Top PCB Suppliers: Finding the Right Partner for Your Project

In today's fast-paced electronics industry, finding reliable PCB suppliers is paramount to success. These partners are the backbone of innovation, providing the foundational printed circuit boards that power our modern world. Whether you're an engineer designing cutting-edge technology or an entrepreneur launching a new device, selecting the right PCB supplier can drastically impact your project’s timeline, budget, and ultimately, its success. This article aims to provide a comprehensive guide to navigating the landscape of PCB suppliers, ensuring you're equipped to make informed decisions.

Understanding Your PCB Needs

Before engaging with PCB suppliers, a thorough assessment of your project's specific requirements is paramount. This involves a detailed understanding of the PCB type, production volume, material specifications, and design intricacies to ensure alignment with the right supplier.

- PCB Type

Identify the necessary PCB structure: single-sided, double-sided, multilayer, or flexible PCBs. Each type has different capabilities and costs associated with their unique construction. - Production Quantity

Determine whether your project requires prototype quantities, low-volume production runs, or large-scale manufacturing. This will help select suppliers that can meet the needs of each production stage. - Material Specifications

Specify the base material (e.g., FR-4, aluminum, polyimide), copper thickness, and other material characteristics. High-frequency applications require specialized materials with low dielectric loss. - Design Complexity

Assess the design's density, number of layers, and use of advanced features such as blind or buried vias. Complex designs require advanced manufacturing capabilities and experienced suppliers. - Prototyping vs. Production Needs

Consider if you need a fast prototype run or long-term production. Some suppliers specialize in quick turnarounds for prototypes, while others focus on high-volume manufacturing.

Key Factors to Evaluate PCB Suppliers

Selecting the right PCB supplier is critical for the success of any electronics project. This decision involves a comprehensive assessment of multiple factors, ensuring a balance between cost and quality while meeting specific project needs.

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | Range of PCB types supported (single-sided, double-sided, multilayer, flexible, rigid-flex), technology (PTH, SMT), and production volume capabilities. | Essential for meeting diverse project requirements from prototypes to mass production. |

| Certification Standards | Compliance with quality standards such as ISO 9001, ISO 13485, and UL certifications. | Crucial for ensuring product reliability and regulatory compliance, especially in regulated industries. |

| Lead Time and Shipping Options | Typical production lead times and available shipping methods, including expedited options. | Affects project timelines and overall time-to-market; fast turnaround is important for prototyping and urgent orders. |

| Pricing | Cost per unit, tooling charges, and any additional fees. | A key factor influencing budget, but should be balanced with quality. |

| Material Quality | Types of materials used in PCB fabrication (FR-4, Rogers, etc) and their quality. | Impacts performance, reliability, and lifespan of the product. |

| Design Support and Customer Service | Availability of design assistance, technical support, and responsiveness to inquiries. | Valuable for addressing design issues and ensuring a smooth communication process. |

| Assembly Options | In-house PCB assembly services, including SMT and through-hole technologies, and testing capabilities. | Can streamline the manufacturing process and reduce costs by offering a single solution for both PCB production and assembly. |

| Reputation and Customer Feedback | Reputation within the industry and feedback from other customers. | Reflects the reliability and quality of the supplier’s services. |

| Payment Terms and Options | Payment methods accepted and credit options available. | Offers flexibility and convenience in transactions. |

| Minimum Order Quantities (MOQ) | Minimum quantities for production runs. | Important for determining suitability for small batch prototypes versus large production volumes. |

Global vs. Local PCB Suppliers: A Comparative Analysis

The decision between global and local PCB suppliers involves evaluating a trade-off between cost, speed, and communication. Global suppliers often present advantages in cost-effectiveness and high-volume production, while local suppliers may excel in rapid turnaround, enhanced communication, and on-site accessibility. Understanding these distinctions is critical for selecting the ideal supplier for your project’s unique requirements.

| Feature | Global PCB Suppliers | Local PCB Suppliers |

|---|---|---|

| Cost | Generally lower, especially for high volumes | Typically higher, may be more competitive for smaller orders |

| Lead Time | Can be longer due to shipping and production location | Shorter lead times, often with faster turnaround |

| Communication | May have language and time zone barriers, potentially slower response times | Easier communication, direct interaction, and quicker response times |

| Shipping | Longer transit times, potentially higher shipping costs, and customs delays | Faster shipping, potentially lower costs, and less concern for customs issues |

| Minimum Order Quantity | Often have higher MOQs | More flexible MOQs, accommodating smaller production runs |

| Site Visits | Difficult due to geographical distance | Easier to conduct site visits and audits |

| Production Volume | Well-suited for large-scale production | Suitable for both small and medium production runs |

| Flexibility | Potentially less flexible in custom specifications | Higher flexibility and better adaptation to changes |

