Shared Medical Device Solution

In an era where healthcare demands innovation and efficiency, the concept of a shared medical device solution is rapidly gaining traction. Healthcare providers worldwide face the challenge of optimizing resource utilization while maintaining high standards of patient care. What if there was a way to significantly reduce capital expenditure on medical equipment, enhance accessibility, and improve overall operational fluidity? This article delves into the transformative potential of shared medical device solutions, highlighting how Zero One Solution Limited, a leader in advanced PCB solutions, is enabling this paradigm shift by providing the critical technological backbone for these complex systems.

The Evolving Landscape of Healthcare Technology

The healthcare industry is undergoing a significant transformation, driven by escalating costs and relentless technological innovation. This dynamic environment necessitates innovative solutions for medical device acquisition and utilization, paving the way for shared medical device models. These models promise to optimize resource allocation, improve access to cutting-edge technologies, and ultimately enhance patient care. Zero One Solution Limited plays a pivotal role in this evolution by providing advanced PCB solutions that are crucial for the functionality and reliability of modern medical devices.

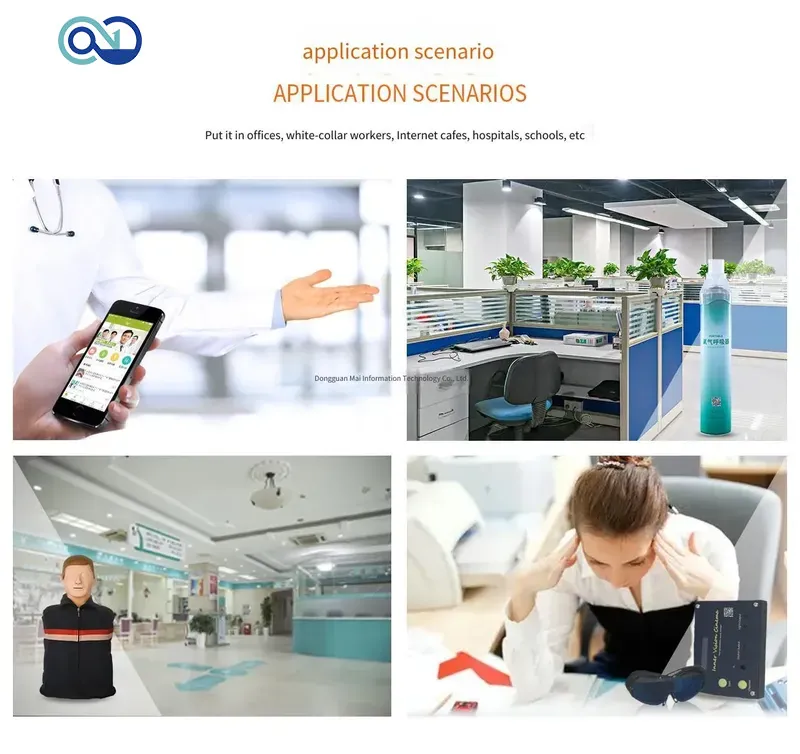

The confluence of rising healthcare expenditures and rapid advancements in medical technology is creating a compelling need for innovative approaches to medical device management. Traditional models of individual device ownership are becoming increasingly unsustainable for many healthcare providers, particularly smaller clinics and hospitals. Shared medical device solutions, encompassing strategies like rental, subscription, and community-based sharing, offer a viable alternative by enabling access to state-of-the-art equipment without the burden of significant capital investments.

