Understanding PCB Board AC Prices: A Comprehensive Guide

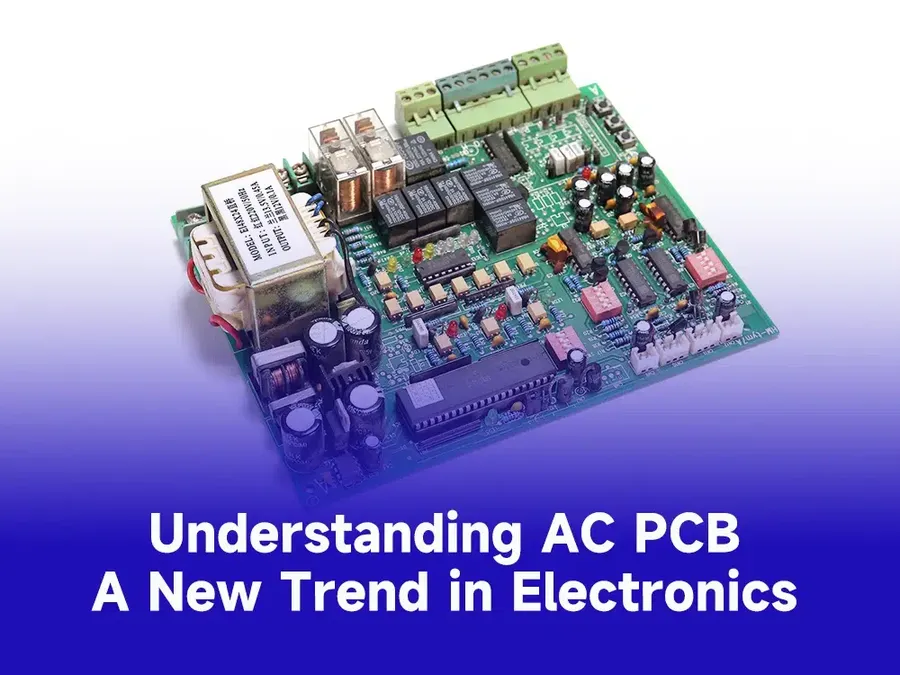

In today's world, air conditioners are indispensable for comfortable living, and at the heart of every AC lies its Printed Circuit Board (PCB). The PCB, the brain of the AC unit, controls all its functions. Whether you're dealing with a faulty PCB or exploring a replacement, understanding 'pcb board ac price' is crucial. This article will delve into the various types of AC PCBs, factors affecting their prices, and provide insights into repair versus replacement options.

Types of AC PCBs and Their Price Ranges

The price of an AC Printed Circuit Board (PCB) varies significantly based on its type and complexity. Generally, AC PCBs can be categorized into three main types: universal PCBs, inverter PCBs, and brand-specific PCBs, each designed to meet specific operational requirements and performance demands within air conditioning systems.

| PCB Type | Description | Typical Price Range (USD) | Complexity |

|---|---|---|---|

| Universal PCBs | Designed for broad compatibility across multiple AC brands and models; offers a cost-effective solution. | $20 - $80 | Low to Medium |

| Inverter PCBs | Incorporates advanced technology for variable-speed compressor control, enhancing energy efficiency and performance. | $80 - $250 | High |

| Brand-Specific PCBs | Manufactured by the AC brand for exact compatibility and optimal performance with their specific models. | $50 - $300+ | Medium to High |

Factors Influencing AC PCB Prices

The price of an AC PCB board is not fixed; it's a dynamic value shaped by a confluence of factors. Understanding these elements is crucial for both consumers and HVAC professionals seeking to navigate the market for 'pcb board ac price' effectively. These factors range from the core design and components to external market forces.

| Factor | Description | Impact on Price |

|---|---|---|

| Brand | Established brands often invest more in R&D and quality control. | Higher prices due to perceived quality and reliability. |

| Type (Inverter vs. Non-Inverter) | Inverter PCBs are more complex, offering variable-speed compressor control for higher energy efficiency. | Inverter PCBs are generally more expensive due to advanced technology and components. |

| Design Complexity | The intricacy of the PCB design, including the number of layers and components. | More complex designs often mean higher prices due to increased manufacturing costs. |

| Materials Used | The quality and type of materials such as copper, FR-4, and electronic components. | Higher-grade materials impact cost significantly due to better performance and durability. |

| Market Demand | Current supply and demand dynamics affect prices based on production volumes and availability. | High demand or limited supply can lead to increased prices and vice-versa. |

