Understanding Atomberg BLDC Fan Circuit Board Prices & Replacement

In today's world, energy efficiency is paramount, and Atomberg BLDC fans stand out with their advanced technology. But what happens when the electronic heart of your fan, the circuit board, needs attention? Understanding the 'atomberg bldc fan circuit board price' is crucial for maintenance and repairs. This article will guide you through the costs, replacement options, and troubleshooting common issues, blending practical advice with an exploration of the technology.

What is a BLDC Fan Circuit Board?

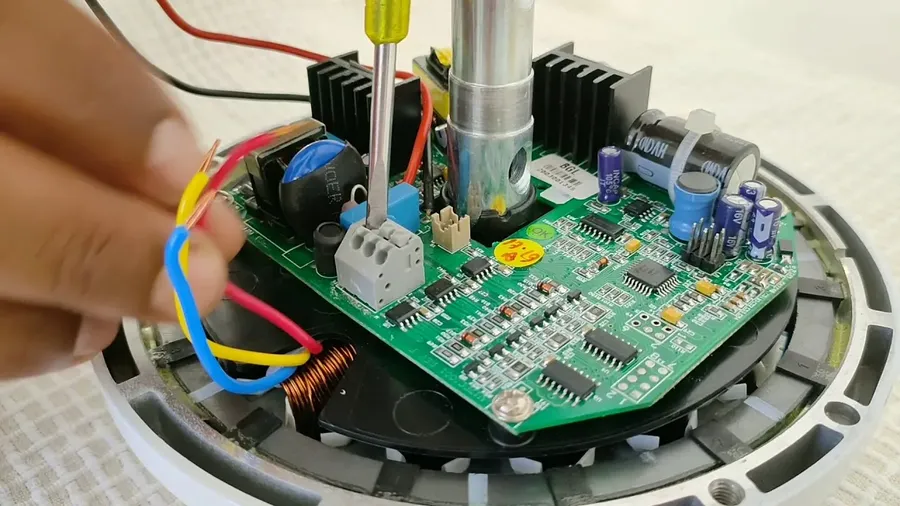

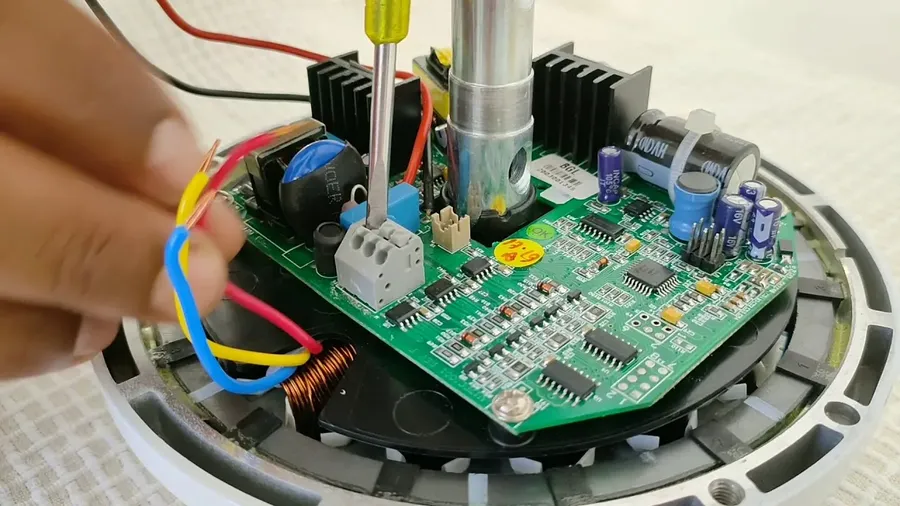

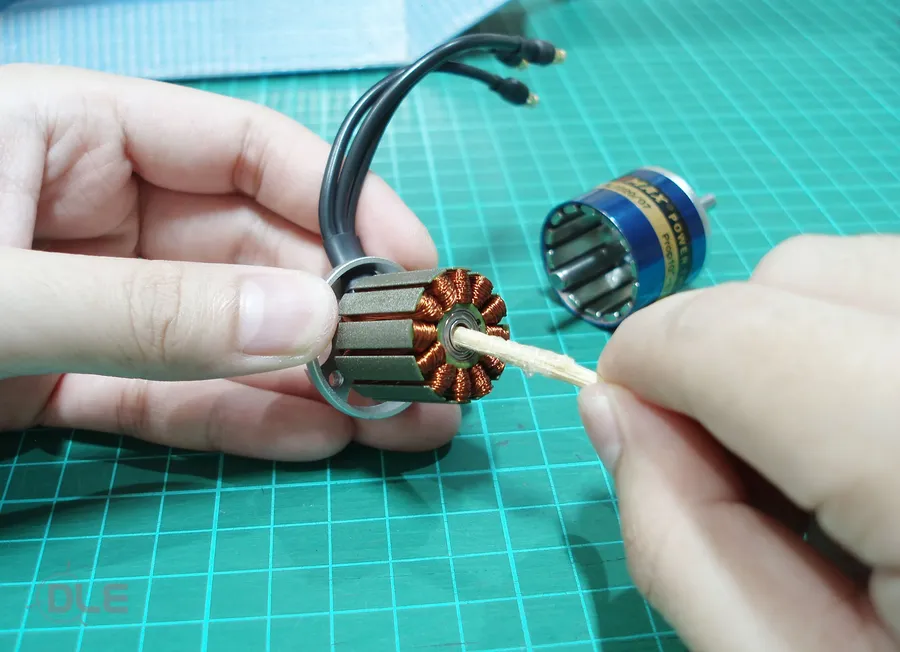

A Brushless Direct Current (BLDC) fan circuit board is the electronic control center of a BLDC fan, orchestrating its precise operation. Unlike traditional AC induction fans, BLDC fans use a sophisticated circuit board to manage the direct current flow to the motor, enabling variable speed control, improved energy efficiency and enhanced performance.

This board integrates several key components:

- Microcontroller:

The 'brain' of the system, processing inputs and controlling the motor's speed and direction. This component uses firmware and integrated software to execute its instructions. - Power Management Circuit:

Regulates the power supply to the motor and other components, ensuring stable and safe operation by converting the AC input voltage to a stable DC voltage required by the BLDC motor. - Motor Driver:

Controls the current flow to the motor windings, using Pulse Width Modulation (PWM) to regulate the motor speed. This driver is essentially the interface between the microcontroller and the actual motor. - Communication Modules:

May include components for remote control, Wi-Fi, or other communication functionalities, allowing the user to interact with the fan via an external device (e.g., smart home hubs or remote control). The communication module is responsible for receiving and interpreting external commands. - Sensors:

Often includes hall-effect sensors or other feedback mechanisms to monitor the motor's position and speed, and provides feedback to the microcontroller to ensure closed-loop control of the BLDC motor. The sensor reading enables precise motor control and performance optimization. - Capacitors, Resistors, and Diodes:

Various passive components to filter voltage and current, protect the system and ensure stability.

The precise control provided by the circuit board allows for advanced features like sleep mode, boost mode, and precise speed adjustments, as well as silent operation compared to traditional AC fans.

The circuit board’s functionality is critical for the efficient performance, reliability, and energy-saving capabilities of BLDC fans, making it a crucial component for modern fan technology.

Factors Affecting Atomberg BLDC Fan Circuit Board Price

The price of an Atomberg BLDC (Brushless Direct Current) fan circuit board is not fixed and is influenced by a variety of factors. Understanding these factors can help consumers make informed purchasing decisions and budget appropriately for replacements or upgrades. Several key elements contribute to the final cost, encompassing both the manufacturing and retail aspects.

