Shared Knife Sharpening and Retrieval Cabinet Solution

In the bustling environment of professional kitchens, hospitality, or even large community settings, maintaining sharp knives is paramount for efficiency, safety, and culinary excellence. However, the traditional methods of knife sharpening are often time-consuming, inconsistent, and pose logistical challenges for shared use and retrieval. At Zero One Solution Limited, drawing on our extensive expertise in rapid-response R&D and PCB assembly solutions, we've identified a critical need for a streamlined, intelligent approach to blade management. This article introduces our cutting-edge Shared Knife Sharpening and Retrieval Cabinet Solution – a revolutionary system designed to automate, secure, and optimize knife maintenance, bringing unparalleled convenience and precision to shared knife environments. How can smart technology transform a seemingly simple task into a seamlessly managed operation?

The Challenge of Knife Sharpening in Shared Environments

Maintaining consistently sharp knives in shared environments poses significant challenges. These challenges range from safety concerns and inconsistent sharpening quality to logistical difficulties in managing knife retrieval. Addressing these issues is critical for ensuring operational efficiency and safety in various settings.

- Safety Risks

Dull knives are a major safety hazard in any kitchen or shared workspace. They require more force to use, increasing the likelihood of slips and serious cuts. Ensuring knives are consistently sharp minimizes these risks and promotes a safer working environment for all users. - Inconsistent Sharpening Quality

Without a standardized sharpening process, the sharpness of knives can vary widely depending on who is performing the sharpening. This inconsistency can lead to frustration and inefficiency, as users struggle with poorly sharpened blades. A reliable sharpening solution ensures consistent, high-quality results every time. - Logistical Complexities in Retrieval

In shared environments, keeping track of knives can be a logistical nightmare. Knives can be misplaced, stolen, or simply not returned to their designated storage locations. This can lead to delays, wasted time searching for knives, and the need for frequent replacements. A secure retrieval system is essential for maintaining accountability and preventing loss. - Damage to Knives

Improper sharpening techniques can cause damage to knives, reducing their lifespan and performance. Over-grinding, uneven sharpening, and using the wrong tools can all contribute to blade damage. Professional or automated sharpening solutions minimize these risks and help preserve the integrity of the knives. - Time and Labor Costs

Manual knife sharpening is a time-consuming task that requires skilled labor. In busy environments, this can be a significant drain on resources. Automating the sharpening process can free up staff to focus on other tasks and reduce overall labor costs. - Maintaining Hygiene Standards

Shared knives can be a breeding ground for bacteria if not properly cleaned and maintained. Ensuring knives are regularly sanitized and stored in a hygienic manner is crucial for preventing cross-contamination and maintaining food safety standards. A dedicated knife sharpening and retrieval cabinet can incorporate hygiene features to address these concerns.

Introducing the Shared Knife Sharpening and Retrieval Cabinet Solution

Zero One Solution Limited introduces an innovative Shared Knife Sharpening and Retrieval Cabinet Solution, engineered to address the critical need for efficient, safe, and consistent knife maintenance in shared environments. This state-of-the-art cabinet automates the knife sharpening process and ensures secure access, optimizing operational workflows and minimizing risks.

Our solution is more than just a cabinet; it's a comprehensive system designed to streamline knife management from sharpening to secure return. Here's a closer look at what the Shared Knife Sharpening and Retrieval Cabinet Solution offers:

- Automated Sharpening Technology

Utilizes precision sharpening mechanisms to ensure each knife is sharpened to the optimal angle and sharpness, extending blade life and enhancing cutting performance. - Secure Access Control

Implements user authentication protocols, such as RFID or biometric scanning, to control access and track knife usage, reducing the risk of theft and misuse. - Real-time Monitoring and Alerts

Features integrated sensors and a PCB-powered system that monitors cabinet status, knife availability, and maintenance schedules, sending alerts for timely action. - Durable and Hygienic Design

Constructed with robust materials resistant to wear and tear, and designed for easy cleaning and sanitation to meet stringent hygiene standards. - Customizable Configurations

