Understanding Inverter Circuit Boards: Function, Types, and Maintenance

In our increasingly electrified world, the silent workhorses powering many of our devices and appliances are often tucked away and overlooked. Among these is the humble yet vital inverter circuit board. These sophisticated pieces of engineering serve as the heart of power inverters, converting direct current (DC) into the alternating current (AC) that our homes and businesses rely upon. From the solar panels on rooftops to the car chargers in our dashboards, the inverter circuit board ensures a smooth flow of usable energy. This article delves into the intricacies of these critical components, examining their function, types, and maintenance needs to give you a deeper understanding of their role in modern life.

What is an Inverter Circuit Board?

An inverter circuit board is the central control unit of a power inverter, tasked with the crucial function of transforming direct current (DC) into alternating current (AC). This conversion is fundamental for enabling devices that require AC power to operate from DC power sources such as batteries or photovoltaic panels, essentially bridging the gap between DC power generation and AC power consumption.

The Core Function of an Inverter Circuit Board

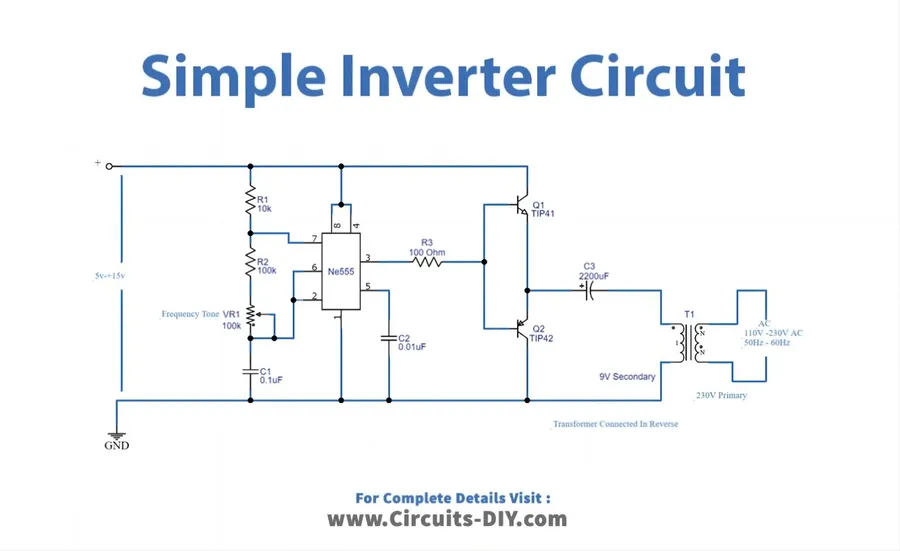

The fundamental role of an inverter circuit board is to convert a direct current (DC) input into an alternating current (AC) output. This conversion process involves rapidly switching the direction of the DC current using electronic components, thereby creating an AC waveform suitable for powering various devices.

At the heart of this operation are semiconductor devices, predominantly transistors like MOSFETs or IGBTs, which act as high-speed switches. These components, working in tandem with capacitors and inductors, manipulate the DC flow, creating the fluctuating voltage characteristic of AC. The precision and speed at which these switches operate determine the quality and characteristics of the output AC waveform.

