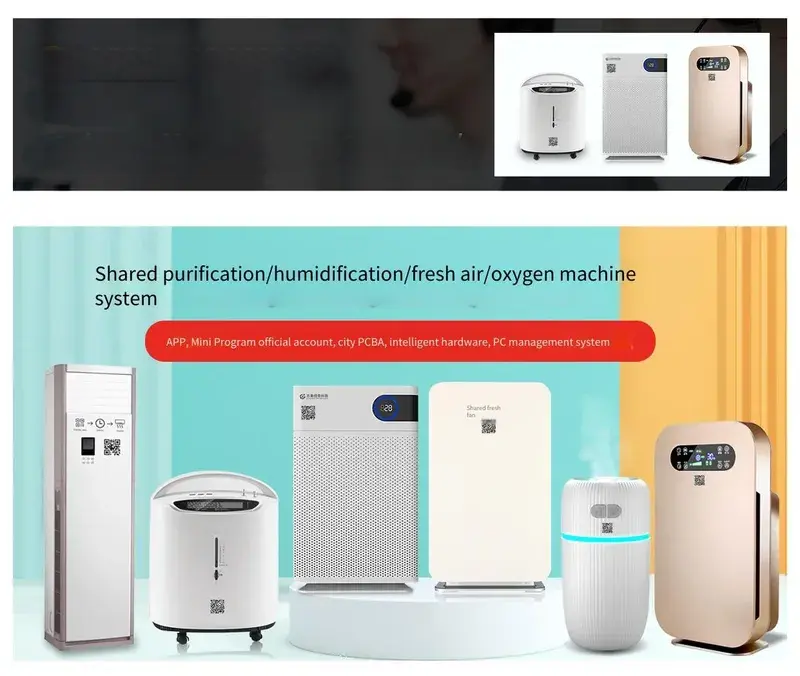

Shared Purification, Humidification, Fresh Air, and Oxygen Machine Solution

In an era where indoor air quality is paramount, the demand for advanced environmental control systems has never been higher. From smart homes to commercial spaces, the need for clean, fresh, and optimally humidified air, along with adequate oxygen levels, is a fundamental expectation. This convergence of requirements has led to the emergence of sophisticated shared purification, humidification, fresh air, and oxygen machine solutions. At Zero One Solution Limited, we understand that the backbone of such cutting-edge technology lies in robust and reliable PCB solutions. As a veteran engineer from Zero One Solution Limited, I'm here to unveil how our rapid prototyping and one-stop PCB services are powering the next generation of these vital systems, delivering unparalleled efficiency and performance to accelerate product development.

The Evolution of Indoor Air Quality: Beyond Basic Filtration

The landscape of indoor air quality has dramatically shifted, moving beyond the era of simple air filtration to a sophisticated demand for comprehensive environmental control. Modern solutions now encompass purification, humidification, and fresh air exchange, addressing a wide array of contaminants and environmental factors. This evolution reflects a growing understanding of the impact of indoor air quality on health, productivity, and overall well-being, spurring the need for integrated systems capable of delivering optimal and shared environmental control.

The demand for shared purification, humidification, fresh air, and oxygen solutions is rising across various settings:

- Offices:

Enhancing employee health and productivity by maintaining optimal air quality in shared workspaces, reducing sick days and improving focus. - Public Spaces:

Ensuring the well-being of visitors and occupants in environments like hospitals, schools, and libraries, where air quality can significantly impact public health. - Multi-Unit Dwellings:

Providing centralized air quality control for apartments and condominiums, offering residents a healthier living environment and potentially reducing energy costs compared to individual units.

These integrated systems address the limitations of basic air filters by:

- Comprehensive Contaminant Removal:

Tackling a wider range of pollutants, including particulate matter, volatile organic compounds (VOCs), and biological contaminants, ensuring a healthier indoor environment. - Humidity Control:

Maintaining optimal humidity levels to prevent the growth of mold and bacteria, alleviate respiratory issues, and enhance overall comfort. - Fresh Air Ventilation:

Introducing outdoor air to dilute indoor pollutants and replenish oxygen levels, combating the stale air often associated with tightly sealed buildings. - Oxygen Enrichment (in some systems):

Increasing oxygen concentration to improve alertness, energy levels, and cognitive function, particularly beneficial in environments with poor ventilation.