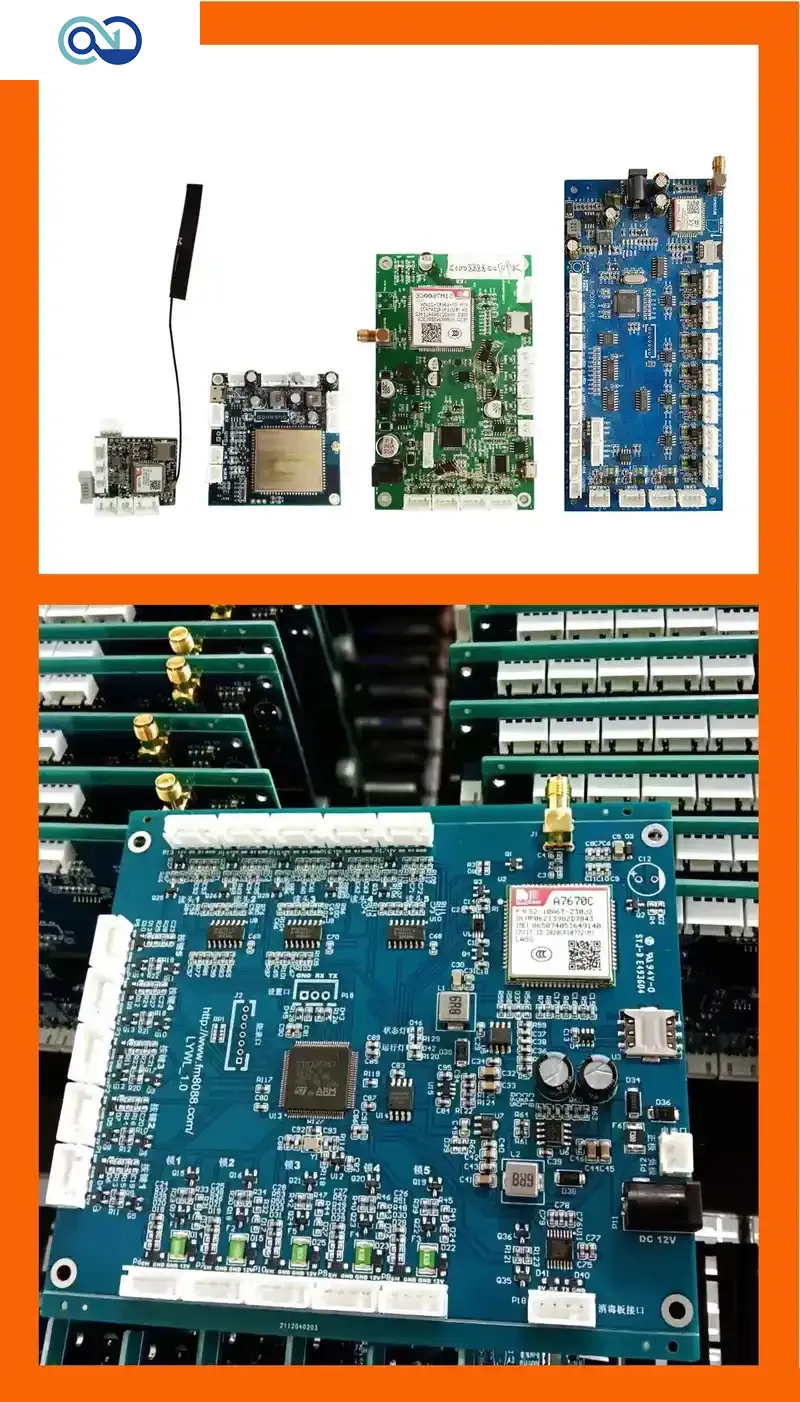

Technological advancements are equally critical in shaping this evolving landscape. Sophisticated imaging systems, robotic surgery platforms, and advanced diagnostic tools are pushing the boundaries of medical care, but their complexity demands robust and reliable electronic components. Printed Circuit Boards (PCBs) form the backbone of these devices, ensuring seamless communication, data processing, and power distribution. Zero One Solution Limited, as a specialized PCB solution provider, is at the forefront of this technological shift, offering customized PCB design, manufacturing, and assembly services tailored to the unique requirements of shared medical devices.

