Understanding Computer Circuit Boards: The Backbone of Modern Electronics

Just as our nervous system forms the communication network for our bodies, the computer circuit board acts as the very backbone of every electronic device, including computers, phones, and countless other appliances that are seamlessly integrated into our modern lives. It provides a structured pathway for electrical signals, ensuring that diverse components of these systems work harmoniously together. This article will delve into the world of computer circuit boards, exploring their fundamental functions, key components, and the critical role they play in powering our technology-driven society.

What is a Computer Circuit Board?

A computer circuit board, more formally known as a printed circuit board (PCB), serves as the foundational platform for electronic components within virtually all electronic devices. It's a composite structure comprising a non-conductive substrate material upon which conductive pathways—typically made of copper—are etched or printed. These pathways establish electrical interconnections between electronic components, allowing them to operate collaboratively to achieve a specific function. The PCB's design and construction are crucial for both the physical support of the components and the integrity of the overall electrical circuit. These boards are the backbone of modern electronics, enabling the miniaturization and reliability of complex systems.

Key Functions of a Computer Circuit Board

The fundamental role of a computer circuit board, or printed circuit board (PCB), is to serve as the structural foundation and electrical pathway for electronic components. It ensures mechanical stability and facilitates effective communication between all interconnected parts, allowing the creation of functional electronic systems.

A PCB's functions can be broken down into the following key aspects:

- Mechanical Support

The board provides a rigid platform on which electronic components are mounted and secured, preventing damage and misalignment during use or transportation. - Electrical Interconnection

Conductive traces (paths) on the board create the necessary electrical connections to enable signal flow and power distribution between different components, facilitating communication. - Signal Integrity

The PCB design ensures minimal signal interference, maintaining the quality of electrical signals as they travel through the board. This is essential for the correct functioning of the components. - Heat Dissipation

The PCB material and design can contribute to thermal management, allowing heat generated by components to be dissipated, thus preventing overheating and potential failure. - Component Integration

PCBs facilitate the integration of various components such as resistors, capacitors, integrated circuits (ICs), and connectors onto a single board, enabling a compact design and easy assembly.