Understanding Shared Purification, Humidification, Fresh Air, and Oxygen Machines

Shared purification, humidification, fresh air, and oxygen machines represent a convergence of technologies designed to comprehensively address indoor environmental quality. These integrated systems combine air purification, humidification, fresh air exchange, and oxygen enrichment to create healthier and more comfortable indoor environments. The 'shared' aspect emphasizes the ability of a single, centralized unit to serve multiple spaces or users, offering advantages in energy efficiency and reduced maintenance compared to individual devices.

Let's explore the core functionalities:

- Air Purification

Utilizes various filtration methods like HEPA filters (for particulate matter), activated carbon filters (for odors and gases), and UV-C sterilization (for microorganisms) to remove pollutants from the air. - Humidification

Employs technologies such as ultrasonic humidifiers (using high-frequency sound waves to create a fine mist) or evaporative humidifiers (passing air over a wet wick) to maintain optimal humidity levels. - Fresh Air Exchange

Incorporates Heat Recovery Ventilation (HRV) or Energy Recovery Ventilation (ERV) systems to introduce fresh, filtered air from outside while recovering energy from the exhaust air, minimizing energy loss. - Oxygen Enrichment

Uses Pressure Swing Adsorption (PSA) technology to concentrate oxygen from the air, providing supplemental oxygen for improved air quality.

The synergy of these functions within a shared system provides several key benefits:

- Enhanced Air Quality

Addresses a wide range of pollutants and environmental factors, creating a healthier and more comfortable indoor environment. - Energy Efficiency

Centralized units can be more energy-efficient than multiple individual devices, especially when combined with heat recovery ventilation. - Reduced Maintenance

Fewer devices translate to less frequent maintenance and filter replacements. - Cost Savings

Lower energy consumption and reduced maintenance contribute to overall cost savings. - Smart Control and Monitoring

Integration with smart home systems allows for convenient control and monitoring of air quality parameters.

- Frequently Asked Questions about Shared Air Purification, Humidification, Fresh Air, and Oxygen Machines

- What are the key benefits of using a shared air purification system compared to individual units?

Shared systems offer enhanced energy efficiency, reduced maintenance costs, and comprehensive air quality management by integrating multiple functions into a single unit. They are particularly beneficial in multi-occupancy settings. - How does the fresh air exchange component in these machines improve indoor air quality?

Fresh air exchange systems, like Heat Recovery Ventilation (HRV), bring in filtered outdoor air while expelling stale indoor air, reducing pollutant concentrations and maintaining a healthy oxygen level. They also recover heat from the exhaust air to minimize energy loss. - What types of pollutants can these integrated systems remove from the air?

These systems can remove a wide range of pollutants, including particulate matter (PM2.5, PM10), volatile organic compounds (VOCs), odors, allergens, bacteria, viruses, and other airborne contaminants, depending on the filtration and sterilization technologies used. - How often do the filters and other components in these machines need to be replaced or maintained?

Maintenance frequency varies depending on the specific model and usage conditions. Generally, filters should be replaced every 3-6 months, while other components may require annual inspection and servicing. Refer to the manufacturer's guidelines for detailed maintenance schedules. - Can these machines be integrated with smart home systems for remote control and monitoring?

Many of these systems offer smart home integration via Wi-Fi or Bluetooth, allowing users to remotely control settings, monitor air quality parameters, and receive maintenance alerts through a smartphone app or other smart home interface. - Are shared purification, humidification, fresh air, and oxygen machines suitable for all types of environments?

These systems are versatile and can be adapted for various environments, including offices, apartments, schools, and healthcare facilities. However, the specific needs of each environment should be considered when selecting a system, such as the size of the space, occupancy levels, and specific air quality concerns. - How does oxygen enrichment work, and who benefits most from it?

Oxygen enrichment uses Pressure Swing Adsorption (PSA) technology to concentrate oxygen from the air. While generally not needed for healthy individuals in well-ventilated spaces, it can benefit those with respiratory issues, athletes, or individuals in environments with low oxygen levels.

The Critical Role of PCBs in Advanced Environmental Control Systems

Printed Circuit Boards (PCBs) are the central nervous system of shared purification, humidification, fresh air, and oxygen machines. They are not merely components; they are the intelligent infrastructure that enables these devices to function efficiently and reliably. High-quality PCB design directly impacts the overall performance and longevity of these sophisticated integrated systems, handling everything from sensor data management to precise control of actuators and efficient power distribution.

