Understanding Electronic Boards: Types, Uses, and How They Power Our World

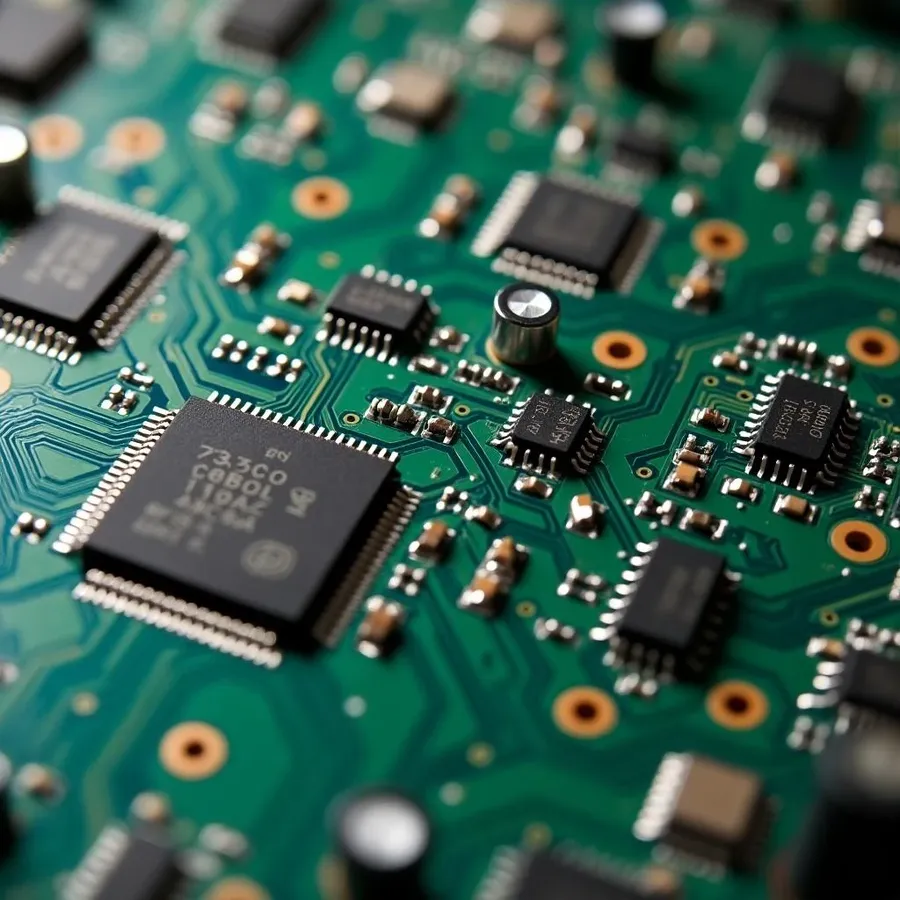

In today's technology-driven world, electronic boards are the unsung heroes powering everything from your smartphone to complex industrial machinery. These intricate components, often referred to as printed circuit boards (PCBs), serve as the foundation for connecting electronic parts and enabling the flow of electricity. This article dives deep into the fascinating world of electronic boards, exploring their various types, functionalities, and crucial role in our daily lives. Let’s uncover the layers of these essential technological cornerstones.

What is an Electronic Board (PCB)?