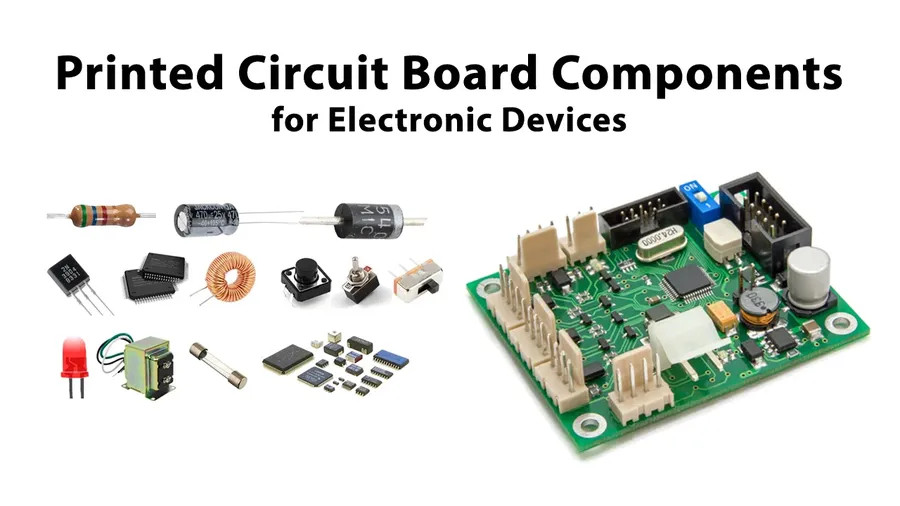

Essential Components of a Computer Circuit Board

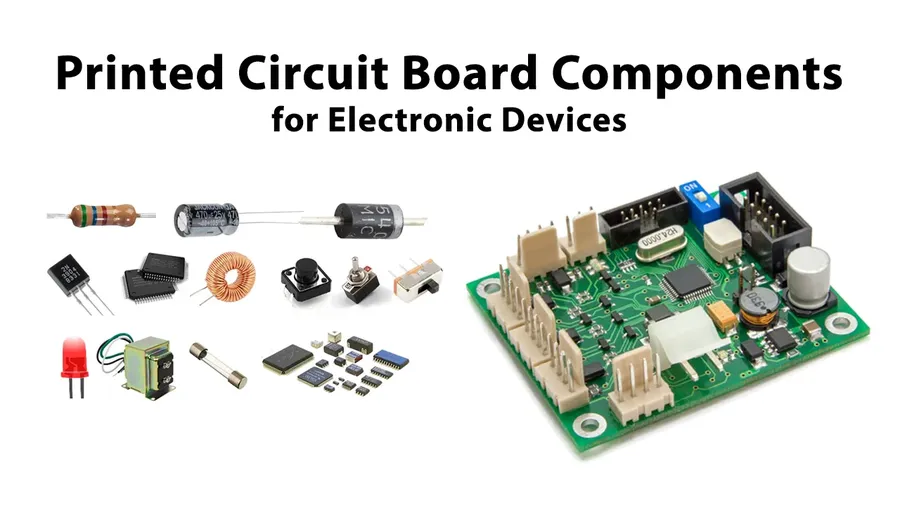

A computer circuit board, or printed circuit board (PCB), is a complex assembly of various components working in harmony to facilitate electronic functions. Understanding these essential elements is critical to comprehending how a circuit board operates. These components can be broadly categorized into conductive pathways, connection points, and mounting technologies.

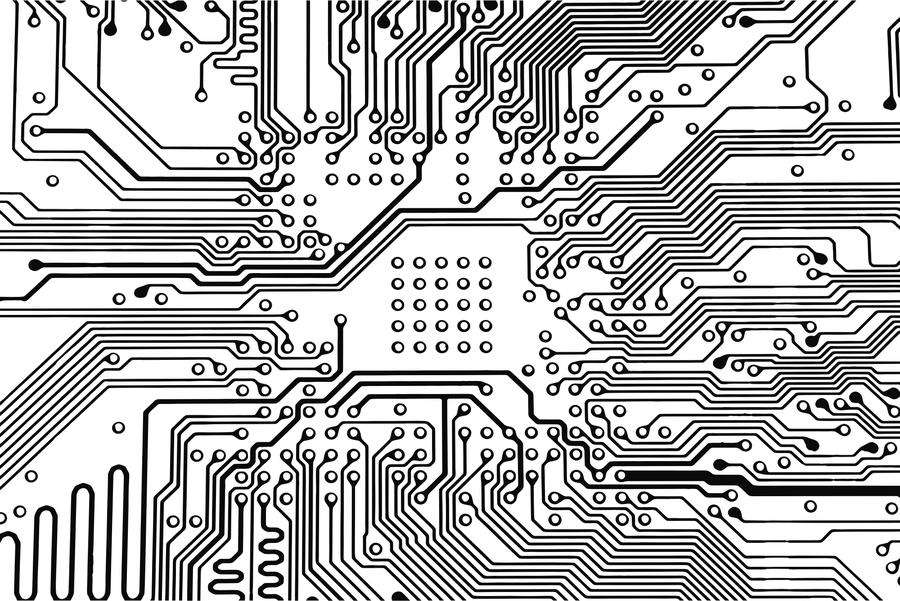

- Conductive Traces

These are the copper pathways etched onto the PCB that carry electrical signals from one component to another. The width and thickness of these traces are carefully designed to handle specific current loads and signal frequencies, ensuring minimal signal loss and efficient power delivery. They are the 'roads' of the circuit, allowing electrons to flow between components. - Pads