Universal vs. Brand-Specific AC PCBs: Cost Comparison

When considering the 'pcb board ac price,' a crucial decision arises between universal and brand-specific AC PCBs. This section provides a comparative analysis of their cost-effectiveness, compatibility, and long-term reliability, empowering informed choices.

| Feature | Universal PCBs | Brand-Specific PCBs |

|---|---|---|

| Initial Cost | Generally Lower | Generally Higher |

| Compatibility | Designed to work with multiple brands/models; may require some adjustments | Designed to work with a specific brand/model |

| Installation | May require more technical knowledge or professional assistance due to possible configuration adjustments. | Usually straightforward, designed for the specific unit. |

| Availability | Widely available and accessible | May be harder to find, especially for older models. |

| Reliability | Can vary in quality depending on the manufacturer; reliability not always guaranteed. | Generally high reliability; quality control standards are usually higher. |

| Warranty and support | Warranty may be limited or less comprehensive. | Usually backed by the manufacturer; may have better warranty and support |

| Long-term costs | Potentially lower upfront cost, but the long-term costs might increase due to reliability issues and potential compatibility issues. | Higher initial cost, but better long-term value due to high reliability, optimal performance, and ease of replacement. |

Universal PCBs are engineered to function across a broad spectrum of AC units, offering an attractive, lower-cost alternative. However, the 'pcb board ac price' advantage should be weighed against potential risks of compatibility and reliability. Brand-specific PCBs, though pricier, are tailored for optimal performance with specific models, thereby reducing compatibility risks and usually offering better long-term reliability and manufacturer support.

Inverter AC PCB Pricing: What to Expect?

Inverter AC PCBs typically command a higher price point compared to their non-inverter counterparts due to the sophisticated technology they incorporate. This increased cost reflects the advanced functionality and improved energy efficiency offered by inverter systems, which directly impacts the overall 'pcb board ac price'.

The core difference lies in the inverter's ability to modulate the compressor speed, leading to more precise temperature control and reduced energy consumption. This feature necessitates more complex circuitry and higher-grade components, translating to a higher manufacturing cost and thus, a higher price for the PCB.

| Feature | Inverter AC PCB | Non-Inverter AC PCB |

|---|---|---|

| Compressor Control | Variable Speed | Fixed Speed |

| Energy Efficiency | Higher | Lower |

| Components | Advanced, More Complex | Simpler |

| Price | Higher | Lower |

Several factors contribute to the higher 'pcb board ac price' for inverters. These include the presence of power modules, microcontrollers, and sensors that enable variable frequency drives. The design intricacy and stringent manufacturing process further add to the cost.

While the initial investment for an inverter AC PCB might be substantial, it's important to consider the long-term benefits, including reduced electricity bills and increased lifespan of the AC unit. This long-term value proposition often outweighs the higher initial cost.

Repairing vs. Replacing AC PCBs: A Cost Analysis

Determining whether to repair or replace a faulty AC PCB is a critical decision that hinges on several factors, primarily the cost implications, the age and condition of the AC unit, and long-term reliability considerations. A thorough cost analysis is crucial to ensure the most economical and practical solution, especially when considering the overall 'pcb board ac price'.

| Factor | Repair | Replacement |

|---|---|---|

| Initial Cost | Generally lower, focusing on component-level repairs. | Significantly higher, involving the cost of a new PCB. |

| Complexity | Depends on the extent of the damage; simpler repairs are cost-effective. | Straightforward in terms of installation, but includes procurement time. |

| AC Unit Age | Cost-effective if the AC unit is relatively new; may not be worthwhile for very old units. | Viable option regardless of the AC unit's age, assuming the unit is still serviceable. |

| Long-Term Reliability | Reliability can vary depending on the quality of repair; risk of recurring issues. | Offers better long-term reliability due to the use of a new board with a warranty. |

| Availability | Replacement components may be unavailable for some AC boards. | AC Boards may not be available for older models |

| Expertise Needed | Requires specific technical skills for diagnosis and repair. | Less technical knowledge is needed for installation, but is essential. |

A detailed cost analysis should include not only the immediate expense of repair or replacement, but also consider potential future costs related to recurring issues or reduced energy efficiency. When considering a repair, the diagnosis cost should be included in the calculation, and when considering the replacement, the time and cost of installlation should also be considered.