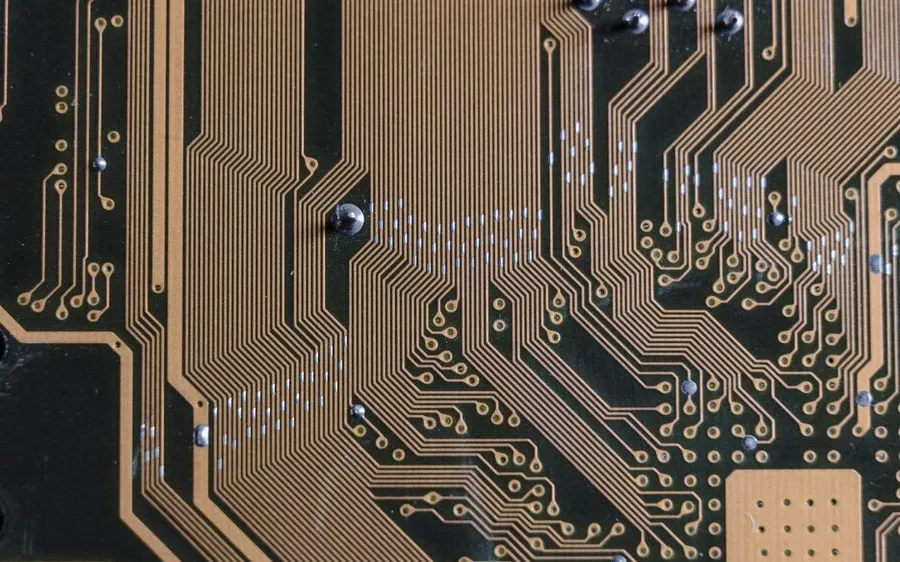

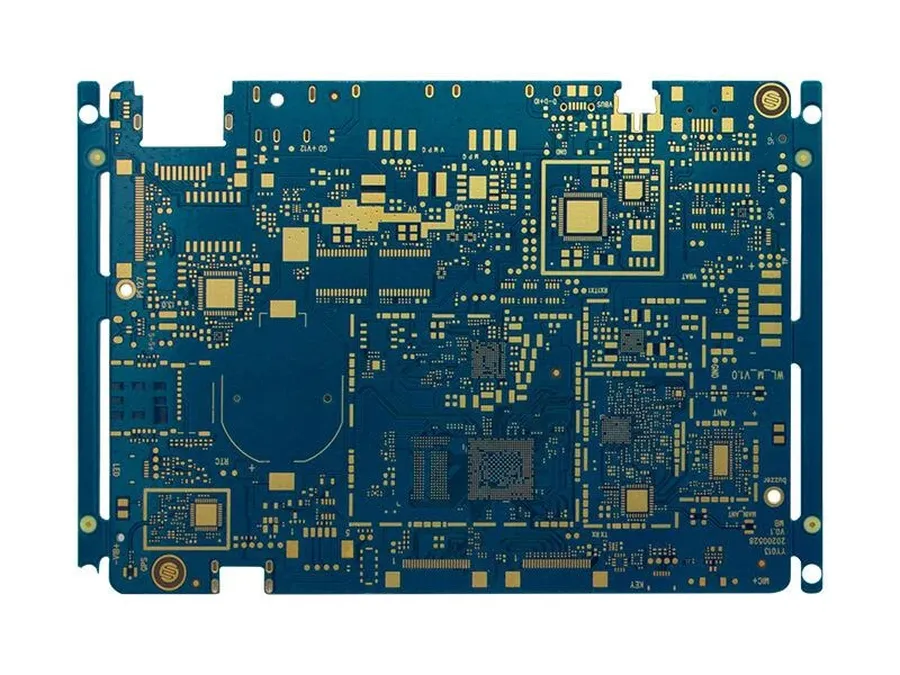

An electronic board, most commonly referred to as a printed circuit board (PCB), serves as the foundational platform for electronic devices. It is a non-conductive substrate that provides mechanical support and electrical connections for electronic components through conductive pathways. These pathways, known as traces, are typically made of copper and are carefully designed to route electrical signals and power to the various components mounted on the board.

The primary function of a PCB is to securely hold electronic components and facilitate their interconnection, eliminating the need for bulky and unreliable wiring. This allows for compact, reliable and efficient circuit design that is scalable for mass manufacturing. The basic components found on a typical PCB include:

- Substrate

The base material of the PCB which is usually a non-conductive material such as FR-4 (a fiberglass composite) or ceramic, which provides the structural foundation. - Conductive Traces

Copper pathways that electrically connect components. These are etched into the substrate and carry electrical signals. - Pads

Small areas of metal (usually copper) that are used to solder components onto the board. - Vias

Holes through the PCB that are plated with a conductive material to allow signals to pass between different layers. - Solder Mask

A protective layer that prevents solder from bridging between traces or pads. - Silkscreen

A printed layer with labels, component outlines and other markings for easy component placement and debugging.

