Shared Warehouse Solution

In the fast-paced world of electronics manufacturing, efficiency and cost-effectiveness are paramount. As a veteran engineer from Zero One Solution Limited, I've witnessed firsthand the challenges companies face in managing complex PCB supply chains, especially when it comes to inventory. This is where a robust shared warehouse solution becomes not just an advantage, but a necessity. At Zero One Solution, a leader in rapid prototyping and one-stop PCB services since 2011, we understand these intricate demands. Our Shared Warehouse Solution is designed to address these pain points directly, offering a strategic approach to inventory management that streamlines operations and empowers faster product development. But what exactly does a shared warehouse entail, and how can it revolutionize your PCB assembly process?

Understanding the Shared Warehouse Solution

A shared warehouse solution represents a paradigm shift from traditional, dedicated warehousing, offering a collaborative ecosystem for storage and distribution. At its core, it's a facility where multiple businesses pool resources to store their goods, optimizing space and reducing individual overhead. This model is particularly relevant for PCB component management, where diverse clients with varying needs can benefit from shared resources, efficient logistics, and cost-effective inventory handling within the electronics sector.

- What is the fundamental difference between a shared warehouse and a traditional warehouse?

A traditional warehouse is typically dedicated to a single company's inventory, whereas a shared warehouse is utilized by multiple companies, sharing space, resources, and costs. - How does a shared warehouse facilitate collaborative storage and distribution?

Shared warehouses enable collaborative storage by consolidating inventory from various clients into a single location. Distribution is facilitated through shared logistics and optimized routing, reducing transportation costs and improving delivery times. - What types of businesses benefit most from shared warehouse solutions?

Businesses with fluctuating inventory levels, limited storage space, or those seeking to reduce operational costs often find shared warehouse solutions particularly beneficial. This includes startups, SMEs, and even larger enterprises looking to optimize their supply chains. - How does a shared warehouse handle the diverse needs of different clients in the electronics sector?

Shared warehouses are equipped to handle diverse needs through flexible storage options, customizable inventory management systems, and specialized handling procedures for different types of electronic components. This ensures that each client's specific requirements are met effectively. - What are the key benefits of using a shared warehouse for PCB component management?

Key benefits include reduced storage costs, improved inventory visibility, faster order fulfillment, and access to advanced warehouse management technologies. These advantages contribute to greater efficiency and cost savings for PCB manufacturers and assemblers.

Key Advantages for PCB Manufacturers

Adopting a shared warehouse solution presents several key advantages for PCB manufacturers, particularly in terms of cost efficiency and streamlined operations. These benefits are especially impactful for R&D-focused companies seeking to optimize resource allocation and accelerate product development cycles.

- Reduced Overhead Costs

Sharing warehouse space translates to significant cost savings. Instead of bearing the full burden of warehouse rent, utilities, and maintenance, PCB manufacturers only pay for the space they utilize. This is particularly beneficial for startups and SMEs with limited capital. - Lower Inventory Holding Costs

A shared warehouse minimizes the financial strain associated with storing PCB components. By leveraging the warehouse's inventory management system and only storing necessary materials, manufacturers can reduce carrying costs, insurance premiums, and potential losses from obsolescence. - Improved Cash Flow

Freeing up capital tied to warehousing and inventory allows PCB manufacturers to reinvest in core business activities, such as research and development, equipment upgrades, and marketing initiatives. This improved cash flow fuels innovation and growth. - Scalability and Flexibility

Shared warehousing offers unparalleled scalability. PCB manufacturers can easily adjust their storage space based on fluctuating production demands. This flexibility is crucial for managing seasonal variations, project-based requirements, and unexpected surges in demand. - Access to Advanced Technology and Expertise

Reputable shared warehouse providers often invest in advanced inventory management systems, security measures, and skilled personnel. PCB manufacturers can leverage these resources without incurring the full cost of implementation and training. - Strategic Location Benefits

Shared warehouses strategically located in key manufacturing hubs, like Zero One Solution Limited's facilities in Shenzhen and Dubai, provide proximity to suppliers, customers, and transportation networks. This optimizes logistics and reduces lead times.

Streamlining the Supply Chain: Efficiency and Speed

A shared warehouse solution revolutionizes the PCB supply chain by boosting efficiency and speed, which is critical for rapid prototyping and quick turnaround projects. By optimizing component accessibility and reducing lead times, this approach directly addresses the need for agile and responsive manufacturing processes.

