Understanding Electronic PCB Board Prices: A Comprehensive Guide

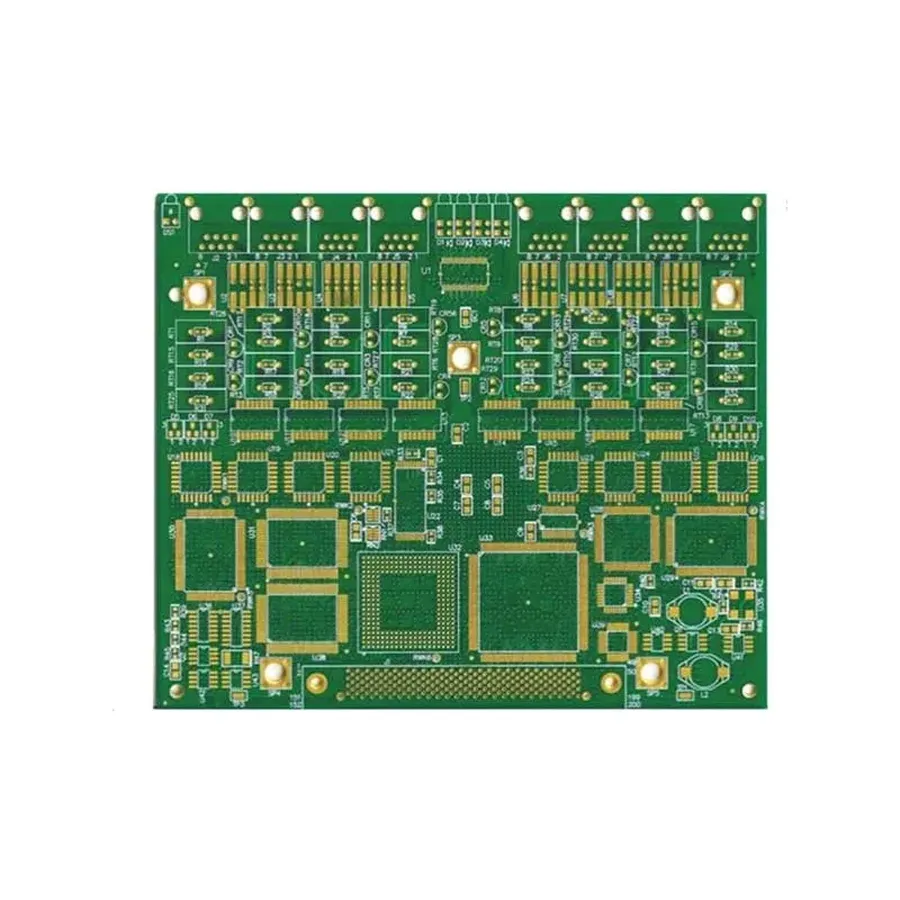

The ubiquitous electronic PCB board is the unsung hero of modern technology, powering everything from smartphones to industrial machinery. Understanding the factors influencing the electronic PCB board price is crucial for both hobbyists and large-scale manufacturers. This article dives deep into the variables impacting cost, offering insights into how to make informed purchasing decisions. From simple prototypes to complex multilayer boards, we'll navigate the landscape of PCB pricing.

Key Factors Influencing Electronic PCB Board Prices

The price of an electronic PCB board is not a fixed value but is influenced by a multitude of factors related to its design, materials, and manufacturing process. Understanding these key determinants is crucial for cost optimization and informed decision-making when sourcing printed circuit boards. These factors interact to define the final cost, requiring a holistic view to achieve cost-effectiveness.