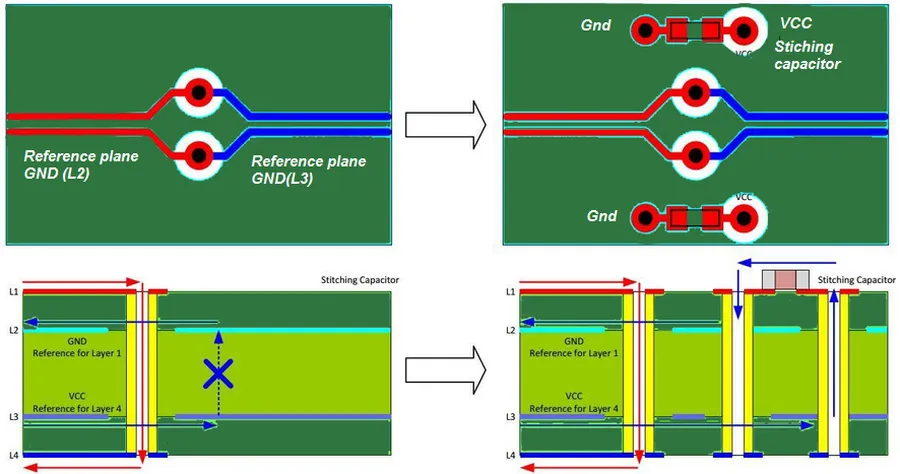

Pads are small areas of exposed conductive material (typically copper) on the PCB where electronic components are soldered and connected to the conductive traces. These pads can be either through-hole or surface mount type and form the termination points for electronic components, ensuring solid connections. - Vias

Vias are small holes that are plated with a conductive material (usually copper) which connect different layers of a multi-layered PCB. These act as 'bridges' allowing signal transfer between different layers of the circuit board, allowing complex circuits to be built in compact space. Vias can be through-hole, blind, or buried depending on their reach within the PCB. - Surface Mount Components (SMT)

SMT components are small electronic components that are directly mounted onto the surface of the PCB. This mounting technology allows for higher density placement of components, reduced board size, and automated assembly using robotic pick-and-place machines. This type of assembly is most popular due to ease of manufacturing, low cost, and compact size of the circuit boards. - Through-Hole Components

Through-hole components have leads that are inserted through drilled holes on the PCB and soldered on the opposite side. This method provides strong mechanical connections, beneficial for components that might experience stress or high current and is used for large components, components that will be connected and disconnected often, or that need to be mechanically robust.

How Circuit Boards Facilitate Signal Flow

Computer circuit boards, through their intricate network of conductive pathways and integrated components, enable the controlled flow of electrical signals. This precise signal transmission is fundamental to the operation of all electronic devices, allowing different components to communicate and perform their designated functions.

The process of signal flow on a circuit board involves several key elements:

- Conductive Traces

These are the copper pathways etched onto the non-conductive substrate of the board. They act as 'wires,' guiding the electrical signals from one point to another. The width and thickness of these traces are carefully designed to manage specific current and impedance requirements. - Pads

These are small, flat areas of metal on the surface of the board, typically where components are soldered. They serve as the termination points for traces, providing a connection point to components. - Vias

Vias are conductive holes that allow signals to pass between different layers of a multi-layered board. This is crucial for managing signal routing and reducing the overall footprint of the PCB. - Component Placement

The careful placement and orientation of electronic components such as resistors, capacitors, integrated circuits (ICs), and transistors is essential for the efficient flow of signals. The position and type of component are chosen to achieve a specific function within the electrical system. - Impedance Control

The careful control of the impedance of the traces and the board's overall structure is important for maintaining the integrity of high-speed signals. Impedance matching minimizes signal reflection and ensures that signals reach their destination with minimal loss or distortion.

The signal flow is not a simple, direct path; it is an organized process where each component plays a specific role. The conductive traces are like highways for electrical currents, and components are like destinations, where a transformation of the signal occurs. All these pathways are arranged in a specific layout that provides both the structural support and signal transmission capability for the electronic device.

Types of Computer Circuit Boards

Computer circuit boards, also known as printed circuit boards (PCBs), are not all created equal. They come in various forms, each designed to meet specific needs and applications. These variations primarily involve the number of conductive layers and the materials used, directly impacting their functionality, cost, and suitability for different electronic devices.

