Understanding Chimney PCB Board Prices: A Comprehensive Guide

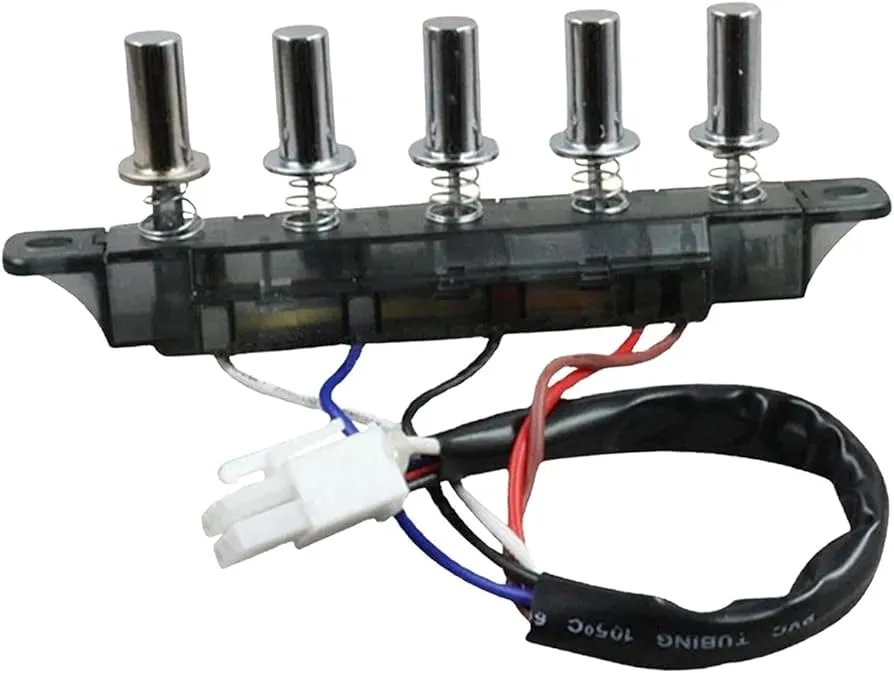

The humble kitchen chimney, a silent sentinel against cooking fumes, relies on a small but vital component: the Printed Circuit Board (PCB). When this board falters, your kitchen's ventilation system can be rendered useless, impacting your family's comfort. Understanding the cost of a chimney PCB board is crucial for budgeting repairs. This article will dissect the factors influencing chimney PCB board prices, common issues, and replacement options, enabling you to make an informed decision. We'll delve into brand specific pricing, common problems, and where to find the best value, linking the intricacies of this tiny electronic device to real-world impact.

Factors Affecting Chimney PCB Board Prices

The price of a chimney PCB (Printed Circuit Board) is influenced by a confluence of factors, extending beyond simple material costs. These elements, ranging from the intricate design of the board itself to the reputation of its manufacturer, collectively determine the final market price. Understanding these factors is crucial for both consumers and those involved in the supply chain.

- Complexity of the PCB Design

A more intricate board design with multiple layers, fine traces, and a high density of components will naturally be more expensive to manufacture. Complex designs require advanced manufacturing processes and higher precision, thereby increasing costs. - Quality of Materials

The type of materials used, such as the substrate material (e.g., FR4, CEM), copper thickness, and the quality of components, directly impact the durability and performance of the PCB. Higher grade materials will result in higher costs but often provide better reliability and longevity. - Manufacturer Reputation

Manufacturers with established reputations for quality and reliability often command higher prices. These manufacturers typically have stringent quality control measures, advanced manufacturing facilities, and highly skilled labor forces, which all contribute to higher production costs, but ultimately result in a more trustworthy product. - Brand Recognition

Well-known brands frequently price their PCB boards at a premium due to perceived higher quality, research and development investments, and strong marketing. The brand name itself can contribute to a higher cost even if the underlying manufacturing process and materials are similar. - Production Volume

The quantity of boards manufactured in a single batch affects the unit cost. Larger production volumes often result in lower per-unit costs due to economies of scale. Smaller batches require more setup and incur higher per-unit costs. - Technological Features

Certain PCB boards will have features that require advanced components or processes. For example, if they require microcontrollers or wireless communication chips, these will raise the price. The degree of features included has a direct effect on the overall cost.

