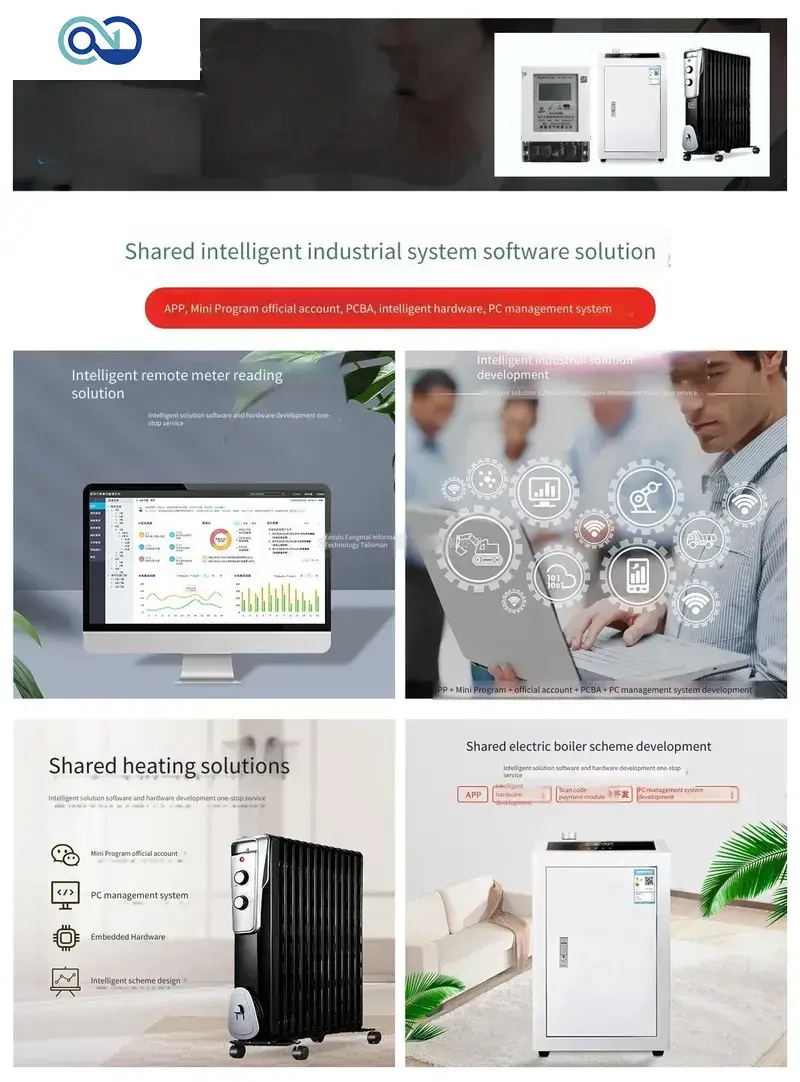

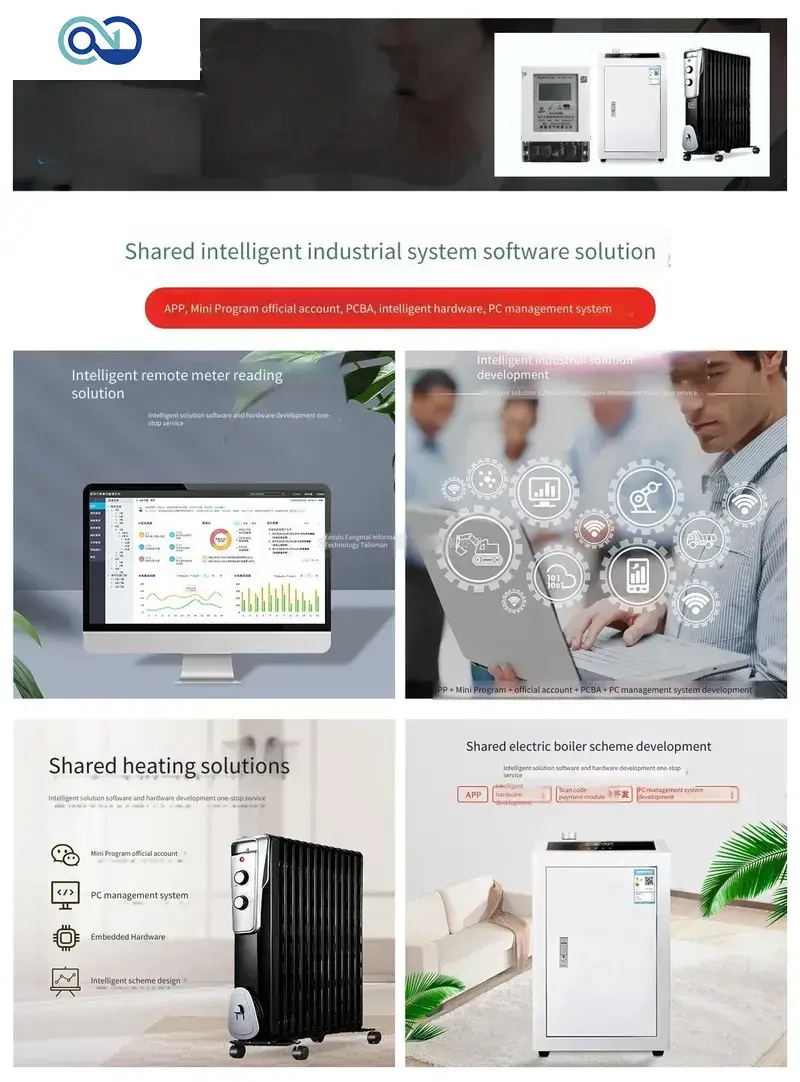

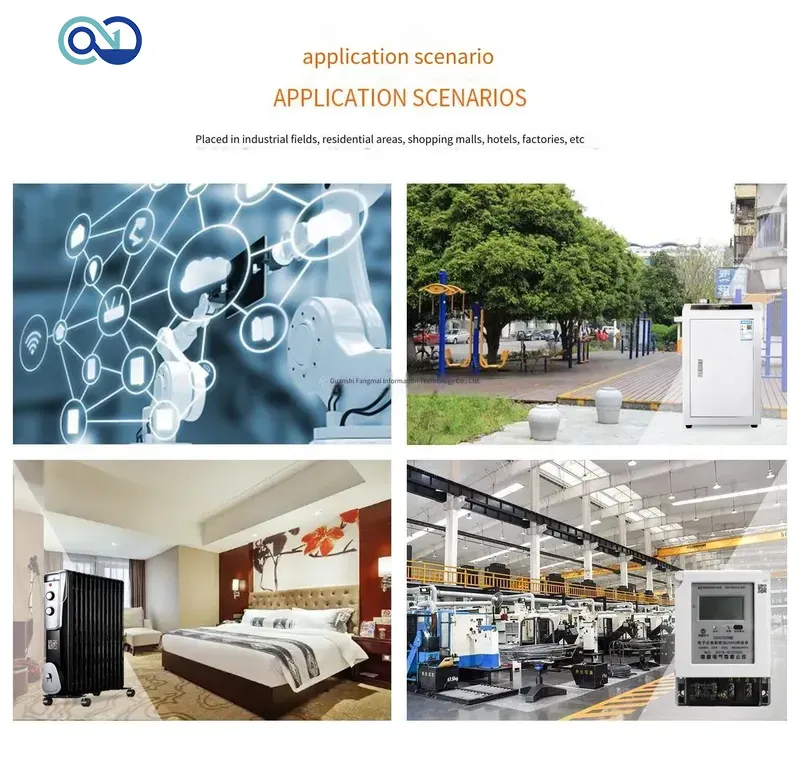

Shared Smart Industrial Solution

In today's fiercely competitive industrial landscape, the fusion of advanced technology and streamlined processes is no longer a luxury but a necessity for survival and growth. Businesses are constantly seeking ways to enhance efficiency, reduce time-to-market, and maintain a competitive edge. This is where the concept of a 'Shared Smart Industrial Solution' emerges as a game-changer. At Zero One Solution Limited, we've pioneered a comprehensive approach that transforms traditional PCB prototyping and manufacturing into an integrated, intelligent ecosystem. How can a truly shared and smart solution redefine your product development lifecycle, from initial concept to final assembly, ensuring unparalleled speed and precision?