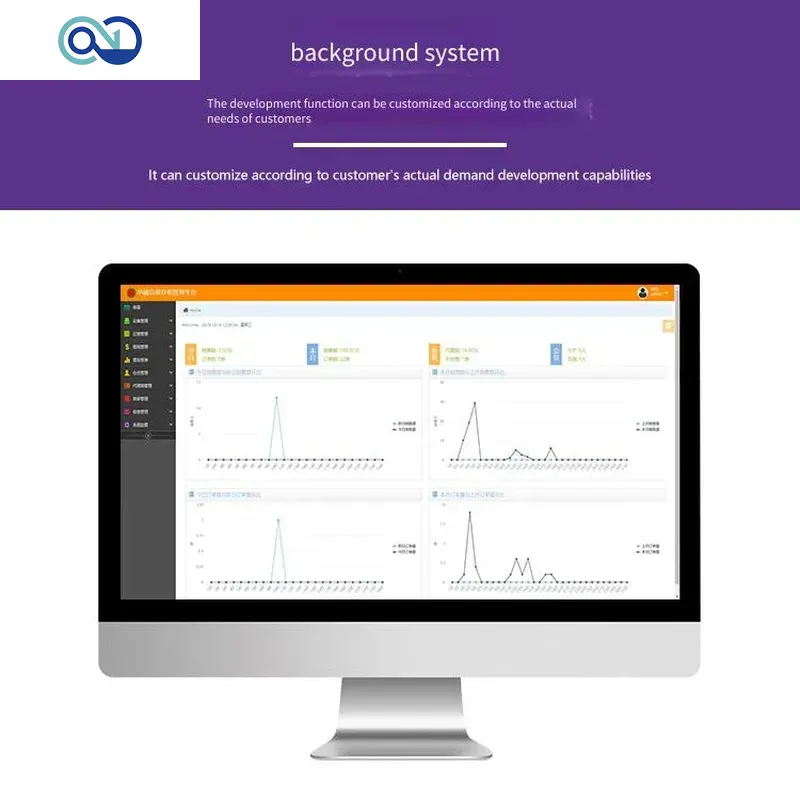

Offers flexible configurations to accommodate various knife sizes, quantities, and sharpening needs, tailored to the specific requirements of different industries and applications. - Data Analytics and Reporting

Generates comprehensive reports on knife usage, sharpening frequency, and maintenance history, providing valuable insights for optimizing inventory management and operational efficiency.

With Zero One Solution Limited's Shared Knife Sharpening and Retrieval Cabinet Solution, organizations can transform their knife management practices, enhancing safety, reducing costs, and improving overall productivity.

Core Features and Technology Behind the Smart Cabinet

The Smart Cabinet by Zero One Solution Limited integrates several core features and advanced technologies to deliver a seamless and secure knife sharpening and retrieval experience. Central to its operation are the automated sharpening mechanisms, secure access controls, and the sophisticated PCB technology that powers the entire system. These components work in harmony to ensure optimal efficiency, safety, and blade maintenance.

- Automated Sharpening Mechanisms

Precision sharpening modules are integrated to guarantee consistent blade edges, extending the life of knives and reducing the risk of injury due to dull blades. Configurable sharpening profiles ensure each knife receives optimal care, based on its type and usage frequency. - Secure Access Controls

User authentication via RFID or biometric scanning restricts access to authorized personnel only, preventing theft and misuse. Access logs provide an audit trail for each knife, ensuring accountability and traceability. - Integrated PCB Technology

At the heart of the smart cabinet lies a custom-designed PCB (Printed Circuit Board), engineered by Zero One Solution Limited. This PCB facilitates real-time monitoring of cabinet operations, controls access permissions, and manages the automated sharpening process. Its robust design ensures reliable performance and seamless integration with other system components. - Real-time Monitoring and Data Analytics

The cabinet is equipped with sensors to monitor blade usage, sharpening frequency, and system health. Data analytics provide insights into knife performance, maintenance needs, and user behavior, enabling data-driven decisions to optimize cabinet operations. - Durable and Hygienic Construction

Constructed from food-grade stainless steel and other durable materials, the cabinet ensures hygiene and longevity even in demanding environments. Easy-to-clean surfaces and sealed components minimize the risk of contamination and simplify maintenance. - Remote Management Capabilities

The system supports remote monitoring and control, allowing administrators to manage user access, adjust sharpening schedules, and receive alerts for maintenance needs from anywhere with an internet connection. This feature enhances convenience and reduces downtime.

Benefits of Implementing a Smart Knife Sharpening Solution

Implementing a smart knife sharpening solution like Zero One Solution Limited's Shared Knife Sharpening and Retrieval Cabinet offers a multitude of benefits, fundamentally reshaping how organizations manage and utilize their knives. The advantages span enhanced safety, improved knife longevity, consistent blade quality, and significant time and cost savings, creating a compelling case for adoption across various industries.