Here's a breakdown of how PCBs contribute to these advanced environmental control systems:

- Sensor Data Management

PCBs act as the hub for receiving and processing data from various sensors (air quality, humidity, temperature). This data is crucial for real-time adjustments and optimal performance. - Actuator Control

PCBs precisely control actuators like fans, humidifiers, valves, and oxygen enrichment mechanisms, ensuring they operate in sync for efficient environmental control. - Communication Protocols

Modern PCBs facilitate seamless communication via Wi-Fi and Bluetooth, enabling smart control, remote monitoring, and integration with smart home ecosystems. - Power Distribution

PCBs ensure efficient and stable power distribution to all components, crucial for handling the diverse power requirements of motors, heaters, and sensors.

Because PCBs are so critical, it's important to be aware of some frequently asked questions:

- What are the key PCB design considerations for shared purification systems?

Key considerations include sensor integration for accurate air quality monitoring, efficient power management to handle varying loads, thermal management to dissipate heat from power components, and robust communication protocols for smart control capabilities. - How does PCB quality affect the performance of a shared humidification system?

Poor PCB design can lead to unreliable sensor readings, erratic actuator control (e.g., inconsistent humidification), and communication failures. High-quality PCBs ensure stable and precise operation for optimal humidification performance and user comfort. - What role does EMC play in PCB design for fresh air exchange systems?

Electromagnetic Compatibility (EMC) is crucial to prevent interference between components on the PCB and with external devices. Proper EMC design ensures stable and reliable operation of the fresh air exchange system, preventing malfunctions and maintaining air quality standards. - How do PCBs enable smart features in oxygen enrichment machines?

PCBs provide the necessary processing power and communication interfaces (Wi-Fi, Bluetooth) for smart features such as remote monitoring, automated adjustments based on air quality data, and integration with smart home systems. This allows users to control and optimize oxygen levels remotely. - What are the challenges in designing PCBs for multi-functional air quality devices?

Designing PCBs for these integrated systems requires careful consideration of component placement, signal integrity, power distribution, and thermal management. Space constraints, diverse component requirements, and the need for reliable performance under varying environmental conditions add to the complexity. - What types of sensors are commonly integrated into PCBs for air quality monitoring?

Common sensors integrated into PCBs include particulate matter sensors (PM2.5, PM10), volatile organic compound (VOC) sensors, humidity sensors, temperature sensors, and carbon dioxide (CO2) sensors. These sensors provide comprehensive data for air quality analysis and automated adjustments. - How can Zero One Solution Limited help in designing PCBs for shared environmental control systems?

Zero One Solution Limited offers comprehensive PCB design, manufacturing, and assembly services tailored for complex environmental control systems. Our expertise includes sensor integration, power management, thermal management, and communication protocol implementation. We provide rapid prototyping services to accelerate product development cycles and ensure reliable, high-performance PCB solutions.

Zero One Solution Limited: Your Partner in PCB Excellence for Shared Environmental Solutions

Zero One Solution Limited stands as a premier PCB solution provider, ideally positioned to support the burgeoning market of shared purification, humidification, fresh air, and oxygen machines. With a firm grasp on the intricate demands of these advanced environmental control systems, we offer comprehensive services spanning PCB design, manufacturing, and assembly. Our commitment to rapid prototyping and a one-stop service model ensures that our clients can accelerate their product development cycles and bring cutting-edge solutions to market with unparalleled efficiency.

Founded in 2011 and strategically located in Shenzhen, China, the heart of electronics manufacturing, with a branch in Dubai, Zero One Solution Limited has cultivated a reputation for excellence in PCBA solutions. We empower innovation by providing seamless access to a global PCBA supply chain network, ensuring that your project benefits from world-class resources and support.

- Rapid Prototyping for Shared Purification Systems

We specialize in rapid prototyping, significantly reducing the time-to-market for shared purification, humidification, fresh air, and oxygen machines. Our agile processes allow for quick iteration and refinement of designs, ensuring optimal performance and efficiency. - One-Stop PCB Solutions for Oxygen Machines

From initial design concepts to final assembly, we provide a complete suite of PCB services tailored to the unique requirements of oxygen machines and other complex environmental control systems. Our expertise covers everything from component selection to rigorous testing and quality assurance. - Expertise in Complex Environmental Control Systems

Our team possesses deep knowledge of the specific challenges and considerations involved in designing PCBs for multi-functional machines. We excel in managing sensor data, controlling actuators, ensuring efficient power distribution, and integrating smart communication protocols. - Global PCBA Supply Chain Network

With our strategic locations and established network, we offer seamless access to worldwide resources and support, ensuring a reliable and cost-effective supply chain for your PCB needs. - Commitment to Quality and Reliability

We adhere to the highest industry standards and employ rigorous quality control measures throughout the entire PCB manufacturing process. Our commitment to excellence ensures that your shared environmental solutions operate with optimal reliability and longevity.