Understanding the Shared Smart Industrial Solution Paradigm

The shared smart industrial solution paradigm represents a fundamental shift in manufacturing, emphasizing collaboration, data integration, and intelligent automation. It's about creating an industrial ecosystem where resources are shared, and technologies work in concert to optimize efficiency and responsiveness. This approach is particularly relevant for PCB solutions and rapid prototyping, where speed and agility are paramount.

At its core, a shared smart industrial solution leverages interconnected systems and data-driven insights to improve decision-making and streamline operations. It moves away from isolated processes towards a more holistic and collaborative environment. For businesses involved in PCB design, manufacturing, and assembly, this translates to faster prototyping cycles, reduced costs, and improved product quality.

The strategic advantage of embracing a shared smart industrial solution lies in its ability to accelerate innovation and optimize resource utilization. By sharing resources and data, companies can respond more quickly to market changes, reduce waste, and improve overall efficiency. This aligns perfectly with Zero One Solution Limited's commitment to providing cutting-edge PCB assembly solutions and rapid-response R&D prototype manufacturing, empowering clients to accelerate product development and bring innovative solutions to market with exceptional efficiency. Our strategic locations in Shenzhen and Dubai further enhance our ability to provide seamless access to a global PCBA supply chain network.

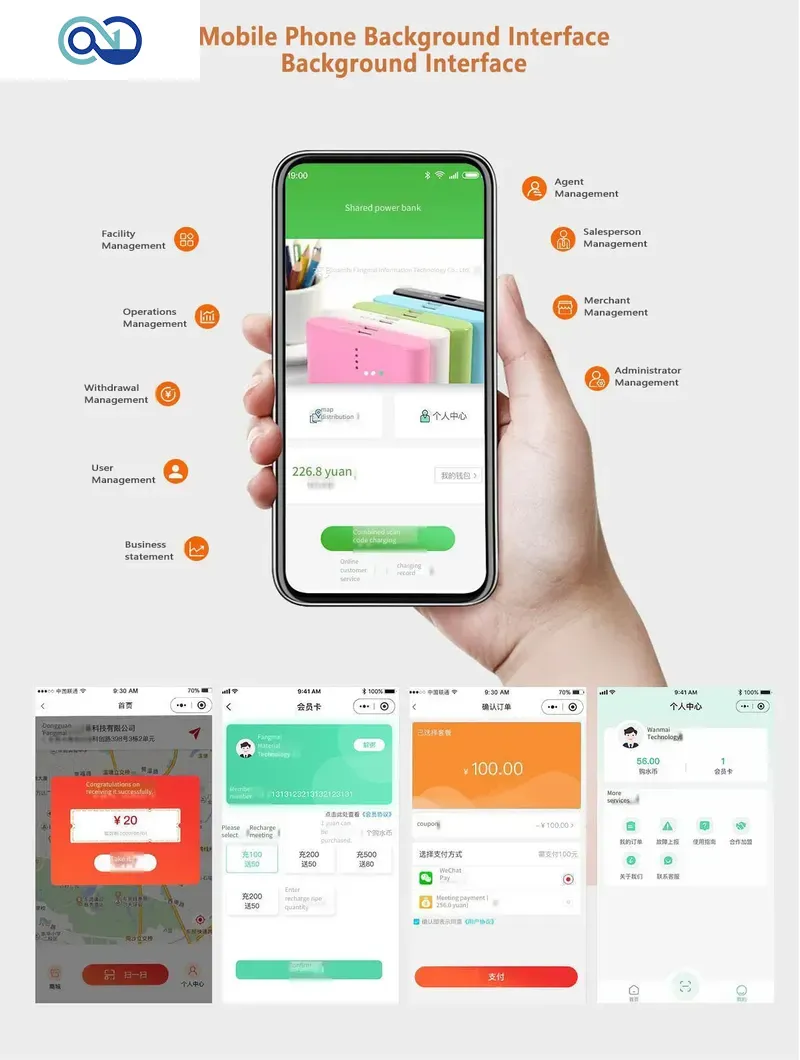

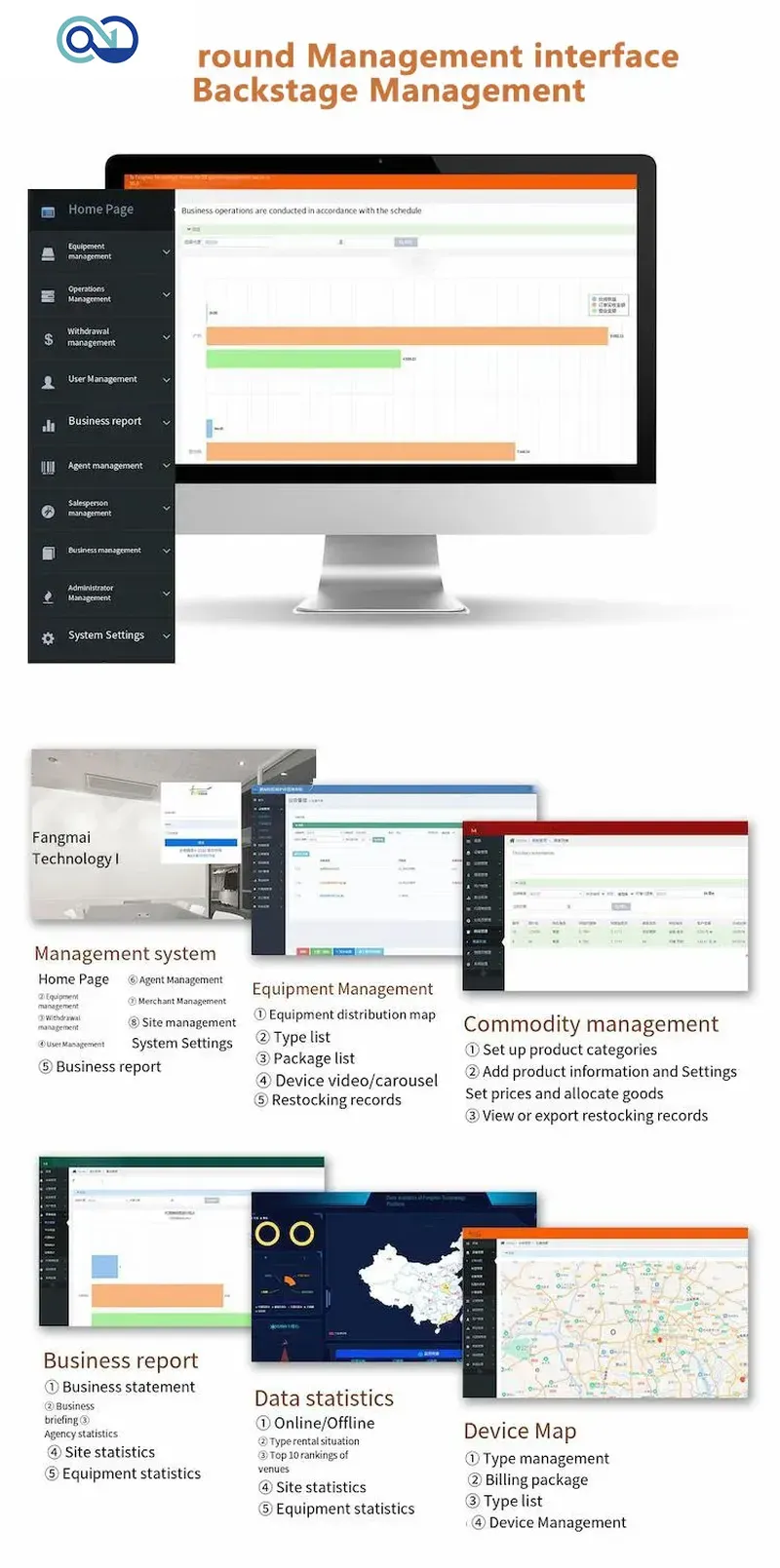

- What are the key components of a Shared Smart Industrial Solution?

Key components include data integration platforms, IoT devices for real-time monitoring, cloud computing for scalable resource sharing, AI-powered analytics for process optimization, and secure communication networks for seamless collaboration. - How does a Shared Smart Industrial Solution improve efficiency?