Typical Price Ranges for Chimney PCB Boards

The cost of a chimney PCB board varies significantly based on several factors. Generally, prices range from budget-friendly options for simpler boards to more expensive ones for advanced models with specialized features. This section provides an overview of the typical price ranges you can expect from different sources, excluding installation costs.

| Source | Price Range (USD) | Notes |

|---|---|---|

| Online Marketplaces | 20 - 80 | Prices can vary widely. Check seller ratings and product reviews. |

| Local Suppliers | 30 - 90 | May offer more personal service and support. Pricing can be competitive. |

| Authorized Service Centers | 40 - 120 | Generally the most expensive option, but often provides the best assurance of compatibility and quality. Parts are more likely to be genuine. |

It's crucial to note that these price ranges are estimates and can fluctuate based on the brand, model, and availability. Always verify the specific details with the seller before making a purchase. Installation costs are typically separate and should be considered when budgeting for a replacement PCB board. The complexity of the chimney, the specific wiring harness, and the location will have some bearing on installation costs.

Brand-Specific PCB Board Pricing: Faber, Hindware, Elica, Glen

The price of a chimney PCB board is significantly influenced by the brand, with established manufacturers often commanding higher prices due to perceived quality, reliability, and brand reputation. This section examines the pricing trends for PCB boards from popular brands such as Faber, Hindware, Elica, and Glen, highlighting the impact of brand recognition and specific features on their costs.

| Brand | Typical Price Range (INR) | Factors Influencing Price |

|---|---|---|

| Faber | ₹1,800 - ₹4,500 | Advanced features, Italian design, premium component quality, strong brand reputation |

| Hindware | ₹1,500 - ₹3,800 | Reliability, Indian brand, mid-range market positioning, widely available parts and support |

| Elica | ₹2,000 - ₹5,000 | Innovative technology, modern designs, Italian origin, focus on performance and efficiency |

| Glen | ₹1,200 - ₹3,500 | Value-oriented products, Indian brand, functional designs, focus on affordability and user-friendliness |

The price ranges listed are indicative and can vary based on the specific model, the complexity of the PCB, and the seller. It is crucial to verify the model number on the existing PCB board before purchase, and to consider the seller’s credibility. Purchasing from authorized service centers or reputable dealers is recommended to ensure compatibility and quality. Furthermore, prices online are often influenced by the specific marketplace and its associated policies.

Common Problems Leading to Chimney PCB Board Failure

Chimney PCB boards, while designed for durability, are susceptible to various issues that can lead to their failure. Understanding these common problems is crucial for taking preventative measures and ensuring the longevity of your kitchen chimney. Failures are often due to external factors rather than inherent flaws in the board itself.

- Power Surges

Sudden spikes in electrical voltage can overwhelm the sensitive components on the PCB, causing irreversible damage. These surges can originate from lightning strikes or fluctuations in the power grid. The result can range from minor operational issues to complete failure. - Voltage Fluctuations

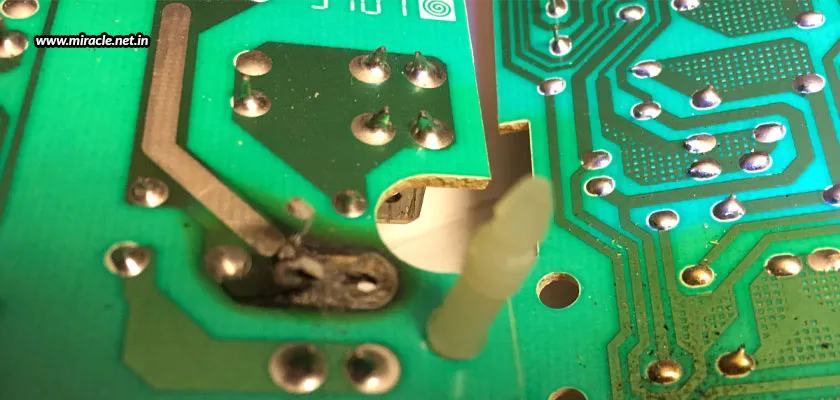

Inconsistent voltage levels, even without a dramatic surge, can stress the PCB components over time. These fluctuations can cause erratic behavior, overheating, and premature failure of specific parts on the board. - Component Degradation