Technical Considerations in PCB Design for Multi-Functional Machines

Designing PCBs for shared purification, humidification, fresh air, and oxygen machines presents unique technical challenges. These multi-functional devices demand careful attention to power management, sensor integration, thermal management, electromagnetic compatibility (EMC), and seamless integration with user interfaces and smart home systems. Addressing these considerations effectively is crucial for ensuring the reliability, performance, and longevity of these advanced environmental control systems.

- Power Management: How to efficiently handle motors and heaters?

Efficient power management is crucial. Employing DC-DC converters with high efficiency minimizes heat generation and maximizes battery life in portable units. Utilizing PWM (Pulse Width Modulation) control for motors and heaters allows for precise adjustment and reduces energy consumption. Consider using power factor correction (PFC) circuits to improve power efficiency and reduce harmonic distortion, especially in systems with high power demands. - Sensor Integration: What are the best practices for air quality and humidity sensors?

Selecting high-accuracy sensors is paramount. Implement proper signal conditioning circuitry to minimize noise and drift. Employ calibration techniques to ensure accurate readings over time. Consider using digital sensors with built-in calibration and communication interfaces (e.g., I2C, SPI) for ease of integration. Shielding sensitive sensor circuitry can further reduce noise and interference. - Thermal Management: How to dissipate heat from power components in fresh air systems?

Employ thermal simulation tools to identify hotspots on the PCB. Utilize heat sinks, thermal vias, and copper planes to dissipate heat effectively. Consider using thermally conductive materials to improve heat transfer from components to the PCB. Optimizing component placement to minimize heat concentration is also critical. Forced air cooling with small fans may be necessary in high-power applications. - Electromagnetic Compatibility (EMC): How to ensure stable operation?

Implementing proper grounding techniques is essential for minimizing noise and interference. Use shielded cables and connectors to prevent electromagnetic radiation. Add filtering components (e.g., capacitors, inductors) to suppress noise on power and signal lines. Comply with relevant EMC standards (e.g., FCC, CE) to ensure product compliance and reliable operation. PCB layout techniques such as ground planes and signal trace routing also play a significant role. - User Interface and Smart Home Integration: What are the key considerations?

Choose appropriate communication protocols (e.g., Wi-Fi, Bluetooth, Zigbee) based on range, bandwidth, and power consumption requirements. Implement robust security measures to protect user data and prevent unauthorized access. Design intuitive user interfaces (e.g., touchscreens, mobile apps) for easy control and monitoring. Consider using standard communication protocols (e.g., MQTT, HTTP) for seamless integration with smart home platforms. - Signal Integrity: How to maintain accuracy for precise sensor readings?

Careful trace routing is crucial to minimize signal reflections and crosstalk. Use impedance control techniques to match trace impedance to component impedance. Minimize trace lengths and avoid sharp bends to reduce signal distortion. Employ differential signaling for critical signals to improve noise immunity. Consider using termination resistors to absorb signal reflections. - What PCB material should I choose for optimal performance in these devices?

Consider materials with high thermal conductivity for efficient heat dissipation. FR-4 is a common and cost-effective choice, but for higher performance, consider materials like Rogers or other specialized laminates with improved electrical and thermal properties. The choice depends on the specific power, frequency, and thermal requirements of the application.

In conclusion, the integration of purification, humidification, fresh air, and oxygen generation into shared, intelligent systems represents a significant leap forward in environmental control. Zero One Solution Limited stands at the forefront of this evolution, providing the critical PCB solutions that make these sophisticated machines not just possible, but highly efficient and reliable. Our commitment to rapid prototyping, design expertise, and comprehensive manufacturing capabilities ensures that our partners can bring their innovative shared environmental control products to market with speed and confidence. Partner with Zero One Solution Limited to transform your vision into reality and contribute to healthier, more comfortable indoor environments for everyone. Contact us today to explore how our expertise can accelerate your next project.

AnyPCBA

AnyPCBA