| Characteristic | DC Input | AC Output |

|---|---|---|

| Current Type | Unidirectional | Bidirectional |

| Voltage | Constant | Varies sinusoidally or in steps |

| Frequency | Zero | Non-zero (e.g., 50 Hz or 60 Hz) |

Types of Inverter Circuit Boards

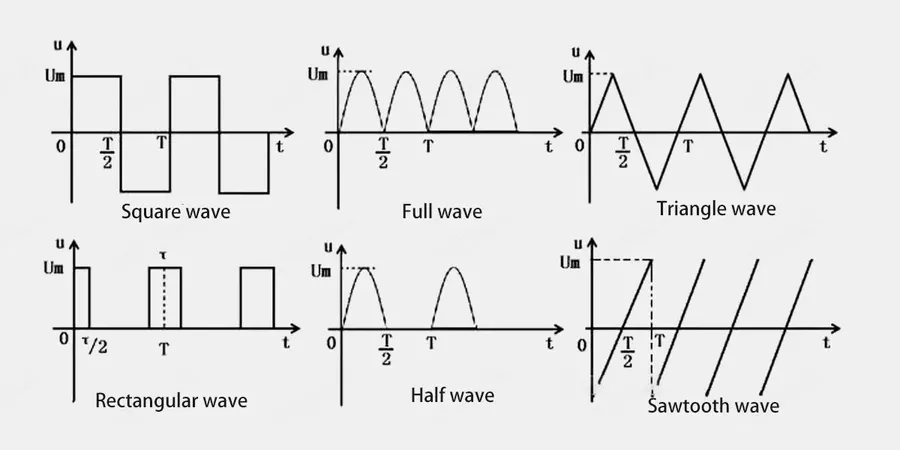

Inverter circuit boards are not monolithic; they are designed with varying specifications to cater to diverse application needs, power handling requirements, and AC waveform output. The three primary types are square wave, modified sine wave, and pure sine wave inverters, each with distinct characteristics and suitability for different applications.

| Type | Waveform | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Square Wave | Square | Simple applications, basic lighting, heating elements | Simplest and cheapest design | Not suitable for most electronic devices; can cause damage or malfunction |

| Modified Sine Wave | Stepped approximation of sine wave | Most common for basic electronics, power tools, and some appliances | More efficient and versatile than square wave; relatively inexpensive | Can cause slight issues with sensitive electronics; may produce audible hum |

| Pure Sine Wave | Smooth sine wave | Sensitive electronics, medical equipment, high-fidelity audio equipment | Produces the highest quality AC power; safe and efficient for all devices | More expensive and complex to manufacture; slightly less efficient at lower power levels |

The choice of inverter type significantly impacts the efficiency and safety of devices connected to it, requiring careful consideration of load requirements and waveform compatibility.

Understanding Waveforms: Square, Modified Sine, and Pure Sine

The output waveform of an inverter circuit board is a critical factor determining the suitability and efficiency of powering various devices. The three primary waveform types—square wave, modified sine wave, and pure sine wave—each possess distinct characteristics that affect how well they power AC equipment. A comprehensive understanding of these differences is essential for selecting an inverter that aligns with specific power requirements.

| Waveform Type | Description | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Square Wave | The simplest waveform; voltage rapidly switches between positive and negative values without a smooth transition. | Simple devices with low sensitivity, such as some basic lighting or heating elements. | Cost-effective and easy to produce. | Inefficient for most electronics; can damage sensitive devices; generates significant harmonic distortion. |

| Modified Sine Wave | An approximation of a sine wave; includes a flat step between positive and negative peaks. | Many household appliances, some power tools, and devices that are less sensitive to waveform distortion. | More efficient and versatile than square wave inverters; better tolerated by a range of devices. | May cause interference or overheating in some devices; not ideal for sensitive electronics. |

| Pure Sine Wave | A smooth, continuous waveform that closely resembles the AC power supplied by the electrical grid. | Sensitive electronics, medical equipment, audio/visual devices, and anything that requires clean and stable power. | Provides the highest quality power; safe and efficient for all types of devices; minimizes electrical noise and interference. | Most expensive type of inverter; more complex to manufacture. |

