Summit PCB: Advanced Manufacturing & Complex Circuit Solutions

In today's fast-paced technological landscape, the demand for advanced and reliable printed circuit boards (PCBs) is higher than ever. Summit PCB stands at the forefront of this industry, providing cutting-edge solutions for complex circuit designs. This article explores Summit PCB’s expertise, focusing on their capabilities in rigid, flex, and rigid-flex PCB manufacturing, and how they contribute to the advancement of modern electronics.

Summit PCB: A Leader in Advanced PCB Manufacturing

Summit PCB stands as a distinguished leader in the realm of advanced printed circuit board (PCB) manufacturing, renowned for its expertise in producing high-technology solutions. Their focus on innovation, precision, and quality has positioned them as a preferred partner for industries demanding the highest levels of performance and reliability in their electronic components. With a strong emphasis on pushing the boundaries of PCB technology, Summit PCB consistently delivers cutting-edge solutions that meet the ever-evolving needs of the electronics industry.

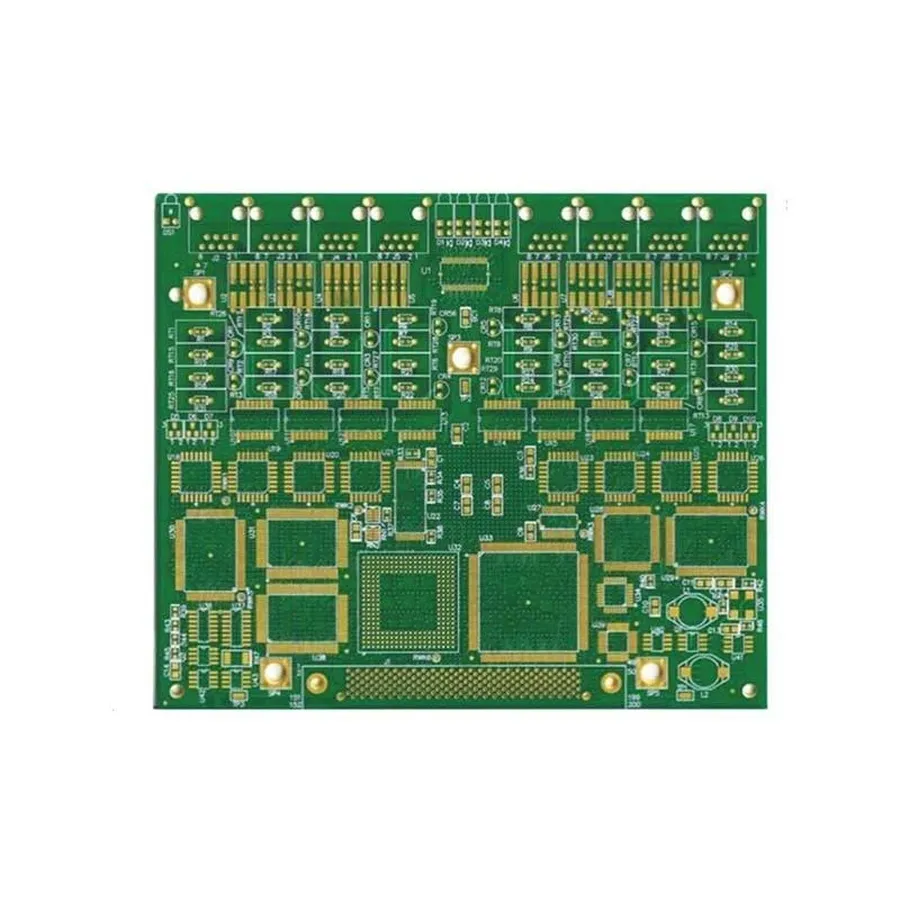

Specialization in Complex Rigid PCBs

Summit PCB distinguishes itself through its advanced capabilities in the manufacturing of complex rigid printed circuit boards. These PCBs are characterized by their high performance, multi-layered designs, and intricate circuitry, catering to demanding applications across various industries.