Types of Electronic Boards

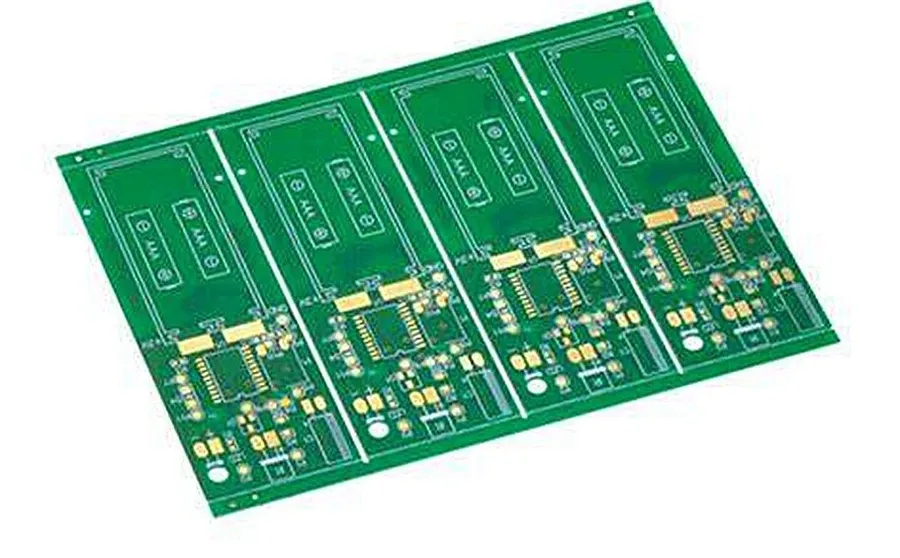

Electronic boards, or printed circuit boards (PCBs), are the foundation of modern electronics. They come in a variety of designs, each tailored to specific application requirements. These designs vary in complexity, material composition, and flexibility, directly impacting their performance and suitability for different devices.

| Type of PCB | Description | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Sided PCB | Components are mounted on one side of the board with conductive traces on the other. | Simple electronics, toys, basic lighting systems. | Lowest cost, simple design, easy to manufacture. | Limited component density, less versatile for complex circuits. |

| Double-Sided PCB | Components and conductive traces are on both sides of the board. | Power supplies, basic computer peripherals, more complex consumer devices. | Increased component density, more complex circuit design possible. | More expensive and difficult to manufacture than single-sided PCBs. |

| Multi-Layer PCB | Consists of three or more layers of conductive patterns, interconnected by vias. | High-performance computing, high-speed data transfer, telecommunications, aerospace. | Highest component density, most versatile for complex circuits, reduced board size. | Most expensive, most complex design and manufacturing process. |

| Rigid PCB | A solid board made of rigid materials like FR-4. | General electronics applications where flexibility is not required. | Durable, cost-effective, ideal for static applications. | Not suitable for flexible or bending applications. |

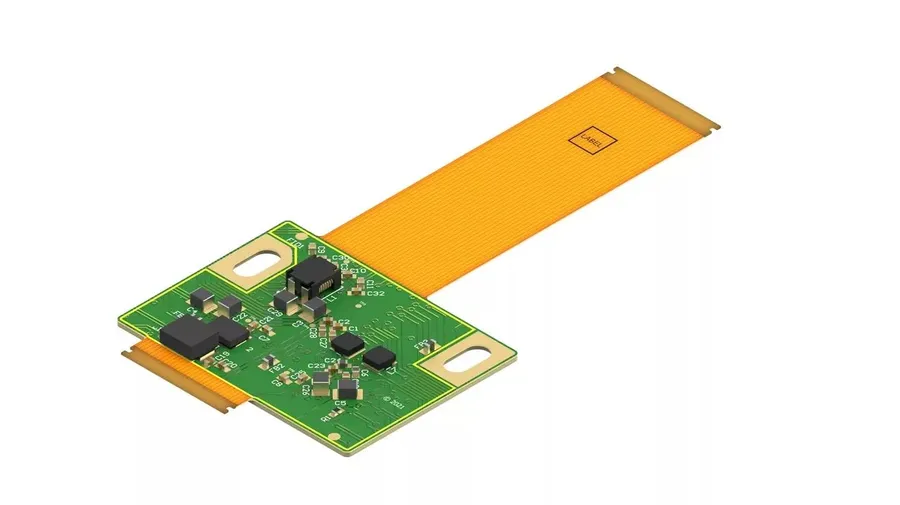

| Flexible PCB | Designed on a flexible base like polyimide allowing for bending and shaping. | Wearable electronics, medical implants, automotive sensors, compact devices. | Highly versatile for small spaces, lightweight, dynamic flexing. | More expensive than rigid PCBs, can be more fragile, sensitive to heat. |

| Rigid-Flex PCB | Combines rigid and flexible sections into a single board. | Advanced medical devices, high-end cameras, aerospace electronics. | Combines advantages of both rigid and flexible PCBs, customizable shape. | Most complex and expensive to manufacture. |