- Material Type

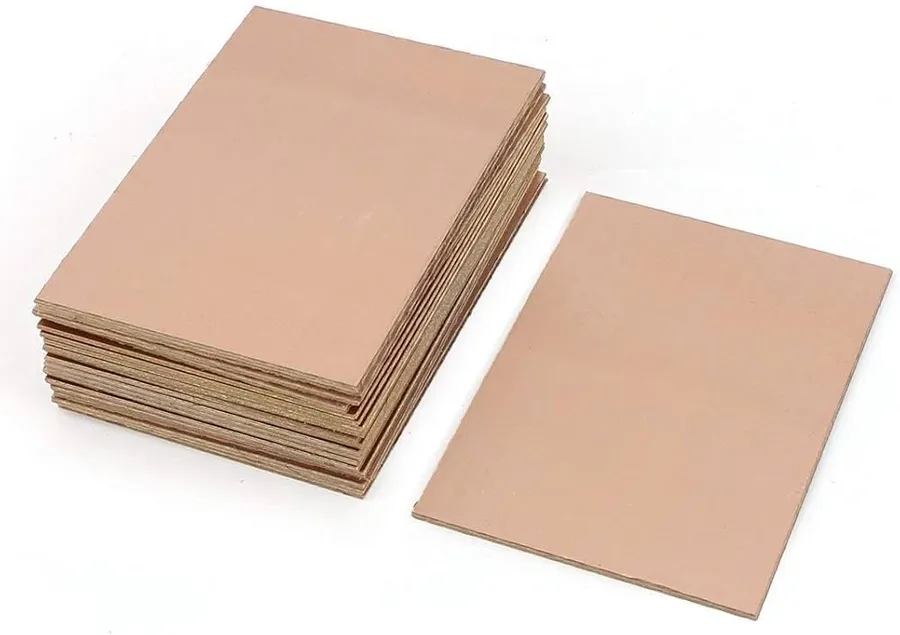

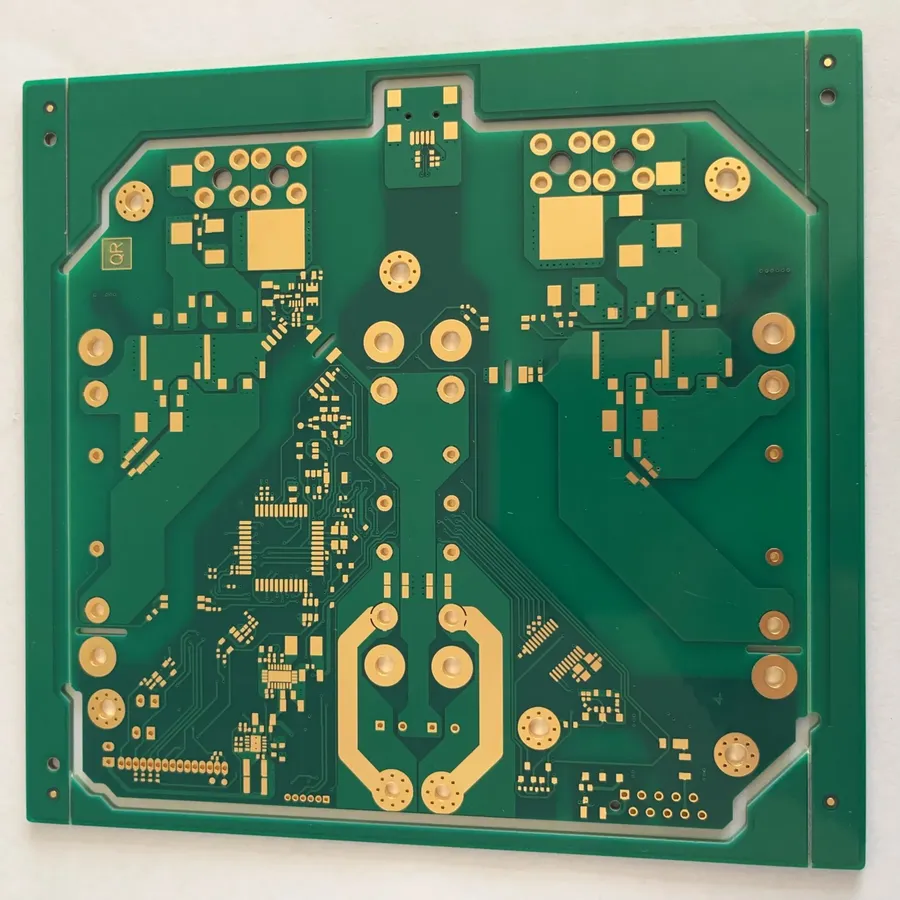

The choice of substrate material (e.g., FR-4, aluminum, flexible substrates) has a direct impact on cost due to varying material expenses and processing complexities. - Board Size and Dimensions