Top PCB Suppliers in North America

North America is home to a variety of PCB manufacturers, each with distinct strengths and specialties. Choosing the right supplier depends heavily on the specific requirements of your project, whether it's rapid prototyping, intricate custom designs, or high-volume production runs. This section explores some of the leading North American PCB suppliers, providing a comparative overview to help inform your decision-making process.

| Supplier | Strengths | Specialties | Typical Lead Time | Notes |

|---|---|---|---|---|

| Advanced Circuits | Quick turn prototyping, high reliability, wide range of materials | Fast PCB prototypes, complex multilayer boards, high layer count PCBs | 1-3 days for prototypes | Known for their quick turn capabilities and reliability |

| Sunstone Circuits | Easy online ordering, good customer service, reasonable pricing | Small to medium volume runs, fast turnaround, custom builds | 2-5 days for standard boards | Offers an online platform for easy ordering. |

| Bay Area Circuits | Technical expertise, complex designs, high-quality | Complex PCBs, HDI boards, high precision manufacturing | 3-7 days, depending on complexity | Specialized in complex and high reliability PCBs |

| TTM Technologies | High volume manufacturing, large scale PCB solutions | Aerospace, defense, large scale production | Varies based on order | Large scale and established manufacturer |

| Sierra Circuits | High-end PCB fabrication | High-speed, high density, and RF PCBs | 2-10 days for prototypes | Known for engineering capabilities and advanced fabrication. |

Leading PCB Suppliers in Asia

Asia is a global hub for PCB manufacturing, offering a wide range of suppliers known for their competitive pricing and high-volume production capabilities. These suppliers, such as JLCPCB, PCBWay, and Allpcb, have become key players in the global electronics industry, catering to diverse project needs, from simple prototypes to complex, large-scale production runs.

| Supplier | Strengths | Specialties | Considerations |

|---|---|---|---|

| JLCPCB | Extremely competitive pricing, fast turnaround | Prototyping, small to medium batch production, online ordering platform | May have longer shipping times for some regions, limited customization options compared to some high-end suppliers |

| PCBWay | Wide range of PCB types and technologies, comprehensive service offerings | Complex PCBs, advanced materials, PCB assembly | Slightly higher pricing compared to JLCPCB but offers more options |

| Allpcb | Focus on quality, established supply chain | High reliability PCBs, large volume production, advanced HDI PCBs | Can be more expensive than other Asian suppliers, better suited for larger projects with demanding quality requirements |

Specialty PCB Suppliers: Focusing on Niche Markets

Certain PCB applications demand highly specialized capabilities beyond standard manufacturing processes. Specialty PCB suppliers focus on niche markets, offering unique materials, advanced design expertise, and stringent quality control tailored to specific project requirements such as flexible PCBs, high-frequency boards, or high-reliability applications, ensuring optimal performance in demanding environments.

The table below highlights different types of specialty PCB suppliers and their focus:

| Specialty Area | Description | Typical Applications | Key Considerations |

|---|---|---|---|

| Flexible PCBs (FPC) | PCBs made from flexible substrates, allowing bending and shaping. | Wearable devices, medical equipment, automotive electronics. | Flexibility requirements, bending radius, material durability, temperature tolerance. |

| High-Frequency PCBs | PCBs designed for high-speed signal transmission with low signal loss. | Telecommunications, radar systems, aerospace, high-speed computing | Signal integrity, impedance control, material dielectric properties, controlled impedance, low signal loss materials. |

| High-Reliability PCBs | PCBs engineered for extreme operating conditions. | Military, aerospace, industrial control systems. | Thermal management, material strength, vibration resistance, operating temperature extremes, conformal coating. |

| Metal Core PCBs (MCPCB) | PCBs using a metal core for superior thermal dissipation. | LED lighting, power electronics, automotive | Heat dissipation requirements, material thermal conductivity, power rating. |

| HDI (High Density Interconnect) PCBs | PCBs with high routing density, microvias, and fine lines. | Smartphones, portable electronics, advanced medical devices. | Miniaturization, trace width/space requirements, via technology, layer count. |

