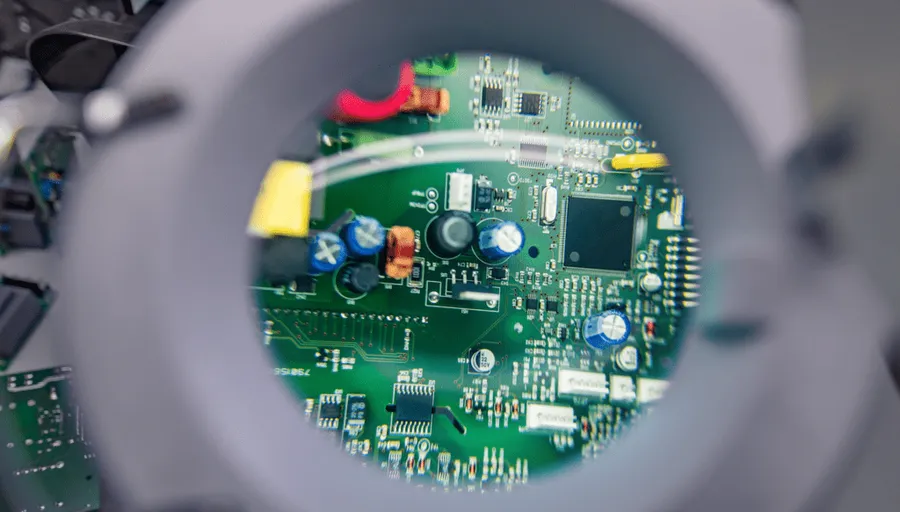

Understanding PCB Controllers: Core Functionality and Applications

From the smart devices we use every day to the complex machinery that powers industries, Printed Circuit Board (PCB) controllers are the unsung heroes, quietly orchestrating the flow of electricity and information. This article delves into the world of PCB controllers, exploring their core functionality, diverse applications, and why they're indispensable in modern electronics. We'll unveil their crucial role by bridging the gap between complex technology and easy to understand applications of controllers in our everyday life.

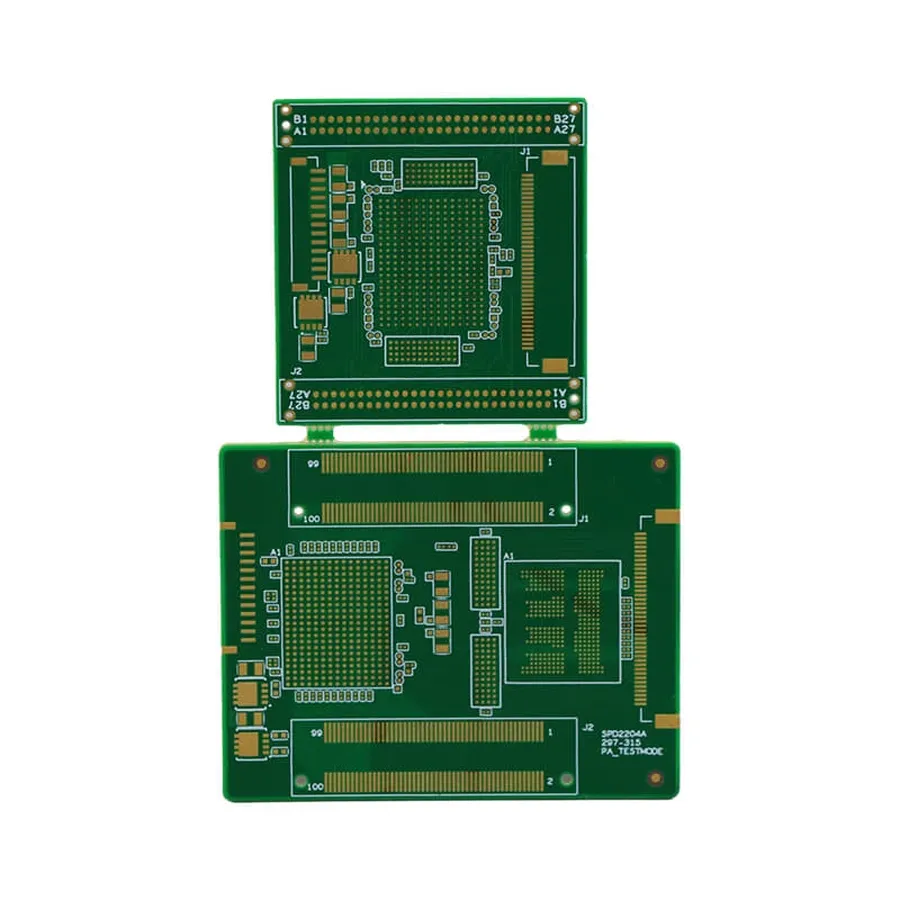

What is a PCB Controller?