Larger boards consume more raw materials, directly increasing the cost, while small and complex boards may present more intricate manufacturing requirements. - Layer Count

The number of conductive layers in the PCB (single-layer, double-layer, multi-layer) increases manufacturing complexity and thus costs. - Complexity of Design

Features such as trace width and spacing, vias, and component density directly affect production difficulty and therefore price. - Surface Finish

Options like HASL, ENIG, and OSP offer varying performance and cost attributes which must be considered. - Production Volume

Larger production runs typically result in lower per-unit costs due to economies of scale, while small batches or prototypes are costlier. - Assembly Services

The total cost escalates with the inclusion of assembly tasks such as component placement, soldering, and testing. This addition has a large cost implication.

Material Types and Their Impact on PCB Cost

The selection of materials for a printed circuit board (PCB) is a crucial factor that significantly influences its final cost. Different materials offer varying electrical, mechanical, and thermal properties, which directly affect the PCB's performance, durability, and ultimately, its price. Understanding these material properties is essential for cost-effective PCB design and procurement.

| Material Type | Description | Cost Implications | Typical Applications |

|---|---|---|---|

| FR-4 | Fiberglass-reinforced epoxy laminate, the most common PCB substrate. | Cost-effective, widely available, standard choice. | Consumer electronics, general-purpose PCBs |

| Aluminum | Metal core PCB with an aluminum base. | Higher cost than FR-4, but provides excellent thermal conductivity. | LED lighting, power electronics, high-power applications |

| Flexible Substrates (e.g., Polyimide) | Flexible polymer substrates used in flexible PCBs. | Higher cost, specialized manufacturing required. | Wearable devices, medical devices, automotive electronics |

| Rogers Materials | High-frequency laminates with superior electrical properties. | Very high cost, used for specialized applications. | RF and microwave circuits, high-speed digital designs |

| CEM-1 | Composite epoxy material with a paper core | Lower cost alternative to FR-4 but with reduced performance. | Single-sided low cost applications. |

