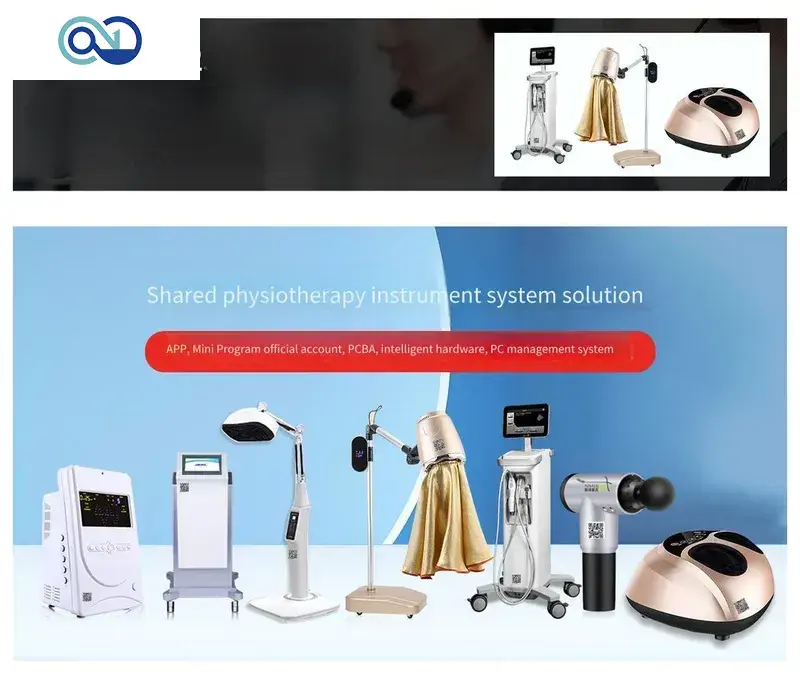

Shared Physiotherapy Device Solution

In the rapidly evolving landscape of healthcare, shared physiotherapy devices are revolutionizing rehabilitation and patient care. These innovative devices, designed for multi-user environments like hospitals and clinics, demand the highest levels of reliability, precision, and safety. At Zero One Solution Limited, we understand the critical role that PCB solutions play in the functionality and effectiveness of these devices. With over a decade of experience in providing rapid prototyping and one-stop services from PCB design to manufacturing and assembly, we are uniquely positioned to empower your physiotherapy device development. This article will delve into the specific PCB challenges and solutions for shared physiotherapy devices, showcasing how Zero One Solution Limited accelerates innovation in this vital field. Much like a well-orchestrated symphony relies on each instrument playing in harmony, these devices require expertly crafted PCBs to deliver precise and reliable therapeutic outcomes.

The Rise of Shared Physiotherapy Devices

The healthcare landscape is witnessing a significant shift towards shared physiotherapy devices, driven by increasing demand for accessible and cost-effective rehabilitation solutions. This trend necessitates robust and reliable PCB solutions to ensure the seamless and safe operation of these devices, ultimately enhancing patient outcomes and optimizing healthcare delivery.

- What factors are driving the increased adoption of shared physiotherapy devices?

Several factors contribute to this rise, including the aging population, increasing prevalence of chronic diseases, and the need for cost-effective healthcare solutions. Shared devices offer economies of scale, making advanced physiotherapy accessible to more patients. - What are the key benefits of using shared physiotherapy devices in healthcare settings?

Shared devices enhance accessibility to advanced therapeutic technologies, optimize resource utilization in clinics and hospitals, and reduce the overall cost of physiotherapy treatments for patients. They also facilitate data collection for improved treatment personalization. - How do shared physiotherapy devices impact the design and functionality requirements of PCBs?

The shared nature of these devices demands PCBs that can withstand frequent use, ensure patient safety through rigorous adherence to standards like IEC 60601, and maintain high reliability to minimize downtime. Precision in therapeutic delivery is also paramount, requiring sophisticated circuit designs. - What types of PCB solutions are best suited for shared physiotherapy equipment?

