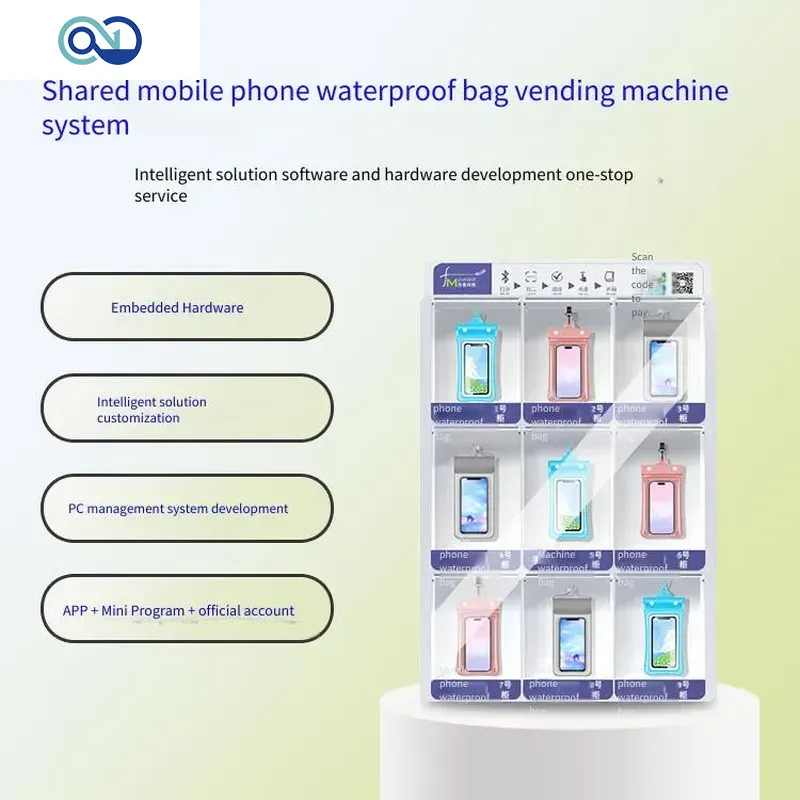

Shared Phone Waterproof Bag Solution

In an increasingly connected world, shared electronic devices like shared phones are becoming ubiquitous. However, their exposure to diverse environments presents a critical challenge: protection from water damage. Imagine the financial implications and operational headaches caused by water-damaged shared devices. This article delves into the intricacies of developing a robust 'Shared Phone Waterproof Bag Solution,' highlighting how advanced PCB design and manufacturing are at the core of ensuring these devices can withstand the elements, extending their lifespan and maximizing their utility. Zero One Solution Limited, a leader in rapid-response R&D prototype manufacturing, offers the specialized PCB solutions essential for bringing such innovative, durable products to market.

