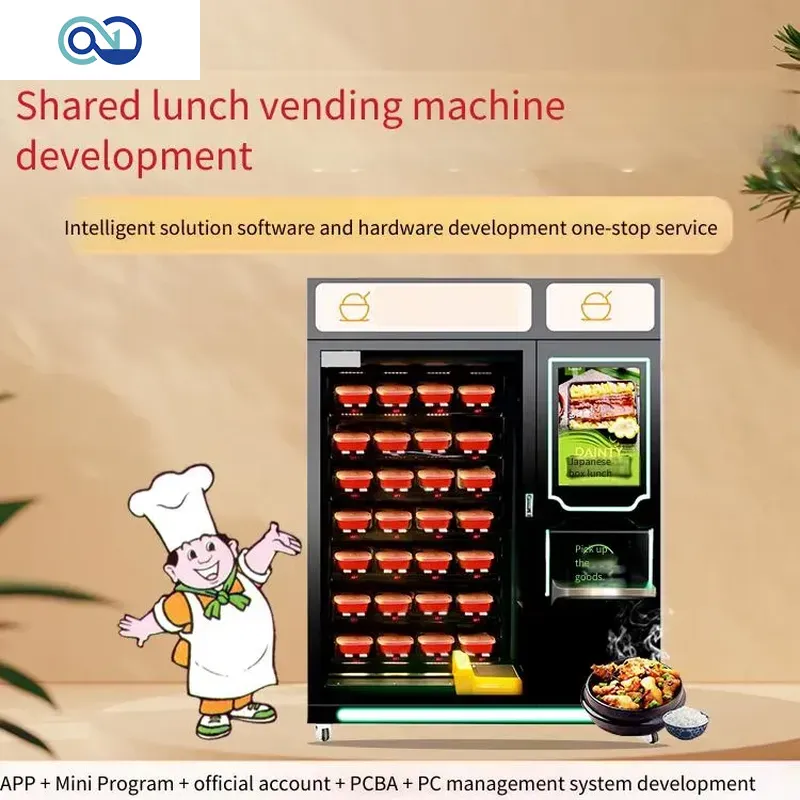

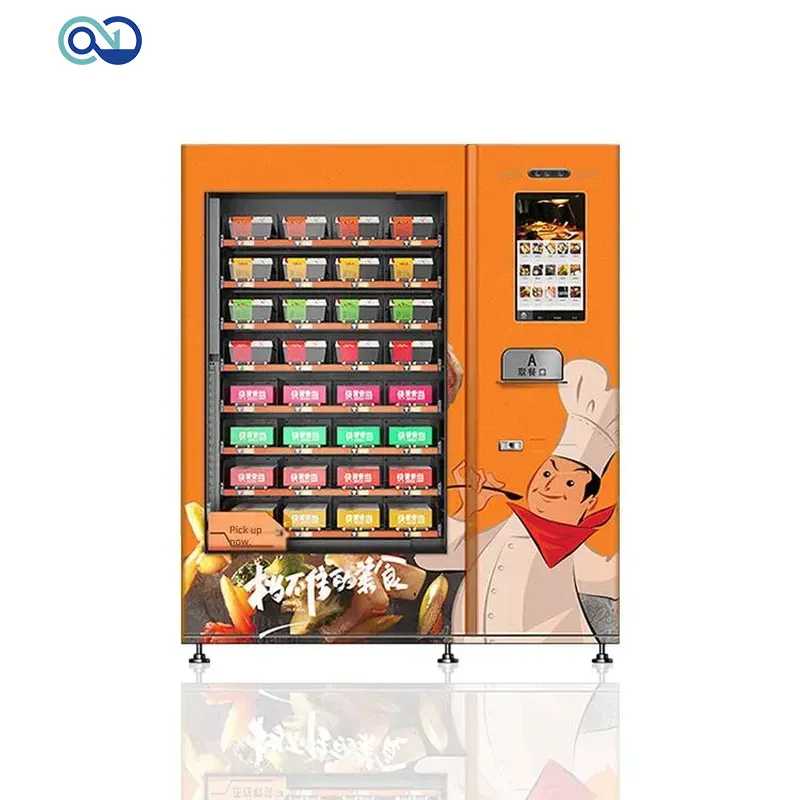

Shared Bento Box Vending Machine Solution

In an era where convenience and efficiency are paramount, the demand for innovative automated solutions is soaring. From smart retail to automated food services, technology is reshaping how we access everyday necessities. This article delves into a groundbreaking advancement in automated food dispensing: the Shared Bento Box Vending Machine Solution. As a veteran engineer at Zero One Solution Limited, a leader in rapid prototyping and PCB assembly, I'll guide you through how our sophisticated PCB solutions are powering these intelligent machines, offering unparalleled convenience and operational excellence. What makes these bento box vending machines not just a trend, but a pivotal step in modern food distribution?

The Evolution of Automated Food Service: Why Bento Box Vending?

The rising demand for convenient and fresh food options has spurred an evolution in automated food service. Shared bento box vending machines are at the forefront of this shift, presenting a modern solution that surpasses the limitations of traditional snack and beverage dispensers. This innovative approach caters to consumers seeking healthier, ready-to-eat meals in accessible formats.

Several factors drive the increasing popularity of bento box vending machines:

- Changing Consumer Preferences:

Consumers are increasingly health-conscious and seek nutritious meal options, even when on the go. Bento boxes, with their balanced portions and diverse food selections, align perfectly with these preferences. - Demand for Convenience:

Busy lifestyles leave limited time for meal preparation. Vending machines offer a quick and easy way to access a complete meal without the need to visit a restaurant or grocery store. - Technological Advancements:

Modern vending machines incorporate advanced technologies like temperature control, remote monitoring, and cashless payment systems, ensuring food safety and operational efficiency. - Workplace Wellness Programs:

Companies are increasingly investing in employee well-being by providing access to healthy food options in the workplace. Bento box vending machines offer a convenient and cost-effective solution. - Sustainability:

Compared to individually packaged snacks, shared bento box systems can reduce waste through reusable containers and efficient inventory management.

The shift towards bento box vending represents a significant upgrade in automated food service, addressing the needs of today's consumers for fresh, convenient, and healthy meal options.

Key Components of a Smart Bento Box Vending Machine

Modern smart bento box vending machines are sophisticated systems integrating hardware and software for efficient operation. Key components include advanced refrigeration, precision dispensing, secure payment, and reliable connectivity, all essential for delivering fresh food conveniently.