High-reliability PCBs with robust thermal management are essential to ensure the longevity and consistent performance of shared physiotherapy devices. Multi-layer PCBs may be required to accommodate complex circuitry for sensor integration and precise therapeutic output control. - How can PCB manufacturers ensure the safety and compliance of PCBs used in shared physiotherapy devices?

Compliance with medical device regulations (e.g., FDA, CE) and safety standards (e.g., IEC 60601) is paramount. This involves rigorous testing, documentation, and adherence to strict manufacturing processes to mitigate risks and ensure patient safety. - What role does rapid prototyping play in the development of shared physiotherapy devices?

Rapid prototyping allows for quick iteration and testing of PCB designs, enabling manufacturers to identify and resolve potential issues early in the development process. This accelerates time-to-market and reduces overall development costs. - How does Zero One Solution Limited contribute to the advancement of shared physiotherapy devices?

Zero One Solution Limited provides specialized PCB solutions tailored for medical devices, including shared physiotherapy equipment. Our expertise in rapid prototyping, advanced manufacturing, and strict quality control ensures that our clients can develop innovative and reliable therapeutic solutions.

Key PCB Requirements for Shared Physiotherapy Devices

Shared physiotherapy devices demand printed circuit boards (PCBs) engineered for peak performance and unwavering reliability. These devices, utilized across diverse patient populations and treatment scenarios, necessitate PCBs designed to meet stringent criteria encompassing safety, durability, and therapeutic precision. Meeting these requirements ensures patient safety, device longevity, and the delivery of accurate, consistent treatments.

- High Reliability

Given the frequent and often continuous usage of shared physiotherapy devices, PCB reliability is paramount. Robust designs, coupled with high-quality components and rigorous testing, minimize downtime and ensure consistent performance. This involves careful consideration of component selection, trace routing, and thermal management strategies to prevent failures under stress. - Compliance with Safety Standards (IEC 60601)

Adherence to IEC 60601 is critical for medical devices, including shared physiotherapy equipment. PCBs must be designed with appropriate insulation, creepage, and clearance distances to prevent electrical shock hazards. Furthermore, comprehensive risk management processes should be implemented during design and manufacturing to identify and mitigate potential safety concerns. - Durability for Frequent Use

Shared physiotherapy devices endure considerable wear and tear. PCBs must withstand frequent handling, cleaning, and potential exposure to moisture or other environmental factors. Conformal coatings and robust component mounting techniques can enhance durability and protect against damage. - Precision for Accurate Therapeutic Delivery

Many physiotherapy devices rely on precise sensor data and controlled electrical stimulation to deliver effective therapy. PCBs must maintain signal integrity and minimize noise to ensure accurate data acquisition and precise therapeutic output. This requires careful attention to impedance control, grounding, and shielding techniques. - Material Selection

The choice of PCB materials is crucial, particularly for medical applications. Materials must be biocompatible, flame retardant, and capable of withstanding the operating temperatures of the device. Rogers, FR-4, and other specialized laminates are often used, depending on the specific requirements of the application. - Thermal Management

Power-generating components on the PCB can create significant heat. Effective thermal management strategies, such as heat sinks, thermal vias, and careful component placement, are essential to prevent overheating and ensure reliable operation. Simulations and thermal analysis should be performed during the design phase to optimize heat dissipation.

Challenges in PCB Design for Shared Medical Equipment

Designing PCBs for shared physiotherapy devices presents unique challenges that demand careful consideration and innovative solutions. These challenges stem from the need to ensure reliability, safety, and performance in high-usage, multi-user environments. Successfully navigating these hurdles is crucial for creating effective and durable shared medical equipment.