- Faster Access to Components

Shared warehousing strategically positions components closer to the point of production. This proximity drastically reduces the time it takes to retrieve and utilize parts, cutting down on delays and accelerating the manufacturing timeline. - Reduced Lead Times

By centralizing component storage and management, shared warehouses minimize the delays associated with traditional supply chains. This streamlined process ensures that manufacturers can quickly obtain the necessary parts, reducing overall lead times and speeding up project completion. - Enhanced Responsiveness to Market Demands

A shared warehouse model enables manufacturers to adapt swiftly to changing market conditions and customer needs. The ability to quickly access and deploy components allows for flexible production schedules and rapid responses to urgent orders or design modifications. - Optimized Logistics

Shared warehouse solutions often include integrated logistics services that streamline transportation and delivery processes. This optimization ensures that components are delivered efficiently and reliably, minimizing disruptions and further reducing lead times. - Improved Collaboration

Shared warehouses facilitate better collaboration between suppliers, manufacturers, and distributors. This enhanced communication and coordination ensures that all parties are aligned and working towards the common goal of efficient supply chain management.

Inventory Management and Risk Mitigation

A shared warehouse solution significantly enhances inventory management and mitigates risks for PCB manufacturers. By providing advanced tools like real-time tracking, demand forecasting, and consignment inventory options, these solutions enable businesses to optimize stock levels, reduce waste, and minimize financial exposure. This proactive approach addresses common challenges such as component obsolescence, damage, and overstocking, ensuring a more resilient and cost-effective supply chain.