- Enhanced Safety

Sharper knives are safer knives. A smart sharpening solution ensures blades are consistently sharp, reducing the force needed for cutting and, consequently, the risk of slips and accidents. Furthermore, the secure retrieval system minimizes the potential for misuse or theft, contributing to a safer working environment. - Improved Knife Longevity

Regular, professional sharpening, as provided by the cabinet, extends the lifespan of knives. By removing only the necessary amount of material to restore the edge, it prevents excessive wear and tear, maximizing the investment in high-quality knives. - Consistent Blade Quality

The automated sharpening mechanism ensures that every knife is sharpened to the same high standard, regardless of who is using it. This consistent blade quality translates to more precise and efficient cutting, improving the quality of the final product, whether it's food preparation or industrial cutting tasks. - Significant Time and Cost Savings

Outsourcing knife sharpening is costly and time-consuming. The smart cabinet eliminates these expenses by providing an in-house solution. Moreover, the increased efficiency from using sharp knives reduces labor time and material waste, leading to further cost savings. - Reduced Risk of Cross-Contamination

In environments where hygiene is critical, such as professional kitchens and healthcare facilities, the automated sharpening and retrieval system minimizes the risk of cross-contamination. Knives are cleaned and sanitized after each use, ensuring that they are safe for the next user. - Streamlined Workflow

The cabinet's intelligent management system streamlines the knife sharpening and retrieval process, making it quick and easy for users to access and return knives. This reduces downtime and improves overall workflow efficiency.

Security and Accountability: Tracking Your Blades

In shared environments, ensuring the security and accountability of knives is paramount. Zero One Solution Limited's Shared Knife Sharpening and Retrieval Cabinet addresses these concerns head-on with its intelligent retrieval system and robust user authentication features. By tracking each blade and logging its usage, the system prevents loss and promotes responsible handling, which is crucial for maintaining a safe and efficient workspace.

Here's how our system ensures security and accountability:

- User Authentication

Access to the cabinet is controlled through secure user authentication, such as RFID cards or PIN codes. This ensures that only authorized personnel can retrieve or return knives. - Real-time Tracking

Each knife is tagged and tracked within the system. The cabinet monitors which user has which knife and for how long, providing a complete chain of custody. - Automated Logging

Every transaction – retrieval and return – is automatically logged, including the user ID, date, and time. This creates an auditable trail for accountability. - Restricted Access Levels

Administrators can set different access levels for users, limiting the types or number of knives that specific individuals can access. - Alerts and Notifications

The system can be configured to send alerts for overdue returns or any unusual activity, allowing for immediate investigation and resolution. - Loss Prevention

By maintaining strict control over knife access and usage, the cabinet significantly reduces the risk of loss or theft. - Data Security

All data related to knife tracking and user activity is securely stored and protected, ensuring confidentiality and compliance with data protection regulations.

Applications Across Industries: Who Can Benefit?

The Shared Knife Sharpening and Retrieval Cabinet Solution is remarkably versatile, offering significant benefits across a spectrum of industries. Its ability to ensure consistently sharp, secure, and readily available knives makes it an invaluable asset in any setting where knife use is prevalent. From bustling professional kitchens to educational culinary programs and demanding industrial environments, the solution adapts to diverse needs, enhancing safety, efficiency, and operational excellence.

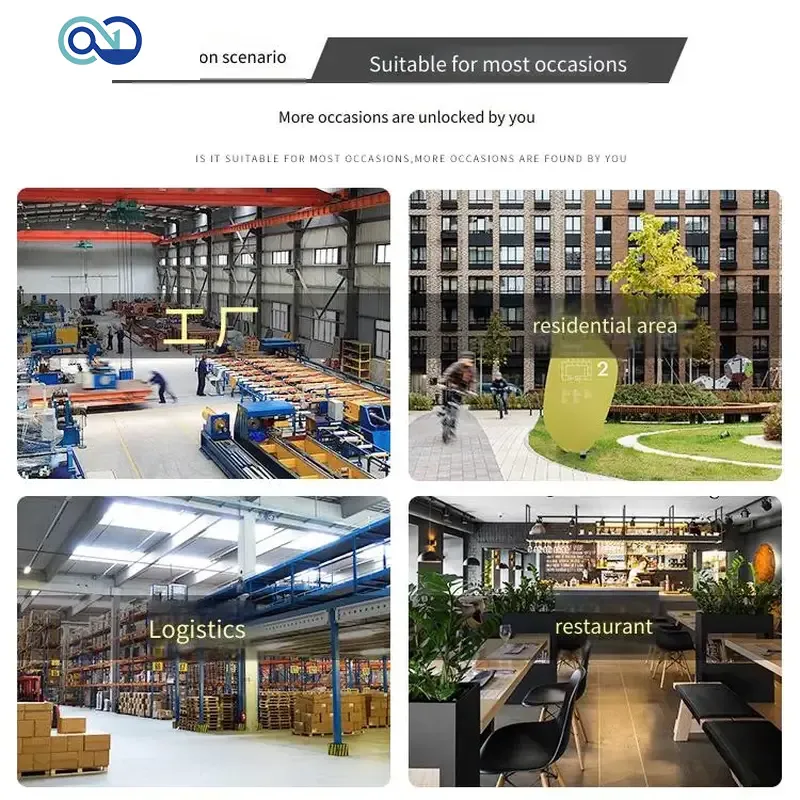

- Professional Kitchens and Restaurants

In fast-paced culinary environments, maintaining sharp knives is crucial for efficiency and safety. The cabinet ensures that chefs always have access to perfectly sharpened knives, reducing the risk of accidents and improving food preparation quality. The secure retrieval system also minimizes knife loss and ensures accountability. - Catering Services