- Managing Thermal Dissipation

Shared physiotherapy devices often operate for extended periods, leading to significant heat generation from components. Effective thermal management is crucial to prevent overheating, which can degrade performance and shorten the lifespan of the device. PCB design must incorporate strategies such as heat sinks, thermal vias, and careful component placement to dissipate heat efficiently. - Ensuring Signal Integrity for Sensor Data

Many physiotherapy devices rely on sensors to collect physiological data. Maintaining signal integrity is vital for accurate therapeutic delivery and reliable monitoring. PCB design must minimize noise and interference, using techniques like impedance matching, proper grounding, and signal routing to ensure the integrity of sensor data. - Accommodating Complex Circuitry in Compact Form Factors

Shared physiotherapy devices often require complex circuitry to support multiple functionalities while maintaining a compact and user-friendly form factor. Efficiently routing signals, managing component density, and utilizing multi-layer PCBs are essential to accommodate complex circuitry within limited space. - Durability and Resistance to Wear and Tear

Shared devices experience frequent use and handling, making them susceptible to wear and tear. PCBs must be designed to withstand physical stress, vibration, and potential impacts. Robust materials, secure component mounting, and protective coatings can enhance durability and ensure long-term reliability. - Meeting Stringent Safety Standards

Medical devices are subject to stringent safety standards, such as IEC 60601, to protect patients and operators. PCB design must comply with these standards, incorporating features like isolation barriers, creepage and clearance distances, and protective earth connections to minimize the risk of electrical shock and other hazards. - Power Management Efficiency

Efficient power management is crucial for shared physiotherapy devices, particularly those that are battery-powered. PCB design should minimize power consumption through optimized component selection, efficient power distribution networks, and low-power operating modes to extend battery life and reduce energy costs. - Electromagnetic Compatibility (EMC)

Medical devices must operate without causing electromagnetic interference to other equipment and must be immune to interference from external sources. PCB design should incorporate EMC mitigation techniques such as shielding, filtering, and grounding to ensure electromagnetic compatibility and prevent malfunctions.

Zero One Solution Limited: Your PCB Partner for Physiotherapy Innovation

At Zero One Solution Limited, we stand at the forefront of PCB solutions, uniquely positioned to empower innovation in the realm of physiotherapy devices. With a relentless commitment to quality, precision, and rapid turnaround, we offer specialized services designed to meet the exacting demands of modern medical device development. Our expertise in rapid prototyping, coupled with comprehensive PCB design, manufacturing, and assembly capabilities, makes us the ideal partner for businesses seeking to revolutionize physiotherapy through cutting-edge technology.

- Expertise in Medical Device PCBs

We possess in-depth knowledge of the stringent requirements and regulations governing medical devices, including IEC 60601 standards. Our PCBs are designed and manufactured to ensure patient safety, device reliability, and compliance with industry best practices. - Rapid Prototyping Capabilities

Time is of the essence in the fast-paced world of medical device development. Our rapid prototyping services enable you to quickly iterate on your designs, test functionality, and accelerate your time to market. - One-Stop PCB Solutions

From initial design and layout to manufacturing and assembly, we offer a complete suite of PCB services tailored to your specific needs. This integrated approach streamlines the development process, reduces costs, and ensures seamless integration of your PCB into your physiotherapy device. - Commitment to Quality and Innovation

We are dedicated to providing the highest quality PCBs that meet or exceed your expectations. Our team of experienced engineers is constantly exploring new technologies and techniques to improve our processes and deliver innovative solutions that enhance the performance and reliability of your devices. - Global Reach with Local Support

Headquartered in Shenzhen, China, with a branch office in Dubai, we offer a global reach with local support. Our strategic presence in these key locations allows us to provide timely and efficient service to clients around the world.

Rapid Prototyping for Accelerated Development

Zero One Solution Limited's rapid prototyping services are designed to dramatically accelerate the development cycle for shared physiotherapy devices. By enabling clients to quickly iterate and test their designs, we significantly reduce time-to-market and associated development costs. Our approach allows for early identification and resolution of potential issues, ensuring a smoother and more efficient path to product launch.

- What is Rapid Prototyping?

Rapid prototyping is an accelerated method of creating physical models and functional prototypes from digital designs. It allows for quick iteration and testing, enabling faster design refinement and problem-solving. - How does Zero One Solution Limited facilitate rapid prototyping for physiotherapy devices?

We offer a comprehensive suite of services, including fast-turn PCB fabrication, component sourcing, and assembly. Our advanced equipment and experienced engineers enable us to deliver high-quality prototypes in a fraction of the time compared to traditional methods. - What are the benefits of rapid prototyping in physiotherapy device development?