The company's expertise in producing these high-performance rigid PCBs is underpinned by cutting-edge manufacturing technologies and stringent quality control processes. This ensures the delivery of reliable and durable circuit boards that meet the specific needs of their clients' complex applications.

| Feature | Description | Benefit |

|---|---|---|

| Multi-Layer Construction | Utilizes advanced lamination techniques to create PCBs with numerous layers for higher density and functionality. | Enables the integration of complex circuitry in a smaller footprint, accommodating advanced functionalities. |

| High-Density Interconnects (HDI) | Employs fine line and space technology for intricate connections. | Facilitates superior signal integrity and higher data transfer rates. |

| Advanced Materials | Utilizes materials with superior electrical and thermal properties. | Improves performance under extreme conditions and enhances reliability. |

| Precision Machining | Employs advanced machining to ensure extremely tight tolerances. | Ensures high-precision and high accuracy in manufacturing of PCBs |

| Stringent Quality Control | Rigorous testing and inspection procedures throughout the manufacturing process. | Guarantees product reliability and high performance. |

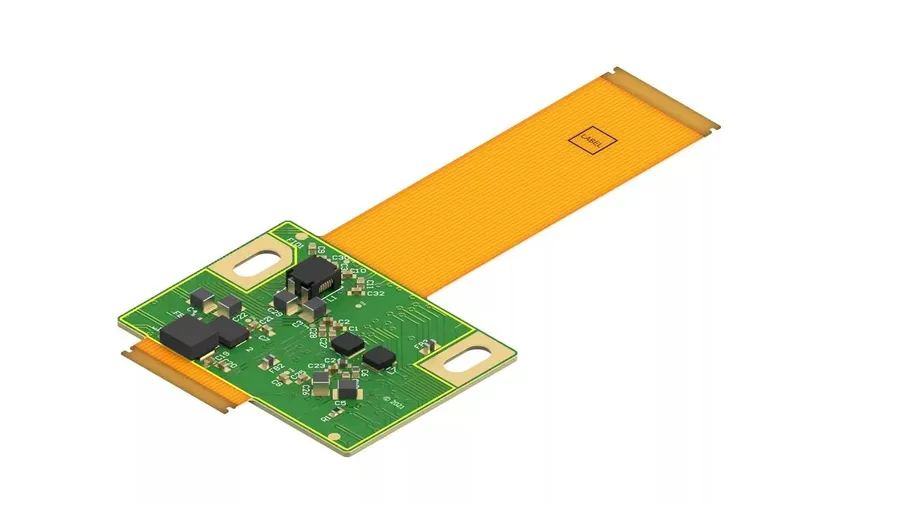

Flex PCB Manufacturing Expertise

Summit PCB demonstrates significant expertise in the manufacturing of flexible printed circuit boards (Flex PCBs), also known as flexible circuits. These PCBs offer unique advantages over rigid boards, especially in applications requiring bending, folding, or dynamic movement. Summit’s capabilities in this area include advanced material handling, precision patterning, and stringent quality control, ensuring reliable and high-performance flex circuits.

Flex PCBs are essential in modern electronics, and Summit's manufacturing capabilities extend across single-sided, double-sided, and multilayer designs. Their expertise allows for complex geometries and high-density interconnections. Here’s a breakdown of the benefits and applications of flexible PCBs:

- Benefits of Flex PCBs

Flexibility and Durability: Enables dynamic bending and folding, providing a durable solution for demanding environments. - Space and Weight Reduction

Thin and lightweight, ideal for compact electronic devices and reducing overall system weight. - Design Versatility

Can conform to complex shapes and tight spaces, offering significant freedom in product design. - Improved Reliability

Fewer interconnections lead to better signal integrity and reduced risk of mechanical failure, enhancing overall product reliability.

Summit's manufacturing processes are designed to meet the diverse needs of clients, from prototyping to high-volume production. Their processes and material selection are tailored to ensure that the flex PCBs meet demanding requirements.

| Feature | Description |

|---|---|

| Material Options | Summit provides a wide selection of flex materials such as polyimide, polyester, and modified epoxy, each chosen based on the application and performance needs. |

| Layer Count | Capabilities include single-sided, double-sided, and multilayer flex circuits, catering to varying levels of design complexity and signal density. |

| Finishes | Various surface finish options, such as ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative), to ensure optimal solderability and reliability. |

| Precision Imaging | Uses advanced photo imaging to achieve tight tolerances and high trace densities, necessary for high-performance flex circuits. |

| Quality Control | Stringent testing procedures are in place at every stage of the process, including electrical, environmental, and mechanical testing, to guarantee that the final product meets the highest quality standards. |

Applications for Summit's flexible PCBs are extensive and varied, reaching several industries that rely on flexible and durable electronic solutions.