The Growing Need for Shared Device Protection

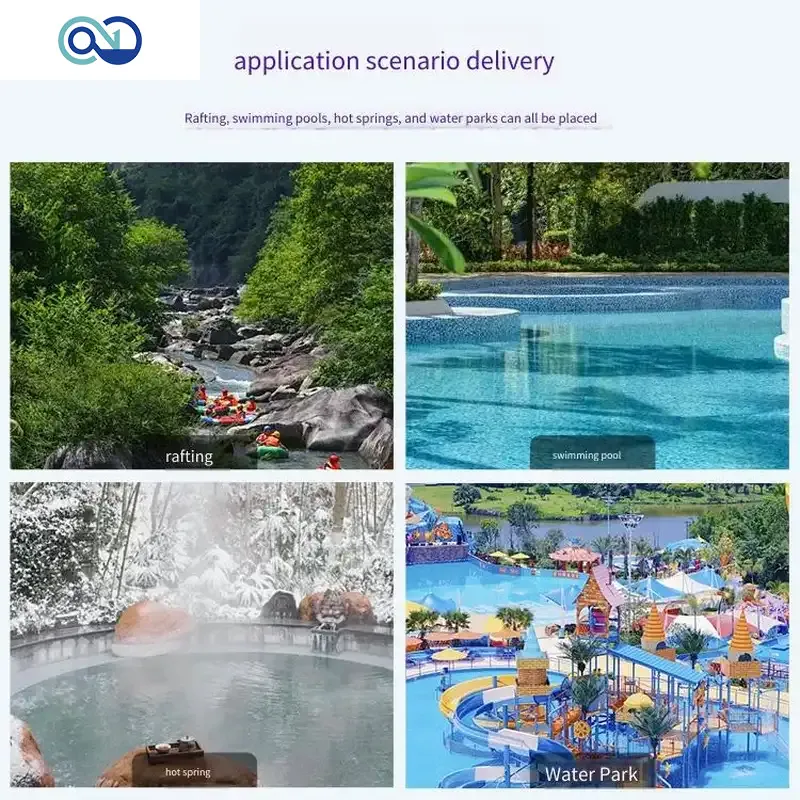

The demand for shared electronic devices is rapidly increasing across various sectors, driven by efficiency, cost-effectiveness, and enhanced user experiences. However, this proliferation brings a heightened risk of environmental exposure, particularly water damage, necessitating robust protection solutions like shared phone waterproof bags. These solutions are no longer a luxury but a necessity to ensure the longevity and reliability of shared devices in diverse and demanding environments.

- Why is there an increasing need for shared device protection?

Shared devices are used in various harsh environments, increasing the risk of damage from water, dust, and impacts. Protecting these devices ensures business continuity, reduces replacement costs, and maintains operational efficiency. - In which sectors is shared device protection most critical?

Industries such as hospitality, healthcare, construction, and logistics rely heavily on shared devices. These sectors expose devices to various environmental hazards, making waterproof solutions essential. - What are the primary risks to shared electronic devices?

The main risks include water damage, dust ingress, physical impacts, and extreme temperatures. Water damage is particularly critical as it can cause immediate device failure and data loss. - How does water damage impact the performance of shared devices?

Water ingress can corrode internal components, short-circuit electronics, and cause irreversible damage. This leads to device malfunction, data loss, and costly repairs or replacements. - What are the benefits of using shared phone waterproof bags?

Waterproof bags provide a protective barrier against water, dust, and other contaminants, extending the lifespan of the device. They reduce downtime, lower maintenance costs, and ensure reliable performance in challenging conditions. - How do shared phone waterproof bags contribute to cost savings?

By preventing water damage, these bags minimize the need for frequent device repairs and replacements. This leads to significant long-term cost savings and reduces the total cost of ownership for shared electronic devices. - What features should users look for in a reliable shared phone waterproof bag?

Key features include a durable, waterproof material, a secure sealing mechanism, and a design that allows for easy device operation. Look for bags with high waterproof ratings (e.g., IP67 or IP68) to ensure maximum protection.

Challenges in Waterproofing Shared Electronic Devices

Waterproofing shared electronic devices, particularly shared phones within waterproof bags, presents unique engineering and design challenges. Unlike personal devices, shared devices endure more frequent handling, diverse environmental exposures, and a higher likelihood of accidental misuse. Creating a solution robust enough to withstand these variables requires careful consideration of several factors, from material selection to sealing mechanisms.

- Material Degradation

Frequent cleaning with harsh chemicals can degrade the waterproof materials over time, compromising the bag's integrity. Selecting chemical-resistant materials is crucial but can be costly. - Sealing Integrity

The sealing mechanism must maintain its integrity despite repeated openings and closings by different users. Wear and tear on zippers, clasps, or other closures can lead to leaks. - User Compliance

Ensuring consistent and correct usage by all users is difficult. Improper closure of the bag or exceeding its capacity can compromise waterproofing. - Environmental Variance

Shared devices may be exposed to a wide range of temperatures, humidity levels, and contaminants (e.g., sand, salt water). The waterproof bag must be designed to withstand these diverse conditions. - Pressure and Immersion

The bag needs to withstand not only splashes but also potential submersion. The depth and duration of immersion protection must be clearly defined and rigorously tested. - Design for Durability vs. Cost

Balancing robust waterproofing with cost-effectiveness is a significant challenge. Over-engineering can increase costs, while under-engineering can lead to premature failure and user dissatisfaction. - Integration with Device Functionality

The bag's design must not impede the phone's functionality (e.g., touchscreen sensitivity, camera use, audio quality). This requires careful selection of transparent materials and ergonomic design.

Key Components of a Robust Shared Phone Waterproof Bag Solution

A robust shared phone waterproof bag solution comprises several essential elements working in concert to provide reliable protection. These include the selection of appropriate materials, the implementation of effective sealing mechanisms, and, critically, the design and manufacturing of custom PCBs for the bag's internal electronics. Each component plays a vital role in ensuring the device remains safe from water damage, even under demanding usage conditions.