Key benefits include reduced time-to-market, lower development costs, early detection of design flaws, improved product performance, and enhanced innovation through iterative testing and refinement. - What types of PCB prototypes can Zero One Solution Limited produce for physiotherapy devices?

We can produce a wide range of PCB prototypes, including single-layer, multi-layer, flexible, and rigid-flex PCBs, tailored to the specific requirements of your physiotherapy device. - How does rapid prototyping help in reducing time-to-market?

Rapid prototyping allows for quick design validation and refinement. Issues can be identified and corrected early in the development process, preventing costly delays and rework later on. This significantly shortens the overall development timeline. - How does rapid prototyping contribute to cost reduction?

By identifying and resolving design issues early, rapid prototyping reduces the risk of expensive redesigns and rework. It also allows for optimization of material usage and manufacturing processes, leading to further cost savings. - What level of design support does Zero One Solution Limited provide during the rapid prototyping phase?

Our team of experienced engineers provides comprehensive design support, including design for manufacturability (DFM) analysis, signal integrity analysis, and thermal management optimization. We work closely with our clients to ensure their designs are optimized for performance, reliability, and manufacturability.

Advanced PCB Manufacturing and Assembly Capabilities

Zero One Solution Limited excels in providing advanced PCB manufacturing and assembly services, essential for the sophisticated requirements of shared physiotherapy devices. Our capabilities ensure that every PCB meets the stringent demands of the medical industry, focusing on high-precision component placement, rigorous quality control, and adherence to industry standards. This commitment guarantees the reliability and performance of your physiotherapy devices.

- High-Precision Component Placement

We utilize state-of-the-art equipment for accurate placement of components, crucial for the functionality and efficiency of physiotherapy devices. This precision minimizes errors and enhances overall performance. - Stringent Quality Control Measures

Our quality control processes are designed to detect and eliminate any defects, ensuring that each PCB meets the highest standards of quality and reliability. We conduct rigorous testing at every stage of the manufacturing process. - Compliance with Industry Standards

We adhere to all relevant industry standards, including ISO 13485 for medical devices, ensuring that our PCBs meet the necessary regulatory requirements for safety and performance. This compliance is vital for the market approval of physiotherapy devices. - Advanced Manufacturing Techniques

Zero One Solution Limited employs cutting-edge manufacturing techniques to create PCBs that meet the complex needs of modern physiotherapy devices. Our expertise includes multi-layer PCBs, HDI PCBs, and flexible PCBs, each tailored to specific application requirements. - Material Selection Expertise

We carefully select materials that are best suited for the demands of medical applications, considering factors such as biocompatibility, thermal resistance, and signal integrity. This ensures the longevity and reliability of the PCBs in physiotherapy devices. - Comprehensive Testing and Validation

Our comprehensive testing and validation processes cover a wide range of parameters, including electrical performance, thermal characteristics, and environmental resistance. This ensures that our PCBs perform reliably under various operating conditions.

Case Studies: Successful Physiotherapy Device Projects

To illustrate the impact and reliability of Zero One Solution Limited's PCB solutions, this section highlights several successful physiotherapy device projects. These case studies demonstrate our commitment to delivering high-performance, reliable PCBs that meet the stringent demands of the medical device industry, ultimately enhancing patient care and treatment outcomes.

Below are detailed examples of how our expertise has contributed to the success of various physiotherapy device innovations:

- Case Study 1: Advanced Muscle Stimulation Device

Challenge: A client specializing in muscle stimulation devices required a PCB solution that could deliver precise and controlled electrical pulses while maintaining patient safety. The device needed to be compact, energy-efficient, and comply with IEC 60601 standards. Solution: Zero One Solution Limited designed a multi-layer PCB with optimized signal routing and insulation to prevent electrical leakage. We incorporated high-precision components and implemented rigorous testing protocols to ensure compliance with safety standards. The rapid prototyping service allowed the client to quickly iterate on their design, reducing development time. Outcome: The client successfully launched their muscle stimulation device, which received positive feedback from healthcare professionals for its accuracy, reliability, and safety features. The device has been widely adopted in rehabilitation centers and sports medicine clinics. - Case Study 2: Portable Ultrasound Therapy System