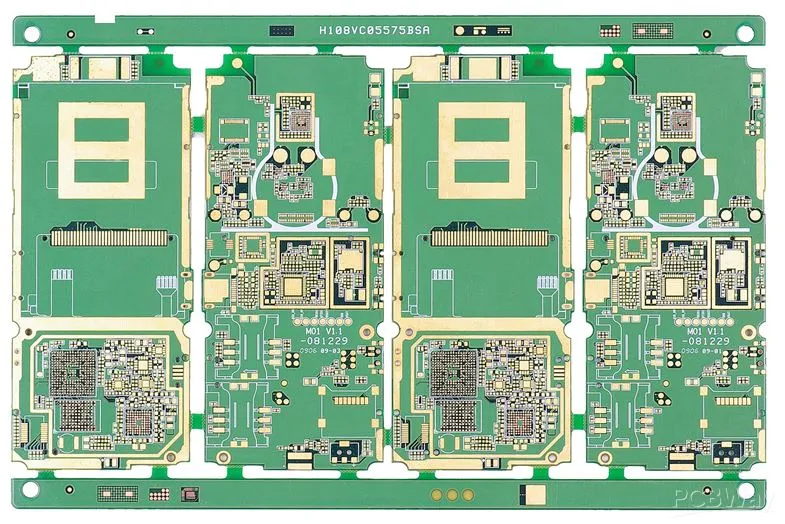

PCB Assembly Services: Streamlining Your Manufacturing Process

Integrating PCB assembly services with manufacturing can significantly streamline the production process, reducing both time and costs. Many PCB suppliers offer comprehensive assembly options, allowing for a more efficient transition from bare boards to fully functional electronic products. This section delves into the benefits and considerations of these services.

PCB assembly services encompass a range of options that cater to different project requirements and design complexities.

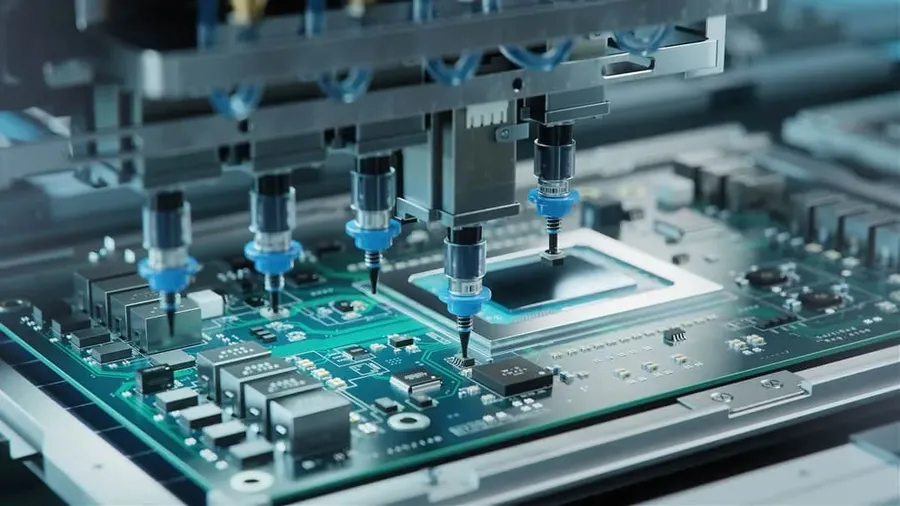

- Surface Mount Technology (SMT)

SMT is the most common assembly method for modern PCBs, involving mounting components directly onto the surface of the board. It's ideal for high-density designs and automated assembly processes. - Through-Hole Assembly

Through-hole assembly involves inserting components with leads through holes in the PCB and soldering them on the other side. It is generally used for larger components or when stronger mechanical connections are required. - Mixed Assembly

Mixed assembly combines both SMT and through-hole assembly techniques on the same board to accommodate different component types and requirements. - Testing Options

Suppliers often include various testing options, such as in-circuit testing (ICT), functional testing, and visual inspection, to ensure the quality and performance of the assembled PCBs.

Choosing a supplier that offers both PCB fabrication and assembly can lead to benefits, including reduced lead times, streamlined project management, and potentially lower costs. However, it's critical to evaluate the supplier's assembly capabilities, quality control processes, and capacity to handle the project's requirements.

Frequently Asked Questions About PCB Suppliers

Navigating the world of PCB suppliers can be complex. This section addresses frequently asked questions to clarify doubts and provide essential information for effective decision-making.

- Who is the largest PCB supplier globally?

Identifying the absolute largest PCB supplier can be dynamic due to market fluctuations and varied reporting metrics. However, companies like TTM Technologies and Unimicron often appear in the top rankings based on revenue and manufacturing volume. These are global players with significant reach and production capacity. - Which PCB supplier provides the best quality?

The notion of 'best' quality is subjective and depends on specific needs. High-reliability sectors such as aerospace and medical devices demand extremely stringent standards. Suppliers specializing in these sectors prioritize advanced quality control processes, material certifications, and precision manufacturing. Companies like NCAB and Wurth Electronics are often associated with high-quality output, but it’s crucial to verify their certifications and customer feedback to ensure they meet individual standards. - How much does a basic PCB cost, and what factors influence pricing?

The cost of a basic PCB is affected by multiple factors: PCB size, the number of layers, material type (FR-4, aluminum, etc.), order quantity, and manufacturing complexity. A simple, single-sided PCB might cost only a few dollars per piece in large quantities, whereas a complex, multi-layer board with tight tolerances and exotic materials could cost significantly more. Factors such as surface finish, via types, and expedited lead times also influence pricing. It is crucial to obtain quotes from several suppliers and compare them against a detailed specification to determine fair market value. - Where can I find PCB suppliers near me?