- Manufacturer

The primary determinant of cost is the manufacturer itself. Atomberg, being a leading brand in BLDC technology, typically prices its components to reflect its R&D investments, quality standards, and brand reputation. Genuine Atomberg boards tend to have a higher price point than generic or third-party alternatives. - Board Complexity

The complexity of the circuit board plays a significant role. More sophisticated boards with advanced features such as higher-speed control, integrated sensors, or more robust surge protection circuits will generally cost more to produce, increasing the final retail price. Features like wireless communication or smart home integration also add to the complexity and cost. - Component Quality

The quality of electronic components used (capacitors, resistors, ICs, etc.) directly affects the cost. Higher-grade components known for greater reliability, durability, and temperature tolerance command a higher price. Manufacturers who prioritize longevity and performance will opt for more expensive components. - Retailer Markup

Retailers, both online and brick-and-mortar, add their markup to cover operational costs and generate profit. This markup can vary significantly based on the retailer's pricing strategy, overheads, and the demand for the product. Online marketplaces often have lower markups due to lower overhead compared to physical stores. Pricing may fluctuate based on promotions or sales. - Replacement vs. Conversion Kit

A simple replacement circuit board will typically cost less than a conversion kit. Conversion kits often include additional components like a motor, wiring, or a new remote control receiver, which justify a higher price. The kit price is higher due to the scope of components it offers, compared to a bare circuit board. - Warranty and After-Sales Service

Circuit boards sold with a warranty or from retailers that offer excellent after-sales service may be priced slightly higher due to the added value and peace of mind they provide. The inclusion of customer support also contributes to the overall cost.

| Factor | Impact on Price | Considerations |

|---|---|---|

| Manufacturer | Higher for established brands like Atomberg | Brand reputation and R&D investments |

| Board Complexity | Higher for advanced features | Features such as smart controls, sensors, surge protection |

| Component Quality | Higher for durable components | Reliability and longevity of the board |

| Retailer Markup | Variable based on the retailer | Online vs physical stores; promotions |

| Replacement vs. Conversion Kit | Conversion kit more expensive | Includes more components, like motor and wiring |

| Warranty/After-sales | Slightly higher where available | Customer support and warranty included |

Common Issues with BLDC Fan Circuit Boards

BLDC (Brushless Direct Current) fan circuit boards, while generally reliable, can experience various issues that impact their functionality. Understanding these common problems is crucial for effective troubleshooting and repair. These issues often stem from electrical stresses, component degradation, or environmental factors.

- Power Surges

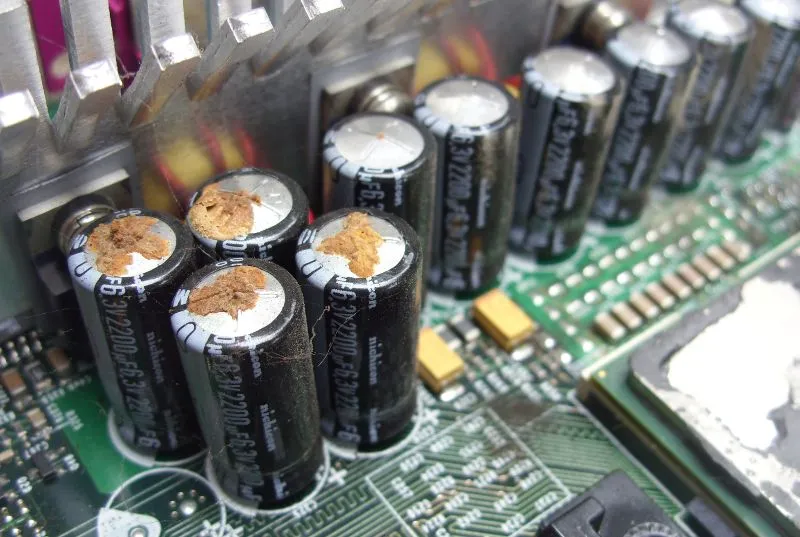

Power surges are a significant threat to sensitive electronic components on the circuit board. These surges can damage the integrated circuits (ICs), microcontrollers, and other critical parts, leading to erratic behavior or complete failure of the fan. This can be caused by lightning strikes, faulty wiring, or issues with the power grid. - Capacitor Failure