Catering companies often operate in diverse locations with varying levels of equipment. The Shared Knife Sharpening and Retrieval Cabinet provides a centralized, secure solution for knife management, ensuring that catering staff can consistently deliver high-quality food preparation, regardless of the venue. - Culinary Schools and Training Programs

For culinary students, learning to work with sharp, well-maintained knives is a fundamental skill. The cabinet offers a safe and educational environment for knife handling, promoting best practices in sharpening, maintenance, and storage. It also instills a sense of responsibility and accountability among students. - Industrial Settings

Many industrial processes rely on knives or blades for cutting, trimming, or shaping materials. The cabinet can be adapted for industrial use, ensuring that workers have access to sharp, safe, and reliable cutting tools. This can improve productivity, reduce waste, and enhance workplace safety. - Butcher Shops and Meat Processing Plants

Maintaining the sharpness of knives is paramount for butchers and meat processors to ensure efficient and safe cutting. This solution guarantees knives are always in optimal condition, reducing physical strain and improving the quality of cuts. The secure system prevents theft and ensures only authorized personnel can access the knives. - Supermarkets and Grocery Stores

Departments such as delis, bakeries, and produce sections rely heavily on knives. A shared knife sharpening and retrieval cabinet streamlines operations by providing a central location for sharpened and sanitized knives, contributing to enhanced food safety and operational efficiency. - Correctional Facilities

In controlled environments like correctional facilities where kitchen knives are used for food preparation, security and accountability are critical. The cabinet offers a way to manage and track knives, preventing them from being misused and enhancing safety protocols.

FAQs About the Shared Knife Sharpening and Retrieval Cabinet

This section addresses frequently asked questions about the Shared Knife Sharpening and Retrieval Cabinet. It covers operation, maintenance, installation, security, and specific features, offering clear answers for potential users seeking a comprehensive understanding of the system.

- How does the automated knife sharpening system work?

The system uses precision grinding wheels and angle guides to ensure consistent and optimal sharpness. Each knife is sharpened according to a pre-programmed profile based on its type, preventing over-sharpening and extending the knife's lifespan. - What types of knives can the cabinet sharpen?

The cabinet is designed to accommodate a wide variety of knives, including chef's knives, paring knives, utility knives, and boning knives. It can handle knives with different blade thicknesses and steel types. Specific knife dimensions and limitations are available in the product specifications. - How often does the sharpening system require maintenance?

The sharpening system is designed for low maintenance. Routine maintenance includes cleaning the grinding wheels and debris collection system, typically recommended every 3-6 months depending on usage. A maintenance schedule and instructions are provided in the user manual. - What are the power requirements for the cabinet?

The cabinet operates on standard AC power (110V or 220V, depending on the region). Power consumption is minimal during standby mode and increases during the sharpening cycle. Detailed power specifications are available in the product datasheet. - How is knife security and accountability ensured?

Each knife is tagged with a unique identifier, and users are required to authenticate via RFID card or PIN code to retrieve a specific knife. The system logs all knife usage, including who retrieved it and when, providing a complete audit trail. - What happens if a knife is not returned to the cabinet?

The system generates an alert if a knife is not returned within a predefined time. Administrators can track the location of the missing knife through the system's reporting features and take appropriate action. The system also prevents further knife retrieval by the user until the missing knife is returned. - Can the system integrate with existing inventory management systems?

Yes, the cabinet's software can be integrated with various inventory management systems via API. This allows for seamless tracking of knife inventory, usage patterns, and maintenance schedules within your existing workflow.

The Shared Knife Sharpening and Retrieval Cabinet Solution represents a significant leap forward in smart kitchen and tool management. By integrating advanced PCB technology and intelligent design, Zero One Solution Limited delivers a system that not only ensures consistently sharp blades but also elevates operational efficiency, security, and hygiene. From the precision of our PCB designs to the robustness of the assembled units, every aspect reflects our commitment to innovation and quality. Embrace the future of knife management with a solution that's as intelligent as it is indispensable. Ready to revolutionize your knife sharpening and retrieval process? Contact Zero One Solution Limited today to discover how our expertise can empower your operations.

AnyPCBA

AnyPCBA