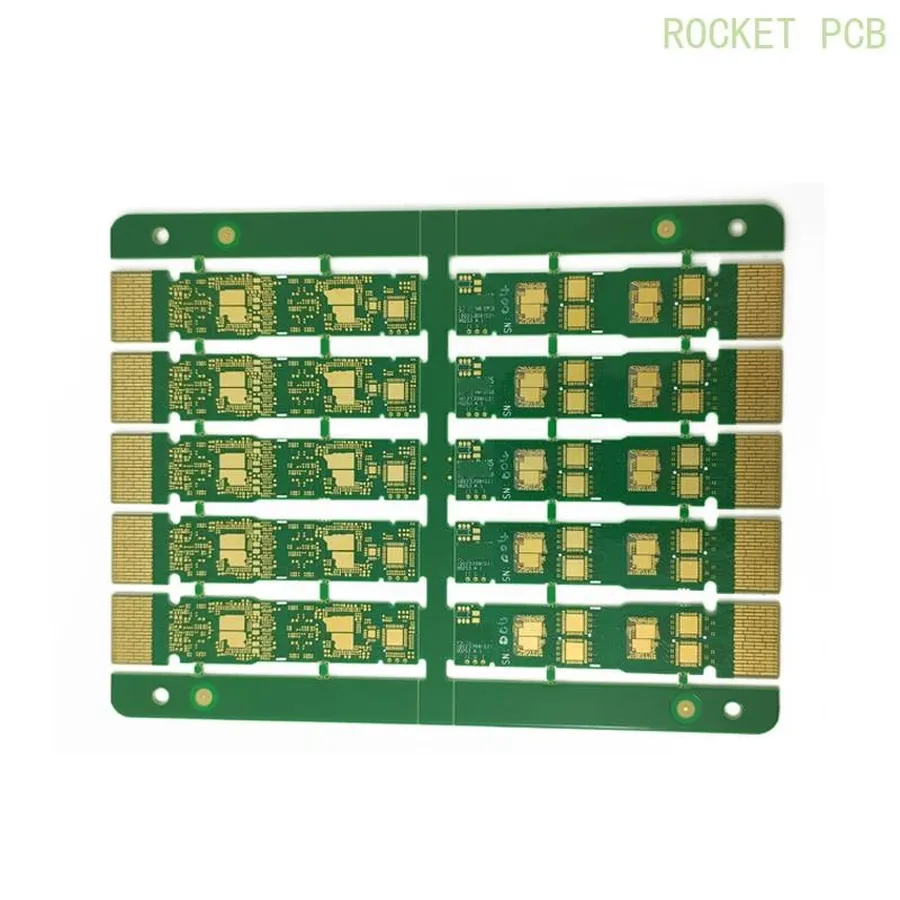

The Role of PCB Layer Count in Pricing

The number of layers in a printed circuit board (PCB) is a primary determinant of its cost and complexity. Each layer adds to the manufacturing process, requiring more materials, intricate alignment, and sophisticated processing techniques which significantly increases the electronic pcb board price.

| Layer Count | Complexity | Typical Applications | Cost Factor |

|---|---|---|---|

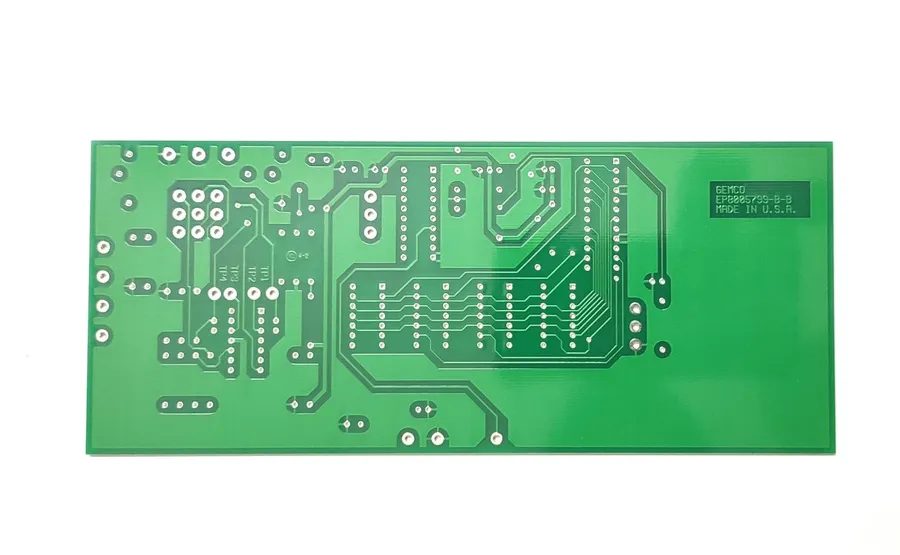

| Single-Layer | Simplest design, components on one side | Basic electronic devices, simple circuits | Lowest cost |

| Double-Layer | Components on both sides, with vias for connections | Common in many consumer electronics, slightly more complex circuits | Low to moderate cost |

| 4-Layer | Two inner signal layers and two outer layers, more routing flexibility | More complex electronics, moderately high density designs | Moderate cost |

| 6-Layer | Increased signal layers with more controlled impedance and signal integrity | Advanced electronics, high-speed digital circuits | Moderately high cost |

| 8+ Layers | Very high signal density and complexity, often with internal power and ground planes | High-end computing, telecommunications, and industrial equipment | High cost |

The increase in layer count leads to more intricate manufacturing steps. For instance, multi-layer PCBs involve laminating several thin layers of conductive material and insulating substrate. Accurate alignment of each layer is crucial and requires precise machinery. Furthermore, vias (conductive pathways between layers) become increasingly complex with more layers, requiring specialized drilling and plating processes. The increased cost is directly tied to the resources, time, and expertise needed to produce boards with higher layer counts.