Finding PCB suppliers locally often benefits from faster turnaround times and better communication. Start by using search engines and platforms like Google Maps, specifying 'PCB suppliers near me.' Industry directories such as Thomasnet or regional trade associations can also be useful. Consider whether you need local support for rapid prototyping or long-term high volume, as proximity affects both. - What are the key differences between different types of PCB suppliers?

PCB suppliers differ in several key aspects: (1) Specialization: Some focus on rapid prototyping, others on high-volume production or niche markets such as flexible or high-frequency PCBs; (2) Manufacturing Capability: Different suppliers possess varying equipment and expertise; (3) Certifications: ISO, UL, and other standards indicate compliance to quality control protocols; (4) Pricing: Pricing varies considerably based on location, specialization, and production scales; (5) Customer Support: The level of design assistance and communication; (6) Lead Time: Times vary from days for quick-turn to weeks for volume production. Choosing the best fit requires careful evaluation. - What certifications should I look for in a PCB supplier?

Key certifications include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management), and UL certifications (safety). Industry-specific certifications, like AS9100 for aerospace, may also be required depending on the application. These certifications signify a commitment to quality, environmental responsibility, and safety standards. - Do PCB suppliers offer design assistance?

Many PCB suppliers offer design assistance ranging from design-for-manufacturing (DFM) checks to full turnkey design services. DFM services help to refine designs for efficient manufacturing, preventing costly errors. Some suppliers provide full PCB layout services which can be especially useful when in-house design expertise is limited. The availability and quality of these services should be considered when choosing a partner.

Choosing the Right PCB Supplier: A Practical Checklist

Selecting the ideal PCB supplier is critical for the success of any electronics project. A systematic evaluation process ensures a good fit between your specific needs and the capabilities of the supplier. This checklist offers a structured approach to assessing potential partners, focusing on key aspects that directly impact product quality, cost, and delivery timelines.

- Define Your Project Specifications

Begin by outlining all necessary specifications, including PCB type (single-sided, double-sided, multilayer, flexible), dimensions, materials, copper thickness, finish requirements, layer count, impedance control, and any special design features. Accuracy here is essential for finding a compatible supplier. - Assess Manufacturing Capabilities

Verify that the supplier can handle your specific technical requirements. This includes the ability to manage layer counts, board thickness, minimum trace/space, drill hole sizes, and via types. Confirm the supplier's technology matches your design complexity. - Confirm Certifications and Quality Standards

Ensure the supplier is compliant with relevant quality standards like ISO 9001 or ISO 13485, and industry-specific certifications (UL for safety, IPC for manufacturing). These certifications indicate a commitment to quality and reliable manufacturing. - Evaluate Material Quality and Availability

Investigate the types of materials (FR4, Rogers, etc.) offered and if these meet the application’s performance demands. Confirm the source of materials and their quality checks to ensure reliability. - Review Pricing and Payment Terms

Request detailed quotes for your specific requirements, including tooling costs, unit prices at different volumes, and shipping costs. Review and understand the supplier’s payment terms and options and ensure there are no hidden charges. - Analyze Lead Times and Shipping

Inquire about the turnaround times for prototyping and production. Ensure their shipping options and timelines align with your project schedule. Confirm if they can provide a tracking system for shipment monitoring. - Check Design Support and Customer Service

Assess the supplier's communication channels and their response time to queries. They should be willing to offer design support, including DFM (Design for Manufacturability) feedback, to enhance the production process. - Investigate Assembly Options

Determine if the supplier offers assembly services for the completed PCB and check their capacity to offer SMT, through-hole, and testing, if needed. Integrated services can save time and money by streamlining processes. - Evaluate Reputation and Customer Reviews

Research the supplier’s reputation by checking online reviews and customer testimonials. Consider reaching out to previous clients if needed to learn more about the experiences with the supplier’s services. - Request Samples and Conduct a Trial Run

Request PCB samples before a full-scale production order to ensure quality meets expectations. Conduct a small trial run to verify performance and identify any unexpected challenges. These tests can provide crucial feedback.

Selecting the right PCB supplier is a critical decision that significantly impacts the success of any electronic project. By thoroughly understanding your needs, evaluating potential suppliers against the factors outlined above, and carefully considering global versus local options, you can find a partner that aligns with your project goals. Whether you choose a supplier known for high-volume production like JLCPCB or one specializing in quick turn prototypes like Advanced Circuits, the right choice will drive efficiency, quality and timely market delivery. Remember to leverage PCB suppliers who can also offer assembly services to further streamline production and help bring your innovations to life.

AnyPCBA

AnyPCBA