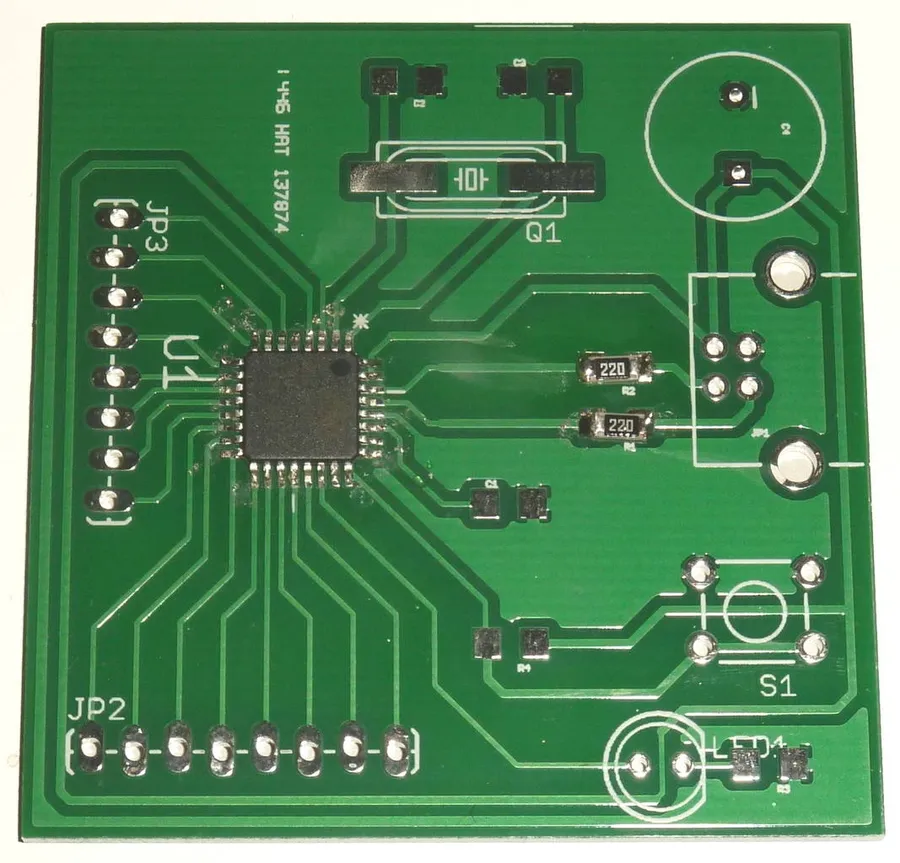

A PCB (Printed Circuit Board) controller is fundamentally a microcontroller or integrated circuit (IC) that acts as the 'brain' of the circuit board. It is responsible for governing the operation of the PCB, managing and coordinating the various electronic components. These controllers dictate the flow of electrical signals and dictate logical operations based on its programmed instructions.

At the heart of a PCB controller are core components such as the central processing unit (CPU), memory (RAM, ROM, or Flash), input/output (I/O) interfaces, and various peripherals. The CPU processes instructions, memory stores data and program code, and I/O interfaces allow the controller to interact with external components. Peripherals include timers, analog-to-digital converters (ADCs), and communication interfaces, allowing the controller to handle a wide array of functions.

Core Functions of a PCB Controller

A PCB controller serves as the central processing unit of a printed circuit board, executing a range of essential functions critical to the operation of the electronic device it inhabits. These functions primarily revolve around data processing, signal management, and power regulation, collectively ensuring the PCB functions according to design specifications.

Fundamentally, a PCB controller's core functions can be broken down into the following key areas:

- Data Processing

The controller processes input data from various sources, performs necessary calculations or logical operations based on pre-programmed instructions, and generates corresponding outputs. This can range from simple data comparisons to complex mathematical computations. - Signal Management

A PCB controller is responsible for managing both digital and analog signals, routing them within the PCB to ensure proper data communication between components. This includes signal amplification, filtering, and timing control. - Power Regulation

The controller manages the distribution of power across the board, often through a voltage regulation process. This function is crucial for maintaining the correct operating conditions for all components and ensuring stability and safety. It may also monitor voltage and current levels for specific components on the PCB, and protect them from damage. - Timing and Synchronization

Many electronic systems rely on precise timing for proper operation. A PCB controller generates clock signals and other timing references to synchronize the activities of various components, ensuring the correct order of operations. - Peripheral Communication

