance, troubleshooting, and warranty services. We are dedicated to ensuring your continued success with our PCB solutions. We provide ongoing support to address any questions or concerns that may arise during the deployment and operation of your vending machines. - How does Zero One Solution Limited leverage its global supply chain to benefit vending machine projects?

Our established global supply chain network allows us to source high-quality components from trusted suppliers worldwide. This ensures the availability of the best materials at competitive prices. We also have the logistical expertise to manage complex supply chains, ensuring timely delivery of components and finished products to your desired location, minimizing lead times and optimizing costs. - What types of vending machine applications can Zero One Solution Limited support?

We support a wide range of vending machine applications, including traditional snack and beverage vending, specialized product vending (e.g., electronics, cosmetics), and even custom vending solutions tailored to unique requirements. Our PCB solutions are designed to be versatile and adaptable, enabling you to create innovative and feature-rich vending machines for any market.

FAQs about Self-Service Smart Vending Machine Solutions

Navigating the world of self-service smart vending machine solutions can bring up a lot of questions. This section addresses frequently asked questions about implementing, utilizing, and benefiting from smart vending machines, with insights into how Zero One Solution Limited supports these advanced systems.

- What are the primary benefits of using smart vending machines compared to traditional ones?

Smart vending machines offer numerous advantages, including remote inventory management, real-time sales data, reduced operational costs through optimized restocking, enhanced security features, and improved customer experience via touchscreens and diverse payment options. These benefits translate to higher profitability and better customer satisfaction. - How does Zero One Solution Limited ensure the reliability of PCBs in smart vending machines?

Zero One Solution Limited adheres to stringent quality control processes throughout PCB design, manufacturing, and assembly. We use high-quality materials, conduct rigorous testing, and implement redundancy measures to ensure our PCBs can withstand the demands of continuous operation in vending environments, minimizing downtime and maintenance. - Can Zero One Solution Limited customize PCB solutions for specific vending machine needs?

Yes, customization is a core strength. We work closely with clients to understand their specific requirements, whether it's for specialized sensors, unique payment systems, or particular environmental conditions. Our team designs and manufactures custom PCB solutions tailored to optimize the performance and functionality of each vending machine. - What security measures are incorporated into Zero One Solution Limited's PCB designs for vending machines?

Security is paramount. Our PCB designs incorporate various security features, including encryption for payment processing, tamper detection mechanisms, and secure boot processes to prevent unauthorized access or modification of the system. These measures protect both the operator's revenue and the customer's data. - How do smart vending machines handle different payment methods?

Smart vending machines are equipped to handle a wide array of payment options, including credit cards, debit cards, mobile payments (like Apple Pay and Google Pay), and even cryptocurrency in some advanced models. The PCBs facilitate secure and seamless transactions, enhancing convenience for customers. - What is the typical lifespan of a smart vending machine PCB, and what maintenance is required?

The lifespan of a smart vending machine PCB designed and manufactured by Zero One Solution Limited is typically several years, depending on the operating environment and usage. Regular maintenance includes occasional cleaning to remove dust and debris, and periodic inspection of connectors and components. Our robust designs minimize the need for frequent replacements. - How can Zero One Solution Limited's PCB solutions support remote management of vending machines?

Our PCB solutions integrate seamlessly with IoT platforms, enabling remote monitoring and management of vending machines. Operators can track inventory levels, monitor sales data, diagnose issues, and even update software remotely, reducing the need for on-site visits and improving operational efficiency.

The self-service smart vending machine revolution is well underway, offering unparalleled convenience and operational efficiency. At the core of this transformation are advanced electronic systems, meticulously designed and manufactured to ensure reliability and performance. Zero One Solution Limited stands as your premier partner, offering comprehensive PCB solutions that empower innovators to bring their smart vending concepts to life. With our expertise in rapid prototyping, design, manufacturing, and assembly, we are uniquely positioned to accelerate your product development cycles and ensure market readiness. Partner with Zero One Solution Limited to unlock the full potential of your smart vending initiatives. Visit our website or contact us today to discuss how our PCB solutions can drive your success.

AnyPCBA

AnyPCBA