Challenge: A company developing a portable ultrasound therapy system needed a PCB solution that could handle high-frequency signals and provide stable power delivery in a compact form factor. The device was intended for use in remote locations, so durability and energy efficiency were critical. Solution: Zero One Solution Limited designed a miniaturized PCB using advanced materials to minimize signal loss and thermal dissipation. We implemented power management circuitry to optimize energy consumption and extend battery life. The PCB was rigorously tested for shock and vibration resistance to ensure reliable performance in harsh environments. Outcome: The portable ultrasound therapy system was successfully deployed in rural healthcare settings, providing patients with access to advanced treatment options. The device's compact size, long battery life, and robust design made it a valuable tool for healthcare providers in underserved areas. - Case Study 3: Smart Rehabilitation Exoskeleton

Challenge: A research team developing a smart rehabilitation exoskeleton required a complex PCB solution to integrate multiple sensors, actuators, and control systems. The PCB needed to be flexible, lightweight, and capable of transmitting data wirelessly. Solution: Zero One Solution Limited designed a flexible PCB using thin-film technology to conform to the exoskeleton's contours. We incorporated wireless communication modules for seamless data transfer and implemented advanced signal processing algorithms to improve sensor accuracy. The PCB was rigorously tested for durability and biocompatibility to ensure patient safety. Outcome: The smart rehabilitation exoskeleton was successfully used in clinical trials, demonstrating its potential to improve patient mobility and rehabilitation outcomes. The device's advanced features and ergonomic design have generated significant interest from researchers and healthcare providers.

Ensuring Compliance and Safety in Medical PCB Design

In the realm of medical devices, particularly shared physiotherapy equipment, adherence to stringent regulatory standards and safety protocols is non-negotiable. PCB design and manufacturing must align with these requirements to ensure patient safety and device efficacy. Compliance with regulations like those set by the FDA in the United States and CE marking in Europe, alongside adherence to safety standards such as IEC 60601, is paramount. These standards dictate rigorous testing, material selection, and manufacturing processes to minimize risks associated with electrical safety, electromagnetic compatibility, and biocompatibility.

- Why is Compliance with Medical Device Regulations Crucial?

Compliance ensures patient safety, device effectiveness, and market access. Non-compliance can lead to recalls, legal liabilities, and reputational damage. Meeting standards like FDA regulations (in the US) and CE marking (in Europe) demonstrates a commitment to quality and safety, building trust with healthcare providers and patients. - What is IEC 60601 and Why is it Important for Physiotherapy Devices?

IEC 60601 is a series of technical standards for the safety and essential performance of medical electrical equipment. For physiotherapy devices, adherence to IEC 60601 ensures protection against electrical shock, fire hazards, and mechanical dangers. It covers aspects like insulation, leakage current limits, and mechanical strength, ensuring devices operate safely under normal and fault conditions. - How Does PCB Design Impact the Safety of a Physiotherapy Device?

PCB design plays a crucial role in device safety by influencing factors such as insulation, creepage and clearance distances, and component placement. Proper design minimizes the risk of electrical arcing, short circuits, and overheating. Additionally, careful routing of high-voltage traces and isolation of sensitive circuits are essential for preventing interference and ensuring accurate therapeutic delivery. - What are the Key Considerations for Material Selection in Medical PCBs?

Material selection is critical for medical PCBs due to biocompatibility and reliability concerns. Materials must be non-toxic, resistant to chemicals and sterilization processes, and capable of withstanding high temperatures without degrading. Additionally, materials should exhibit excellent electrical properties, such as low dielectric loss, to ensure signal integrity and minimize power dissipation. - How Does Zero One Solution Limited Ensure Compliance and Safety in its PCB Solutions?

Zero One Solution Limited prioritizes compliance and safety by adhering to industry best practices, employing stringent quality control measures, and conducting thorough testing throughout the design and manufacturing process. Our expertise in medical device regulations, combined with our advanced manufacturing capabilities, enables us to deliver PCB solutions that meet the highest standards of safety and performance. We offer comprehensive documentation and support to assist clients in achieving regulatory approvals for their physiotherapy devices. - What Documentation is Required for Medical PCB Compliance?