- Consumer Electronics

Used extensively in smartphones, wearable devices, and cameras due to their flexibility and compact size. - Medical Devices

Ideal for implantable devices, diagnostic equipment, and patient monitoring systems. - Automotive

Employed in sensors, control modules, and infotainment systems due to their durability and resistance to vibrations. - Aerospace

Essential for satellite systems, avionics, and other high-reliability applications. - Industrial Automation

Used in robotic systems, control panels, and other industrial equipment where durability and flexibility are required.

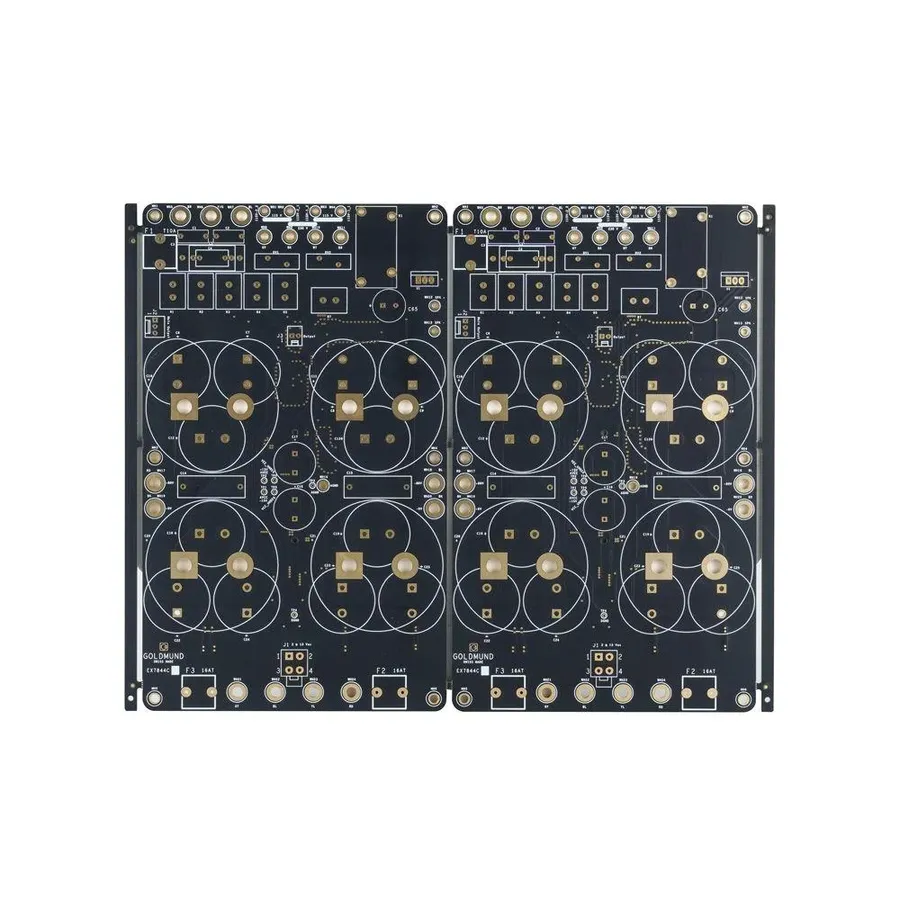

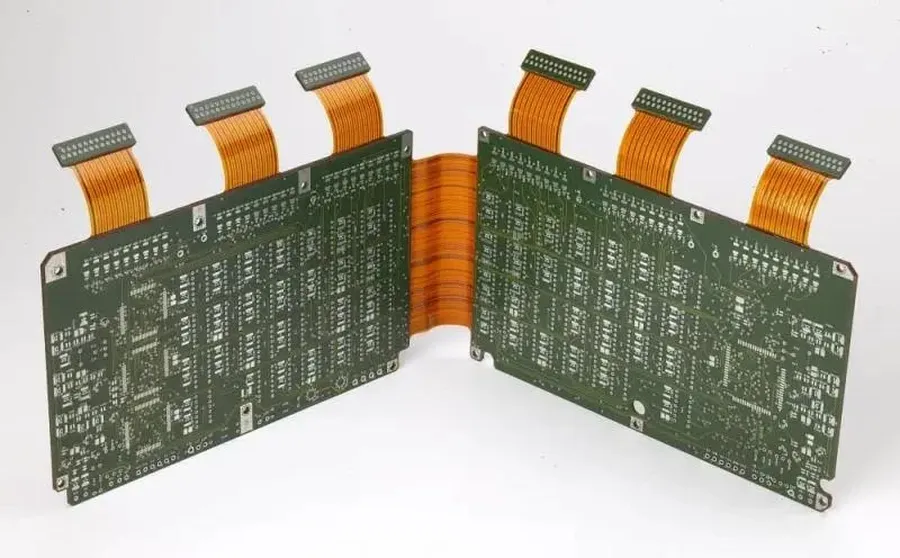

Rigid-Flex PCB Solutions

Summit PCB excels in the design and fabrication of rigid-flex printed circuit boards, which integrate the benefits of both rigid and flexible PCB technologies. These solutions are crucial for applications requiring compact size, dynamic movement, and high reliability.