- High-Quality Materials

The outer layer of the waterproof bag must be constructed from durable, waterproof materials such as TPU (Thermoplastic Polyurethane) or PVC (Polyvinyl Chloride). These materials offer excellent water resistance and can withstand the rigors of daily use. Transparent materials should maintain clarity for easy phone use. - Secure Sealing Mechanisms

Effective sealing is paramount. Options include robust zipper-lock closures with multiple seals, airtight buckles, or heat-sealed edges. These mechanisms prevent water ingress even when the bag is submerged or exposed to heavy rain. - Custom PCB Design

The internal electronics, often overlooked, are just as crucial. A custom-designed PCB (Printed Circuit Board) should be compact, energy-efficient, and, ideally, coated with a waterproof layer to protect against condensation or minor leaks. The PCB may include features like charging ports or connectivity enhancements. - Waterproof Connectors

If the bag includes external connectors (e.g., for headphones or charging), these must be waterproofed using gaskets, O-rings, or specialized waterproof connectors to maintain the enclosure's integrity. - Internal Cushioning and Support

To protect the phone from impacts, the bag should incorporate internal cushioning made from materials like foam or gel. This also helps to maintain the phone's position within the bag. - Testing and Certification

A robust solution undergoes rigorous testing to meet industry standards like IP (Ingress Protection) ratings. Certification provides assurance that the bag can withstand specific levels of water exposure.

Zero One Solution Limited's Expertise in Waterproof PCB Solutions

Zero One Solution Limited excels in designing and manufacturing specialized PCBs tailored for harsh environments, particularly for applications like shared phone waterproof bags. Our expertise lies in rapid prototyping and delivering high-reliability solutions that meet the stringent demands of devices exposed to water and other environmental factors. We offer comprehensive services encompassing PCB design, manufacturing, and assembly, ensuring a seamless process from concept to final product.

- Rapid Prototyping Services

Zero One Solution Limited provides rapid prototyping services, enabling quick turnaround times for testing and refining designs for waterproof PCB solutions. This allows clients to accelerate their product development cycles and bring innovations to market faster. - High-Reliability PCB Manufacturing

Our manufacturing processes are optimized for high reliability, ensuring that the PCBs used in shared phone waterproof bags can withstand demanding conditions. We adhere to strict quality control measures and utilize advanced manufacturing techniques to guarantee consistent performance. - Specialized PCB Design for Harsh Environments

We specialize in designing PCBs that are specifically engineered to perform in harsh environments. This includes selecting appropriate materials, implementing protective coatings, and optimizing layouts to resist water ingress and corrosion. - One-Stop PCB Services

From initial design to final assembly, Zero One Solution Limited offers a comprehensive suite of PCB services. This integrated approach streamlines the development process, reduces lead times, and ensures seamless coordination between design and manufacturing teams. - Global Supply Chain Network

Headquartered in Shenzhen, China, with a branch office in Dubai, we operate within a global PCBA supply chain network. This strategic positioning allows us to access worldwide resources and support, ensuring efficient sourcing of components and timely delivery of solutions. - Customized Waterproof PCB Solutions

Understanding that each application has unique requirements, Zero One Solution Limited offers customized PCB solutions tailored to specific needs. Our engineering team works closely with clients to develop solutions that meet their exact specifications and performance expectations.

The PCB's Role in Ensuring Shared Phone Waterproof Bag Durability

The durability of a shared phone waterproof bag hinges significantly on the quality and design of its internal Printed Circuit Board (PCB). The PCB acts as the central nervous system, connecting and controlling all electronic components. Its robustness is paramount to withstanding the rigors of shared use and environmental challenges, directly affecting the bag's ability to protect the phone inside.