| Type of PCB | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Sided PCB | Features a single layer of conductive material (typically copper) on one side of the board. | Simple electronic devices, toys, LED lighting. | Cost-effective, easier to manufacture. | Limited component density, less complex circuitry. |

| Double-Sided PCB | Has conductive layers on both sides of the board, connected by vias. | Consumer electronics, power supplies, intermediate-complexity circuits. | Higher component density than single-sided PCBs, greater flexibility in design. | More complex and expensive to manufacture compared to single-sided PCBs. |

| Multi-Layer PCB | Consists of three or more conductive layers, allowing for complex routing and high component density. | High-end computers, smartphones, complex communication devices, servers. | Very high component density, suitable for complex circuits, excellent signal integrity. | Most expensive and complex to manufacture. |

| Flexible PCB (Flex PCB) | Made from flexible base materials, allowing the board to bend and conform to various shapes. | Wearable devices, automotive applications, tight-space electronics. | Flexible, space-saving, durable. | Can be more expensive, requires specialized manufacturing. |

| Rigid-Flex PCB | Combines rigid and flexible PCB sections. | Aerospace, military, high-performance electronics. | Combines the benefits of rigid and flexible PCBs, high performance. | Most complex and expensive to manufacture. |

The choice of materials in PCB construction is also crucial. Common substrates include FR-4 (Flame Retardant 4), which is a glass-reinforced epoxy laminate. Other materials like aluminum, polyimide, and ceramics are used for more specialized applications demanding higher thermal or electrical performance. The selection of materials influences not only the electrical properties of the board but also its thermal characteristics, mechanical stability, and environmental resistance.

The Manufacturing Process of PCBs

The manufacturing of Printed Circuit Boards (PCBs) is a complex, multi-stage process requiring high precision and control. From the initial design to the final product, each step is critical to ensure the board functions as intended. The process involves a combination of chemical, mechanical, and electrical engineering techniques.

The fabrication of a PCB follows a sequence of well-defined steps:

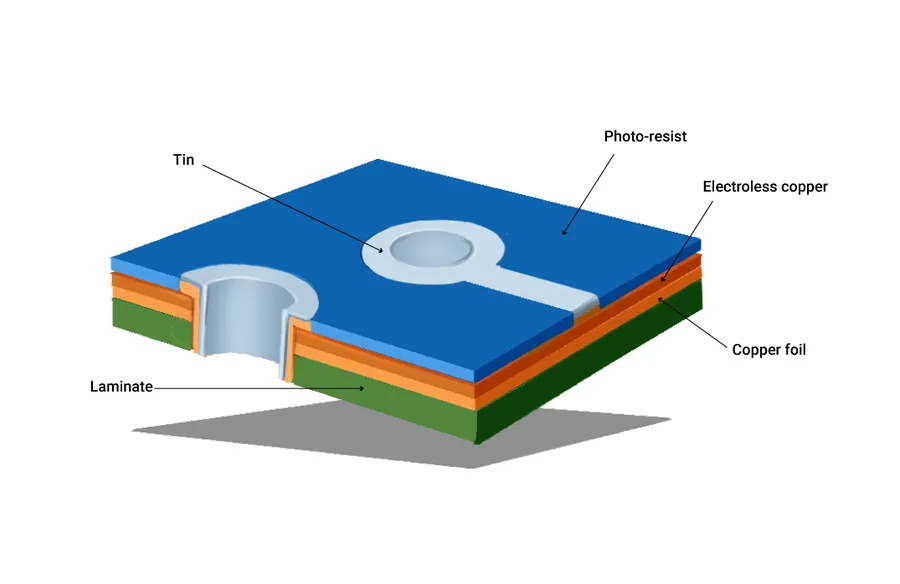

- Design and Layout

The process begins with the electronic circuit design which is translated into a physical layout using specialized software. This layout determines the arrangement of conductive traces, pads, and vias. - Printing the Circuit Pattern

A photo-reactive material, known as photoresist, is applied to a copper-clad substrate. A mask containing the circuit pattern is then placed on the photoresist layer and exposed to UV light. The exposed photoresist hardens, and the unexposed areas are washed away. - Etching

The board is then treated with a chemical etchant which removes the unwanted copper, leaving only the desired circuit traces protected by the hardened photoresist. This step precisely defines the conductive pathways. - Drilling

Small holes, known as vias or through-holes, are drilled through the board. These holes provide electrical connections between different layers of the board or are used for mounting through-hole components. - Plating

To ensure good electrical conductivity, copper is plated into the drilled holes. Often, the entire board surface is also plated with a layer of metal, such as tin or gold. - Solder Mask Application