Rigid-flex PCBs combine the robustness of rigid boards with the flexibility of flexible circuits. This hybrid approach enables designers to create innovative products that can fit into tight spaces, withstand mechanical stress, and offer enhanced signal integrity. Summit PCB's expertise in this area makes them a preferred partner for complex electronic designs.

| Feature | Rigid PCB | Flexible PCB | Rigid-Flex PCB |

|---|---|---|---|

| Rigidity | High | Low | Hybrid |

| Flexibility | None | High | Partial |

| Dimensional Stability | High | Low | High in Rigid Areas |

| Complexity | Moderate | Moderate | High |

| Cost | Moderate | Moderate | High |

| Typical Applications | Static Devices | Dynamic Connections | Complex and compact devices |

The advantages of rigid-flex PCBs are numerous. They reduce the need for connectors and cables, which in turn improves reliability and reduces assembly costs. By incorporating the rigid and flexible materials into a single circuit board, it is possible to decrease the size and weight of the final product. Moreover, the ability to dynamically flex the flexible sections of the design increases design freedom and enables new and creative design solutions. The design of rigid-flex PCBs is complex and demands specialized expertise; Summit PCB's experience in materials science and fabrication techniques ensures that each customer receives optimal product performance.

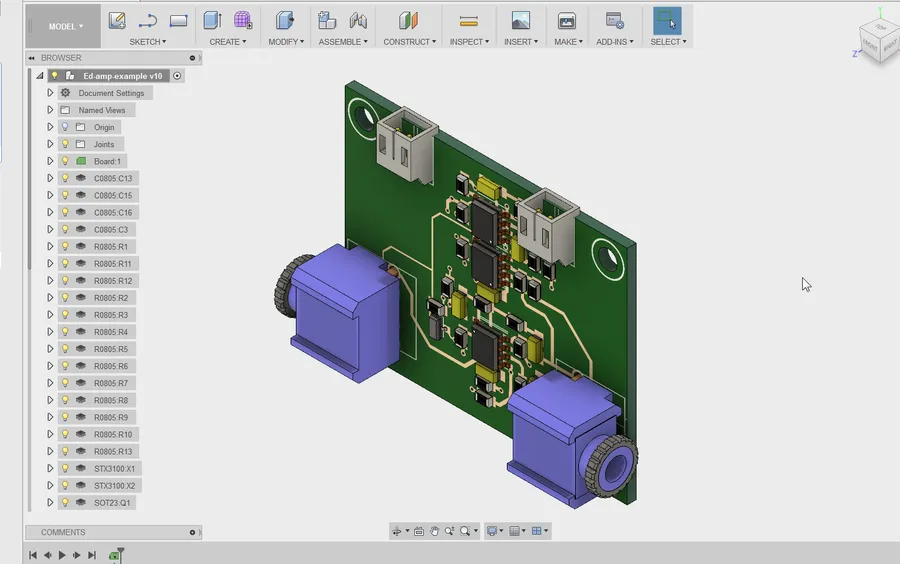

The Importance of Advanced Technology in PCB Design

Advanced technology is paramount in modern PCB design, significantly influencing the quality, performance, and reliability of Summit PCB products. The integration of cutting-edge materials, fabrication techniques, and design methodologies directly translates to enhanced electrical performance, miniaturization, and durability.

Key aspects of advanced technology in PCB design include:

- High-Density Interconnect (HDI) Technology

HDI technology allows for the placement of more components in a smaller area with finer lines and vias, enabling higher circuit density and improved electrical performance, essential for complex applications. - Advanced Materials

The utilization of advanced materials with superior dielectric properties, thermal conductivity, and mechanical strength leads to improved signal integrity, thermal management, and durability in harsh environments. - Precise Fabrication Techniques

Advanced fabrication techniques such as laser direct imaging (LDI), microvia drilling, and precise plating processes ensure high accuracy and consistency in manufacturing, reducing defects and enhancing reliability. - Simulation and Modeling Tools

The use of sophisticated simulation and modeling tools allows engineers to predict PCB performance under various operating conditions, optimizing designs and preventing potential issues before production. - Automated Optical Inspection (AOI)

Implementing AOI during the manufacturing process ensures that PCBs meet stringent quality standards and that defects can be detected early, minimizing waste and maximizing quality.