Surface Finish Options and Their Cost Implications

The surface finish applied to a Printed Circuit Board (PCB) is a critical factor that influences its performance, reliability, and ultimately, the electronic PCB board price. Different finishes offer varying levels of solderability, corrosion resistance, and cost. Selecting the appropriate surface finish is crucial for optimizing both the functionality and the budget of your electronic device.

| Surface Finish | Description | Advantages | Disadvantages | Cost Implication |

|---|---|---|---|---|

| HASL (Hot Air Solder Leveling) | A process where molten solder is applied to the board and then leveled using hot air knives. | Low cost, good solderability, widely available. | Uneven surface, not suitable for fine-pitch components, contains lead (in leaded version). | Low |

| ENIG (Electroless Nickel Immersion Gold) | A two-layer metallic finish that coats the copper with nickel and then with a thin layer of gold. | Excellent solderability, good surface planarity, long shelf life, suitable for fine-pitch components. | More expensive, can suffer from 'black pad' issues if not properly processed. | High |

| OSP (Organic Solderability Preservative) | An organic coating that protects the copper from oxidation and enhances solderability. | Low cost, good planarity, environmentally friendly. | Short shelf life, sensitive to handling, may require specific soldering parameters. | Low |

| Immersion Tin | A metallic finish that applies a layer of tin over the copper. | Good solderability, good planarity, lower cost than ENIG. | Tin whiskers may grow over time, affecting reliability, shorter shelf life than ENIG. | Medium |

| Immersion Silver | A metallic finish that deposits a thin layer of silver over the copper. | Excellent solderability, good planarity. | Can tarnish over time, and is sensitive to contaminants. | Medium |

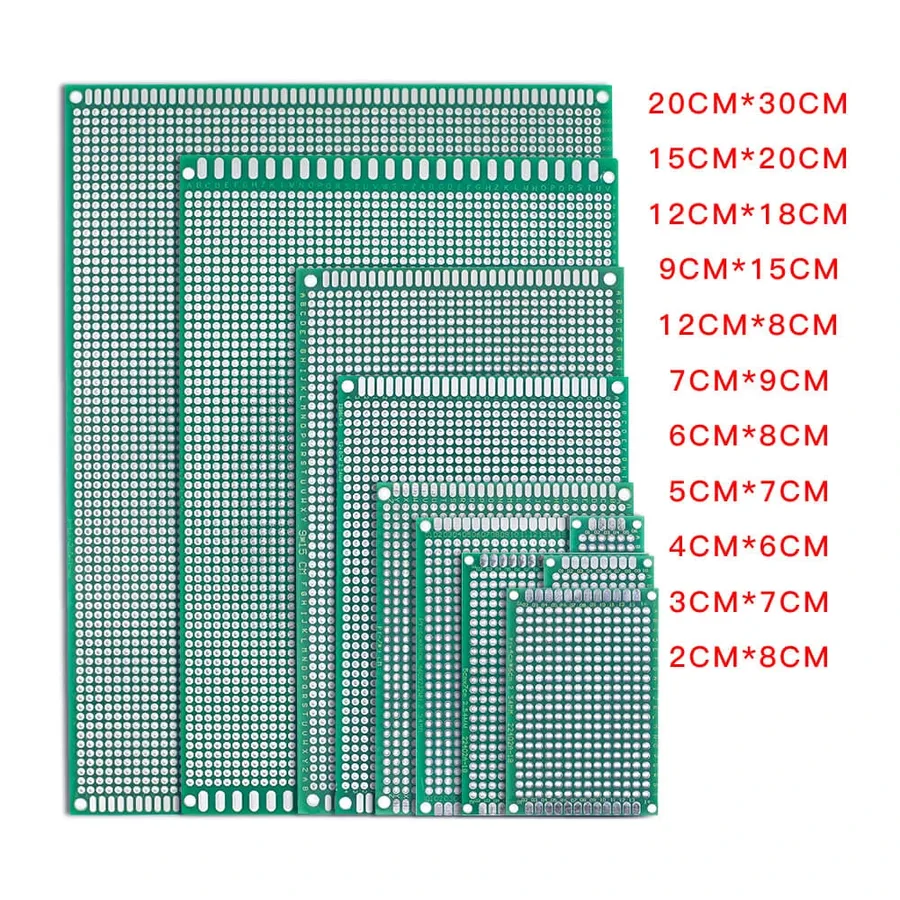

Understanding PCB Size and Its Effect on Pricing

The physical dimensions of a Printed Circuit Board (PCB) are a crucial determinant of its cost, directly influencing material consumption and processing time. Typically measured in square inches or square centimeters, a larger PCB necessitates more raw materials, such as substrate, copper, and solder mask, thereby increasing the overall production expense. The relationship between PCB size and price is not always linear, as larger boards may also incur higher processing costs due to increased handling complexity and specialized tooling requirements.