- Refrigeration System

Maintains optimal temperature to preserve bento box freshness, with precise controls and monitoring for food safety. - Dispensing Mechanism

Ensures smooth and reliable delivery of bento boxes, designed for various sizes and shapes while minimizing damage. - Payment Gateway

Facilitates secure and seamless transactions, supporting cashless options like credit cards, mobile payments, and digital wallets for user convenience. - Connectivity Module

Enables remote monitoring, inventory management, and data analytics through wireless technologies (e.g., Wi-Fi, cellular) for efficient operation and optimization. - User Interface

Provides an intuitive touch screen for easy browsing, selection, and purchase, enhancing user experience. - Control System

The central processing unit manages all vending machine functions, coordinating actions between hardware and software to ensure smooth operation. - Security Features

Protects against theft and tampering with surveillance cameras, alarm systems, and secure locking mechanisms.

Zero One Solution's Role: Powering Innovation with Advanced PCB Solutions

Zero One Solution Limited stands at the forefront of enabling innovation in shared bento box vending machine technology through our advanced PCB solutions. Our expertise in rapid prototyping and PCB assembly provides the critical electronic backbone necessary for these sophisticated vending systems to function reliably and efficiently. We empower our clients to push the boundaries of what's possible in automated food service.

Our commitment to quality and innovation makes us an ideal partner for companies developing cutting-edge vending solutions. Here's how we contribute to the success of shared bento box vending machines:

- Rapid Prototyping Expertise

We accelerate the development process with our rapid prototyping services, enabling quick iterations and faster time-to-market for new vending machine designs. - Comprehensive PCB Assembly

From component sourcing to final assembly, we offer a complete PCB assembly service, ensuring the highest quality and reliability for your vending machine electronics. - Customized Solutions

We tailor our PCB designs to meet the specific requirements of each vending machine project, accommodating unique sensor integrations, display interfaces, and control systems. - Stringent Quality Control

Our rigorous quality control processes ensure that every PCB meets the highest standards of performance and durability, essential for the continuous operation of vending machines. - Global Supply Chain Network

With our headquarters in Shenzhen and a branch office in Dubai, we provide seamless access to a global network of resources, ensuring efficient sourcing and support for our clients.

