Understanding Induction Circuit Board Prices: A Comprehensive Guide

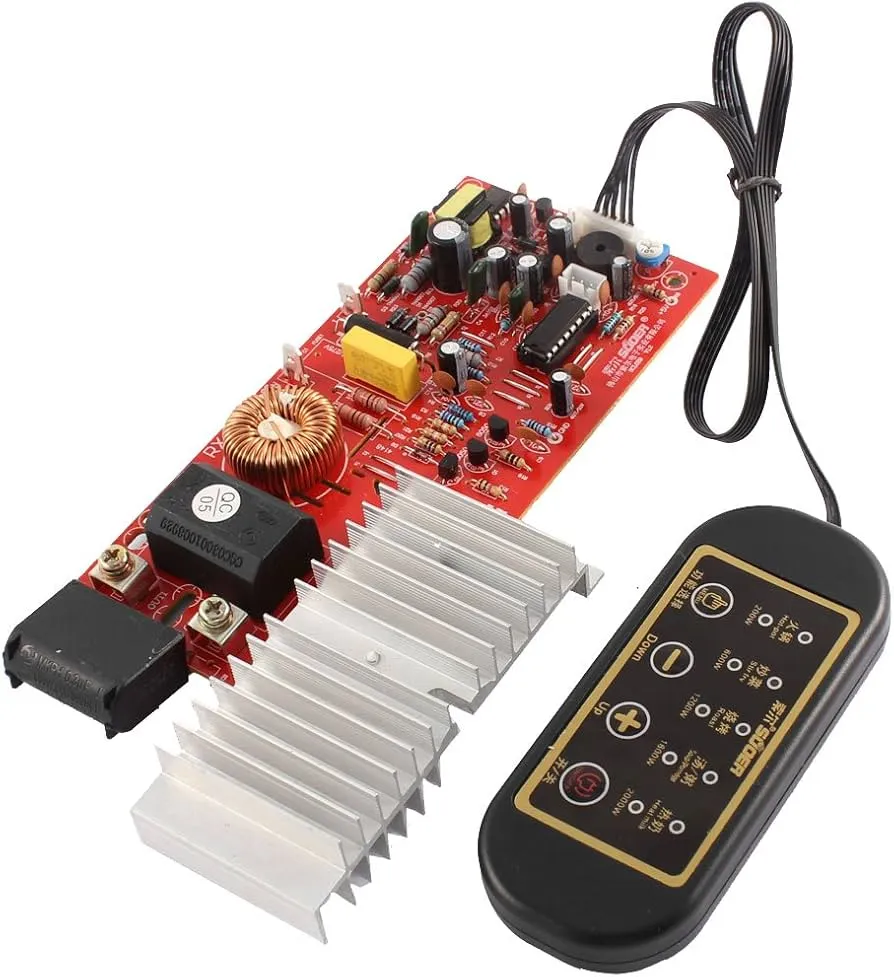

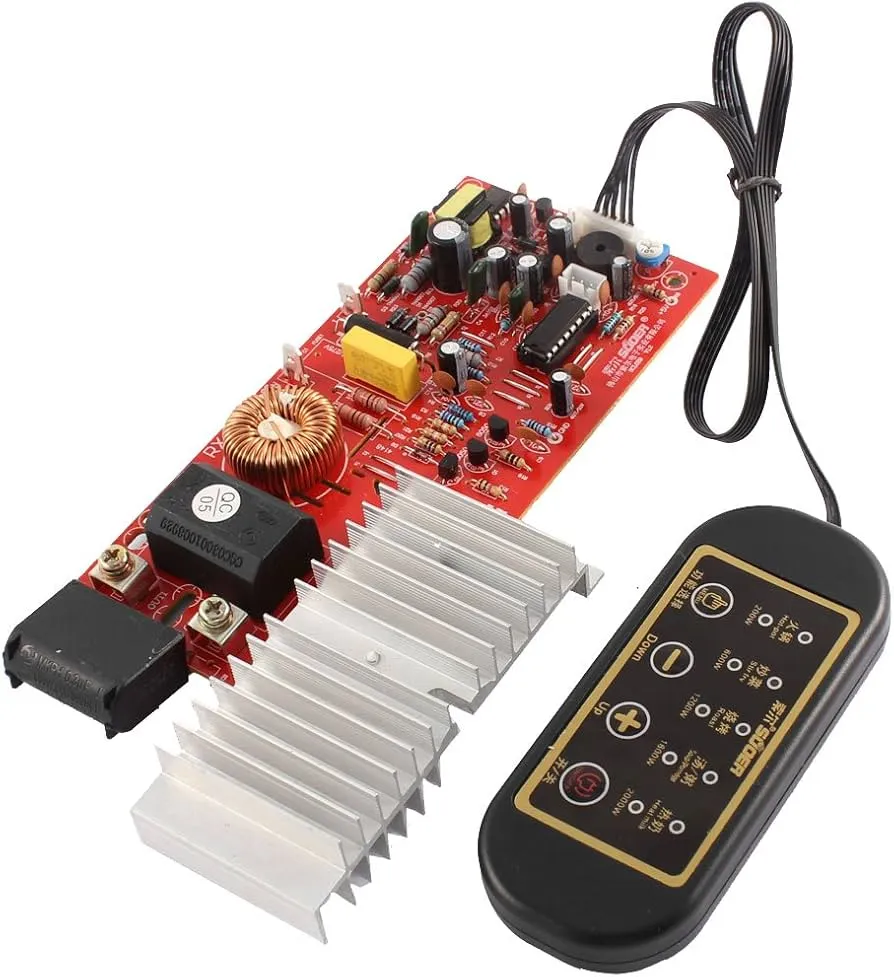

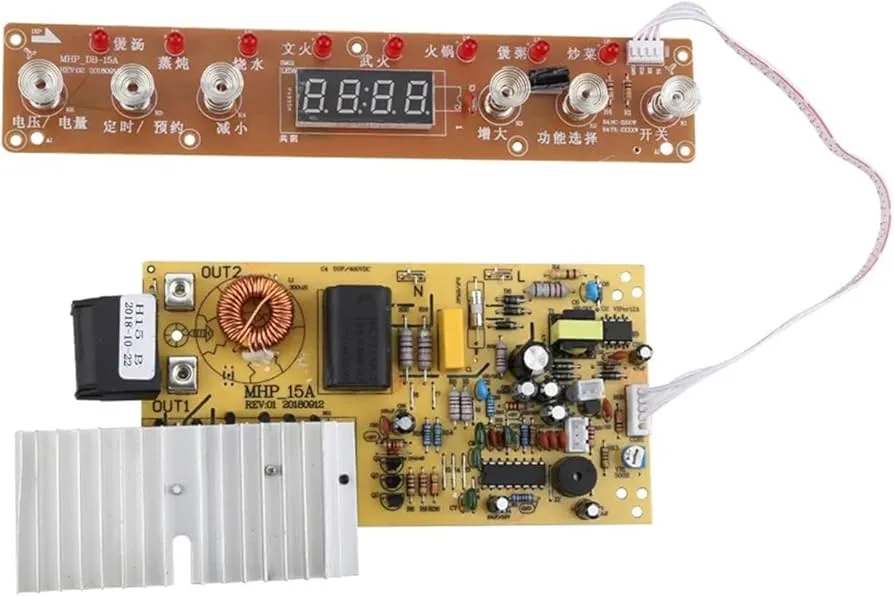

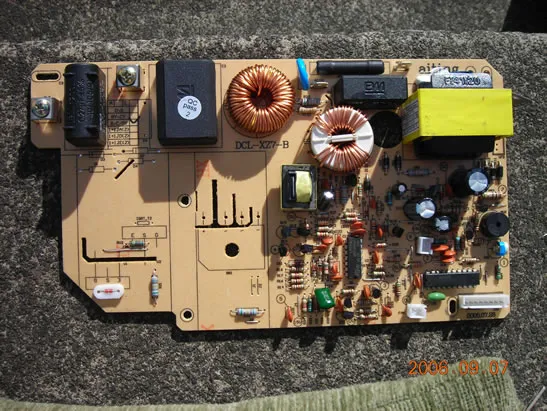

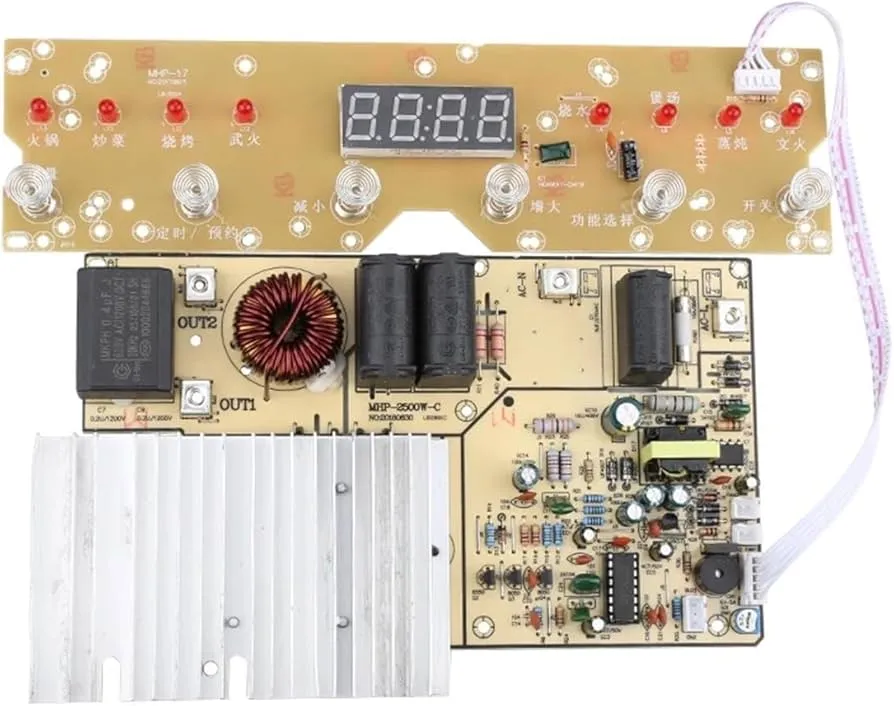

In today's tech-driven world, induction cooking has become increasingly popular, bringing efficiency and safety to our kitchens. At the heart of these appliances lies the induction circuit board, a key component that dictates performance and functionality. This article delves into the intricacies of 'induction circuit board price', examining the various aspects that influence cost and providing you with the knowledge to make well-informed decisions, whether you're looking to repair or replace your unit. Understanding the factors affecting induction circuit board costs is crucial for consumers, repair professionals, and electronics enthusiasts alike.

Factors Influencing Induction Circuit Board Prices

The price of an induction circuit board is not fixed; it fluctuates based on several key factors. These include the raw materials used, the intricacies of the design, and the chosen manufacturing processes. Understanding these elements is crucial for anyone looking to purchase or repair an induction cooktop.