By enabling real-time data sharing and analysis, bottlenecks can be quickly identified and addressed. Automation reduces manual errors and speeds up processes. Shared resources minimize redundancy and optimize utilization. - What are the benefits of adopting a Shared Smart Industrial Solution for PCB manufacturing?

Benefits include faster prototyping, reduced material waste, improved product quality, enhanced supply chain visibility, and increased responsiveness to customer demands. It allows for more efficient resource allocation and cost management. - How does data integration contribute to a Smart Industrial Solution?

Data integration allows for the seamless flow of information between different systems and processes. This enables a holistic view of operations, facilitating informed decision-making and process optimization. Access to real-time data allows for proactive adjustments and prevents potential issues. - What role does automation play in a Shared Smart Industrial Solution?

Automation streamlines repetitive tasks, reduces human error, and increases throughput. In PCB manufacturing, automated assembly lines and quality control systems improve efficiency and consistency. - How can Zero One Solution Limited help implement a Shared Smart Industrial Solution?

Zero One Solution Limited offers comprehensive PCB solutions, from design to manufacturing and assembly. Our expertise in rapid prototyping, coupled with our global supply chain network, allows us to provide clients with the resources and support they need to implement a shared smart industrial solution successfully.

Zero One Solution Limited: Your Partner in Smart Industrial Growth

Zero One Solution Limited stands as a leading PCB solution provider uniquely positioned to drive smart industrial growth. Since our inception in 2011, we've been committed to empowering clients through rapid prototyping and comprehensive one-stop services encompassing PCB design, manufacturing, and assembly. Our expertise aligns seamlessly with the demands of the shared smart industrial ecosystem, offering clients access to cutting-edge facilities and unparalleled industry knowledge.

Here's a closer look at how Zero One Solution Limited facilitates smart industrial growth:

- History and Expertise:

Founded in 2011, Zero One Solution Limited has rapidly become a trusted name in PCB assembly solutions. Our extensive experience in rapid prototyping allows us to provide efficient and effective solutions for clients across various industries. - Comprehensive One-Stop Services:

We offer a complete suite of services, from initial PCB design to manufacturing and final assembly. This integrated approach streamlines the entire process, reducing lead times and ensuring the highest quality standards. - Commitment to Innovation:

We are dedicated to empowering our clients to accelerate product development and bring innovative solutions to market swiftly. Our focus on rapid-response R&D prototype manufacturing enables us to meet the evolving needs of the smart industrial landscape. - Alignment with Smart Industrial Ecosystem:

Our capabilities are designed to align with the demands of a shared smart industrial ecosystem. We provide clients with access to state-of-the-art facilities, advanced technologies, and a team of experienced professionals. - Strategic Global Presence:

Headquartered in Shenzhen, China's electronic manufacturing hub, with a branch office in Dubai, we operate strategically within a global PCBA supply chain network. This ensures seamless access to worldwide resources and support, optimizing cost-effectiveness and mitigating supply chain risks.

The Pillars of Our Rapid Prototyping Advantage

Rapid prototyping is not just a service; it's a cornerstone of the smart industrial solution, enabling agility and innovation in PCB development. At Zero One Solution Limited, we recognize this critical role and have honed our rapid prototyping capabilities to provide unparalleled advantages to our clients. Our expertise in quick-turn PCB manufacturing, advanced assembly techniques, and rigorous quality control procedures allows us to significantly reduce development cycles, lower costs, and accelerate market entry for new products, ensuring efficient PCBA manufacturing. This section will delve into the specific pillars that constitute our rapid prototyping advantage.

- Quick-Turn PCB Manufacturing:

Our quick-turn PCB manufacturing service is engineered for speed without compromising quality. We utilize advanced manufacturing processes and optimized workflows to dramatically reduce lead times. This means you can get your prototypes faster, test your designs sooner, and iterate more efficiently, accelerating your entire product development lifecycle. - Advanced Assembly Techniques:

We employ cutting-edge assembly techniques, including automated component placement and advanced soldering methods, to ensure precise and reliable assembly of your prototypes. Our skilled technicians are adept at handling complex designs and challenging components, guaranteeing the functionality and performance of your PCBs. - Rigorous Quality Control:

Quality is paramount in rapid prototyping. We implement stringent quality control measures at every stage of the process, from initial design review to final inspection. Our quality control team utilizes advanced testing equipment and methodologies to identify and eliminate potential defects, ensuring the reliability and performance of your prototypes. - Reduced Development Cycles:

By combining quick-turn manufacturing, advanced assembly, and rigorous quality control, we significantly reduce development cycles. This allows you to get your products to market faster, giving you a competitive edge and maximizing your return on investment. - Lower Costs:

Our rapid prototyping services help lower costs by identifying design flaws early in the process, preventing costly rework and redesigns. We also optimize our manufacturing processes to minimize waste and maximize efficiency, further reducing your overall prototyping expenses. - Faster Market Entry:

Ultimately, our rapid prototyping advantage translates to faster market entry for your new products. By accelerating the development process and reducing costs, we enable you to bring your innovative solutions to market sooner, capturing valuable market share and establishing yourself as a leader in your industry.

Integrated PCB Design to Assembly: A Seamless Workflow

Zero One Solution Limited provides a seamless, end-to-end service encompassing every stage from the initial PCB design consultation through to final assembly and rigorous testing. This integrated approach streamlines the entire production chain, eliminating common bottlenecks, ensuring design integrity, and optimizing for maximum efficiency and quality. Clients benefit from a true 'one-stop' solution for all their PCB and PCBA manufacturing needs.

Here’s a breakdown of the key stages in our integrated workflow:

- PCB Design Consultation

Our expert team collaborates with clients to understand their specific requirements, offering design guidance to optimize performance, manufacturability, and cost-effectiveness. This includes schematic capture, layout design, and design for manufacturing (DFM) analysis. - Component Selection and Sourcing

Leveraging our global supply chain network, we assist clients in selecting the most appropriate components and managing procurement, ensuring availability and competitive pricing. - PCB Manufacturing

Utilizing state-of-the-art equipment and advanced techniques, we manufacture high-quality PCBs to meet stringent specifications, including single-layer, multi-layer, rigid, flexible, and metal core PCBs. - PCB Assembly

Our automated assembly lines ensure precise and efficient component placement and soldering, adhering to industry best practices and quality standards. We handle SMT, through-hole, and mixed technology assembly. - Testing and Inspection

Rigorous testing and inspection procedures are implemented throughout the process, including AOI, X-ray inspection, and functional testing, to ensure the reliability and performance of the assembled PCBs. - Quality Assurance

We adhere to strict quality control measures throughout the entire process, ensuring that all PCBs meet or exceed industry standards and client expectations. Our commitment to quality assurance guarantees the robustness and performance of your products. - Logistics and Delivery

We handle all aspects of logistics and delivery, ensuring timely and secure shipment of finished PCBs to clients worldwide. Our global PCBA supply chain network enables us to provide efficient and cost-effective delivery solutions.

By choosing Zero One Solution Limited, you benefit from a streamlined workflow, reduced lead times, improved quality, and cost savings, ultimately accelerating your product development and time to market.

Leveraging Global Supply Chain for Unparalleled Resource Access

In today's fast-paced electronics industry, having access to a reliable and efficient global supply chain is not just an advantage, it's a necessity. Zero One Solution Limited excels in this area, offering clients unparalleled resource access through our strategically positioned global PCBA supply chain network. By leveraging our presence in Shenzhen and Dubai, we ensure seamless access to a vast ecosystem of resources, components, and expertise, mitigating supply risks and optimizing cost-effectiveness.

Here’s how our global supply chain benefits you:

- Strategic Locations:

Our headquarters in Shenzhen, China's electronics manufacturing hub, and our branch office in Dubai, UAE, position us at the crossroads of global trade and technology. - Worldwide Resource Access:

We tap into a global network of suppliers, ensuring access to a wide range of components, materials, and technologies. - Risk Mitigation:

A diversified supply chain reduces reliance on any single source, minimizing disruptions and ensuring consistent supply. - Cost Optimization:

Our network enables us to source components at competitive prices, optimizing your project's cost-effectiveness. - Expertise on Demand:

Benefit from the collective knowledge and experience of our global network of partners and specialists.