Capacitors are essential for voltage regulation and filtering. Over time, or due to poor quality components, capacitors can dry out, bulge, or leak. This often manifests as inconsistent fan speed, buzzing noises, or the fan not starting at all. Capacitor failure is a common issue due to heat and age. - IC Malfunctions

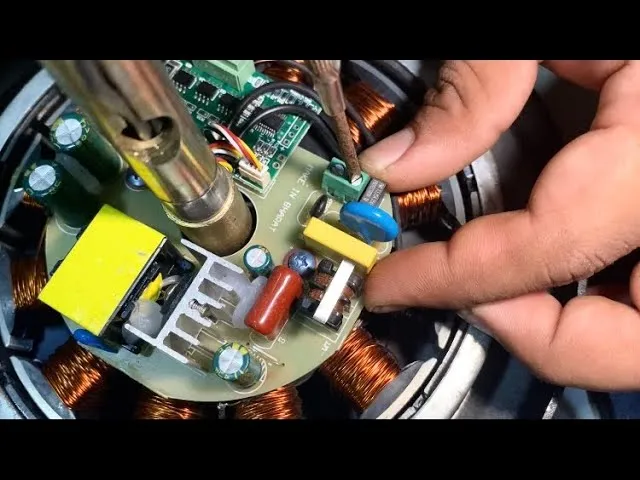

Integrated circuits (ICs), especially those that manage the motor's speed and direction, can be susceptible to damage. Overheating, voltage spikes, or manufacturing defects can lead to IC malfunctions, resulting in erratic fan behavior, no rotation, or failure to respond to control signals. Identifying a faulty IC often requires specialized equipment and skills. - Soldering Joint Issues

Over time, solder joints on the circuit board can become weak due to thermal stress and vibrations. This can cause intermittent contact, leading to fan operation that is unreliable or ceases altogether. Visual inspection, sometimes with magnification, can help diagnose this issue. Re-soldering is often a solution. - Loose Connectors and Wiring Issues

Loose connections between the board and the motor, or between the control panel, can lead to intermittent operation or a complete loss of function. Over time, the pins in connectors can loosen or oxidize, creating resistance. It is essential to check all connections for any sign of damage and ensure they are secure.

Troubleshooting a suspected circuit board issue often involves a systematic approach. Before assuming the board is at fault, rule out other potential issues such as motor problems, faulty wiring, or issues with remote control. Key indicators of a circuit board problem include:

- Complete Failure

The fan does not operate at all, with no indication of power or response to control signals. - Erratic Behavior

The fan speed fluctuates uncontrollably, stops and starts intermittently, or does not respond correctly to the speed settings. - Audible Issues

Unusual buzzing or hissing noises emanating from the fan, suggesting a problem with voltage regulation or a faulty component. - Overheating

The fan or its circuit board becomes excessively hot to the touch, which could indicate a short circuit or faulty components.

If these symptoms are present, further diagnostics are necessary. Visual inspection for blown capacitors or burn marks on components is a good first step. A multimeter can be used to test the voltage and continuity across various points on the board. However, more complex diagnosis often requires expertise and the right tools.