| Factor | Description | Impact on Price |

|---|---|---|

| Material Costs | The type and quality of materials used, such as copper, fiberglass (for the PCB substrate), and electronic components, directly affect cost. Higher-grade materials lead to better performance and durability, but at a premium. | Higher material costs translate to higher overall board prices. |

| Design Complexity | Complex designs with multi-layered PCBs, sophisticated circuitry, and miniaturized components require advanced manufacturing techniques and testing procedures. | More intricate designs increase manufacturing costs due to increased complexity and precision requirements. |

| Manufacturing Processes | Production methods including etching, soldering, and component placement, each contribute to the cost. Advanced methods like surface-mount technology (SMT) and automated assembly lines can increase efficiency but come with higher initial investment costs. | Advanced manufacturing processes might increase cost but provide better product performance. |

| Production Volume | The quantity of circuit boards manufactured affects the per-unit cost. Larger production runs allow for economies of scale, reducing the overall cost per board. | High volume production lowers the price per unit. |

| Component Sourcing | The source of electronic components significantly impacts costs, with brand-name components typically being more expensive than generic alternatives. Furthermore, global market conditions and lead times can lead to fluctuations in component prices. | Brand-name components and supply chain challenges can increase component prices. |

| Quality Control and Testing | Rigorous quality control measures, including multiple stages of inspection and testing, impact the cost but ensure higher reliability. | Stringent quality assurance processes increase costs, but improve reliability. |

New vs. Replacement Circuit Boards: Cost Comparison

The decision between purchasing a new induction circuit board and replacing a faulty one is often driven by cost and the extent of damage. While a new board offers guaranteed performance and longevity, a replacement may seem more economical. This section will explore the factors influencing this cost comparison and provide guidance on selecting the most appropriate option.