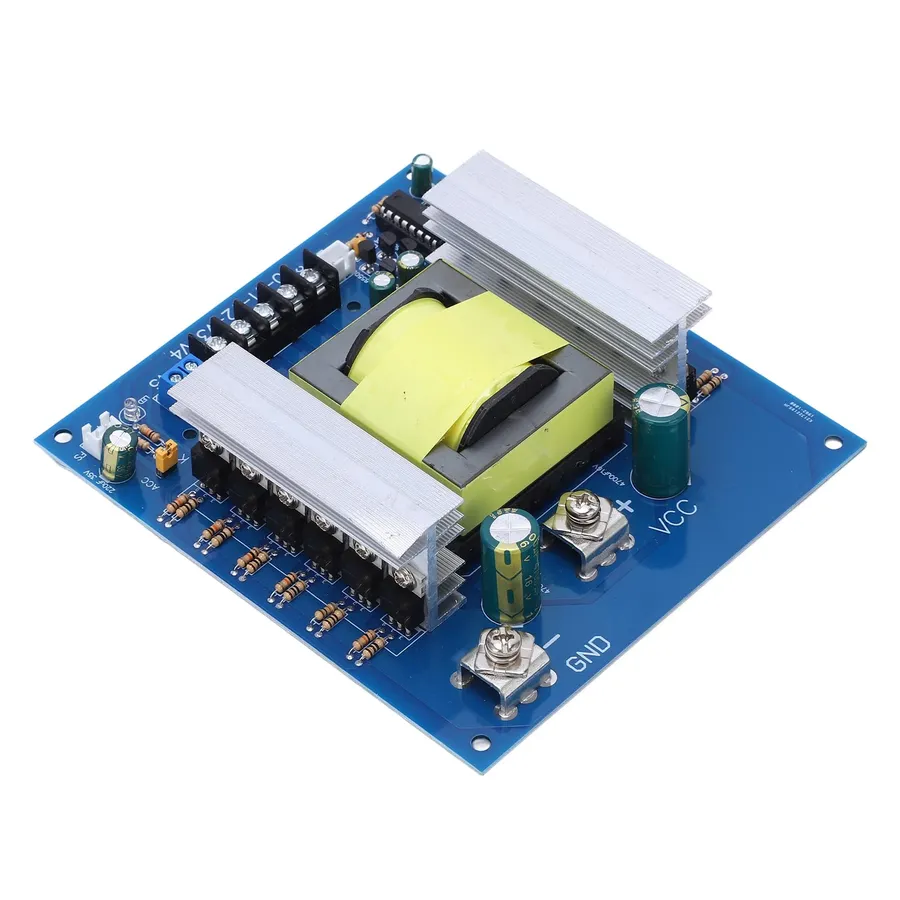

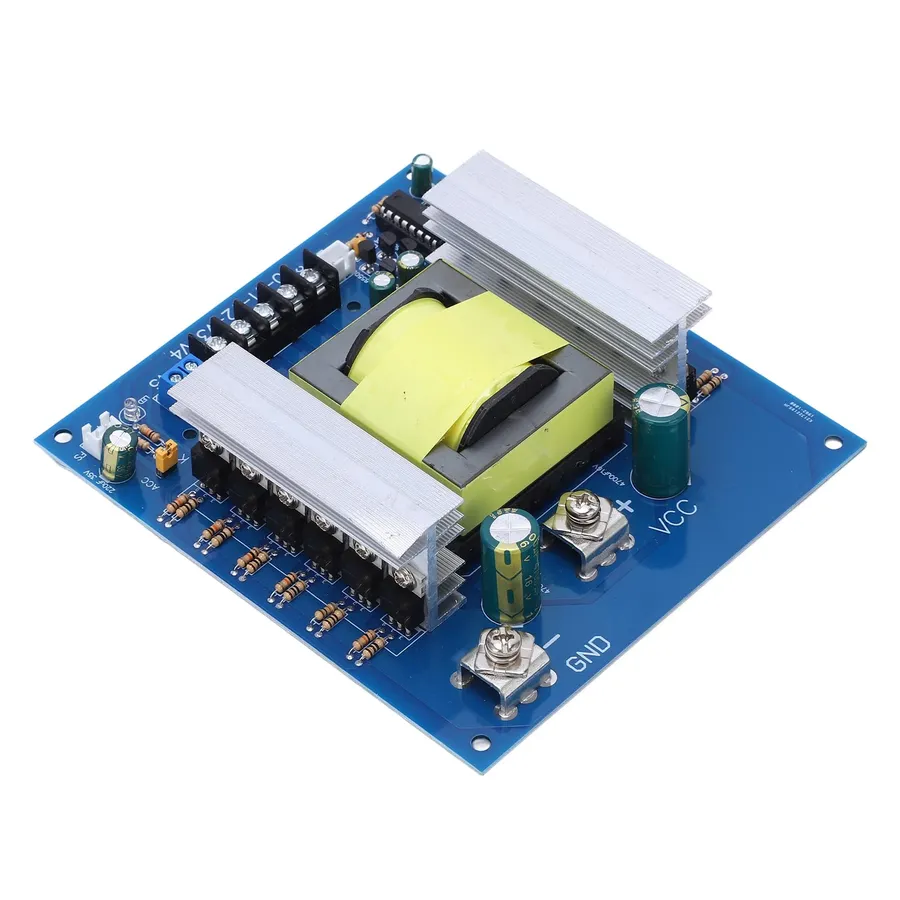

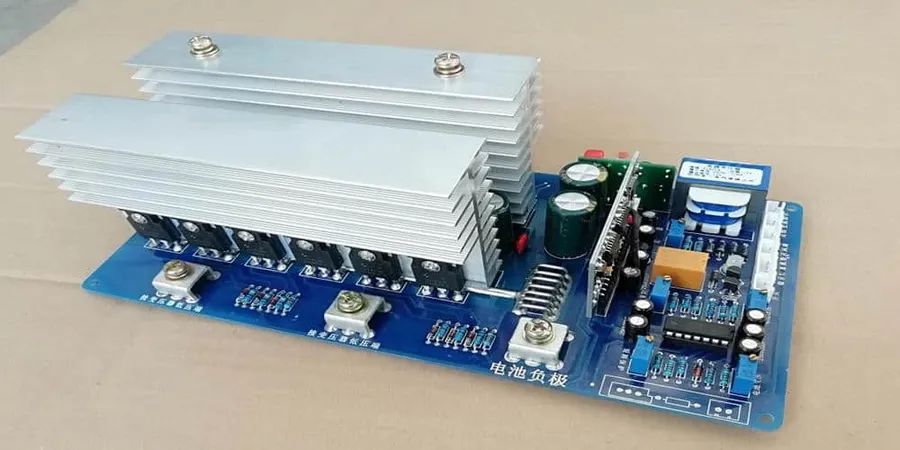

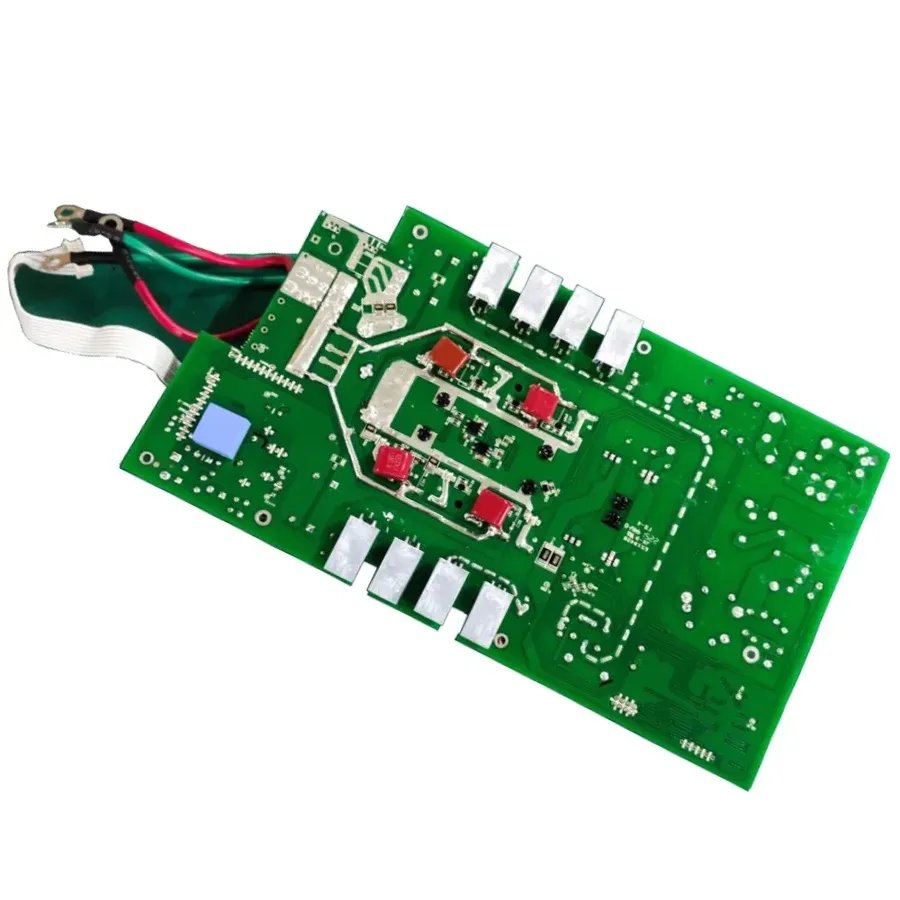

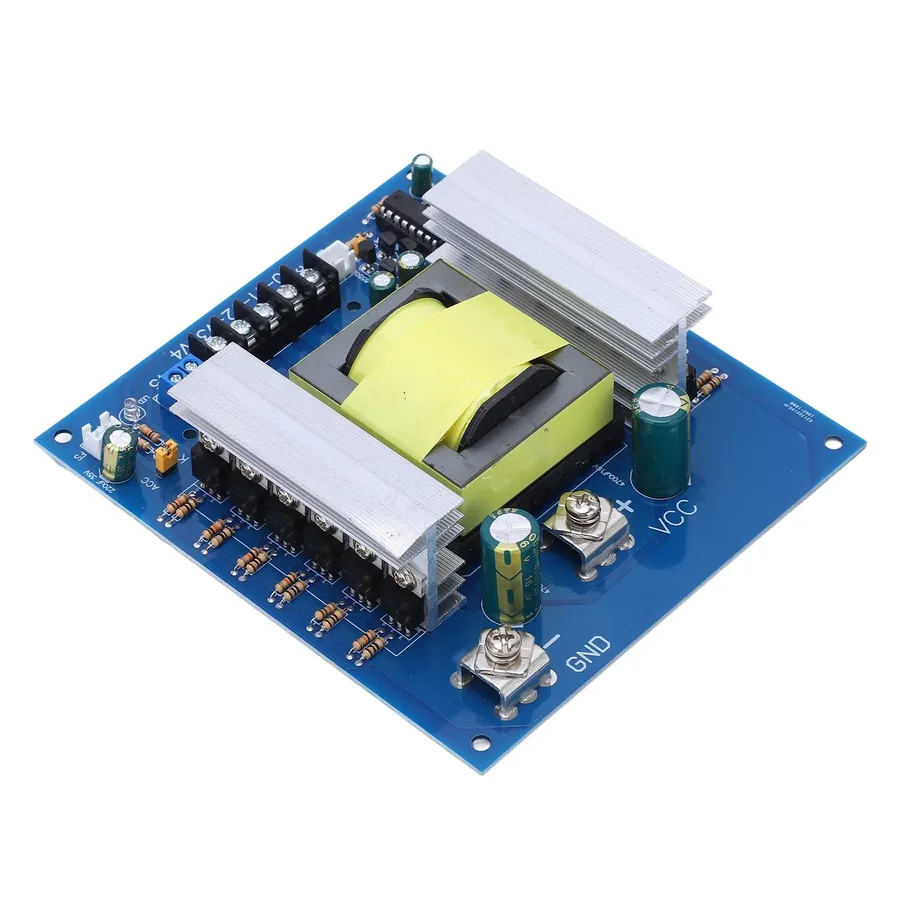

Key Components of an Inverter Circuit Board

An inverter circuit board's functionality hinges on the synergistic interaction of several key components, each playing a distinct yet vital role in the DC-to-AC power conversion process. These components not only enable the conversion but also influence the overall performance, efficiency, and reliability of the inverter.