Through these advanced technologies, Summit PCB ensures that its products meet the demanding requirements of industries such as aerospace, medical, and automotive, where high reliability and performance are critical.

Applications of Summit PCBs Across Industries

Summit PCBs are integral to a diverse range of industries, owing to their high reliability, advanced technology, and adaptability to complex designs. Their applications span sectors requiring stringent performance and quality standards.

Here are some key industries where Summit PCBs play a critical role:

- Aerospace

In aerospace, Summit PCBs are utilized in mission-critical applications such as avionics, communication systems, and control units, where reliability and performance are paramount. These PCBs need to withstand extreme temperatures, vibrations, and G-forces, making Summit's advanced manufacturing crucial. - Medical Devices

Medical devices rely on Summit PCBs for precise and dependable functionality. These PCBs are found in diagnostic equipment, patient monitoring systems, and surgical instruments. The need for high precision and reliability is vital, meeting the stringent regulatory standards in the medical field. - Automotive

The automotive industry integrates Summit PCBs into various applications including engine control units (ECUs), advanced driver-assistance systems (ADAS), and infotainment systems. Summit PCBs meet the high-reliability standards and environmental stress required in automotive electronics, crucial for both safety and comfort. - Telecommunications

Summit PCBs are essential in telecommunications infrastructure, including networking equipment, routers, and base stations. Their high-speed signal integrity and low-loss characteristics contribute to reliable data transmission, supporting seamless communication networks. - Industrial Automation

Summit PCBs are used in industrial automation systems such as programmable logic controllers (PLCs), robotics, and control systems. They provide reliable and robust performance in harsh industrial environments, ensuring operational efficiency and system uptime. - Consumer Electronics

In consumer electronics, Summit PCBs are incorporated into devices like smartphones, tablets, and wearable technology. These PCBs enable complex functionality in compact form factors, providing high performance, and supporting integration of features that consumers expect today. - Defense

Summit PCBs are integral to defense systems, including communication equipment, radar systems, and missile guidance systems. The PCBs must meet the stringent performance requirements and reliability needed for critical defense applications.

Frequently Asked Questions About Summit PCB Manufacturing and Services

This section addresses common questions about Summit PCB, encompassing aspects such as pricing, manufacturing capabilities, and service offerings. Understanding these FAQs will provide a clearer picture of what Summit PCB offers and how they can meet your specific PCB needs.

- What types of PCBs does Summit PCB manufacture?

Summit PCB specializes in advanced technology printed circuit boards, including complex rigid PCBs, flexible PCBs (flex circuits), and rigid-flex PCBs. Their capabilities cover a wide range of applications, focusing on high-performance and demanding designs. - How can I get a quote for my PCB project?

To get a quote, you typically need to provide your project's design files (Gerber files), specifications (material, layer count, dimensions, etc.), and quantity requirements. Contact Summit PCB directly through their website or sales channels to initiate the quoting process. They will review your requirements and provide a tailored quote. - What is the typical lead time for PCB production at Summit PCB?

Lead times vary based on the complexity of the PCB, the quantity ordered, and current production capacity. Standard lead times can range from a few days for simple designs to several weeks for highly complex PCBs. Contact Summit PCB for specific lead times based on your project requirements. - Does Summit PCB offer PCB design services?

While primarily a manufacturer, Summit PCB works closely with customers on design for manufacturability (DFM) to ensure optimized production processes. They may offer design support to ensure manufacturability of your design. Direct design service options may vary. - What industries does Summit PCB serve?

Summit PCB provides its services to a wide range of sectors. including the aerospace, medical, automotive, and industrial automation. This indicates their versatile ability to meet rigorous industry standards for high reliability, high-performance, and complex PCB designs across varied industries. - What certifications does Summit PCB hold?

Summit PCB holds certifications such as ISO 9001 which highlight their commitment to quality management. These certifications are crucial for ensuring that their products meet industry standards and customer expectations, indicating a reliable and quality driven manufacturing process. - How does Summit PCB ensure the quality of its PCBs?