Comprehensive documentation is essential for demonstrating compliance with medical device regulations. This typically includes design specifications, material certifications, manufacturing process controls, test reports, and risk assessments. Documentation should provide a clear audit trail, demonstrating that the PCB design and manufacturing processes meet all applicable requirements. Zero One Solution Limited provides complete documentation packages to support clients in their regulatory submissions.

Future Trends in PCB Technology for Physiotherapy

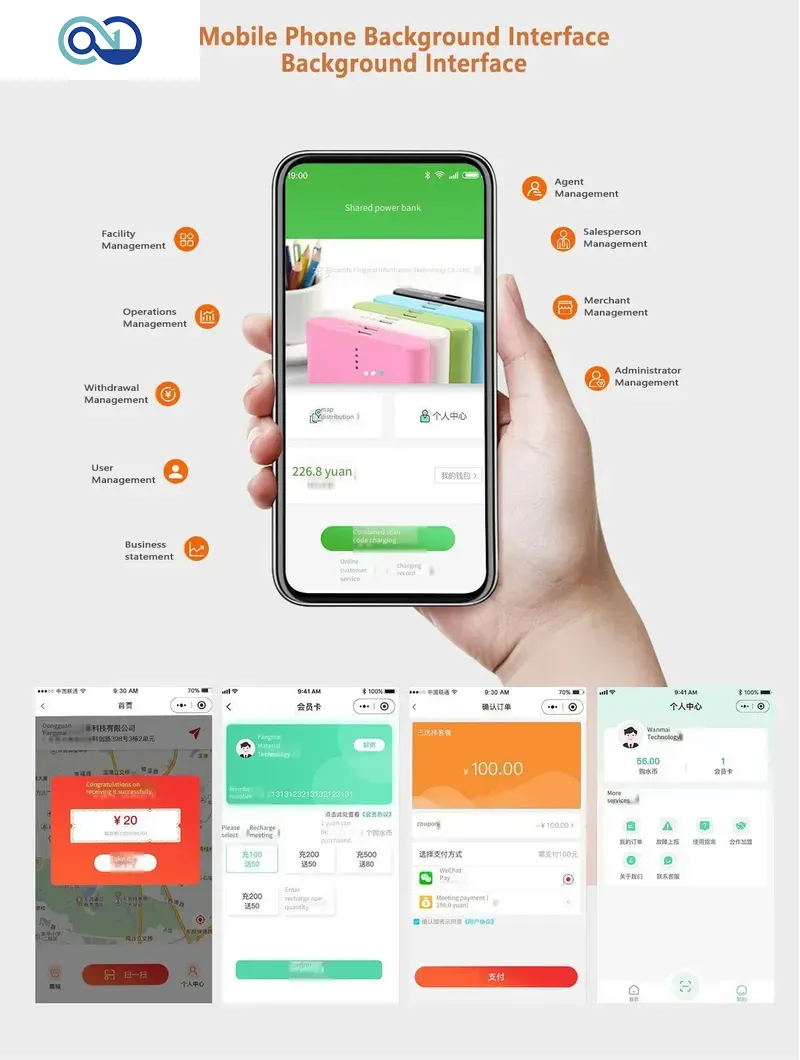