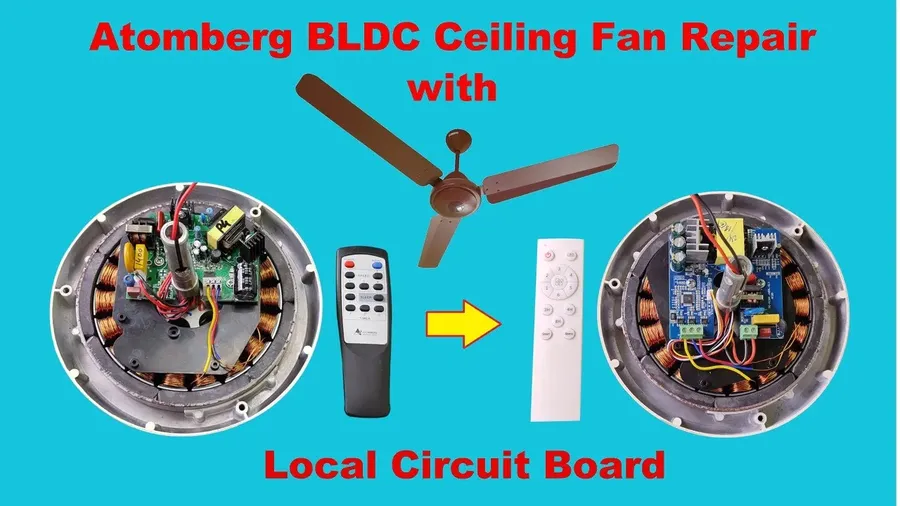

Atomberg BLDC Fan Circuit Board Replacement Options

When your Atomberg BLDC fan's circuit board malfunctions, prompt replacement is crucial to restore functionality. Several avenues are available for acquiring a replacement board, each with its own set of advantages and drawbacks regarding cost, time, reliability, and warranty coverage. Understanding these options will enable you to make an informed decision.

- Direct Purchase from Atomberg

Purchasing a replacement circuit board directly from Atomberg ensures compatibility and often includes a warranty. This option provides the highest level of assurance in terms of quality and performance but may come at a higher price and potentially longer lead time. - Third-Party Suppliers

Numerous third-party suppliers offer compatible BLDC fan circuit boards. These can be a more economical option than purchasing directly from Atomberg; however, it is important to verify the supplier's reputation and product quality. Warranty coverage is not always guaranteed and the performance may be variable. - Local Repair Shops

Local electronics repair shops can be a viable option for circuit board replacement. They may offer quick turnaround times and potentially lower prices than direct manufacturer purchases. However, the quality of repair and the type of components used may vary significantly. It's essential to vet the repair shop for experience with BLDC fan repairs and their warranty policy.

| Option | Cost | Time | Reliability | Warranty |

|---|---|---|---|---|

| Atomberg Direct | Higher | Medium to Longer | High | Usually Included |

| Third-Party | Lower | Variable | Variable | Not Always Included |

| Local Repair Shop | Medium to Lower | Faster | Variable | May Vary |

Where to Buy Atomberg BLDC Fan Circuit Boards

Acquiring a replacement circuit board for your Atomberg BLDC fan requires careful consideration of both the source and price. Several avenues exist, each with its own implications for cost, authenticity, and warranty. This section provides a guide to navigating these options.

The table below outlines typical sources for purchasing Atomberg BLDC fan circuit boards, and provides insights into prices you may find.

| Source | Description | Price Range | Pros | Cons |

|---|---|---|---|---|

| Atomberg Direct | Purchasing directly from the manufacturer's website or authorized service centers. | Generally higher than third-party options. | Authenticity guaranteed, potential for warranty. | Higher price, may have longer lead times. |

| Online Marketplaces (e.g., Amazon, Flipkart, IndiaMART) | Various sellers offer Atomberg and compatible boards. | Varies widely; can be competitive. | Convenience, wide selection, price competition. | Risk of counterfeit parts, warranty may be unclear. |

| Authorized Dealers | Local retailers and service providers authorized by Atomberg. | Competitive, close to manufacturer's price. | Authentic products, potential for warranty support. | May not be as easily accessible as online sources. |

| Third-Party Suppliers | Companies that manufacture compatible boards. | Often the most cost-effective option. | Lower price point, wide availability. | Potential quality concerns, compatibility issues, warranty may be limited. |

When choosing a source, always check seller reviews, return policies, and warranty information.

Specifics on pricing:

- Atomberg Direct:

Expect to pay a premium for genuine parts, usually with warranty coverage. Prices can range from ₹1500 to ₹3000. - Online Marketplaces:

Prices are highly variable. Be wary of suspiciously low prices, they may indicate counterfeit parts. Prices can range from ₹800 to ₹2500. - Authorized Dealers:

Prices are close to manufacturer suggested retail price. Can be a good balance of price and reliability, often priced between ₹1200 to ₹2800. - Third-Party Suppliers:

Prices are the most competitive, but quality should be carefully assessed before purchasing. Prices may range from ₹500 to ₹1800.