By choosing Zero One Solution Limited, vending machine developers gain a competitive edge through reliable, high-performance PCB solutions that drive innovation and ensure customer satisfaction.

Customizable PCB Design for Unique Vending Requirements

At Zero One Solution, we understand that no two vending machine projects are exactly alike. That's why we offer customizable PCB design services tailored to the specific and unique requirements of shared bento box vending machines. Our expertise allows us to create PCB solutions that precisely match your operational demands, whether it's integrating specialized sensors for freshness monitoring or developing unique display interfaces for enhanced user interaction.

Our customizable PCB design services offer a wide array of adaptations to meet diverse operational needs:

- Sensor Integration

We design PCBs that seamlessly integrate with various sensors to monitor temperature, humidity, and food freshness, ensuring optimal quality control within the vending machine. - Display Interface Customization

Our designs support a range of display options, from simple LCD screens to advanced touchscreens, allowing for intuitive user interfaces and detailed product information displays. - Payment System Integration

We can tailor PCB designs to accommodate different payment systems, including credit card readers, mobile payment options, and even biometric authentication, providing flexibility and security for transactions. - Connectivity Modules

Our PCBs can be designed with various connectivity options, such as Wi-Fi, Bluetooth, and cellular, enabling remote monitoring, inventory management, and software updates. - Power Management

We optimize power distribution and consumption within the vending machine, ensuring energy efficiency and prolonged operational life. - Security Features

Customizable security features can be integrated into the PCB design to protect against tampering and unauthorized access, safeguarding both the machine and its contents.

The Advantages of Our One-Stop PCB Service for Vending Machine Developers

Zero One Solution Limited offers a comprehensive, one-stop PCB service designed to streamline the development process for vending machine developers, accelerating their time to market. By integrating PCB design, manufacturing, and assembly into a single, cohesive service offering, we eliminate the complexities of managing multiple vendors, reduce potential communication errors, and ensure a seamless transition from concept to deployment for shared bento box vending solutions.

- Accelerated Development Cycles

Our integrated service approach significantly shortens development timelines. By handling all aspects of PCB production in-house, we minimize delays associated with vendor coordination, allowing you to bring your bento box vending solutions to market faster. - Reduced Costs

Engaging multiple vendors for design, manufacturing, and assembly can lead to increased costs due to markups and logistical overhead. Our one-stop service consolidates these expenses, offering a more cost-effective solution for vending machine developers. - Improved Communication and Collaboration

With all PCB-related services under one roof, communication is streamlined, and collaboration is enhanced. This ensures that design specifications are accurately translated into the final product, minimizing errors and rework. - Enhanced Quality Control

Our comprehensive service includes rigorous quality control measures at every stage of the PCB production process. From design verification to final assembly inspection, we ensure that your vending machine PCBs meet the highest standards of reliability and performance. - Customization and Flexibility

We offer customizable PCB design services to meet the unique requirements of your bento box vending machines. Whether you need specific sensor integrations, display interfaces, or power management solutions, our team can tailor our services to your exact needs. - Simplified Logistics

Managing multiple vendors can be a logistical nightmare. Our one-stop service simplifies the supply chain, reducing the burden of coordinating shipments, tracking orders, and managing invoices. - Expert Support

Our team of experienced engineers and technicians provides expert support throughout the entire PCB development process. From initial consultation to final product delivery, we are committed to helping you succeed.

Ensuring Reliability and Scalability in Shared Vending Machine Deployments

The reliability and scalability of shared bento box vending machine deployments hinge significantly on robust PCB engineering. These machines must endure continuous operation, adapt to fluctuating environmental conditions, and accommodate future upgrades and expansions within the vending network. High-quality PCB design and manufacturing are paramount to ensuring these demands are met, minimizing downtime, and maximizing return on investment.

- What PCB design considerations are most important for ensuring reliability in bento box vending machines?