| Component | Function | Significance |

|---|---|---|

| Transistors (MOSFETs, IGBTs) | Act as high-speed switches, controlling the flow of current to create AC waveforms. | Enable efficient and rapid switching, essential for generating AC from DC. |

| Diodes | Allow current to flow in one direction while blocking it in the opposite direction, often used for rectification and protection. | Crucial for protecting the circuit from reverse current and ensuring correct current direction. |

| Capacitors | Store electrical energy and release it as needed, used for smoothing voltage fluctuations and filtering noise. | Maintain stable voltage and smooth out the AC waveform, reducing voltage ripple. |

| Inductors | Store energy in a magnetic field, used for filtering and energy storage in power conversion circuits. | Help to shape the AC waveform and reduce harmonic content. |

| Controller (Microcontroller or IC) | Manages the operation of the entire inverter by controlling the switching of transistors and monitoring the output. | Acts as the brain of the inverter, ensuring accurate conversion and protecting against overloads and other faults. |

Selecting the Right Inverter Circuit Board

Selecting the correct inverter circuit board is crucial for ensuring the efficient and safe operation of any AC-powered device using a DC source. The selection process should primarily consider the power requirements of the intended load, the voltage characteristics of the DC source, and the desired quality of the AC output waveform.

| Factor | Description | Considerations |

|---|---|---|

| Power Requirements of the Load | The total power consumption (in Watts) of the AC devices that will be powered by the inverter. | Ensure the inverter's continuous power rating exceeds the total load to prevent overload. Account for startup power surges of appliances, which can be 2-3 times their running power. |

| Voltage of the DC Source | The voltage provided by the DC power source, such as a battery or solar panel. | The inverter must be compatible with the DC input voltage (e.g., 12V, 24V, 48V). Mismatched voltages can cause damage or malfunction. |

| Desired AC Output Waveform | The required quality of the AC output which could be Square Wave, Modified Sine Wave, or Pure Sine Wave. | Pure sine wave inverters are ideal for sensitive electronics. Modified sine wave inverters may work for basic devices.Square wave are rarely used and have limited compatibility. Consider the nature of the devices to be powered and choose accordingly. |

| Efficiency | The ratio of output AC power to input DC power. Higher efficiency means less power is wasted as heat, leading to longer battery life and lower running costs | Consider inverters with high-efficiency ratings for prolonged use or for applications involving solar power. A 90% efficiency inverter will output 90W of AC power for every 100W of DC input, 10W is lost due to heat |

| Protection Features | Features like overload protection, short-circuit protection, over-temperature protection, and low-voltage shut-off. | These features provide enhanced safety and prolong the inverter's lifespan. For example, low-voltage protection will protect the battery from fully depleting. |

Common Issues and Troubleshooting of Inverter Circuit Boards

Inverter circuit boards, while crucial for power conversion, are prone to several issues that can compromise their functionality and longevity. These issues primarily stem from the harsh operational conditions they endure, including high voltage and current switching, which generates significant heat. Understanding these common problems is essential for effective troubleshooting and maintenance.

Common problems with inverter circuit boards include overheating, which is often a result of inadequate cooling or component degradation over time. Component failure, such as transistors (MOSFETs, IGBTs), capacitors, and diodes, can occur due to thermal stress, electrical overloads, or manufacturing defects. Short circuits are also prevalent, typically arising from insulation breakdown, loose connections, or the ingress of foreign materials. These can lead to complete failure of the board and pose a safety hazard. Diagnosing these problems requires a systematic approach, starting with visual inspections for signs of damage, then utilizing diagnostic tools like multimeters to measure voltages and resistances to isolate the source of malfunction.

| Issue | Causes | Troubleshooting Steps |

|---|---|---|

| Overheating | Inadequate cooling, component degradation, high ambient temperature | Ensure proper ventilation, check heat sinks and cooling fans, monitor operating temperature, replace degraded components |

| Component Failure (Transistors, Capacitors, Diodes) | Thermal stress, electrical overloads, manufacturing defects | Visually inspect for damage, use multimeter to check component values, replace defective components |

| Short Circuits | Insulation breakdown, loose connections, foreign material | Visually inspect for burnt areas, check for loose wiring, clean debris, repair or replace shorted components |

Inverter Circuit Board FAQs

This section addresses frequently asked questions about inverter circuit boards, providing concise answers to common concerns regarding their function, failure modes, and essential maintenance procedures.