The reliability and performance of PCBs are paramount in the context of shared medical equipment. These devices are often subjected to intensive use and must adhere to stringent regulatory standards to guarantee patient safety. Zero One Solution Limited's commitment to quality and its expertise in rapid prototyping enable the development of highly dependable PCB solutions that meet the rigorous demands of the medical sector. By providing one-stop services from design to assembly, Zero One Solution Limited empowers medical device manufacturers to accelerate product development and deliver innovative solutions that enhance the efficiency and effectiveness of shared medical device models.

Understanding the Shared Medical Device Solution Model

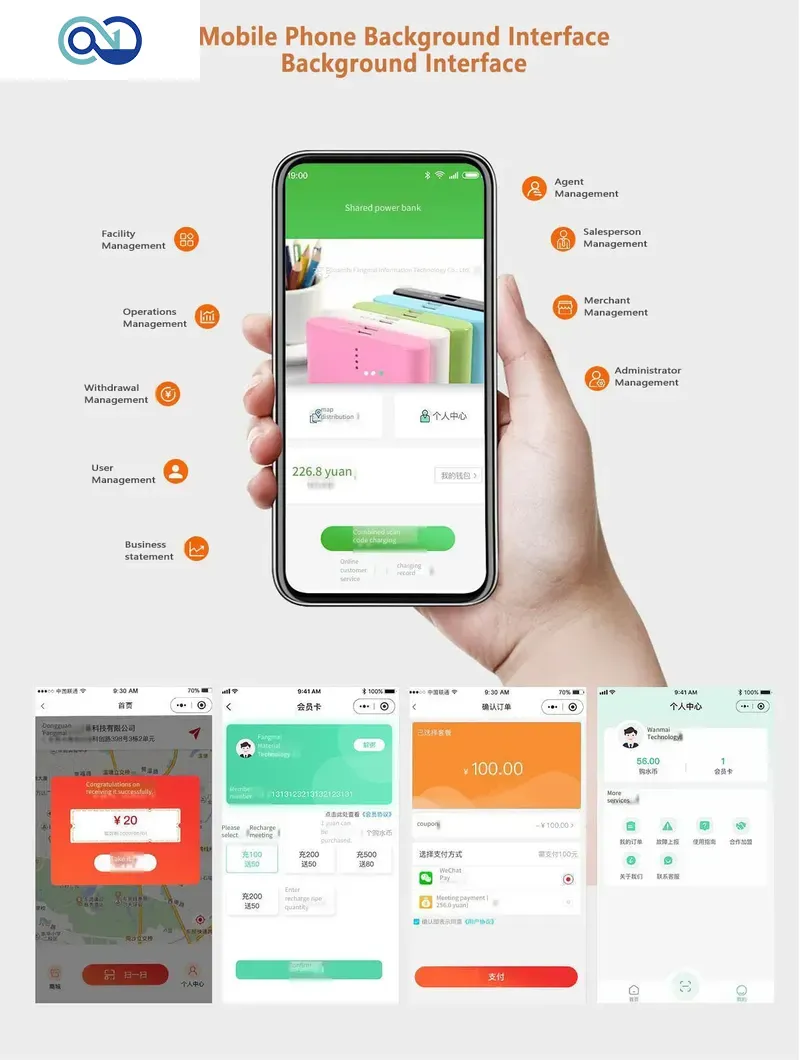

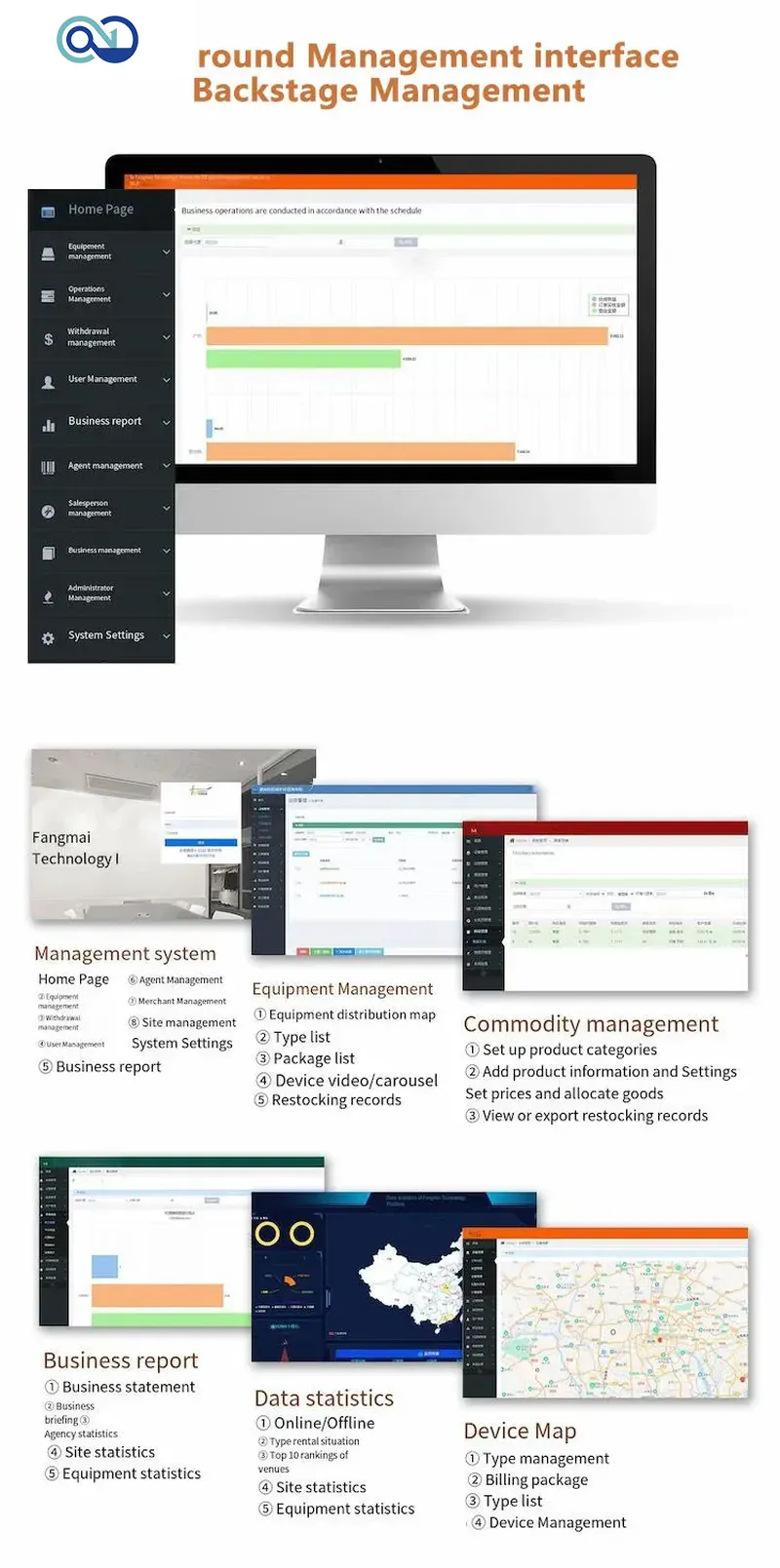

The Shared Medical Device Solution Model represents a paradigm shift in healthcare, moving away from individual ownership to collaborative access of essential medical equipment. This innovative approach encompasses various operational frameworks, including rental, subscription, and community-based sharing, each designed to optimize resource utilization and enhance healthcare delivery. At the heart of these models lies a sophisticated technological infrastructure, where robust and reliable PCB solutions are indispensable for ensuring seamless interconnectivity and functionality across all shared devices.