| Factor | New Circuit Board | Replacement Circuit Board |

|---|---|---|

| Initial Cost | Higher, reflecting the price of a complete, new unit with warranty. | Potentially lower, depending on the source and condition of the replacement part. |

| Condition | Brand new, with full functionality and expected lifespan. | Variable, may be used, refurbished, or new-old stock. Condition can affect long-term reliability. |

| Warranty | Usually comes with a manufacturer's warranty, offering peace of mind. | May come with a limited warranty or no warranty at all, depending on the source. |

| Compatibility | Guaranteed to be fully compatible with the original induction unit. | Requires careful matching to ensure compatibility, potentially requiring research or expert advice. |

| Longevity | Expected to have a full service life if correctly installed and maintained. | Lifespan can be variable, based on the condition and history of the part. |

| Availability | Generally easier to find, especially for current models. | May be harder to source for older or less common induction unit models. |

Choosing between a new and a replacement circuit board is a matter of balancing initial costs against long-term value and reliability. If the existing board has a history of failures or the unit is older, investing in a new board may be the most cost-effective strategy. Conversely, for minor faults, a high-quality replacement may extend the service life of your induction cooktop without the larger initial outlay.

Induction PCB Repair Costs: When to Fix and When to Replace

Determining whether to repair or replace an induction cooktop's printed circuit board (PCB) involves a careful analysis of repair costs versus the price of a new board. While repair might seem like the cheaper option initially, it's crucial to consider the potential for recurring issues and the overall long-term cost-effectiveness.

| Factor | Repair | Replacement |

|---|---|---|

| Cost | Potentially lower upfront cost; varies based on damage complexity. | Higher initial cost, but new board with warranty. |

| Complexity of Damage | Viable for minor component-level issues, might not be feasible or cost-effective for severe damage. | Resolves all existing issues. |

| Long-Term Reliability | Repaired boards may have a higher risk of future failures. | New boards are reliable and come with warranty. |

| Labor Costs | Can include both diagnosis and repair labor charges. | Includes only replacement labor charges. |

| Downtime | Repair process can take time, especially if specialized parts are required. | Faster resolution with board replacement. |

| Availability of Parts | Sourcing specific components for repair can be challenging and time-consuming. | New board is readily available (dependent on brand/model). |

When deciding, consider the following points: If the cost of repairs exceeds 50% of a new board, replacement is usually more sensible. Component-level repairs might fix some problems, but often fail because of underlying circuit or overcurrent issues that are harder to diagnose and fix. In addition, when the damage is caused by severe events like liquid spillage, it is often much more difficult to completely fix all problems with the PCB.

Common Induction Circuit Board Issues and Their Impact on Price

Understanding common issues with induction circuit boards is crucial for assessing repair or replacement costs. These issues can range from minor component failures to significant damage affecting overall performance, directly influencing the price of solutions.

- Overheating Components

Excessive heat can damage sensitive electronic components on the board, such as MOSFETs, capacitors, and inductors. This can lead to reduced performance, intermittent functionality, or complete failure. Overheating is often a symptom of other underlying issues, such as poor design or component degradation and will need replacement of these failed components or even the whole PCB if the damage is extensive. The severity of damage dictates the cost of repair or replacement. - Capacitor Failure

Capacitors are prone to failure over time, especially electrolytic types, which can bulge or leak. A failed capacitor can lead to erratic behavior, reduced power output, or complete system shutdown and will need component level replacement if the PCB is not extensively damaged. The cost depends on the capacitor's type and the labor involved in replacement. - MOSFET or IGBT Failure

These semiconductor devices are key for switching power in the induction circuit. Failure of these components often results in no heat generation or erratic heating. Depending on the design, these components may be easy or difficult to replace on the PCB, therefore impacting the cost. Replacement cost is influenced by the specific device and its complexity. - Damaged or Burned Traces

High current or short circuits can cause damage or burn the copper traces on the PCB. Minor burns might be repairable, but extensive damage may require board replacement as repair may be unreliable. The complexity of trace repair contributes to the overall repair cost. - Connector Issues

Loose, corroded or damaged connectors can cause intermittent power supply and erratic circuit board behavior. Connector issues often lead to low performance and improper function. Repair costs depend on the type of connector, and if the PCB needs to be replaced. - Control Circuit Failures

Issues within the control IC's and related circuitry that manage the induction process may result in inaccurate heating or complete system failure. Replacing ICs requires specific tools and expertise, which increases repair costs as well as the cost of the chip itself.