Materials Used in Electronic Board Construction

The performance and durability of an electronic board are critically dependent on the materials used in its construction. These materials can be broadly categorized into substrates, conductive materials, and other essential components like solder masks and silkscreens. Each material is selected for its specific properties, ensuring the board can meet the demands of its intended application.

| Material Category | Material Example | Key Properties | Typical Application |

|---|---|---|---|

| Substrate | FR-4 (Flame Retardant 4) | Good electrical insulation, mechanical strength, cost-effective | Most common type of PCB; general-purpose electronics |

| Substrate | Ceramic | High temperature resistance, excellent thermal conductivity | High-power electronics, high-frequency applications |

| Substrate | Polyimide | Flexible, high temperature resistance | Flexible circuits, aerospace applications |

| Conductive Material | Copper | Excellent electrical conductivity, solderable | Traces and vias for signal and power transmission |

| Other Material | Solder Mask | Protects traces from oxidation and shorts | All PCBs; provides protection and improves reliability |

| Other Material | Silkscreen | Provides component identification and board information | All PCBs; facilitates assembly and maintenance |

How Electronic Boards Work

Electronic boards, primarily Printed Circuit Boards (PCBs), function as the foundational platform for electronic devices. Their operation hinges on the strategic arrangement of conductive pathways, known as traces, which facilitate the controlled flow of electrical signals and power between various electronic components. These traces, typically made of copper, are etched onto a non-conductive substrate, usually made of FR-4 or similar materials.

The process begins with the connection of components like resistors, capacitors, integrated circuits (ICs), and diodes onto the board. These connections are established through soldering, where molten solder creates a permanent electrical and mechanical bond between component leads and the conductive traces. This process enables the creation of an electrical circuit, allowing components to interact according to the design.

Functionally, the traces serve as low-resistance pathways for electrical current, enabling signals and power to be distributed efficiently to various parts of the circuit. The design of these pathways is critical to the performance of the electronic device. Impedance matching, signal integrity, and crosstalk reduction are key design considerations to achieve optimum functionality. Complex circuits can be built by combining multiple layers of traces, allowing for highly integrated and compact devices.

In essence, an electronic board provides the physical infrastructure and electrical connections necessary for electronic components to interact and perform designated functions, ranging from simple circuits to complex control and processing units.

The Manufacturing Process of Electronic Boards

The manufacturing of electronic boards, or printed circuit boards (PCBs), is a complex, multi-stage process requiring precision and control. It transforms a digital design into a physical platform that supports and interconnects electronic components. This process encompasses design, prototyping, fabrication, and assembly, each with its own intricacies.

- Design and Layout

The process begins with the electronic circuit's design, usually using CAD (Computer-Aided Design) software. This involves defining the board's dimensions, component placement, and conductive pathways (traces) for electrical connections. Critical considerations include signal integrity, thermal management, and manufacturability. - Prototyping

Before mass production, a prototype PCB is often created to test the design's functionality and identify any potential issues. This allows for adjustments and refinements, ensuring the final product meets the required specifications. - Fabrication

Fabrication involves several sub-processes: * **Substrate Preparation:** The base material, typically FR-4, is cut to size and cleaned. * **Copper Cladding:** A thin layer of copper is laminated onto the substrate. * **Imaging:** A photosensitive resist is applied, exposed to UV light through a photomask, and developed, leaving areas of copper to form the circuit pattern. * **Etching:** Unwanted copper is chemically removed, leaving only the desired traces and pads. * **Drilling:** Holes are drilled for component leads and vias (interlayer connections). * **Plating:** Hole walls are plated with copper, creating conductive pathways for interconnections between layers. * **Solder Mask Application:** A protective layer of solder mask is applied, preventing solder from bridging between pads during assembly. * **Silkscreen Printing:** Component designators and other markings are printed onto the board. - Assembly

The assembly stage involves attaching electronic components to the fabricated board, including: * **Solder Paste Application:** Solder paste is applied to the pads where components will be placed. * **Component Placement:** Components are placed onto the board using automated pick-and-place machines. * **Soldering:** The board is heated in a reflow oven, melting the solder paste and creating permanent electrical and mechanical connections. For through-hole components, soldering may be done manually or by wave soldering. * **Inspection and Testing:** Assembled boards undergo visual inspection and electrical testing to ensure proper functionality before being packaged and shipped.

Applications of Electronic Boards in Various Industries

Electronic boards, also known as printed circuit boards (PCBs), are indispensable components that power a vast array of applications across diverse industries. Their versatility and ability to integrate complex circuitry into compact forms make them essential for modern technology, with applications ranging from everyday consumer products to sophisticated industrial systems.