Key considerations include component selection with extended temperature ranges, redundant power supplies, conformal coatings to protect against moisture and contaminants, and rigorous testing under simulated operating conditions. Proper thermal management design is also crucial to prevent overheating and ensure long-term reliability. - How can PCB design enhance the scalability of a shared bento box vending machine network?

Scalability is improved through modular PCB designs that allow for easy upgrades and expansions. This includes incorporating standardized interfaces for new sensors, payment systems, or communication modules. Also, choosing components that are readily available and have long lifecycles reduces the risk of obsolescence and simplifies future production runs. - What types of environmental factors should PCB design account for in shared vending machines?

PCBs should be designed to withstand a wide range of temperatures, humidity levels, and potential exposure to dust and vibrations. Using ruggedized components, conformal coatings, and robust mounting techniques can help mitigate these environmental challenges and ensure reliable operation in diverse settings. - How does Zero One Solution ensure the PCBs they manufacture are suitable for demanding vending machine applications?

Zero One Solution leverages its rapid prototyping capabilities to quickly iterate on designs and identify potential weaknesses. We employ rigorous testing procedures, including environmental stress screening and accelerated life testing, to validate the reliability of our PCBs. Our expertise in PCB assembly ensures proper component placement and soldering, minimizing the risk of failures. - What role do advanced materials play in ensuring PCB reliability for bento box vending machines?

Advanced materials, such as high-Tg laminates and thermally conductive substrates, can significantly improve PCB reliability. High-Tg laminates offer better resistance to heat and moisture, while thermally conductive substrates help dissipate heat more effectively, reducing the risk of component failures and extending the lifespan of the vending machine. - Can remote monitoring and diagnostics be integrated into the PCB design of shared bento box vending machines?

Yes, incorporating sensors and communication modules into the PCB design enables remote monitoring of key parameters, such as temperature, humidity, and power consumption. This data can be used to proactively identify potential issues and perform preventative maintenance, minimizing downtime and maximizing the lifespan of the vending machine. - How does component selection impact the long-term reliability and scalability of vending machine PCBs?

Selecting high-quality components with proven reliability and long lifecycles is crucial. Choosing components that are readily available from multiple suppliers ensures supply chain stability and simplifies future production runs. Standardized components also make it easier to upgrade or replace parts as needed, enhancing the scalability of the vending machine.

Case Studies: Successful Implementations of Smart Vending with Zero One Solution PCBs

Zero One Solution Limited's PCBs are at the heart of numerous successful smart vending machine deployments. Our commitment to quality, rapid prototyping, and comprehensive PCB assembly services has enabled our clients to bring innovative shared bento box vending solutions to the market efficiently and reliably. Here are a few illustrative examples:

- University Campus Deployment: Enhancing Student Meal Options

A leading university partnered with a vending machine operator to install shared bento box vending machines across its campus. These machines, powered by Zero One Solution PCBs, offer students a convenient and healthy meal alternative. The PCBs manage the refrigeration, payment processing, and inventory tracking, resulting in a 99.9% uptime and a significant reduction in food waste due to precise inventory management. The university reported a 40% increase in student satisfaction with on-campus dining options. - Corporate Office Solution: Streamlining Employee Lunch Programs

A large corporation implemented a shared bento box vending solution in its office buildings to provide employees with subsidized lunch options. Zero One Solution's PCBs ensured seamless integration with the company's existing payment system and employee ID cards. The vending machines experienced high usage rates, with a 30% reduction in employees leaving the premises for lunch. The company also benefited from reduced administrative overhead associated with traditional catering services. - Hospital Cafeteria Upgrade: Providing 24/7 Access to Nutritious Meals

A hospital upgraded its cafeteria with shared bento box vending machines to offer staff and visitors access to nutritious meals around the clock. Zero One Solution provided PCBs that met stringent medical-grade standards, ensuring reliability and hygiene. The vending machines contributed to a 20% increase in overall cafeteria sales and improved staff satisfaction by providing convenient meal options during off-peak hours. - Transportation Hub Implementation: Catering to Travelers' Needs

An international airport installed shared bento box vending machines in its terminals to provide travelers with fresh, readily available meal options. The PCBs from Zero One Solution are designed to withstand the high-traffic environment and varying temperatures. The vending machines have become a popular amenity, with customer surveys indicating high satisfaction with the quality and convenience of the bento box offerings. - Smart City Initiative: Promoting Healthy Eating in Public Spaces

As part of a smart city initiative, several shared bento box vending machines were deployed in public parks and community centers. These machines, equipped with Zero One Solution PCBs, promote healthy eating habits by offering a variety of nutritious meal choices. The vending machines are integrated with a mobile app, allowing users to locate machines, view menus, and make cashless payments, contributing to increased public engagement with healthy food options.