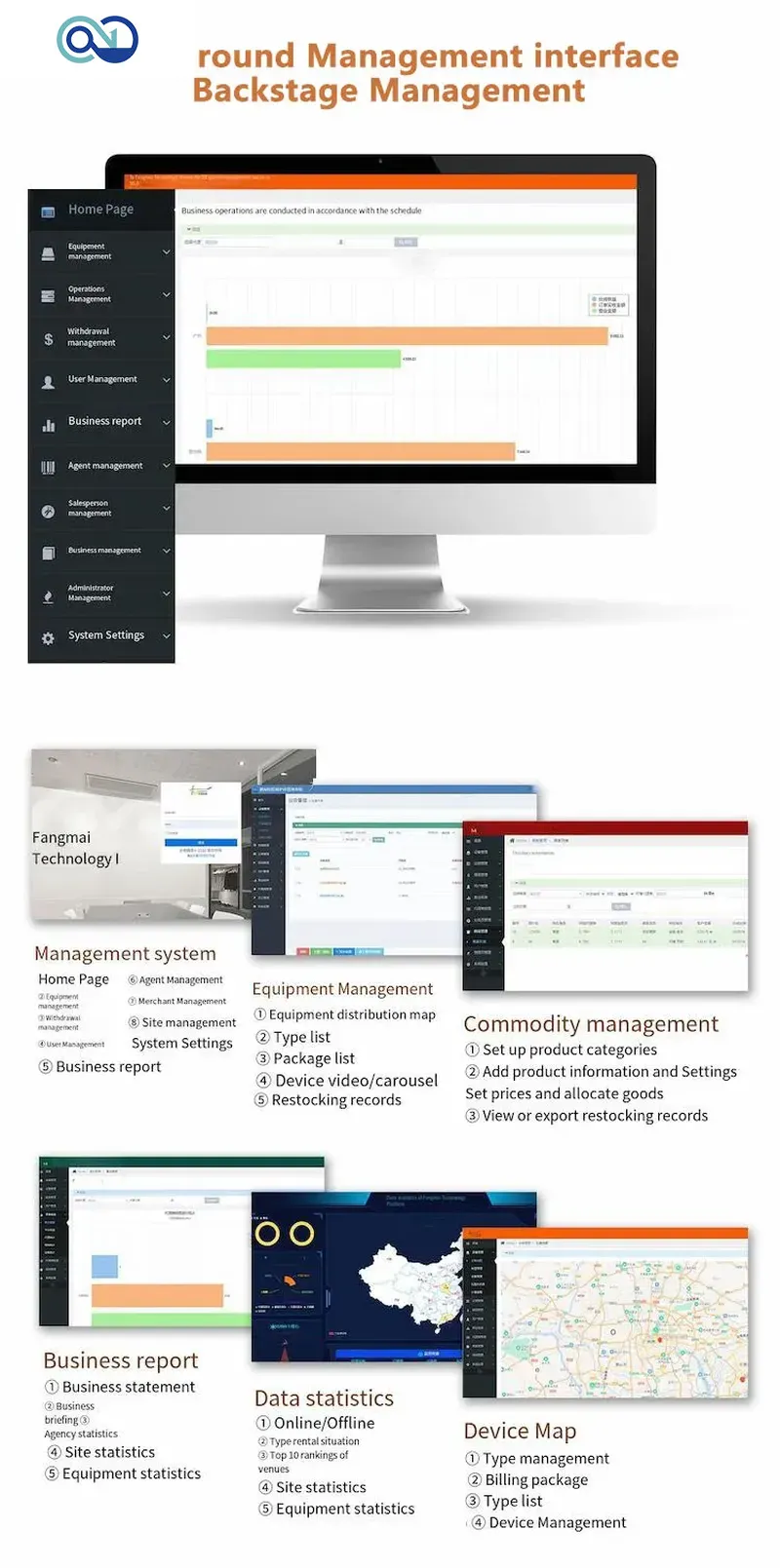

- Real-Time Inventory Tracking

Provides up-to-the-minute visibility into stock levels and locations, enabling informed decision-making and preventing stockouts or overstocking. This allows for immediate adjustments based on actual usage and demand. - Demand Forecasting

Utilizes historical data and predictive analytics to forecast future component needs, ensuring optimal inventory levels and reducing the risk of shortages or surpluses. Advanced algorithms consider factors like seasonality, market trends, and production schedules. - Consignment Inventory

Allows manufacturers to store components in the shared warehouse without taking ownership until they are used. This reduces upfront costs and minimizes the risk of holding obsolete or unused inventory. Suppliers retain ownership and responsibility until the components are consumed. - Obsolescence Management

Proactively identifies and manages components that are nearing obsolescence, allowing manufacturers to make informed decisions about replacements or last-time buys. This prevents production disruptions and minimizes the financial impact of obsolete inventory. - Damage Reduction

Ensures proper storage and handling of sensitive electronic components, minimizing the risk of damage from environmental factors or mishandling. Temperature and humidity controls, along with specialized packaging, protect components from degradation. - Overstock Prevention

Helps prevent overstocking by providing accurate demand forecasting and real-time inventory tracking, ensuring that components are only ordered when needed. This reduces holding costs and minimizes the risk of inventory write-offs.

Zero One Solution Limited's Unique Approach to Shared Warehousing

Zero One Solution Limited distinguishes itself in the shared warehousing landscape through strategically positioned facilities and a comprehensive service model tailored to the fast-paced PCB industry. Our commitment extends beyond mere storage; we provide an integrated ecosystem designed to accelerate prototyping and streamline manufacturing processes for our clients.

- Strategic Global Locations

With prime locations in Shenzhen, China, and Dubai, UAE, Zero One Solution Limited offers unparalleled access to both Eastern and Western markets. Shenzhen, a global electronics manufacturing hub, allows us to leverage cutting-edge technologies and efficient supply chains. Dubai serves as a strategic gateway to the Middle East, Africa, and Europe, facilitating seamless international distribution and support. - One-Stop Service Ecosystem

Unlike conventional warehousing solutions, we provide a holistic suite of services encompassing PCB design, manufacturing, and assembly. This integrated approach minimizes lead times, reduces logistical complexities, and ensures superior quality control at every stage of the production process. Our clients benefit from a streamlined workflow, from initial design to final product delivery. - Rapid-Response R&D Prototyping

Zero One Solution Limited is dedicated to supporting rapid-response R&D prototype manufacturing. Our shared warehousing solutions are optimized for quick access to components, enabling agile development cycles and faster time-to-market for innovative products. This agility is crucial for companies looking to stay ahead in competitive markets. - Customized Inventory Solutions

We understand that each client has unique inventory management needs. Zero One Solution Limited offers tailored solutions that include real-time inventory tracking, demand forecasting, and consignment inventory options. These customized services help mitigate risks associated with obsolescence, damage, and overstocking, ensuring optimal inventory levels and cost efficiency. - Advanced Technology Integration