- Consumer Electronics

PCBs are the backbone of nearly all consumer electronics. Smartphones, laptops, tablets, televisions, and gaming consoles all rely on PCBs to integrate their complex electronic functions. These boards enable compact designs, efficient power management, and signal processing, all critical for the functionality of these devices. The high-volume production and cost-effectiveness of PCBs make them an ideal choice for these markets. - Automotive Industry

The automotive sector uses electronic boards extensively in various applications, including engine control units (ECUs), anti-lock braking systems (ABS), infotainment systems, and advanced driver-assistance systems (ADAS). Modern vehicles often include dozens of interconnected PCBs to control different features, enhancing safety, performance, and driver comfort. The rigorous environment of automotive applications requires PCBs to be reliable, durable, and able to withstand extreme temperature variations and vibrations. - Medical Devices

In healthcare, electronic boards are crucial components in diagnostic equipment, monitoring devices, and therapeutic tools. Medical devices such as MRI machines, ultrasound equipment, pacemakers, and patient monitoring systems rely on PCBs to accurately and reliably perform their functions. High precision, reliability, and strict regulatory compliance are key considerations for PCBs in medical applications, ensuring patient safety and diagnostic accuracy. - Aerospace Industry

The aerospace industry uses PCBs in critical control systems, navigation equipment, communication systems, and satellite technologies. Electronic boards in aerospace applications must withstand harsh environments, including extreme temperatures, radiation, and physical stress. Reliability and high performance are paramount, necessitating stringent testing and high-quality manufacturing of PCBs. - Industrial Automation

Electronic boards are fundamental to industrial automation systems, controlling machinery, robotic systems, and process control equipment. Programmable logic controllers (PLCs), motor drives, and sensor interfaces rely heavily on robust PCBs to maintain seamless operations in demanding industrial environments. Durability and the ability to handle high electrical loads are crucial for these applications. - Telecommunications

From networking hardware to cellular base stations, electronic boards are vital for telecommunications infrastructure. Routers, switches, and other communication devices use PCBs for high-speed data transfer and signal processing. These boards must meet stringent performance standards to ensure reliable communication networks.

Frequently Asked Questions About Electronic Boards

This section addresses common queries regarding electronic boards, also known as printed circuit boards (PCBs). We aim to provide clear and concise answers to help enhance your understanding of these fundamental components of modern electronics. This section will cover questions from basic terminology, to repair, and functionality.

- What are electronic boards commonly called?

Electronic boards are most commonly referred to as Printed Circuit Boards (PCBs). This term accurately describes their structure, where electronic components are connected via conductive pathways printed onto the board. Sometimes, they may also be called circuit boards or simply 'boards' in electronic contexts. - How do electronic boards function?

Electronic boards function by providing a substrate and conductive pathways for electronic components to connect. The conductive pathways, known as traces, typically made of copper, transmit electrical signals between components mounted on the board. This arrangement allows for controlled and efficient flow of electricity, enabling devices to perform their intended functions. - How do you troubleshoot and fix an electronic circuit board?

Troubleshooting a PCB involves systematic testing and visual inspection, including checking for physical damage such as broken traces or overheated components. Repair often involves replacing faulty components, repairing broken traces by soldering or using conductive adhesives and cleaning flux residue with isopropyl alcohol. Advanced troubleshooting and repairs may require schematics, specialized tools, and in some cases, replacement of the entire board. - What are electronic boards made of?

Electronic boards are typically made from a non-conductive substrate, such as FR-4 (a fiberglass composite) or ceramic material, which provides structural support. Conductive materials, such as copper, form the traces that transmit electrical signals. Other materials may include solder for connecting components, and various coatings to protect the board from environmental factors like moisture or oxidation. - What are the main applications of electronic boards?

Electronic boards are used in nearly all electronic devices, across various industries such as consumer electronics (smartphones, laptops), automotive (engine control units, infotainment systems), medical devices (patient monitoring systems), aerospace (avionics), and industrial automation (control systems). They are the foundation for integrating electronic components in these diverse applications. - What is an electronic message board?

An electronic message board is a display device that uses LEDs or LCDs to present text, images or other information. Unlike PCBs which facilitates component connections, these boards are designed to communicate information to an audience and are used for advertising, public announcements, or displaying information in various settings. - What are the key considerations when designing an electronic board?