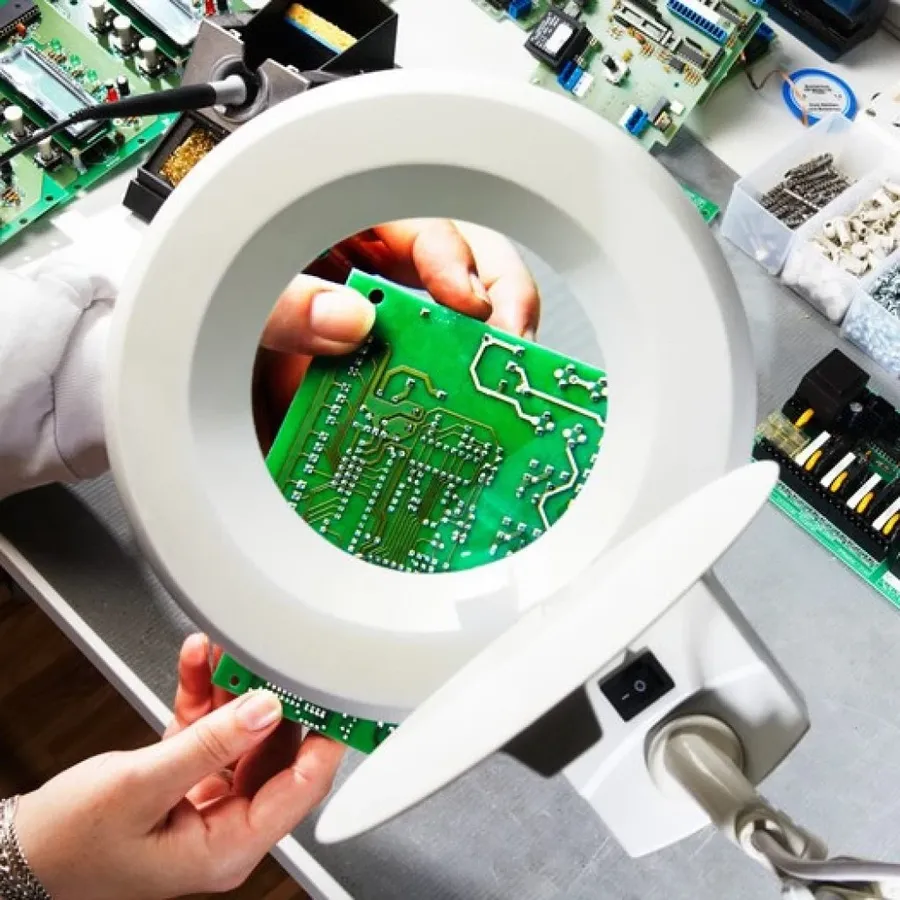

Summit PCB employs rigorous quality control measures, including automated optical inspection (AOI), electrical testing, and in-process checks at each stage of production. They adhere to industry standards such as IPC-A-600 to ensure that every PCB meets the highest performance and reliability standards. This robust approach results in products with high quality.

Summit PCB's Commitment to Quality and Innovation

Summit PCB's unwavering commitment to quality and innovation is central to its operations, driving its position as a leader in the advanced PCB manufacturing sector. This dedication is manifested through rigorous quality control processes, adoption of cutting-edge technologies, and a continuous pursuit of improved manufacturing techniques to meet and exceed customer expectations.

The company's approach to quality is not merely a set of checks but an integrated philosophy that permeates every aspect of its operations. From initial design verification to final product inspection, Summit PCB ensures that each board meets the highest standards of performance and reliability. This proactive approach is supported by a culture of continuous improvement, which encourages employee participation and the implementation of best practices in manufacturing processes.

Furthermore, Summit PCB’s focus on innovation is evident in its investments in research and development, allowing the company to remain at the forefront of technological advancements within the PCB industry. By actively exploring new materials, designs, and manufacturing methodologies, Summit PCB is able to provide cutting-edge solutions for highly demanding applications across aerospace, medical, automotive, and other sectors.

This focus on quality and innovation not only enables Summit PCB to produce superior products but also helps to reduce production cycle times, improve yields, and provide customers with more cost-effective solutions without compromising product integrity. This dual focus enables Summit PCB to maintain a competitive edge in a rapidly evolving market.

Summit PCB is a pivotal player in the printed circuit board industry, with a focus on advanced, complex PCB designs such as rigid, flex, and rigid-flex circuits. Their dedication to quality, combined with innovative manufacturing techniques, enables them to serve diverse industries with cutting-edge electronic solutions. As technology continues to advance, Summit PCB remains at the forefront, pushing the boundaries of what's possible in circuit board design and production.

AnyPCBA

AnyPCBA