- What is the primary function of an inverter circuit board?

An inverter circuit board's core function is to convert direct current (DC) electricity into alternating current (AC) electricity. This conversion enables the use of battery or solar-generated DC power to operate devices designed for AC power. - Why are inverter circuit boards essential?

Inverter circuit boards are essential because many electronic devices and appliances rely on AC power, while sources like batteries and solar panels produce DC power. The inverter bridges this gap, making DC power sources usable for common AC loads. - What is the function of an inverter AC PCB board specifically?

The inverter AC PCB (Printed Circuit Board) specifically contains the necessary circuitry to transform DC into AC, including components like transistors, capacitors, and inductors. These components work in concert to generate a stable and usable AC waveform. - What are common reasons for inverter circuit board failure?

Inverter circuit boards often fail due to overheating, component degradation (such as capacitors drying out), short circuits caused by improper connections or physical damage, and environmental factors like moisture or dust accumulation, all of which degrade component performance and reliability. - How can I extend the lifespan of my inverter circuit board?

To extend the lifespan of an inverter circuit board, ensure proper ventilation to prevent overheating, conduct regular inspections for loose connections or damage, maintain a clean operating environment, and replace any failing components promptly. These practices help prevent premature failure and optimize performance. - Are there different types of inverter circuit boards?

Yes, inverter circuit boards vary significantly depending on the waveform they output – primarily square wave, modified sine wave, and pure sine wave. Each type has different applications and is optimized for specific loads, with pure sine wave inverters being the most versatile for sensitive electronics. - Can a faulty inverter circuit board be repaired?

Whether a faulty inverter circuit board can be repaired depends on the severity of the damage and the availability of replacement components. Minor issues, such as a failed capacitor, can often be repaired; however, extensive damage may necessitate a full board replacement. Professional assessment is usually recommended.

Maintenance Tips for Inverter Circuit Boards

Ensuring the longevity and reliability of inverter circuit boards hinges on consistent and careful maintenance. Proactive measures, such as routine inspections, proper cleaning, and adequate ventilation, are crucial in preventing common issues and extending the operational life of these critical components.

- Visual Inspections

Regularly inspect the circuit board for any signs of damage, such as burnt components, loose connections, or corrosion. Early detection of these issues can prevent more significant problems from developing. - Cleaning the Circuit Board

Dust and debris accumulation can cause overheating and component malfunction. Use compressed air or a soft brush to gently remove any particles. Avoid using liquids, unless specifically designed for electronic cleaning, as moisture can cause short circuits. - Ensuring Adequate Ventilation

Proper airflow is crucial to dissipate heat generated during operation. Ensure that the inverter's ventilation openings are not blocked and that the unit is placed in an environment with sufficient air circulation. Overheating is a primary cause of inverter circuit board failure. - Component Replacement

If a component shows signs of wear, damage, or if it fails, promptly replace it with a suitable, high-quality substitute. Regularly check the condition of capacitors and transistors, as these are frequent failure points. Only use components that match the original specifications to ensure proper operation and compatibility. - Tightening Connections

Periodically check all the electrical connections on the circuit board and ensure they are secure. Loose connections can cause intermittent operation, arcing, or other failures. Secure connections are essential for proper power transfer and safe operation.

The inverter circuit board is undeniably a key component in modern electrical systems, enabling us to utilize the energy stored in batteries and solar panels. Whether you're powering a small electronic device or running a household appliance, understanding the basics of inverter circuit boards is essential. By knowing their function, types, selection criteria, and maintenance needs, you can ensure the efficient and safe operation of your power inverter and the devices they supply. As technology evolves, so too will the design and capabilities of the inverter circuit board, but its foundational role in power conversion will remain crucial in an increasingly electricity-dependent world.

AnyPCBA

AnyPCBA