Key design considerations for an electronic board include thermal management to dissipate heat, signal integrity to ensure clean signal transmission, appropriate component placement to minimize interference, and the use of Computer-Aided Design (CAD) software to create functional and reliable PCBs. Also critical are considerations for manufacturability, testing, and cost.

Design Considerations for Effective Electronic Boards

Designing an effective electronic board requires a holistic approach, considering multiple factors that impact performance, reliability, and manufacturability. These considerations range from thermal management and signal integrity to component placement and the selection of appropriate design software.

- Thermal Management

Effective heat dissipation is critical to prevent component failure and maintain optimal performance. This involves selecting components with appropriate thermal properties, using heat sinks or thermal vias, and ensuring adequate airflow around heat-generating devices. Poor thermal management can lead to premature failure and reduced lifespan of the electronic board. - Signal Integrity

Maintaining signal quality is paramount, particularly in high-speed applications. This includes minimizing impedance mismatches, controlling trace lengths, and using proper termination techniques. Signal integrity issues can result in signal degradation, data loss, and unstable operation of the electronic board. - Component Placement

Strategic component placement is crucial to optimize circuit performance and routing efficiency. High-frequency components should be placed close to their associated circuitry to minimize signal travel distance. Components with large heat dissipation should be spaced adequately to ensure effective heat removal. Careful consideration of component orientation and spacing helps minimize signal interference and optimizes thermal dissipation. - Importance of CAD Software

Computer-Aided Design (CAD) software is essential for designing complex electronic boards. It facilitates schematic capture, PCB layout, and design rule checking. Selecting appropriate CAD software with simulation and analysis capabilities is essential for creating efficient and reliable electronic boards. Features include signal integrity analysis, thermal simulation, and manufacturability assessment.

| Design Consideration | Description | Impact of Poor Design |

|---|---|---|

| Thermal Management | Efficient heat dissipation to prevent component overheating. | Component failure, reduced lifespan, performance degradation. |

| Signal Integrity | Maintaining signal quality to minimize interference. | Signal degradation, data loss, unstable operation. |

| Component Placement | Strategic placement of components to optimize routing and performance. | Increased interference, poor thermal performance, routing inefficiencies. |

| CAD Software | Use of software for schematic, layout and design verification. | Design errors, manufacturing problems, and increased development time |

Future Trends in Electronic Board Technology

The field of electronic board technology is rapidly evolving, driven by the demand for smaller, faster, and more versatile devices. This section explores the key trends shaping the future of electronic boards, encompassing advancements in flexible electronics, miniaturization, high-speed PCBs, and the innovative application of new materials.

- Flexible Electronics

Flexible PCBs are moving beyond niche applications, finding use in wearable tech, medical sensors, and advanced displays. These boards utilize flexible substrates like polyimide, enabling devices to conform to curved or dynamic surfaces. - Miniaturization

The push for smaller and more powerful devices is driving the miniaturization of electronic boards. This trend involves finer trace widths and spacing, more compact component packaging, and integration of multiple functionalities into a single chip or board. - High-Speed PCBs

As data transfer rates increase, the demand for high-speed PCBs is rising. These boards must be designed to minimize signal loss, interference, and impedance mismatches, often employing advanced materials and impedance-controlled trace designs. - Advanced Materials

New materials are playing a critical role in enhancing the performance and reliability of electronic boards. This includes the use of new substrate materials with better thermal properties, improved dielectrics for high-speed applications, and novel conductive materials beyond standard copper. - 3D Printing of PCBs

Additive manufacturing techniques, specifically 3D printing, are increasingly being used in PCB prototyping and even limited production runs. This allows for faster design iterations and the creation of custom boards with complex geometries. - Integrated Photonics

Integrating photonic components directly into PCBs allows for optical data transfer, offering faster and more energy-efficient solutions. This is particularly relevant for high-bandwidth applications such as data centers and telecommunications. - Artificial Intelligence in PCB Design

AI algorithms are being used to optimize PCB layouts, identify design flaws, and automate aspects of the design and manufacturing process. This can lead to faster design times, improved board performance, and reduced costs.

Electronic boards, the backbone of modern electronics, are integral to our daily lives. From the simple PCBs in our toasters to the complex boards in spacecraft, their role is fundamental. As technology advances, the electronic board continues to evolve, and innovations in materials and design will shape the future of electronics. Understanding these fundamental components is key to comprehending the future of technology.

AnyPCBA

AnyPCBA