Our commitment to a shared smart industrial solution means that our clients benefit directly from our extensive network, gaining a competitive edge in the market. This 'shared' aspect of our solution provides you with resources and capabilities that would otherwise be difficult to obtain.

Here are some frequently asked questions to help you understand better how we utilize our Global Supply Chain:

- How does Zero One Solution Limited's global presence benefit my PCB project?

Our strategic locations in Shenzhen and Dubai provide access to a broad range of suppliers, competitive pricing, and reduced lead times for components, directly benefiting your project's timeline and budget. - What measures does Zero One Solution Limited take to mitigate supply chain risks?

We diversify our supply sources, maintain buffer stocks of critical components, and closely monitor geopolitical and economic factors to proactively address potential disruptions. - Can Zero One Solution Limited source specialized or hard-to-find components for my PCB assembly?

Yes, our extensive global network and experienced sourcing team enable us to locate and procure specialized and obsolete components, ensuring comprehensive support for your project. - How does Zero One Solution Limited ensure the quality of components sourced through its global supply chain?

We implement rigorous quality control measures, including supplier audits, component testing, and adherence to industry standards, to guarantee the reliability and performance of all sourced materials. - Does Zero One Solution Limited offer supply chain management services as part of its PCB solutions?

Yes, we provide comprehensive supply chain management services, including procurement, logistics, and inventory management, to streamline your PCB production process and minimize administrative overhead. - How does Zero One Solution Limited's global supply chain contribute to cost savings for clients?

Our global network allows us to leverage competitive pricing, optimize shipping routes, and minimize tariffs, resulting in significant cost savings that we pass on to our clients.

Quality Assurance and Reliability: The Foundation of Trust

At Zero One Solution Limited, quality assurance and reliability aren't just checkpoints; they are the bedrock upon which we build trust with our clients. We understand that the performance and longevity of your products depend on the integrity of the PCB design, manufacturing, and assembly processes. That's why we implement stringent quality control measures and adhere to the highest reliability standards at every stage.

Our commitment to quality is unwavering, ensuring that every PCB solution we deliver meets or exceeds industry expectations. By prioritizing robustness and performance, we empower our clients to confidently bring their innovative products to market, knowing that they are built on a foundation of trust and excellence.

- What quality control measures are in place during PCB manufacturing?

Zero One Solution Limited employs a multi-tiered quality control system. This includes automated optical inspection (AOI), in-circuit testing (ICT), and functional testing to identify and rectify any defects early in the manufacturing process. We also conduct rigorous material testing and validation to ensure component quality and adherence to specifications. - How does Zero One Solution Limited ensure the reliability of its PCB assemblies?

Reliability is paramount. We conduct environmental stress testing, including thermal cycling and humidity testing, to simulate real-world operating conditions. This helps us identify potential failure points and optimize the design and assembly processes for maximum durability. Furthermore, we adhere to IPC standards and implement robust process controls to minimize variability and ensure consistent performance. - What certifications does Zero One Solution Limited hold to demonstrate its commitment to quality?

Zero One Solution Limited is committed to adhering to the highest industry standards. While specific certifications may vary, we often maintain certifications such as ISO 9001 (Quality Management System) and IPC standards compliance. These certifications demonstrate our dedication to quality management, process control, and continuous improvement. - Can Zero One Solution Limited provide customized testing solutions for specific PCB requirements?

Yes, we understand that certain applications may demand specialized testing. We offer customized testing solutions tailored to your unique PCB requirements. This may include specialized environmental testing, signal integrity analysis, or other specific validation procedures. Contact our engineering team to discuss your specific needs. - What traceability measures are in place to track components and materials used in PCB assembly?

We maintain comprehensive traceability throughout the PCB assembly process. This includes tracking the origin and lot numbers of all components and materials used. This allows us to quickly identify and address any potential issues related to specific components or batches, ensuring accountability and facilitating efficient root cause analysis. - How does Zero One Solution Limited handle non-conforming materials or products?

Our non-conforming material and product handling process is designed to prevent defective products from reaching our customers. We have clearly defined procedures for identifying, segregating, and analyzing non-conforming items. Corrective and preventive actions are implemented to address the root causes of non-conformances and prevent recurrence. This ensures that only high-quality, fully functional PCBs are shipped. - What is Zero One Solution Limited's approach to continuous improvement in quality and reliability?