- Rental Model

This model involves leasing medical devices for a specific period. It is ideal for short-term needs or when evaluating new technologies. The rental model enables healthcare providers to access cutting-edge equipment without the upfront capital expenditure. PCB solutions are critical for ensuring the device's reliability and functionality throughout the rental period. - Subscription Model

A subscription-based approach offers continuous access to medical devices for a recurring fee. This model is beneficial for facilities that require consistent use of equipment but prefer predictable costs. The PCBs within these devices must be designed for longevity and consistent performance, ensuring the subscription remains a valuable asset. - Community-Based Sharing

This model allows multiple healthcare providers within a community to share medical devices, optimizing resource utilization across different facilities. This approach reduces redundancy and ensures that even smaller clinics have access to advanced technology. The PCBs in community-shared devices must support secure data sharing and reliable operation across various environments. - Cost Reduction

By sharing medical devices, healthcare facilities can significantly reduce capital expenditure, maintenance costs, and the overall financial burden associated with equipment ownership. Advanced PCB solutions enhance the longevity and reliability of shared devices, further driving down costs and maximizing return on investment. - Improved Access to Advanced Equipment

Shared medical device solutions enable healthcare providers to access cutting-edge technology that would otherwise be unaffordable. This access improves diagnostic accuracy, treatment efficacy, and patient outcomes. High-performance PCBs are vital for supporting the advanced features and capabilities of these shared devices. - Enhanced Operational Flexibility

These solutions provide healthcare facilities with greater flexibility in managing their equipment inventory, allowing them to quickly adapt to changing needs and technological advancements. Robust PCB designs ensure that shared devices can be easily integrated into existing workflows and operated efficiently.

Key Benefits of Adopting a Shared Medical Device Solution

Adopting a shared medical device solution offers significant advantages for healthcare facilities, primarily centered around cost efficiency and access to advanced technology. These benefits extend to capital expenditure savings, reduced maintenance costs, and the ability to utilize cutting-edge equipment without substantial upfront investments, all while promoting environmental sustainability. Reliable and high-performance PCBs, such as those provided by Zero One Solution Limited, are crucial in realizing these benefits within shared medical equipment.

- Reduced Capital Expenditure

Shared medical device solutions eliminate the need for individual healthcare facilities to purchase expensive equipment outright. This model allows for access to advanced technology without tying up large sums of capital, freeing up resources for other critical areas. - Lower Maintenance Costs

Maintenance responsibilities and costs are typically shared or handled by the solution provider, reducing the burden on individual healthcare facilities. This includes repairs, calibration, and software updates, leading to predictable operational expenses. - Access to Cutting-Edge Technology

Shared models facilitate access to the latest medical devices, ensuring that healthcare providers can offer state-of-the-art diagnostics and treatments. This is particularly beneficial for smaller facilities that may not otherwise be able to afford such equipment. - Environmental Sustainability

By optimizing equipment utilization and reducing redundancy, shared medical device solutions contribute to environmental sustainability. Fewer devices need to be manufactured overall, leading to reduced resource consumption and waste. - Enhanced Operational Flexibility

Shared solutions provide flexibility in scaling equipment needs based on demand. Healthcare facilities can access additional devices during peak periods without the long-term commitment of ownership. - Improved Resource Allocation

Cost savings from shared medical device solutions can be reinvested into other crucial areas, such as staffing, training, and infrastructure improvements, ultimately enhancing patient care. - Risk Mitigation

Technology obsolescence is a significant concern in healthcare. Shared solutions mitigate this risk by ensuring that equipment is regularly updated or replaced, keeping facilities at the forefront of medical technology.

Technological Foundation: The Role of Advanced PCB Solutions

Printed Circuit Boards (PCBs) are the backbone of modern medical devices, acting as the central hub for all electronic components. In the context of shared medical equipment, the demands placed on these PCBs are amplified, requiring a foundation of reliability, security, and connectivity to ensure seamless and safe operation. Zero One Solution Limited stands at the forefront, providing sophisticated PCB solutions tailored to meet these stringent requirements.