Like all electronic components, those on the PCB board are subject to wear and tear. Over time, resistors, capacitors, and integrated circuits can degrade due to heat, electrical stress, or even just age. This degradation can lead to intermittent failures, reduced performance, or complete board failure. - Moisture Damage

Kitchen environments often experience high humidity and exposure to moisture. This moisture can corrode the conductive tracks and components on the PCB board, leading to short circuits, malfunctions, and eventually, failure. Condensation from cooking can also seep into the chimney housing if not properly sealed. - Overheating

Poor ventilation or blocked air passages in the chimney can lead to excessive heat buildup within the unit. This can cause components on the PCB board to overheat, damaging them and ultimately leading to board failure.

DIY Repair vs. Professional PCB Replacement

Deciding whether to repair a faulty chimney PCB board yourself or hire a professional is a critical decision that involves evaluating your technical expertise, understanding potential risks, and considering cost implications. While a DIY approach may seem appealing initially due to cost savings, it carries significant risks compared to professional repair or replacement services.

| Aspect | DIY Repair | Professional Replacement |

|---|---|---|

| Technical Skill Required | High; requires knowledge of electronics and PCB repair | Low; requires basic knowledge of the chimney model. |

| Cost | Potentially lower initial cost for components only | Higher initial cost but includes labor, warranty, and often diagnostic service |

| Safety | Higher risk of electrical shock, further damage to the board, and improper reassembly. | Lower risk, handled by trained technicians with appropriate equipment. |

| Time | Potentially lengthy and unpredictable, depending on repair complexity and skill level. | Typically faster, with scheduled appointment and quicker turn-around |

| Warranty | Typically voids any existing manufacturer's warranty; repair may not be guaranteed. | Often includes a warranty on parts and labor; provides assurance of proper functionality. |

| Long-Term Reliability | Uncertain; potential for recurring issues if repair is not done correctly. | Higher likelihood of long-term reliability due to professional expertise and testing. |

| Access to Tools & Parts | Requires access to specialized tools such as soldering irons, multimeters, and may be difficult to source suitable replacement components. | Technicians have all necessary tools and direct access to reliable parts. |

Finding Affordable Chimney PCB Boards

Locating cost-effective replacement PCB boards for your kitchen chimney requires careful consideration of both online and offline sources. Verifying compatibility with your specific chimney model is paramount to ensure proper function and avoid potential damage.

- Online Marketplaces

Major e-commerce platforms often list a wide array of chimney PCB boards. These sites frequently offer competitive pricing and user reviews, providing insights into product quality and seller reliability. However, carefully review the seller's credentials and return policies to safeguard against fraudulent sellers or incompatible products. - Local Electronics Stores

Local electronics retailers may stock some common PCB boards or have the ability to source them, providing the advantage of physical inspection before purchase. This allows for verification of the product’s quality and physical specifications, facilitating a better match. Additionally, staff may be able to offer guidance on compatibility. - Authorized Service Centers

Purchasing from authorized service centers of your specific chimney brand offers the highest degree of assurance regarding product quality and compatibility. Although prices may be slightly higher, the availability of a warranty and expert installation services can justify the additional cost. It may also be the only option to secure a genuine replacement part. - Manufacturer Websites

The official website of the chimney manufacturer is a reliable source for purchasing genuine replacement parts, although pricing may not be the most competitive. Buying directly ensures compatibility and offers a warranty, which can be beneficial in the long term.