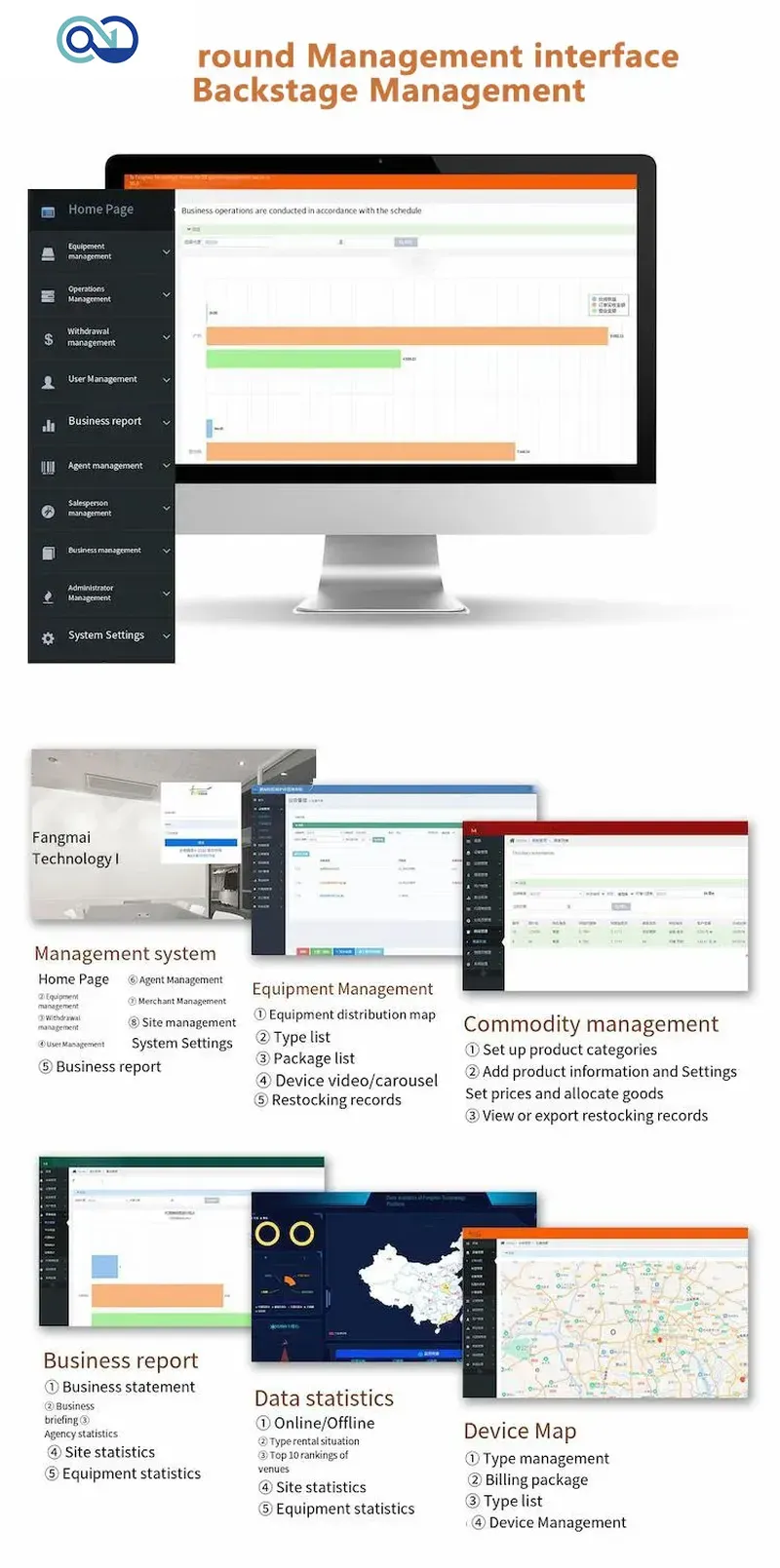

The landscape of PCB technology is constantly evolving, and the field of physiotherapy devices is poised to benefit significantly from these advancements. Looking ahead, several key trends are expected to shape the design and functionality of PCBs in shared physiotherapy equipment, enhancing therapeutic outcomes and user experiences. These trends include flexible PCBs for adaptable designs, miniaturization for compact and portable devices, and wireless connectivity for seamless data transmission and remote monitoring.