DIY PCB Replacement vs. Professional Installation: Cost Implications

Deciding between replacing an AC PCB yourself and hiring a professional involves a critical evaluation of cost versus risk. While DIY replacement can initially appear cheaper, it’s crucial to factor in the potential for errors, damage, and the long-term implications for your AC unit's performance and longevity. Professional installation, while more expensive upfront, provides expertise, warranty, and typically reduces the risk of future complications.

| Factor | DIY Replacement | Professional Installation |

|---|---|---|

| Initial Cost | Lower (parts cost only) | Higher (labor + parts) |

| Risk of Damage | High (potential for incorrect wiring, damage to other components) | Low (experienced technicians, proper tools) |

| Warranty | Typically none | Often provided on parts and labor |

| Expertise | Limited to your own skill set | High level of expertise and knowledge |

| Time Commitment | Significant, requires time for research and execution | Minimal, typically scheduled and completed efficiently |

| Long-term Cost | Potentially higher due to errors and lack of warranty. | Lower due to professional work and warranty. |

| Tools | Requires own or rented tools. | All tools provided. |

The cost trade-off extends beyond the immediate expense. Incorrect installation can lead to further damage, requiring additional repairs or even premature replacement of the entire AC system. Thus, a seemingly cheaper DIY route can sometimes result in a higher total cost in the long run. The overall impact on 'pcb board ac price' is significant, with professional installation often proving to be a worthwhile investment for peace of mind and the continued operation of the AC unit.

Frequently Asked Questions About AC PCB Board Prices

This section addresses common queries regarding AC PCB board prices, repair costs, and replacement options, providing clarity on factors influencing the final expense.

- What is the average cost to repair an AC PCB?

The average cost to repair an AC PCB varies widely based on the complexity of the damage and the technician's labor costs. Simple repairs, such as replacing a capacitor or a relay, can range from $50 to $150. Complex repairs or component-level troubleshooting can range from $150 to $300 or more. It's often more economical to replace the board if the repair cost exceeds 50-60% of a new PCB's cost. - How much does a complete AC PCB board replacement typically cost?

The cost to replace an AC PCB board differs by the type and brand. Universal boards range from $30 to $100, whereas brand-specific or inverter boards can range from $100 to $300+. Consider additional expenses like professional installation, which varies from $50 to $150+ . The total cost can thus range from $80 to over $450. Inverter PCBs generally have a higher cost due to advanced components and technology. - Is it generally feasible to repair an AC PCB, or is replacement usually necessary?

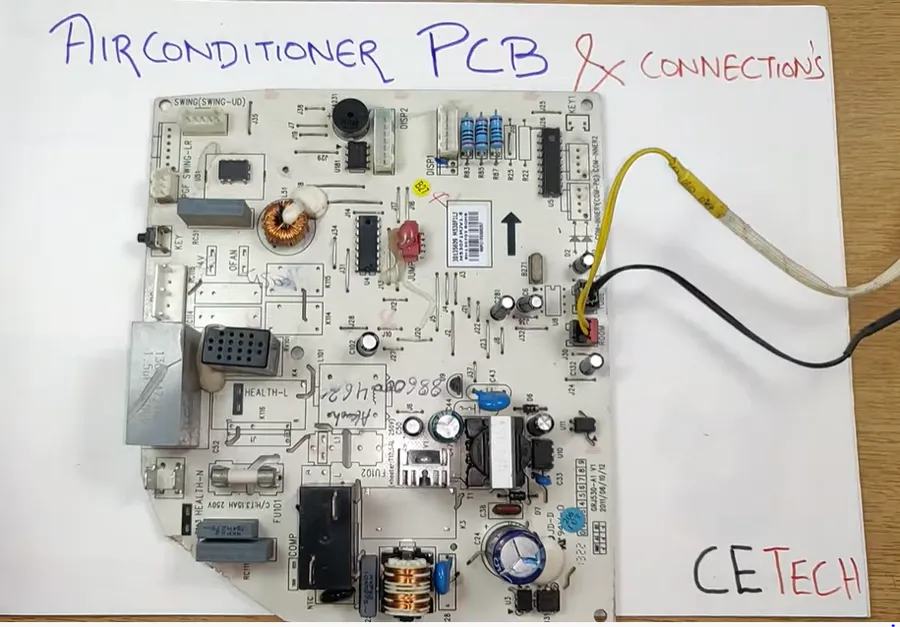

Repairing an AC PCB is feasible if the damage is minor, and the faulty components can be identified. However, if the damage is extensive, or involves multiple failed components, replacement is a better option. Factors like the age of the PCB, the availability of replacement parts, and repair costs compared to replacement cost play a role. A general rule of thumb is to consider replacement if repair costs are more than 60% of the new board's price. - How do I determine the specific cost of an AC PCB board for my unit?