Induction Circuit Board Prices Across Different Brands and Models

The pricing of induction circuit boards is significantly influenced by the brand and model of the appliance they are intended for. This variability stems from factors such as the manufacturer's design specifications, component quality, and brand recognition, all of which affect the final cost of the replacement part. This section explores these price variations among different brands, providing insight into how brand and model specifics can impact overall expenses.

| Brand | Typical Price Range (USD) | Factors Influencing Price |

|---|---|---|

| Pigeon | $15 - $40 | Generally lower-end market, simpler designs. |

| Philips | $30 - $70 | Mid-range market, moderate complexity, and better quality components. |

| Bajaj | $25 - $60 | Mid-range market, varying complexity, component quality comparable to Philips |

| Other Brands (Generic) | $10 - $30 | Lower cost, simpler design, variable quality. |

It is crucial to note that these price ranges are approximations and can fluctuate based on the specific model, retailer, and current market conditions. The table highlights that premium brands like Philips tend to have higher prices, reflecting their higher quality components and design, and the complexity of their boards. Generic boards are often the least expensive option but may not always be the best in terms of reliability and longevity.

The complexity of the circuit design also plays a significant role. More advanced features in high-end cooktops, like multiple heating zones and precise temperature control, require more complex circuit boards, which in turn leads to higher prices. Moreover, proprietary designs and components can contribute to a higher cost, as manufacturers may restrict sourcing to their approved vendors or maintain unique designs to deter unauthorized repairs.

Buying Guide: Where to Find Affordable Induction Circuit Boards

Sourcing an affordable induction circuit board requires careful consideration of various vendors and platforms. This section provides a comparative analysis of different online marketplaces, along with crucial advice on ensuring you purchase from a reliable source to avoid counterfeit or substandard components. The goal is to balance cost-effectiveness with the assurance of quality and reliability.

| Platform | Pros | Cons | Considerations |

|---|---|---|---|

| Amazon | Wide selection, generally fast shipping, customer reviews, buyer protection policies. | Prices can be higher than other platforms, some sellers may be unreliable, potential for counterfeit products. | Check seller ratings, read customer reviews carefully, verify product specifications before purchasing. |

| Alibaba | Direct access to manufacturers, bulk purchase options, potentially lower prices. | Longer shipping times, higher minimum order quantities, increased risk of fraud, less buyer protection compared to platforms like Amazon, quality control can be variable. | Ideal for bulk purchases, verify supplier credentials, obtain samples if possible, consider using a secure payment method like escrow. |

| AliExpress | Lower prices, wide variety of suppliers, smaller order quantities acceptable. | Longer shipping times, quality control can be variable, risk of counterfeit parts, limited buyer protection | Suitable for smaller orders, verify seller feedback, order samples for quality check, consider buyer protection options. |

| Specialized Electronics Distributors | High-quality components, detailed product specifications, reliable technical support, trusted by industry professionals. | Potentially higher prices, may not stock boards for all appliance models, less variety of brands. | Excellent for critical applications, prioritize quality over cost, use to find a reliable source of information. |

| Local Electronics Suppliers | Immediate availability, ability to inspect components before purchase, direct communication with supplier. | Limited selection, higher prices compared to online options, may not specialize in appliance circuit boards. | Use as a last resort when speed and inspection are the highest priorities or when specific parts are needed quickly. |

Frequently Asked Questions About Induction Circuit Board Prices

This section addresses common questions regarding induction circuit boards, their pricing, functionality, and related issues. These FAQs aim to provide clarity and assist users in making informed decisions.

- What is the average cost of an induction circuit board?

The average cost of an induction circuit board varies significantly based on several factors including brand, complexity, and required components. Generally, prices can range from $30 to $200 or more. Replacement boards for high-end models with complex features or uncommon designs will typically be more costly. It's also essential to factor in potential installation costs. Prices also fluctuate based on material costs, especially those of semiconductors. - What circuit is required for an induction cooktop to function?