| PCB Size (Square Inches) | Relative Material Cost | Relative Processing Cost | Potential Impact on Price |

|---|---|---|---|

| Up to 5 | Low | Low | Minimal |

| 5 - 25 | Medium | Medium | Moderate |

| 25 - 100 | High | Medium to High | Significant |

| Over 100 | Very High | High | Substantial |

Production Volume and Economies of Scale

The quantity of PCBs ordered has a significant impact on the per-unit cost, primarily due to the principle of economies of scale. Larger production runs generally result in lower per-unit prices, while smaller runs, especially prototyping, tend to have higher costs. This variation is driven by the fixed costs associated with PCB manufacturing, which are spread across the total number of units produced.

| Order Volume | Typical Application | Per-Unit Cost | Considerations |

|---|---|---|---|

| Prototyping (1-10) | Initial design testing and validation | Highest | May involve additional setup fees, and quick turnaround times. |

| Small Batch (10-100) | Pilot runs, low-volume products | High to Moderate | Can be cost-effective for initial production, but still subject to higher per-unit costs. |

| Medium Batch (100-1000) | Moderate production runs, smaller scale product launches | Moderate to low | Better cost-efficiency due to economies of scale, ideal for early market entry. |

| Large Batch (1000+) | Mass production, high volume product needs | Lowest | Most cost effective due to optimized production, ideal for large scale deployments. |

- Fixed Costs

These costs, such as machine setup, tooling, and initial programming, remain relatively constant regardless of the order volume. Therefore, as the production quantity increases, these fixed costs are distributed across more units, resulting in a lower per-unit cost. - Variable Costs

These costs, such as materials, labor, and electricity, generally increase with production volume. However, these increases are often not linear, as bulk purchasing of materials can lead to reduced prices. - Prototyping Costs

Initial PCB prototype runs incur higher costs per unit due to the setup requirements and lower quantities, where it is important to consider initial high cost per unit before volume production is considered. - Bulk Ordering

When ordering PCBs in large quantities, the per-unit cost decreases significantly. This is because manufacturers can streamline the production process, reduce waste, and negotiate better prices with suppliers. This can lead to a more cost efficient outcome.

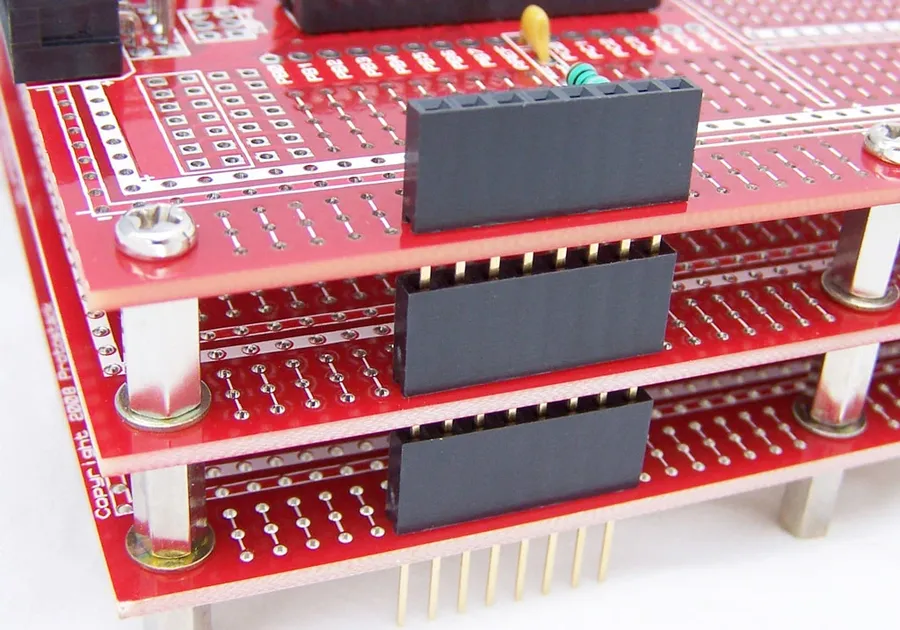

PCB Assembly Services and Associated Costs

The total cost of an electronic PCB board extends beyond the bare board fabrication and includes the assembly process. PCB assembly involves the placement of electronic components onto the bare board, soldering these components to establish electrical connections, and conducting tests to ensure the functionality of the assembled board. Each of these steps introduces associated costs that contribute to the final electronic PCB board price.