Chimney PCB Board FAQs: Addressing Common Questions

This section addresses frequently asked questions regarding chimney Printed Circuit Boards (PCBs), providing clear and concise answers to common concerns. Understanding these FAQs can aid in troubleshooting and informed decision-making.

Preventing Future Chimney PCB Board Issues

Preventing future PCB board failures in your chimney is crucial for long-term cost savings and operational reliability. By implementing simple preventative measures, you can significantly extend the life of your chimney's electronic components and avoid costly replacements.

- Install Surge Protectors

Power surges are a common cause of PCB board damage. Using a surge protector will safeguard the board against sudden, excessive voltage spikes. - Use Voltage Stabilizers

Voltage fluctuations can stress the components on the PCB board. A voltage stabilizer ensures that your chimney receives a consistent and stable power supply, preventing damage. - Ensure Proper Ventilation

Moisture is a major threat to electronic circuits. Proper ventilation around your chimney helps to reduce condensation and prevent moisture-related issues. Ensure that the surrounding area is well-ventilated to keep moisture at bay. - Regular Cleaning and Maintenance

Dust and grease accumulation can lead to overheating and component failure. Regularly clean your chimney and its components, paying special attention to the PCB board housing. - Avoid Overloading the Chimney

Overloading the chimney by using it more frequently or for extended periods than recommended by the manufacturer could result in excessive heat and strain on its components, including the PCB board. Refer to the user manual for recommended usage guidelines. - Professional Inspection

Schedule periodic inspections by qualified technicians to identify potential issues before they escalate. Early detection of component degradation can save money in the long run.

Comparative Analysis of Chimney PCB Board Suppliers

Selecting the right supplier for a chimney PCB board is critical for ensuring cost-effectiveness and reliability. This section provides a detailed comparative analysis of major suppliers, focusing on pricing, shipping options, minimum order quantities, and customer feedback to help guide your purchasing decisions.

| Supplier | Pricing | Shipping Options | Minimum Order Quantity | Customer Reviews | Notes |

|---|---|---|---|---|---|

| Alibaba | Generally competitive, varies widely based on manufacturer | Various options including sea, air, and express shipping; lead times vary significantly | Flexible, often negotiable; suppliers may set minimums for bulk orders | Wide range of reviews from various sellers; careful vetting is needed; customer reviews are seller-specific, not platform-wide | Vast selection of PCB boards from many suppliers; consider verifying supplier credentials |

| IndiaMART | Competitive, but prices may vary depending on the seller | Various shipping options available from Indian suppliers; lead times depend on location and courier | Negotiable; some suppliers require minimum purchase quantities | Reviews and ratings are seller-specific, vary widely in detail and reliability; verify seller credibility carefully | Specific to Indian market; verify PCB board standards compatibility with your chimney |

| Global Sources | Reasonable; suppliers from different countries; pricing affected by region and demand | Multiple shipping methods, including sea freight, air freight, and courier services; lead times vary | Generally medium to high minimums, catering to bulk procurement | Verified suppliers but still some variability; ratings are supplier-specific, not platform-wide | Good for international procurement; verify product standards for your region; may require import duties |

| Authorized Service Centers | Typically higher, but includes technical support and warranty | Local or express shipping options may be available depending on the location of the center | Usually no minimum order quantity for individual replacements | Generally good due to direct manufacturer support; can provide direct service feedback to manufacturers | Higher cost but guarantees compatibility; manufacturer certified parts with reliable service |

Understanding chimney PCB board prices is crucial for cost-effective maintenance. Prices range from a few dollars to over a hundred depending on brand, features and supplier. By understanding the factors that influence pricing, exploring repair vs replacement options, and preventative measures, you can better maintain and extend the lifespan of your kitchen chimney. This knowledge empowers you to make the best choices when the heart of your chimney, the PCB board needs attention. Remember to check [chimney pcb board price] from different suppliers before finalizing your decision. Knowing common failure points and preventative actions can help you avoid future costs and keep your kitchen running efficiently.

AnyPCBA

AnyPCBA