Induction cooktops require a sophisticated power electronics circuit including a high frequency inverter and a microcontroller circuit for control. The core is an inverter circuit that generates a high-frequency alternating current (AC) which feeds the induction coil. This coil creates an alternating magnetic field, inducing heat in the cookware. Additional circuits support features such as user interface, safety protection, and power supply management. - Why are some induction circuit boards so expensive?

Several factors contribute to the cost of induction circuit boards. The primary driver is the cost of the materials, particularly the electronic components like IGBTs (Insulated Gate Bipolar Transistors) and microcontrollers, which can fluctuate based on market demand and supply. Design complexity also affects cost; boards with advanced control features or multiple zones require more sophisticated circuitry. Additionally, manufacturing processes, including the precision required for surface mount technology (SMT), add to the overall cost. - How does an induction cooker circuit actually work?

An induction cooker circuit operates by using an alternating current to generate a fluctuating magnetic field in the induction coil. When a ferromagnetic pan is placed on the cooktop, this magnetic field induces an electrical current within the pan's base. This induced current, due to the pan's electrical resistance, generates heat that cooks the food. The circuit includes sensors and controllers to regulate the power and ensure safe operation. - Are all induction cooktop circuit boards the same?

No, induction cooktop circuit boards are not all the same. They vary significantly depending on the brand, model, and features of the appliance. Higher-end models often have more complex circuit designs, incorporating advanced control systems, additional safety features, and more powerful components. Lower-end models tend to have simpler circuits with fewer features. Consequently, the replacement circuit boards are not interchangeable and require the correct model to ensure compatibility. - Can a damaged induction circuit board be repaired?

Yes, some damaged induction circuit boards can be repaired, especially if the damage is limited to specific components like capacitors, resistors, or diodes. However, the feasibility of repair depends on the extent and location of the damage. Issues with the main microcontroller or damaged PCB traces may be more difficult and potentially more costly to fix than replacement. It's often more economical to replace the board if a major component is faulty or the damage is widespread. - Where can I purchase replacement circuit boards for my induction cooktop?

Replacement induction circuit boards can be purchased from various sources. Direct purchase from the manufacturer of your cooktop is a reliable option, although often the most expensive. Online marketplaces like Amazon, eBay, and specialized appliance parts retailers are also common avenues but be cautious to verify the supplier's reputation. Also, local appliance repair shops may offer repair services or sell replacement boards. Always check for compatibility with your specific model before buying.

DIY vs Professional Installation: Impact on Cost

The decision between DIY and professional installation of an induction circuit board significantly impacts the overall cost. While DIY installations can save on labor costs, they also carry risks and may not be suitable for everyone. Professional installation, though more expensive upfront, ensures proper setup and may prevent future issues.

| Aspect | DIY Installation | Professional Installation |

|---|---|---|

| Initial Cost | Lower (primarily the cost of the circuit board) | Higher (includes cost of the board plus labor) |

| Skill Level Required | Requires basic electrical knowledge and comfort with handling electronic components. | No specific skill required |

| Time Investment | Can be time-consuming, especially for first-timers | Generally quicker |

| Risk of Damage | Higher, potential for improper installation or damaging the unit. | Lower, professionals have the expertise and tools. |

| Warranty | May void manufacturer's warranty if improperly installed. | Often comes with a labor warranty and ensures manufacturer's warranty is not voided. |

| Tools | Requires basic tools like screwdrivers, multimeters, and potentially soldering equipment. | Professionals have all the necessary tools, no extra investment needed. |

| Long-term Cost | Potentially higher if errors occur and require troubleshooting. | Potentially lower due to guaranteed correct installation and avoiding errors. |

Choosing between DIY and professional installation should be based on an honest assessment of your technical skills, availability of tools, and comfort level with electrical work. While the upfront cost of a DIY installation may seem appealing, the risks associated with incorrect installation could lead to more significant expenses in the long run.

Understanding the 'induction circuit board price' involves evaluating various factors, including the brand, model, repair complexity, and the source of the replacement. Whether you're opting for a repair or a full replacement, making an informed choice requires careful consideration of all these elements. As technology advances, the cost and efficiency of these boards will continue to evolve, emphasizing the importance of staying informed for the best solutions. This knowledge empowers you to make cost-effective and practical decisions regarding your induction cooking appliances.

AnyPCBA

AnyPCBA