A protective solder mask layer is applied over the conductive traces to prevent short circuits during soldering. This mask exposes only the pads where components will be placed and soldered. - Component Assembly

Electronic components, either surface mount (SMT) or through-hole, are placed onto the board using automated machinery. The components are then soldered to the conductive pads, securing them in place and establishing electrical connection. - Testing and Quality Control

The completed PCB is rigorously tested to ensure its functionality and reliability. These tests verify electrical continuity, signal integrity, and overall performance before the PCBs are shipped for use in electronic devices.

| Manufacturing Step | Purpose | Key Technologies/Materials |

|---|---|---|

| Design | Define the circuit layout and component placement | CAD Software |

| Photoresist Application | Create a temporary mask for etching | Photoresist material, UV light |

| Etching | Remove unwanted copper | Chemical Etchants |

| Drilling | Create vias and mounting holes | CNC Drilling Machines |

| Plating | Ensure good conductivity | Electroplating processes |

| Solder Mask Application | Protect traces, expose pads for soldering | Solder mask ink |

| Component Assembly | Place and solder electronic components | SMT and Through-hole Assembly Machines |

| Testing | Ensure functionality and reliability | Electrical testing equipment |

Importance of PCBs in Modern Technology

Printed circuit boards (PCBs) are fundamental to modern technology, serving as the backbone for nearly all electronic devices. Their ability to provide both mechanical support and electrical connections makes them indispensable in today's world, underpinning the functionality of everything from basic appliances to advanced computational systems.

The pervasive nature of PCBs is evident in numerous applications across various sectors. They are not merely components in high-tech gadgets; they are the critical infrastructure upon which these devices operate.

- Consumer Electronics

In consumer electronics, PCBs are crucial for devices like smartphones, tablets, laptops, and televisions. These devices rely on PCBs for power distribution, signal processing, and communication between various subcomponents. Their compact design, facilitated by advancements in PCB miniaturization, has enabled the creation of increasingly powerful and portable electronics. - Automotive Industry

Modern vehicles are filled with PCBs, playing a vital role in functions ranging from engine management and safety systems (e.g., ABS, airbags) to infotainment and navigation. The automotive sector's shift towards autonomous driving further amplifies the reliance on PCBs for complex computing and sensor integration. These boards must be highly reliable to perform their functions in extreme conditions, withstanding high temperatures and vibrations. - Healthcare and Medical Devices

In the healthcare industry, PCBs are essential components in medical devices such as imaging equipment (MRI, CT scanners), patient monitoring systems, and diagnostic tools. The precision and reliability of PCBs are paramount in these applications as they directly impact patient care. Advancements in PCB technology have enabled smaller, more sophisticated medical devices, contributing to improved healthcare outcomes. - Aerospace and Military

Aerospace and military applications require PCBs with the highest standards of performance, resilience, and reliability. These PCBs are used in flight control systems, radar technology, communication equipment, and satellite systems, where failure could have catastrophic consequences. These sectors are pushing the boundaries of PCB technology, requiring boards that can withstand severe environments and operate flawlessly under extreme conditions. - Industrial Equipment and Automation

PCBs are the backbone of industrial control systems, enabling the automation and precise operation of machinery, robotics, and process control equipment. The reliability and durability of PCBs are essential for maintaining continuous operations and ensuring the efficiency of industrial processes.

In summary, PCBs are more than just a part of our electronics; they are the critical foundation upon which our modern technological world is built, enabling the seamless operation of diverse and essential systems across various sectors. The ongoing development and refinement of PCB technology continue to drive innovation and shape the future of modern technology.

Frequently Asked Questions About Computer Circuit Boards

This section addresses common questions regarding computer circuit boards, providing clarity on their function, value, and identification of issues. The goal is to offer practical information to both novice and experienced users.

- What exactly is the role of a circuit board in a computer?

A computer circuit board, or PCB, acts as the foundational platform for electronic components. It provides both the mechanical support and the electrical pathways needed for components to communicate and function as a system. Without it, a computer's components would not be able to work together effectively. - What differentiates a motherboard from a general circuit board?