We are committed to continuous improvement in all aspects of our operations. We regularly monitor key performance indicators (KPIs) related to quality and reliability. We actively solicit feedback from our customers and employees to identify areas for improvement. We invest in training and technology to enhance our processes and capabilities. This ongoing commitment to excellence ensures that we consistently deliver the highest quality PCB solutions to our clients.

FAQs about Shared Smart Industrial Solutions and Zero One Solution Limited

This section addresses frequently asked questions about shared smart industrial solutions, rapid prototyping, PCB assembly, and the benefits of partnering with Zero One Solution Limited, offering concise answers to common client inquiries regarding lead times, technological capabilities, and project management processes.

- What are the primary advantages of using a shared smart industrial solution for PCB assembly?

Shared smart industrial solutions offer several key advantages, including increased efficiency through resource optimization, reduced costs by sharing resources and infrastructure, faster turnaround times due to streamlined processes and advanced automation, and improved collaboration among different stages of the manufacturing process. These solutions also facilitate data-driven decision-making, leading to better quality control and continuous improvement. Partnering with Zero One Solution Limited provides access to these benefits, enhancing your competitive edge. - How does Zero One Solution Limited ensure the quality and reliability of its PCB assembly services?

Zero One Solution Limited maintains stringent quality control measures at every stage of the PCB design, manufacturing, and assembly process. This includes rigorous testing, adherence to international standards (such as IPC), and continuous monitoring of processes to identify and rectify any potential issues. Our commitment to quality ensures that clients receive robust and reliable PCB solutions that meet their specific requirements. - What types of rapid prototyping services does Zero One Solution Limited offer?

Zero One Solution Limited specializes in rapid prototyping services designed to accelerate product development cycles. Our capabilities include quick-turn PCB manufacturing, advanced assembly techniques, and comprehensive testing and validation. We support a wide range of technologies and materials, allowing us to meet the diverse needs of our clients and enable faster market entry for new products. - Can Zero One Solution Limited handle both small and large production volumes?

Yes, Zero One Solution Limited is equipped to handle both small and large production volumes. Our flexible manufacturing processes and scalable infrastructure allow us to efficiently manage projects of any size, from initial prototypes to mass production runs. We work closely with our clients to understand their specific needs and tailor our services to meet their volume requirements. - What is the typical lead time for PCB assembly projects at Zero One Solution Limited?

Lead times for PCB assembly projects at Zero One Solution Limited vary depending on the complexity of the design, the availability of components, and the production volume. However, our focus on rapid prototyping and efficient processes allows us to offer competitive lead times. We provide detailed project timelines upfront and keep clients informed throughout the manufacturing process to ensure transparency and timely delivery. - How does Zero One Solution Limited leverage its global supply chain to benefit clients?

Zero One Solution Limited's strategic presence in Shenzhen and Dubai provides access to a vast global PCBA supply chain network. This enables us to source components quickly and cost-effectively, mitigate supply chain risks, and ensure timely delivery of materials. Our extensive network also allows us to leverage the expertise and resources of our partners, providing clients with a comprehensive and competitive solution. - What design support does Zero One Solution Limited offer to clients?

Zero One Solution Limited offers comprehensive design support to assist clients throughout the PCB development process. Our services include design consultation, layout optimization, and design for manufacturability (DFM) analysis. We work closely with clients to ensure that their designs are optimized for performance, reliability, and cost-effectiveness, helping them achieve their product goals efficiently.

The future of industrial manufacturing is inherently shared and intelligent. Zero One Solution Limited's Shared Smart Industrial Solution embodies this vision, offering a robust, end-to-end framework that empowers businesses to navigate the complexities of modern product development with unprecedented agility and confidence. By leveraging our expertise in rapid prototyping, integrated PCB assembly, and global supply chain management, you're not just getting a service provider; you're gaining a strategic partner committed to your success. Experience the Zero One Solution Limited difference and accelerate your innovation. Contact us today to discuss how our Shared Smart Industrial Solution can revolutionize your next project.

AnyPCBA

AnyPCBA