A well-designed PCB contributes to the overall durability of a shared phone waterproof bag in several crucial ways:

- Component Selection

Choosing high-quality, ruggedized components ensures that the PCB can withstand shocks, vibrations, and temperature fluctuations common in shared usage scenarios. Components with wider operating temperature ranges and higher tolerances for voltage variations contribute to increased reliability. - Circuit Layout

An optimized circuit layout minimizes signal interference and heat generation. Proper routing of traces and strategic placement of components can prevent hotspots and ensure efficient power distribution, extending the lifespan of both the PCB and the electronic components. - Material Selection

The base material of the PCB, typically FR-4 or similar composites, should be chosen for its mechanical strength, thermal stability, and resistance to moisture absorption. Higher-grade materials offer superior performance in harsh environments. - Conformal Coating

Applying a conformal coating, such as acrylic or epoxy, protects the PCB from moisture, dust, and chemical contaminants. This coating acts as a barrier, preventing corrosion and short circuits that can lead to premature failure. - Manufacturing Process

A precise and controlled manufacturing process is essential for ensuring the quality and reliability of the PCB. This includes proper soldering techniques, thorough cleaning, and rigorous quality control checks at each stage of production. Zero One Solution Limited employs advanced manufacturing techniques to ensure high-quality PCBs. - Testing and Validation

Comprehensive testing, including environmental testing (temperature cycling, humidity testing) and functional testing, is crucial for identifying potential weaknesses in the PCB design or manufacturing process. This ensures that the PCB meets the required performance and reliability standards.

In essence, the PCB's role extends beyond simply connecting components; it serves as a protective backbone for the entire electronic system within the shared phone waterproof bag. Its design and construction directly influence the bag's ability to withstand harsh conditions and provide reliable, long-term protection for the device it houses.

Design Considerations for Optimal Waterproof Performance

Achieving superior waterproof performance in shared phone waterproof bags hinges on meticulous design considerations. These factors span from material selection and component placement to advanced coating techniques and rigorous testing protocols. A comprehensive approach to these design elements is crucial for ensuring the reliability and longevity of the waterproof bag and the safety of the device it protects.

- Component Selection for Waterproof PCBs

Choosing components rated for harsh environments is paramount. Opt for waterproof connectors, sealed switches, and encapsulated sensors to prevent water ingress at vulnerable points. Furthermore, select components with a wide operating temperature range to accommodate varied environmental conditions. - Conformal Coating Application on Waterproof PCBs

Apply a high-quality conformal coating to the PCB to provide a protective barrier against moisture. Ensure complete coverage, especially around sensitive components and traces. Consider using automated coating techniques for consistent and reliable application. Common coating materials include acrylic, silicone, urethane, and epoxy resins. Select the appropriate material based on the specific environmental conditions and performance requirements. - Circuit Layout Optimization for Waterproof PCBs

Design the circuit layout to minimize the risk of short circuits and corrosion. Increase trace spacing in areas prone to moisture accumulation. Implement guard rings around sensitive components to divert leakage currents. Route traces away from the edges of the PCB to prevent edge ingress. - Testing Protocols for Waterproof PCBs

Implement rigorous testing protocols to validate the waterproof performance of the shared phone waterproof bag. Conduct ingress protection (IP) testing according to industry standards (e.g., IP67, IP68). Perform functional testing before and after waterproofing to ensure that the device operates correctly under wet conditions. Consider using accelerated aging tests to simulate long-term exposure to moisture and temperature variations. - Material Selection for the Waterproof Bag

Select durable, waterproof materials for the bag's construction. Consider using materials such as TPU (Thermoplastic Polyurethane) or PVC (Polyvinyl Chloride) for their excellent water resistance and flexibility. Ensure that seams are properly sealed using techniques such as ultrasonic welding or high-frequency welding to prevent water penetration. - Sealing Mechanisms

Implement reliable sealing mechanisms to prevent water from entering the bag. Use waterproof zippers, airtight closures, or roll-top designs with secure buckles. Ensure that the sealing mechanisms are easy to use and maintain their integrity over time.

Benefits of Partnering with Zero One Solution Limited for Your Waterproof Projects

Partnering with Zero One Solution Limited offers significant advantages for companies seeking to develop and manufacture shared phone waterproof bag solutions. Our one-stop PCB services, encompassing design, manufacturing, and assembly, streamline the entire process, accelerating time-to-market and ensuring the highest quality for your waterproof electronic products. By leveraging our expertise, clients can mitigate risks, reduce costs, and achieve superior product performance.