Several specific PCB requirements are critical for shared medical equipment:

- Reliability

Shared medical devices experience frequent use and handling, demanding PCBs that can withstand mechanical stress, temperature variations, and constant operation. High-quality materials and robust manufacturing processes are essential to prevent failures and ensure consistent performance over the device's lifespan. - Data Security

Protecting patient data is paramount. PCBs must support encryption and secure data transmission protocols to prevent unauthorized access. Secure PCB design and component selection are crucial for safeguarding sensitive information in shared medical environments. - Connectivity (IoT)

Shared devices benefit from IoT integration, enabling remote monitoring, diagnostics, and software updates. PCBs must facilitate seamless connectivity through Wi-Fi, Bluetooth, or cellular technologies, allowing for real-time data exchange and efficient device management. - Remote Diagnostics

Remote diagnostic capabilities minimize downtime and maintenance costs. PCBs should support sensors and communication interfaces that allow technicians to remotely assess device performance, identify potential issues, and perform necessary repairs or updates. - Power Efficiency

Energy efficiency is vital for portable and battery-powered shared medical devices. PCBs must be designed to minimize power consumption, extending battery life and reducing the overall environmental impact. Efficient power management circuitry and component selection are key to achieving this.

Zero One Solution Limited excels in delivering PCB solutions that meet these exacting demands. Their expertise in design, materials, and manufacturing processes ensures that shared medical devices are equipped with PCBs that are not only reliable and secure but also optimized for connectivity and power efficiency. By focusing on these critical aspects, Zero One Solution Limited empowers medical device manufacturers to create innovative and effective shared solutions that enhance patient care and improve healthcare outcomes.

Zero One Solution Limited: Powering the Future of Shared Medical Devices

Zero One Solution Limited stands at the forefront of enabling the shared medical device revolution through its specialized expertise in PCB (Printed Circuit Board) design, rapid prototyping, manufacturing, and assembly. With a commitment to the medical sector, Zero One Solution Limited offers a comprehensive suite of services and a robust global supply chain network to support the creation of secure, reliable, and high-performance shared medical device solutions.

Here's how Zero One Solution Limited contributes to powering the future of shared medical devices:

- Expertise in PCB Design

Zero One Solution Limited excels in crafting PCB designs tailored to the unique demands of shared medical equipment. These designs prioritize signal integrity, miniaturization, and efficient power distribution. - Rapid Prototyping Capabilities

Understanding the need for speed in medical device innovation, Zero One Solution Limited provides rapid prototyping services. This allows for quick iteration and validation of PCB designs, accelerating the development cycle for shared medical devices. - Manufacturing and Assembly Excellence

With state-of-the-art manufacturing facilities, Zero One Solution Limited ensures the production of high-quality PCBs that meet the stringent requirements of the medical industry. Their PCBA (Printed Circuit Board Assembly) services guarantee precise component placement and reliable connections. - One-Stop Service

From initial design to final assembly, Zero One Solution Limited offers a comprehensive one-stop service. This streamlined approach reduces complexity and ensures seamless integration of PCB solutions into shared medical devices. - Global Supply Chain Network

Zero One Solution Limited's strategically positioned headquarters in Shenzhen and branch office in Dubai, coupled with its extensive global PCBA supply chain network, ensures access to worldwide resources and support. This enables efficient sourcing of components and timely delivery of PCB solutions, regardless of the client's location. - Contribution to Functionality and Sharing Capabilities

Zero One Solution Limited's PCBA solutions directly enhance the functionality and sharing capabilities of medical devices by supporting features such as remote monitoring, data encryption, and secure wireless communication. This is vital for ensuring the safe and efficient operation of shared medical equipment.

By focusing on these key areas, Zero One Solution Limited empowers medical device manufacturers to create innovative and reliable shared solutions that improve healthcare accessibility and efficiency.

Overcoming Challenges in Shared Medical Device Implementation

Implementing a shared medical device solution presents significant challenges, including ensuring data privacy, effective sanitization processes, managing complex logistics, and adhering to stringent regulatory compliance. Addressing these hurdles effectively is crucial for the successful adoption and operation of shared medical device programs, demanding robust technological and procedural safeguards.