FAQs about Shared Bento Box Vending Machine Solutions and PCB Integration

This section addresses frequently asked questions about shared bento box vending machine solutions, covering aspects from technology and benefits to implementation, maintenance, and the pivotal role of specialized PCB solutions. These FAQs are designed to provide quick, insightful answers to common queries from potential operators and developers.

- What are the primary benefits of using a shared bento box vending machine?

Shared bento box vending machines offer several key benefits, including convenience for consumers seeking quick and healthy meal options, reduced food waste through efficient inventory management, and potential revenue generation for operators in high-traffic locations. They also provide a cost-effective alternative to traditional cafeterias or restaurants, especially in corporate or educational settings. - How does PCB design impact the performance of a bento box vending machine?

The PCB design is crucial for controlling the vending machine's functionality. It manages the refrigeration system to maintain food safety, controls the dispensing mechanism for efficient operation, integrates payment systems for seamless transactions, and manages connectivity for remote monitoring and updates. A well-designed PCB ensures reliability, energy efficiency, and optimal performance of the vending machine. - What types of PCB solutions are best suited for bento box vending machines?

Given the demanding operational environment of vending machines, robust and reliable PCB solutions are essential. This typically includes PCBs with enhanced thermal management to handle heat generated by refrigeration and other components, as well as durable materials that can withstand continuous use and vibration. Additionally, PCBs with good connectivity options are beneficial for remote monitoring and management. - How do I maintain a shared bento box vending machine to ensure food safety?

Maintaining food safety involves regular cleaning and sanitization of the machine's interior, especially the dispensing area. It's also critical to monitor the refrigeration system to ensure it's maintaining the correct temperature for food storage. Implementing a system for tracking expiration dates and removing expired items is also necessary. Regular maintenance checks of the PCB and other electronic components can prevent malfunctions that could compromise food safety. - Can Zero One Solution Limited customize PCB designs for specific bento box vending machine features?

Yes, Zero One Solution Limited specializes in customizable PCB designs tailored to meet the unique requirements of various vending machine features. Whether it's integrating specific sensors, designing unique display interfaces, or optimizing power consumption, our team can create bespoke PCB solutions that enhance the functionality and efficiency of your bento box vending machine. - What are the cost considerations for integrating advanced PCB solutions into bento box vending machines?

While advanced PCB solutions may involve a higher upfront cost, they can lead to long-term savings through improved reliability, reduced maintenance, and enhanced energy efficiency. It's essential to consider the total cost of ownership, including potential downtime and repair expenses, when evaluating PCB options. Investing in quality PCB solutions can also enhance the vending machine's lifespan and overall performance, providing a better return on investment. - How can Zero One Solution's one-stop PCB service accelerate the development of my vending machine project?

Zero One Solution's one-stop PCB service streamlines the entire development process, from initial design and prototyping to manufacturing and assembly. By providing a comprehensive solution, we eliminate the need to coordinate with multiple vendors, reducing lead times and ensuring seamless integration of all components. This allows vending machine developers to accelerate their time to market and focus on other critical aspects of their business.

The Shared Bento Box Vending Machine Solution represents a significant leap forward in automated food service, driven by the robust and reliable PCB technology engineered by Zero One Solution Limited. By integrating our expertise in rapid prototyping, design, manufacturing, and assembly, we empower businesses to deploy high-performance, scalable, and secure vending ecosystems. This fusion of culinary convenience and cutting-edge electronics is not just transforming how we grab a quick, fresh meal; it's defining the future of accessible food. Are you ready to innovate your automated food service? Partner with Zero One Solution Limited to turn your next-gen vending concept into a tangible, market-ready solution. Contact us today to discuss how our bespoke PCB solutions can power your vision.

AnyPCBA

AnyPCBA