- Accelerated Time-to-Market

Zero One Solution Limited's rapid prototyping capabilities significantly reduce the development cycle for waterproof PCB solutions. Our efficient processes enable quick iteration and testing, allowing you to bring your shared phone waterproof bag to market faster than competitors. - Comprehensive One-Stop Service

From initial PCB design to final assembly, we offer a complete suite of services. This integrated approach ensures seamless communication and coordination, minimizing errors and delays often associated with using multiple vendors. - Expertise in Waterproof PCB Design and Manufacturing

Our team possesses extensive knowledge and experience in designing and manufacturing PCBs specifically for harsh environments. We understand the critical design considerations, such as component selection, conformal coating, and layout optimization, necessary for achieving superior waterproof performance. - High-Reliability Solutions

We are committed to delivering high-reliability PCB solutions that meet the stringent demands of shared phone waterproof bags. Our rigorous testing protocols and quality control measures ensure that our PCBs can withstand challenging conditions and provide long-term performance. - Cost-Effective Solutions

By consolidating your PCB needs with Zero One Solution Limited, you can benefit from economies of scale and reduced overhead costs. Our efficient processes and competitive pricing help you optimize your budget without compromising quality. - Access to a Global PCBA Supply Chain Network

Headquartered in Shenzhen, China, and with a branch office in Dubai, we operate strategically within a global PCBA supply chain network. This enables us to source high-quality components at competitive prices and provide seamless access to worldwide resources and support. - Customized Solutions Tailored to Your Needs

We understand that every project is unique. We work closely with our clients to develop customized PCB solutions that meet their specific requirements and performance goals for shared phone waterproof bags and other waterproof applications.

Frequently Asked Questions About Shared Phone Waterproof Bag Solutions

Navigating the world of shared phone waterproof bag solutions can bring up several questions. This section addresses the most common inquiries, providing clear and concise answers about the technology, manufacturing, and reliability of these essential protective accessories.

- What level of water submersion can a shared phone waterproof bag withstand?

The water resistance level of a shared phone waterproof bag typically depends on its Ingress Protection (IP) rating. Bags rated IP67 can withstand immersion in water up to 1 meter for 30 minutes, while IP68-rated bags can handle deeper and longer submersion periods. Always check the product specifications to ensure it meets your needs. - How does a waterproof bag protect a shared phone's PCB from water damage?

A high-quality waterproof bag creates a watertight seal that prevents water from reaching the phone and its internal components, including the PCB. Additional measures like conformal coatings on the PCB itself provide an extra layer of protection against moisture and corrosion, safeguarding the device's functionality and longevity. - Can the touch screen still be used effectively when the shared phone is inside the waterproof bag?

Yes, most shared phone waterproof bags are designed with a transparent, touch-sensitive window that allows users to operate the phone's touch screen without removing it from the bag. The material used for the window is crucial; it should be thin enough to transmit touch commands but durable enough to resist punctures and tears. - What materials are typically used to make a shared phone waterproof bag?

Shared phone waterproof bags are commonly made from materials like PVC, TPU (Thermoplastic Polyurethane), or other waterproof fabrics. These materials are chosen for their flexibility, durability, and ability to create a watertight seal when properly constructed. The seams are usually welded or sealed to further enhance the bag's waterproof capabilities. - How often should shared phone waterproof bags be inspected for damage?

Shared phone waterproof bags should be inspected each time before use. Check for any signs of wear and tear, such as punctures, tears, or damage to the sealing mechanism. Regular inspection can help identify potential issues before they lead to water damage of the enclosed phone. - Are there any specific maintenance tips to prolong the life of a shared phone waterproof bag?

To extend the life of a shared phone waterproof bag, rinse it with fresh water after exposure to saltwater or chlorine. Avoid exposing the bag to extreme temperatures or direct sunlight for prolonged periods, as this can degrade the materials. Store the bag in a cool, dry place when not in use. - Can Zero One Solution Limited assist with custom PCB design for shared phone waterproof bag solutions?

Yes, Zero One Solution Limited specializes in designing and manufacturing custom PCBs for various applications, including shared phone waterproof bags. Their expertise in rapid prototyping and high-reliability solutions makes them an ideal partner for ensuring the durability and performance of electronic components within waterproof devices.

The 'Shared Phone Waterproof Bag Solution' is more than just a protective accessory; it's a testament to the power of meticulous engineering and advanced PCB technology. By prioritizing robust design and manufacturing, we can ensure the longevity and reliability of shared devices in diverse environments. Zero One Solution Limited stands ready as your trusted partner, offering unparalleled expertise in PCB design, rapid prototyping, and assembly. With our one-stop services, we empower innovators to overcome the challenges of complex electronics and deliver durable, high-performance products. Contact us today to discuss how our bespoke PCB solutions can bring your next waterproof technology project to fruition and accelerate your product development lifecycle.

AnyPCBA

AnyPCBA