- Component Placement

Automated pick-and-place machines are commonly used for high-volume production, while manual placement may be used for prototypes or small runs. The accuracy and speed of placement, as well as the complexity of the board, influence this cost. The number of components and type (surface mount or through-hole) significantly impact assembly price. - Soldering

Soldering methods such as reflow soldering for surface mount technology (SMT) and wave soldering for through-hole components have different cost implications. The type of solder used, such as leaded or lead-free, also factors into the price. Proper soldering is critical for reliable connections and adds to the overall cost. - Testing

Post-assembly testing ensures the correct functionality of the assembled PCB. Methods include in-circuit testing (ICT), flying probe testing, and functional testing, each with varying cost implications. The depth and range of the testing will reflect directly on the final cost. - Other Factors

Additional cost factors include stencil costs for solder paste application, the cost of solder paste itself, cleaning and inspection of the boards, and the handling and packaging of the assembled PCBs.

Frequently Asked Questions About Electronic PCB Board Prices

Navigating the complexities of electronic PCB board pricing can be challenging. This section addresses common questions to provide clarity and practical guidance.

- How much does a PCB cost?

The cost of a PCB varies widely based on several factors, including material type, layer count, size, complexity, surface finish, and order volume. A simple, single-layer board might cost a few dollars, while a complex, multi-layered board with specialized finishes can cost significantly more. It's best to get a custom quote from a manufacturer. - Is it worth replacing a PCB board?

The decision to replace a PCB board depends on the board's value, the cost of replacement, and the potential risks associated with repair. If the board is relatively inexpensive and the cost of repair exceeds replacement, replacing the board makes more sense. For critical boards, repair might be the only option to avoid downtime. - What is the typical cost range for a basic PCB?

A basic PCB, typically a double-sided board made from FR-4 material with standard finish, can range from a few dollars for very small quantities to less than a dollar for large production runs. The cost will depend on the size of the board and the complexity of the design. However, this should be used as a benchmark for very basic designs only. - What does the term 'PCB cost' generally refer to?

When discussing 'PCB cost,' it usually refers to the manufacturing cost of the bare printed circuit board. However, it's important to consider associated costs, such as assembly, components, testing, and shipping. These additional costs can substantially increase the final price of a fully functional board. - How does the complexity of the PCB design affect its price?

More complex designs with finer traces, vias, and higher layer counts will result in higher manufacturing costs. Complex boards require more precision in fabrication, and they may have lower yields, which increases the per-unit cost. Additionally, advanced surface finishes add to the complexity and thus affect the price. - Can the quantity of PCBs affect the overall price?

Yes, absolutely. The unit price of PCBs usually decreases with larger quantities due to economies of scale. Manufacturers often have fixed setup costs; therefore, increasing the order volume spreads these costs across more units, resulting in a lower per-unit price. Ordering in bulk can lead to significant savings, particularly for long term projects. - Are there ways to reduce PCB costs without compromising quality?

Yes, there are several strategies to reduce PCB costs. These include optimizing the design for manufacturability, choosing a standard material, using standard component sizes and packages, minimizing the number of layers if possible, and considering alternative surface finishes. Partnering with a manufacturer early in the design phase can also lead to cost-saving recommendations.

How to Get the Best Electronic PCB Board Price: Tips and Strategies

Securing the best price for electronic PCB boards involves strategic planning, informed decision-making, and a keen understanding of the factors influencing cost. This section provides actionable strategies to lower your electronic PCB board price.