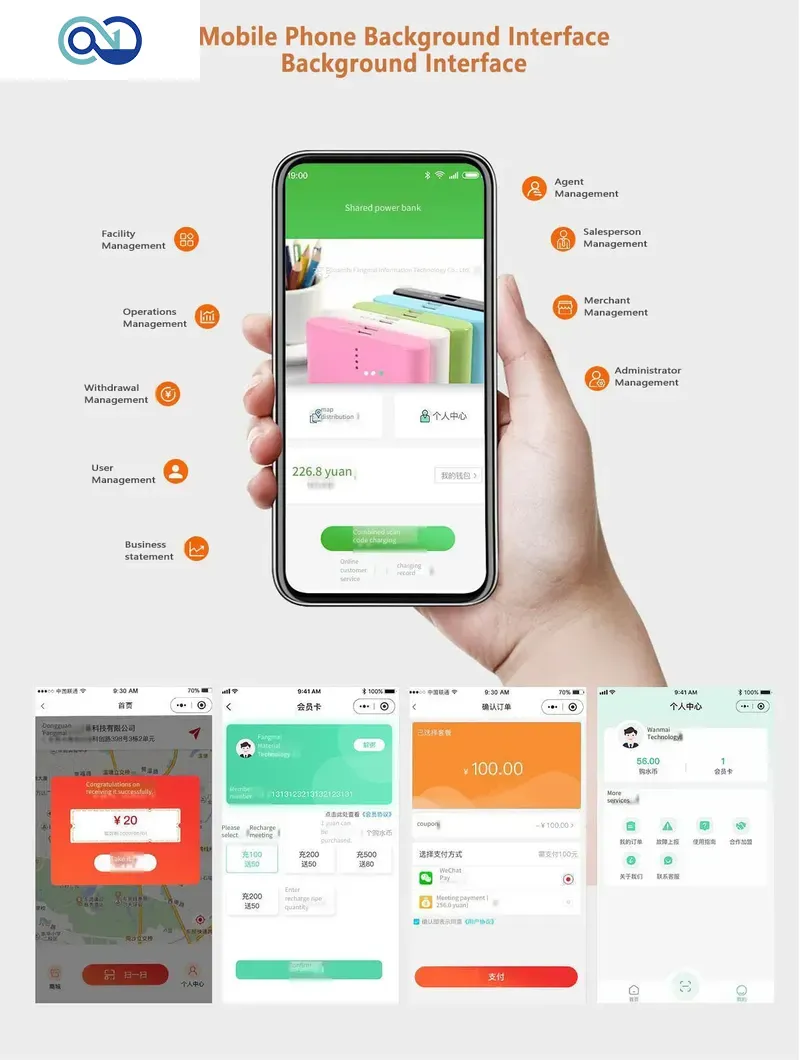

Our shared warehouses are equipped with state-of-the-art technology, including automated storage and retrieval systems (AS/RS), advanced security measures, and seamless integration with ERP and supply chain management platforms. This technological infrastructure ensures accuracy, efficiency, and transparency in all warehousing operations.

Who Can Benefit from a Shared Warehouse Solution?

Shared warehouse solutions are not a one-size-fits-all answer, but a strategic advantage for specific types of businesses. These are companies that can significantly benefit from reduced operational complexity, improved financial efficiency, and faster product launches. Startups, SMEs, and large enterprises within the electronics industry stand to gain the most, particularly those involved in rapid prototyping and quick-turn PCB assembly.

- Startups

For startups, capital is king. Shared warehousing minimizes upfront investment in infrastructure, freeing up funds for R&D, marketing, and other critical areas. Startups also benefit from the scalability of shared warehousing, allowing them to adjust storage space as their needs evolve. - Small to Medium-Sized Enterprises (SMEs)

SMEs often struggle with balancing growth and cost control. A shared warehouse offers a cost-effective way to manage inventory and streamline logistics without the burden of managing a dedicated facility. This allows SMEs to compete more effectively with larger players. - Large Enterprises

Even large enterprises can find value in shared warehousing, especially for specific product lines or regions. It allows them to optimize their supply chains, reduce risks associated with obsolescence and overstocking, and improve responsiveness to changing market demands. Shared warehousing can also serve as a testing ground for new market entry without significant capital expenditure. - R&D-Focused Companies

Companies like Zero One Solution Limited's clients, who specialize in rapid-response R&D prototype manufacturing, are prime candidates. The ability to quickly access components and scale storage based on project needs is crucial for maintaining a competitive edge. - Companies Seeking to Reduce Operational Complexity