- Flexible PCBs

Flexible PCBs are revolutionizing device design by allowing circuits to conform to curved or irregular surfaces. In physiotherapy, this translates to more ergonomic and comfortable wearable devices, such as sensors that monitor patient movement or deliver targeted electrical stimulation. The ability to integrate circuits directly into textiles or flexible materials opens up new possibilities for personalized and unobtrusive therapeutic solutions. This also extends to creating more adaptable interfaces on larger machines, improving user interaction and device versatility. - Miniaturization

The relentless push for miniaturization is enabling the development of smaller, more portable, and less obtrusive physiotherapy devices. Advanced PCB fabrication techniques, such as microvia technology and high-density interconnects (HDI), allow for more components to be packed into a smaller area without sacrificing performance or reliability. This is particularly beneficial for devices used in home-based rehabilitation or remote patient monitoring, where compact size and ease of use are paramount. Miniaturization also reduces material costs and energy consumption, contributing to more sustainable and cost-effective healthcare solutions. - Wireless Connectivity

Wireless connectivity is transforming how physiotherapy devices collect, transmit, and analyze data. Integrating wireless modules, such as Bluetooth, Wi-Fi, or cellular, directly onto PCBs enables seamless communication between devices, cloud-based platforms, and healthcare providers. This allows for real-time monitoring of patient progress, remote adjustments to treatment parameters, and data-driven insights to optimize therapeutic interventions. Wireless connectivity also facilitates the development of telehealth solutions, expanding access to physiotherapy services for patients in remote areas or with limited mobility.

FAQs about PCB Solutions for Shared Physiotherapy Devices

This section addresses frequently asked questions concerning PCB design, manufacturing, and assembly for shared physiotherapy devices. It aims to provide clear and concise answers to common queries, aiding in informed decision-making and a better understanding of the PCB aspects in shared physiotherapy equipment.

- What are the key considerations for PCB design in shared physiotherapy devices?

Key considerations include ensuring high reliability and durability to withstand frequent use, adhering to stringent safety standards such as IEC 60601, managing thermal dissipation effectively, ensuring signal integrity for accurate sensor data transmission, and optimizing for compact form factors to fit within device constraints. - How does Zero One Solution Limited ensure the quality and reliability of PCBs for physiotherapy devices?

Zero One Solution Limited implements rigorous quality control measures throughout the PCB manufacturing process, including advanced testing methodologies, high-precision component placement, and strict adherence to industry standards. We also utilize high-quality materials and advanced manufacturing techniques to ensure long-term reliability. - What safety standards are critical for PCBs used in shared physiotherapy equipment?

Compliance with IEC 60601 is paramount. This standard ensures the safety and essential performance of medical electrical equipment. Our PCBs are designed and manufactured to meet these stringent safety requirements, minimizing risks to patients and operators. - Can Zero One Solution Limited handle rapid prototyping for physiotherapy device PCBs?

Yes, Zero One Solution Limited specializes in rapid prototyping. Our rapid prototyping services allow clients to quickly iterate and test their physiotherapy device designs, accelerating the development process and reducing time-to-market. We provide fast turnaround times without compromising quality. - What types of PCB assembly services does Zero One Solution Limited offer for medical devices?

We offer a comprehensive range of PCB assembly services, including surface mount technology (SMT), through-hole assembly, mixed technology assembly, and box build assembly. Our advanced assembly capabilities ensure precise component placement and reliable connections, meeting the demanding requirements of medical devices. - How does PCB miniaturization benefit shared physiotherapy devices?

PCB miniaturization allows for the creation of more compact and portable physiotherapy devices. This is particularly beneficial for shared devices used in various locations. Miniaturization also enhances device aesthetics and ergonomics, improving user experience. - What emerging PCB technologies are relevant to the future of physiotherapy devices?

Emerging trends include flexible PCBs, which enable the design of wearable and conformable devices; advanced thermal management solutions for high-power applications; and wireless connectivity integration for remote monitoring and control. These technologies are driving innovation in physiotherapy device design.

Shared physiotherapy devices represent a significant advancement in rehabilitation technology, offering effective and accessible treatment options for patients. Zero One Solution Limited is committed to providing cutting-edge PCB solutions that empower manufacturers to develop high-quality, reliable, and safe physiotherapy devices. With our rapid prototyping capabilities, advanced manufacturing facilities, and unwavering focus on quality, we are your ideal partner for accelerating innovation in this crucial field. Contact Zero One Solution Limited today to discuss your physiotherapy device PCB needs and experience the difference of working with a trusted industry leader. Visit our website or contact our sales team to learn more about our services and how we can help bring your innovative physiotherapy device to market faster and more efficiently.

AnyPCBA

AnyPCBA