To find the specific cost, begin by identifying the brand and model of your AC unit, and the exact PCB part number or the PCB board model number printed on the board. This can typically be found on the board itself. Then you can search online through reliable vendors and compare prices, or contact the AC manufacturer or authorized part distributors to get the accurate cost of your required PCB board. Prices may vary widely, so be sure to verify product compatibility. - Are there significant price differences between universal and brand-specific AC PCBs?

Yes, there are usually significant price differences. Universal PCBs are designed to work with multiple AC brands and are often more affordable, with prices ranging from $30 to $100. Brand-specific PCBs, manufactured for specific AC models, typically have more features and precise compatibility, making them more expensive, often costing $100 to $300 or more. Additionally, inverter PCBs designed for variable speed compressors typically cost more than non-inverter PCBs, often being more than double the cost. - Why are inverter AC PCBs more expensive than non-inverter PCBs?

Inverter AC PCBs are more costly due to their advanced technology and complex design. They require more components, sophisticated microcontrollers, and more precise manufacturing. The advanced circuit design for inverter functionality, including variable speed control, leads to increased costs. Additionally, inverter PCBs often have additional protection circuits, further increasing production costs. - What is the cost of an Inverter AC Outdoor PCB?

Inverter AC outdoor PCBs often have higher cost compared to indoor unit PCBs, due to the complexity of their control circuits, often including the compressor and fan motor control. Prices typically range from $150 to $400, with high-end models exceeding this range. It's essential to verify compatibility with the specific AC model prior to purchase to guarantee proper function.

Where to Buy AC PCBs and What to Watch Out For

Purchasing AC PCBs requires careful consideration to ensure you obtain a genuine, compatible, and reliable component at a fair price. Whether you're buying online or offline, understanding the risks and necessary precautions is crucial to avoid counterfeit products and ensure value for your investment in a 'pcb board ac price'.

- Online Marketplaces

Online platforms offer a wide range of AC PCBs, often at competitive prices. However, they also pose a higher risk of counterfeit products. Prioritize reputable sellers with positive reviews and clear return policies. Verify seller credentials and product specifications before committing to a purchase. - Authorized Distributors

Purchasing from authorized distributors ensures the authenticity and quality of the AC PCB. While prices may be slightly higher, the peace of mind regarding product quality and warranty coverage is often worth the extra cost. - Local Retailers

Local electronic component retailers can offer a direct buying experience. Evaluate their reputation and verify that they stock genuine, reliable parts. This option allows for physical inspection of the PCB before purchase and often provides immediate availability. - Manufacturer-Direct

Purchasing directly from the AC unit manufacturer is generally the safest route for ensuring compatibility and authenticity, especially for brand-specific PCBs. However, this option may be more expensive and have longer lead times. - Beware of Counterfeit Products

Counterfeit PCBs often look identical to genuine ones, but they use inferior components, which can lead to poor performance and premature failure. Be wary of drastically low prices and unfamiliar brands. If the price seems too good to be true, it probably is. - Warranty and After-Sales Support

A warranty provides protection against defects and malfunctions, ensuring you're not left with a faulty product. Inquire about the warranty period and the return/replacement policy. Also, ensure that the seller offers adequate after-sales support for any issues that might arise. - Technical Specifications

Before purchasing, carefully verify the technical specifications of the PCB, including its model number, compatibility, and revision. Confirm that the specifications match your AC unit to avoid incompatibility issues. It can also be useful to cross reference the model with any available compatibility charts or guides provided by the manufacturer.

Understanding the 'pcb board ac price' is vital for making informed decisions about your AC unit's maintenance. By considering the type of PCB, cost factors, and repair options, you can ensure efficient operation and long-term reliability. Whether you opt for a cost-effective universal board or a more advanced inverter model, remember to always prioritize quality and compatibility. As AC technology continues to advance, staying informed about PCB prices and repair options will empower you to maintain a comfortable living environment.

AnyPCBA

AnyPCBA