Managing a warehouse involves complex logistics, staffing, and technology investments. Outsourcing these functions to a shared warehouse provider allows companies to focus on their core competencies, such as product design, manufacturing, and marketing. - Businesses Aiming for Financial Efficiency

Shared warehousing translates directly into cost savings through shared overhead, reduced inventory holding costs, and improved cash flow. These savings can be reinvested into other areas of the business, driving growth and innovation. - Organizations Prioritizing Speed and Agility

In today's fast-paced electronics industry, speed is essential. A shared warehouse provides faster access to components, reduced lead times, and enhanced responsiveness to market demands, enabling companies to accelerate product launches and stay ahead of the competition.

Frequently Asked Questions (FAQs) about Shared Warehouse Solutions

Navigating the intricacies of shared warehousing can raise several questions. This section addresses common inquiries, providing clear and concise answers to potential client concerns regarding security, system integration, storage flexibility, and the unique benefits for various electronic components. Let's clarify some key aspects to help you understand how a shared warehouse solution can benefit your PCB manufacturing and component management.

- What security measures are in place within a shared warehouse to protect my PCB components?

Shared warehouses employ robust security protocols, including 24/7 surveillance, controlled access, and advanced inventory tracking systems. Components are stored in secure areas, and stringent procedures are in place to prevent theft, damage, or loss. Regular audits and compliance checks further ensure the safety and integrity of your inventory. - How does a shared warehouse solution integrate with my existing inventory management systems?

Most shared warehouse providers offer integration capabilities with popular inventory management systems via APIs or other data exchange methods. This allows for real-time visibility into your stock levels, order tracking, and automated reporting, streamlining your overall supply chain management. We, at Zero One Solution Limited, can tailor integration to your specific systems. - What level of storage flexibility does a shared warehouse offer for different types of electronic components?

Shared warehouses provide flexible storage options to accommodate a wide range of electronic components, from small, sensitive components requiring specialized packaging to larger, bulk items. Storage solutions can be customized based on temperature, humidity, and other environmental requirements to ensure optimal preservation and prevent damage. We offer customized storage solutions to meet the diverse needs of our clients. - What are the specific benefits of using a shared warehouse for PCB components compared to traditional warehousing?

Shared warehousing offers several advantages over traditional warehousing, including cost savings through shared overhead, reduced inventory holding costs, improved cash flow, and increased supply chain efficiency. It also provides access to advanced inventory management technologies and expertise without the need for significant upfront investment. This is particularly beneficial for R&D-focused companies aiming to accelerate product development. - How does a shared warehouse handle returns or defective PCB components?

Shared warehouses typically have established procedures for handling returns and defective components. These procedures may include inspection, quarantine, and disposal or return to the supplier. Clear documentation and tracking are maintained throughout the process to ensure accountability and compliance. We adhere to strict quality control measures to minimize defects and manage returns efficiently. - Can I easily scale my storage space up or down in a shared warehouse as my PCB production needs fluctuate?

Yes, one of the key benefits of a shared warehouse is its scalability. You can easily adjust your storage space based on your changing production demands, avoiding the fixed costs and long-term commitments associated with traditional warehousing. This flexibility is crucial for businesses experiencing rapid growth or seasonal fluctuations in demand. We offer scalable solutions to support your evolving needs. - What happens to my PCB components if the shared warehouse facility experiences a disruption, such as a natural disaster?

Reputable shared warehouses have comprehensive disaster recovery plans in place to mitigate the impact of disruptions. These plans typically include backup power systems, fire suppression systems, and insurance coverage to protect your inventory. They also have alternative storage locations available to ensure business continuity. We prioritize business continuity and risk mitigation to safeguard your valuable assets.

The Shared Warehouse Solution offered by Zero One Solution Limited is more than just a storage service; it's a strategic partnership designed to empower your business in the competitive electronics landscape. By embracing this model, you gain unparalleled flexibility, significant cost reductions, and accelerated time-to-market, all while leveraging our global PCBA supply chain expertise. From our Shenzhen headquarters to our Dubai branch, we are committed to providing the innovative solutions that drive your success. Don't let inventory management be a bottleneck. Contact Zero One Solution Limited today to discover how our Shared Warehouse Solution can optimize your operations and propel your next innovation forward. Let's build the future, together.

AnyPCBA

AnyPCBA