- Data Privacy

Protecting patient data is paramount. Shared devices must incorporate robust security measures to prevent unauthorized access and ensure compliance with regulations like HIPAA. Solutions include advanced encryption, secure authentication protocols, and comprehensive audit trails to monitor data access and usage. - Sanitization

Thorough sanitization between uses is essential to prevent the spread of infections. Implementing standardized cleaning protocols and using materials resistant to harsh disinfectants are crucial. Technologies like UV sterilization can also be integrated into device designs for enhanced sanitization. - Logistics

Managing the movement and availability of shared devices requires efficient logistics. Real-time tracking systems, automated inventory management, and optimized transportation strategies are necessary to ensure devices are available when and where they are needed, minimizing downtime and maximizing utilization. - Regulatory Compliance

Shared medical devices must comply with various regulations, including those related to safety, performance, and data privacy. This requires meticulous documentation, rigorous testing, and adherence to industry standards such as ISO 13485. Partnering with experienced PCB solution providers like Zero One Solution Limited, who prioritize quality and compliance, is critical. - Connectivity and Interoperability

Ensuring seamless connectivity and interoperability between shared devices and hospital networks is vital for data transfer and remote monitoring. Standardized communication protocols and secure interfaces are essential to facilitate data exchange and integration with existing healthcare systems. - Device Security

Protecting shared medical devices from cyber threats is crucial. Implementing robust security measures, such as intrusion detection systems and regular security audits, can help prevent unauthorized access and protect sensitive data.

Zero One Solution Limited addresses these challenges through advanced PCB design and integrated solutions. Their commitment to quality and compliance ensures secure data transfer and reliable operation in shared medical device environments. By focusing on robust design, secure connectivity, and adherence to regulatory standards, Zero One Solution Limited helps mitigate risks and enables the successful implementation of shared medical device solutions.

Case Studies and Future Outlook

The shared medical device solution model is gaining traction, evidenced by emerging success stories and promising future trends. These narratives underscore the transformative potential of shared resources in healthcare, propelled by innovations in advanced electronics and PCB technology. As we explore these case studies and future directions, the pivotal role of Zero One Solution Limited in enabling this evolution becomes increasingly apparent.

Let's examine some hypothetical, yet realistic, scenarios where shared medical devices have made a significant impact:

- Case Study 1: Rural Healthcare Improvement

A network of rural clinics implements a shared ultrasound device program. High-quality, portable ultrasound machines, equipped with robust PCBs for reliable imaging and data transmission, are shared among the clinics. This dramatically improves diagnostic capabilities in underserved areas, reduces the need for patients to travel long distances, and lowers overall healthcare costs. Zero One Solution Limited's durable and efficient PCBAs ensure the devices withstand the rigors of transport and frequent use. - Case Study 2: Cost-Effective Rehabilitation Centers

A consortium of rehabilitation centers adopts a shared robotic rehabilitation system. Advanced robotic exoskeletons, reliant on complex PCBs for precise motor control and sensor integration, are shared amongst the facilities. This allows each center to offer cutting-edge rehabilitation services without the prohibitive cost of individual ownership. Zero One Solution Limited provides PCBs that meet the stringent safety and performance requirements of these robotic systems. - Case Study 3: Optimized Hospital Resource Allocation

A large hospital implements a shared inventory of specialized surgical instruments. These instruments, incorporating sophisticated PCBs for real-time monitoring and control, are tracked and managed using an IoT-enabled system. This minimizes instrument downtime, reduces the risk of lost or misplaced equipment, and optimizes surgical workflow. Zero One Solution Limited's expertise in connectivity solutions makes this seamless sharing and tracking possible.