Do It Yourself (DIY) vs. Professional Repair

When facing issues with your Atomberg BLDC fan circuit board, a crucial decision arises: should you attempt a Do-It-Yourself (DIY) repair, or should you seek the assistance of a professional technician? This section provides a comprehensive guide to help you make an informed choice, outlining the necessary skills, tools, and considerations for each approach.

Opting for a DIY repair can be appealing due to the potential cost savings, but it requires a certain level of technical expertise and access to the right tools. Conversely, professional repair services provide a higher degree of assurance in terms of quality and expertise but at a higher cost. The following comparison provides a more detailed view.

For a successful DIY repair of a BLDC fan circuit board, the following skills and tools are typically necessary:

- Essential Skills:

Basic understanding of electronics, ability to read circuit diagrams, soldering skills. - Required Tools:

Soldering iron, solder wire, multimeter, precision screwdrivers, wire strippers, desoldering pump or wick, and possibly an oscilloscope for advanced diagnostics.

Attempting a repair without the proper skills and tools can lead to further damage of the circuit board, potentially increasing repair costs or even rendering the board unusable. It's important to honestly assess your abilities before attempting a DIY repair. Consider whether you are comfortable working with delicate electronic components and handling hot soldering equipment.

| Factor | DIY Repair | Professional Repair |

|---|---|---|

| Cost | Lower (parts only) | Higher (labor + parts) |

| Time | Potentially Longer (learning curve) | Usually Faster |

| Skill Level | Requires technical knowledge | Requires no technical knowledge |

| Risk | Higher (damage possible) | Lower (expert handling) |

| Tools Needed | Soldering iron, multimeter, etc. | No tools needed |

| Warranty | Usually none | May have repair warranty |

Deciding whether to repair your Atomberg BLDC fan circuit board yourself or seek professional help depends on various factors. This section provides a detailed comparison to help you make an informed decision.

| Factor | DIY Repair | Professional Repair |

|---|---|---|

| Cost | Lower (parts only) | Higher (labor + parts) |

| Time | Potentially Longer (learning curve) | Usually Faster |

| Skill Level | Requires technical knowledge | Requires no technical knowledge |

| Risk | Higher (damage possible) | Lower (expert handling) |

| Tools Needed | Soldering iron, multimeter, etc. | No tools needed |

| Warranty | Usually none | May have repair warranty |

This table summarizes key differences. DIY repairs offer cost savings but require technical aptitude and carry higher risks. Professional repair is more convenient and safer, but at a higher cost. Consider these points carefully when deciding how to proceed with your BLDC fan circuit board repair.

Frequently Asked Questions about Atomberg BLDC Fan Circuit Boards

This section addresses common questions regarding Atomberg BLDC fan circuit boards, focusing on repairs, troubleshooting, and comparisons with other brands. Understanding these FAQs can help users make informed decisions about maintenance and replacements.

- What is the typical cost for an Atomberg fan circuit board repair?

The cost of repairing an Atomberg fan circuit board can vary significantly based on the extent of the damage and the repair method. Minor issues such as capacitor replacement may be inexpensive while more complex repairs or a full board replacement can be substantially more. Consulting with a local technician or Atomberg authorized service center is the best way to estimate repair costs. - What should I do if my Atomberg fan is not functioning correctly?

If your Atomberg fan isn't working, begin by checking the power supply and connections. Ensure the fan is receiving power and there are no loose wires or connectors. If the issue persists, the circuit board could be the culprit. Detailed diagnostics by a professional are recommended to confirm whether the issue is the circuit board or another component. - What is the role of the PCB in a BLDC fan?