The motherboard is a specific type of circuit board. It is the primary board in a computer system that houses and connects critical components, such as the CPU, RAM, and expansion slots. While all motherboards are PCBs, not all PCBs are motherboards. Motherboards are more complex and perform a broader range of functions than typical circuit boards. - Do old computer circuit boards have any value?

Yes, old circuit boards can have value due to the presence of valuable metals such as gold, silver, and copper. Recycling companies often purchase these boards to extract these materials. The value depends on the type of board, its condition, and the current market rates for precious metals. Typically, boards from high performance equipment like servers can yield a higher value. - How can I identify if a circuit board has failed or is malfunctioning?

Identifying a faulty circuit board often involves looking for physical signs of damage such as burnt components, corrosion, or cracked traces. Functionally, issues might manifest as erratic or non-existent operation of the electronic device it's in. However, pinpointing the exact issue usually requires specialized testing equipment and expertise. - What are the most common causes of circuit board failure?

Circuit board failures can stem from various factors, including excessive heat, power surges, physical damage, and component degradation over time. Environmental conditions such as moisture and dust can also contribute to corrosion and malfunction. Improper handling during installation or repairs is another common cause of failure. - Can a damaged circuit board be repaired, and is it cost-effective?

Repairing a damaged circuit board is possible, but it’s not always cost-effective. Minor issues like a loose connection may be easily fixed, but more complex damage, especially to multilayer boards, can be labor-intensive and costly. The decision to repair should consider the cost of repair versus replacement, the value of the device, and the availability of replacement components. - What materials are commonly used to manufacture computer circuit boards?

Computer circuit boards are generally made from a non-conductive substrate material, such as fiberglass-reinforced epoxy or a polymer, with conductive traces made of copper. Solder is also vital for attaching components to the board. The materials used are chosen to provide mechanical strength, heat resistance, and good electrical properties.

Future Trends in PCB Technology

The field of Printed Circuit Board (PCB) technology is rapidly evolving, driven by the constant demand for smaller, more efficient, and environmentally friendly electronics. Key trends include flexible PCBs, miniaturization, and sustainable manufacturing processes.

- Flexible PCBs

Flexible PCBs utilize materials like polyimide, enabling them to bend and conform to various shapes. This flexibility opens doors for innovative designs in wearable technology, curved displays, and aerospace applications, where space and weight are critical constraints. They are more durable and can withstand vibration and stress better than rigid boards. - Miniaturization

The continuous drive towards miniaturization is pushing PCB technology to new limits. Smaller and more tightly packed components, facilitated by techniques like surface-mount technology (SMT) and microvias, allow for more functionality in smaller devices. This trend is vital for the development of increasingly compact and powerful electronic devices, such as smartphones, medical implants, and IoT devices. - Sustainable Manufacturing

Sustainability concerns are prompting the adoption of eco-friendly practices in PCB manufacturing. This includes using recyclable materials, reducing waste, and implementing energy-efficient production methods. There is also a growing push for lead-free soldering and the use of less hazardous chemicals in etching and plating. Sustainable manufacturing is increasingly a key focus for electronics manufacturers worldwide. - Advanced Materials

Research into novel materials is crucial for the future of PCBs. This includes materials with improved electrical properties, enhanced thermal management, and greater mechanical robustness. Advanced composites, ceramics, and graphene are being explored for their potential in future generations of electronic devices. This allows for more efficient high-frequency operations and better heat dissipation, crucial for high-performance applications. - 3D Printing of PCBs

Additive manufacturing, or 3D printing, is emerging as a promising technology for PCB fabrication. This method allows for rapid prototyping, customization, and the creation of complex 3D circuit structures, enabling the creation of circuits on non-planar surfaces. 3D-printed PCBs are expected to become increasingly relevant in rapid prototyping and customized electronic designs.

The computer circuit board stands as a critical invention that has revolutionized the way we interact with technology. From the complex data processing in a high-powered computer to the simple functions in a household appliance, PCBs are integral. Understanding their construction and function is essential to grasping the inner workings of the digital world and the continued innovations that shape our future. As technology continues to advance, the importance of the computer circuit board and the need for more sophisticated designs will only continue to grow. We will see even more innovative applications of PCBs in the future.

AnyPCBA

AnyPCBA