Looking ahead, the future of shared medical device solutions is bright, with several exciting trends on the horizon:

- AI Integration

Artificial intelligence will play an increasing role in optimizing the utilization and performance of shared medical devices. AI algorithms can analyze usage patterns, predict maintenance needs, and personalize treatment protocols. High-performance PCBs will be essential for supporting the computational demands of these AI-powered systems. - Predictive Maintenance

Shared medical devices will increasingly incorporate sensors and analytics to predict potential failures and schedule maintenance proactively. This minimizes downtime, extends the lifespan of the equipment, and reduces the risk of unexpected disruptions. Robust and reliable PCBs are critical for ensuring the accuracy and consistency of these predictive maintenance systems. - Further Miniaturization

The trend towards smaller, more portable medical devices will continue, driven by advancements in PCB technology. Smaller devices are easier to share, transport, and integrate into various healthcare settings. Zero One Solution Limited is at the forefront of this miniaturization trend, providing high-density interconnect (HDI) PCBs that enable smaller and more powerful devices.

Zero One Solution Limited is poised to remain a key enabler of the shared medical device revolution. Our commitment to innovation, quality, and compliance ensures that our PCB solutions meet the evolving needs of this dynamic market. By providing reliable, high-performance, and secure PCBAs, we empower healthcare providers to deliver better care at a lower cost, ultimately improving patient outcomes.

Frequently Asked Questions About Shared Medical Device Solutions

Navigating the landscape of shared medical device solutions can bring up several questions. This section addresses common inquiries concerning their implementation, advantages, and technical underpinnings, providing succinct and insightful answers, particularly regarding the crucial role of reliable PCB solutions.

- What exactly is a shared medical device solution?

A shared medical device solution involves a model where medical equipment is utilized by multiple healthcare providers or departments, optimizing resource allocation and reducing individual capital expenditure. This can take the form of rental agreements, subscription services, or community-based sharing programs. - What are the primary benefits of adopting a shared medical device model?

The key advantages include reduced capital expenditure, access to advanced technology without hefty upfront costs, lower maintenance expenses, enhanced operational flexibility, and a smaller environmental footprint due to optimized resource utilization. - How does PCB design impact the reliability of shared medical devices?

PCB design is paramount for reliability. Shared medical devices require robust PCBs to ensure consistent performance under frequent use and varying environmental conditions. High-quality PCB design, like that offered by Zero One Solution Limited, minimizes failure rates and ensures long-term operational stability. - What are the data security considerations for shared medical devices, and how are they addressed?

Data security is a critical concern. Secure PCB design incorporates features like encryption, secure boot, and tamper detection to protect sensitive patient data. Compliance with HIPAA and other data privacy regulations is also essential, and robust PCB solutions contribute significantly to meeting these standards. - How do shared medical devices handle sanitization and prevent cross-contamination?

Sanitization protocols are vital. The design of shared medical devices must facilitate easy and thorough cleaning. PCBs play a role by utilizing materials resistant to harsh cleaning agents and by ensuring that all components are securely sealed to prevent ingress of contaminants. - What role does remote diagnostics play in shared medical device solutions?

Remote diagnostics enables proactive maintenance and reduces downtime. Advanced PCBs equipped with IoT connectivity allow for real-time monitoring of device performance, enabling early detection of potential issues and facilitating remote troubleshooting. - What is the importance of compliance and certification in shared medical devices?

Compliance with medical device standards (e.g., ISO 13485, FDA regulations) is non-negotiable. Certified PCB solutions guarantee that the shared medical device meets stringent safety and performance requirements, ensuring patient safety and regulatory adherence.

The shared medical device solution represents a significant leap forward in healthcare resource management, promising enhanced accessibility, reduced costs, and improved patient outcomes. Zero One Solution Limited stands at the forefront of this evolution, leveraging our deep expertise in PCB design, manufacturing, and assembly to power the next generation of medical equipment sharing platforms. Our commitment to rapid prototyping and one-stop service ensures that innovators in the medical technology space can bring their vision to reality with unparalleled speed and reliability. Partner with Zero One Solution Limited to transform your medical device initiatives. Visit our website or contact us today to explore how our cutting-edge PCB solutions can accelerate your success in the rapidly evolving healthcare landscape.

AnyPCBA

AnyPCBA