The Printed Circuit Board (PCB) is the core of a BLDC fan's electronic control system. It houses the components that control the fan's speed, direction, and other functions. In an Atomberg BLDC fan, the PCB plays a critical role in efficiently managing power and maintaining performance. - How does the reliability and repair cost of Atomberg BLDC fans compare to Havells?

Comparing Atomberg and Havells BLDC fans, both brands have good reputations for reliability. The repair costs will vary depending on the extent of damage and availability of the spare parts. Atomberg is known for its energy efficiency and advanced electronics, which might have a higher initial cost or repairs, while Havells may be more accessible. However, the specific cost and reliability will vary according to the fan models within the brands and the individual cases. - Can I replace the Atomberg BLDC fan circuit board myself?

Replacing the circuit board yourself is possible if you have the relevant technical expertise, experience with electronics repair, and proper tools. However, due to the complex electronic components, it is recommended to seek professional help to avoid further issues, ensure the correct installation and retain any warranty that may be applicable. Improper installation may cause damage or void warranties. - Are there any specific indicators that suggest the circuit board is faulty?

Yes, several indicators can suggest a faulty circuit board, such as inconsistent speed control, the fan not turning on, or unusual noises. If these symptoms persist after standard troubleshooting, it's highly probable the circuit board is malfunctioning. - How long should a BLDC fan circuit board typically last?

The typical lifespan of a BLDC fan circuit board is heavily influenced by operational conditions, including power quality and environmental factors such as humidity and dust. Although designs are made for longevity, varying factors may result in a wide range of usable life. Consistent maintenance practices, such as cleaning and using a surge protector can extend its life considerably.

Tips for Extending the Lifespan of Your BLDC Fan Circuit Board

Extending the life of your Atomberg BLDC fan's circuit board involves proactive maintenance and preventative measures. These boards, while robust, are susceptible to environmental factors and power fluctuations. By adhering to the following guidelines, you can significantly reduce the risk of failure and ensure the continued efficient operation of your fan.

- Use Surge Protectors

Power surges are a significant threat to electronic components. Install a high-quality surge protector to shield your BLDC fan's circuit board from voltage spikes that can cause damage to sensitive circuits, capacitors, and other components. This simple step will significantly prolong the lifespan of your circuit board. - Ensure Proper Ventilation

Adequate ventilation is crucial for preventing overheating. Ensure the fan’s motor and electronics housing have sufficient air circulation. Avoid placing the fan in enclosed spaces that can trap heat. Overheating can lead to the deterioration of electronic components and potentially cause premature failures. - Regular Cleaning

Dust accumulation on the circuit board can trap heat and also potentially cause electrical shorts. Use a soft brush or a can of compressed air to gently clean the fan's motor and internal components periodically. Always ensure the fan is disconnected from the power before cleaning. - Avoid Moisture

Moisture can lead to corrosion and short circuits. Keep the fan away from damp or humid environments. If your fan is installed in a humid environment, consider using a dehumidifier or ensuring the space is well ventilated. - Secure Installation

Ensure that the fan is securely installed to minimize vibrations which may lead to component fatigue over time. Check for loose connections or mounting and address them immediately. - Avoid Frequent On/Off Cycling

While BLDC fans are designed for efficient operation, avoid frequently turning them on and off within short periods. This cycling can put stress on the electronic components, particularly the capacitors. Allow a short pause between uses, especially when changing fan speeds.

By taking these proactive measures, you can significantly extend the life of your Atomberg BLDC fan's circuit board, minimize the likelihood of component failure, and save money on potential repair costs. Regular maintenance is key to ensuring optimal fan performance and maximizing its lifespan.

Understanding the 'atomberg bldc fan circuit board price' and the factors influencing it is vital for the maintenance and longevity of your fan. Whether you opt for a DIY fix or professional assistance, being informed about the cost and process will help ensure that your Atomberg BLDC fan continues to operate efficiently and reliably, reducing energy consumption and improving your living environment. By understanding the inner workings of this smart technology, you're also making a step towards more sustainable practices.

AnyPCBA

AnyPCBA