- Optimize Your PCB Design

Streamlining your PCB design is crucial. Reduce complexity by minimizing the number of layers, using standard component sizes, and avoiding unnecessary features. A simpler design generally translates to lower manufacturing costs. Consider Design for Manufacturability (DFM) principles early in the design process. - Select the Right Materials

Choosing the appropriate material is essential. While FR-4 is a cost-effective option, alternative materials may offer better performance for specialized applications, at a potentially higher cost. Analyze the requirements of your product and choose the material that provides the best balance of performance and price. - Consider Surface Finish Options

Surface finishes impact both the cost and reliability of your PCB. HASL is generally the most economical option, while ENIG offers better solderability and corrosion resistance but is more expensive. Choose a finish that meets your application needs without unnecessary expense. - Consolidate Your Orders

Take advantage of volume discounts. Ordering in larger quantities can significantly reduce the per-unit cost of your PCBs. If feasible, consider consolidating orders for different projects to meet minimum production quantities. This strategy leverages economies of scale to achieve cost savings. - Negotiate with Suppliers

Don’t hesitate to negotiate prices with multiple suppliers. Obtain quotations from various manufacturers and compare their offerings. Building strong relationships with suppliers can lead to more favorable terms. Be transparent about your budget and requirements. This often results in better pricing and service. - Standardize Components

Using commonly available components reduces the complexity for the assembly process. Standardizing on components you frequently use can drive costs down due to higher volume purchases and reduced inventory costs for the manufacturer. It simplifies the supply chain and ultimately results in lower prices. - Plan Ahead

Avoid rush orders. Last-minute changes and expedited shipping can dramatically increase costs. Plan your projects carefully and allow ample time for design, manufacturing, and delivery. This proactive approach saves you money and reduces stress.

Comparative Analysis of PCB Pricing: Vendors and Services

Selecting the right PCB vendor is crucial for controlling costs and ensuring quality. This section provides a comparative overview of different vendors, pricing models, and service offerings, designed to assist you in making an informed decision that aligns with your budget and project requirements.

| Vendor | Pricing Model | Service Offerings | Lead Time | Minimum Order Quantity (MOQ) | Specialization | Typical Electronic PCB Board Price |

|---|---|---|---|---|---|---|

| Vendor A | Tiered Pricing (based on quantity and complexity) | Prototyping, small-batch production, large-scale manufacturing | 1-3 weeks | 1-5 pieces for prototype; 100+ for bulk production | Specializes in high-layer count PCBs | Variable, with prototypes starting from $50 and bulk orders being $0.50 - $5 per board |

| Vendor B | Fixed Price per Board (for standard designs) | Quick-turn PCB fabrication, standard assembly services | 1-2 weeks | MOQ 5 pieces | Good for simple and standard PCBs | Standard designs from $2 to $8 per board, depending on board size |

| Vendor C | Quote-Based Pricing | Complex PCB fabrication, advanced assembly, design consultation | 2-4 weeks | 1 piece for complex prototypes, 50+ for bulk orders | Focus on complex designs, high reliability requirements | Complex designs and assemblies can range from $10 to $50+ per board |

| Vendor D | Subscription Based Pricing | PCB design, PCB fabrication, quick turn assembly | 1 week | 1 piece | Focus on rapid prototyping | subscription plans begin at $99 for a small number of simple designs, complex designs and assemblies can range from $5 to $20 per board |

**Notes:** * **Pricing Model:** Tiered pricing involves reduced per-unit cost with higher order quantities; Fixed price per board is straightforward with little flexibility for customizations or complexity; Quote-based pricing is suitable for more complex designs and assemblies, where costs are dependent on the specifications. * **Service Offerings:** Vendors may offer services ranging from prototyping to mass production. * **Lead Time:** The lead time varies from a week for basic PCBs up to 4 weeks for complex assemblies. * **Minimum Order Quantity:** MOQs can range from one for prototyping to hundreds or thousands for larger production runs. * **Specialization:** Vendors often specialize in types of PCBs. Some focus on high layer count, complex designs while others focus on standard, simple PCB's. * **Electronic PCB Board Price:** This price is a guideline. It is highly dependent on the board complexity, layer count, and surface finish.

Understanding electronic PCB board price involves navigating a complex web of factors, from material choices to manufacturing volume. By taking into account the key elements discussed in this article and performing a thorough cost-benefit analysis, you can make informed decisions that ensure your project's success while optimizing your budget. As technology advances, so too will PCB fabrication and pricing, making it an essential area of ongoing learning for engineers, makers, and businesses.

AnyPCBA

AnyPCBA