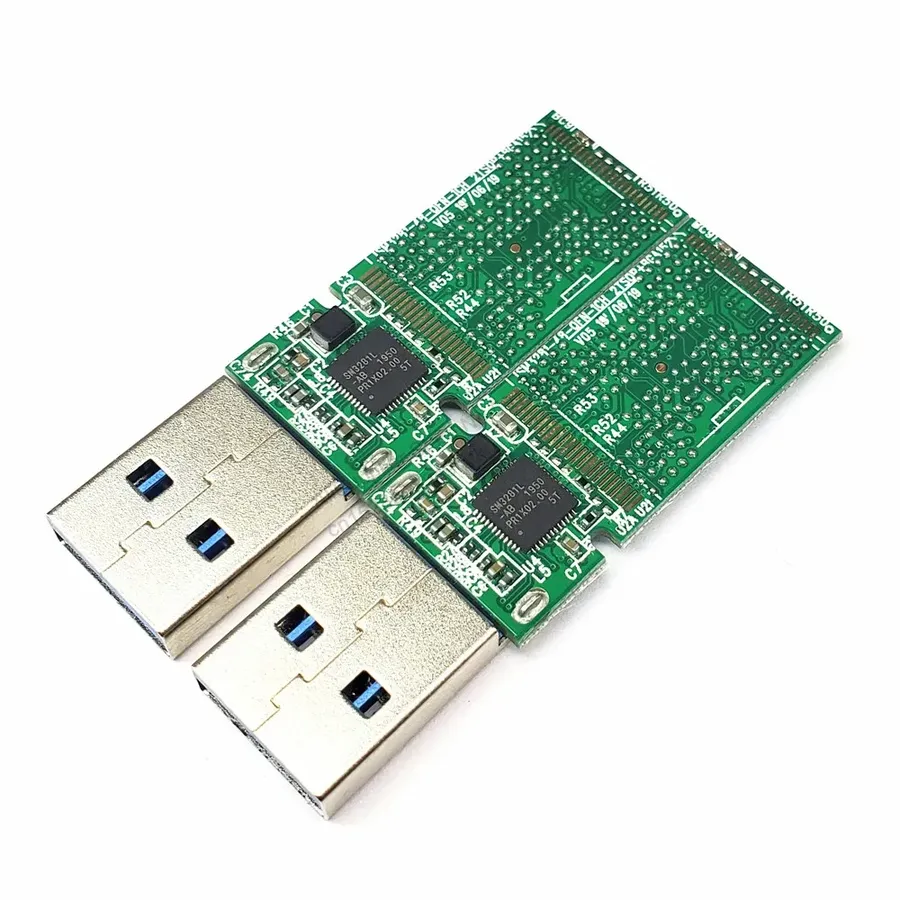

Controllers commonly interface with external devices or peripherals using communication protocols such as SPI, I2C, UART, and USB. They manage the exchange of data between the PCB and other systems or components.

For example, in a simple temperature control system, a PCB controller would receive data from a temperature sensor, process this data to determine if the temperature is within the desired range, and then manage the activation of a heater or cooler accordingly. In more complex systems like motor drives, the controller regulates the speed and torque of the motor based on feedback received from sensors. The controller is also responsible for managing communication between the motor drive system and external control systems, allowing for remote operation and fault monitoring.

The controller's ability to integrate these functions makes it an essential component for a wide variety of electronic applications.

Types of PCB Controllers

PCB controllers encompass a spectrum of integrated circuits (ICs), each tailored for specific applications and performance requirements. From versatile microcontrollers to specialized dedicated chips, the choice of controller is critical for a PCB's functionality, cost-effectiveness, and overall design complexity.

| Controller Type | Description | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| General-Purpose Microcontrollers | Programmable ICs designed to execute a wide range of tasks; often include CPU, memory, and peripherals. | Highly flexible; programmable for various tasks; cost-effective for moderate complexity. | Performance may be limited for very demanding applications; may require more complex programming. | Consumer electronics, embedded systems, IoT devices. |

| Dedicated ICs | Specialized chips with fixed functionality for specific control tasks; optimized for certain operations. | High performance for target tasks; efficient and often consume less power. | Limited flexibility; not suitable for varied tasks; higher upfront cost for design and production. | Motor control, power regulation, signal processing, memory controllers. |

| FPGAs (Field-Programmable Gate Arrays) | Configurable integrated circuits that allow for hardware-level programming to execute high-speed logic functions | High-performance and customisable architecture; can be reprogrammed after manufacturing | Higher complexity, higher cost; requires hardware description language (HDL) expertise. | High-speed signal processing, data acquisition, AI inferencing. |

| ASICs (Application-Specific Integrated Circuits) | Custom-designed integrated circuits for specific applications; optimised for one application | Extremely high-performance; lowest power consumption; optimal for mass production | Very high upfront cost; inflexible and cannot be reprogrammed after manufacturing | High-volume production; large-scale industrial equipment; data centres; cryptocurrency mining |

PCB Controller Applications Across Industries

PCB controllers are integral to a vast array of industries, serving as the brains behind countless electronic devices and systems. Their versatility and adaptability allow them to manage diverse functionalities, ranging from simple tasks to complex processes, driving innovation and efficiency across various sectors.

Here are some specific applications:

- Consumer Electronics

In consumer electronics, PCB controllers manage functions in smartphones, tablets, laptops, and home appliances, controlling user interfaces, data processing, and power management. For instance, they drive display functionality, regulate power consumption, and execute user commands. The ubiquitous nature of these devices means that controllers are a high-volume, high-impact technology in this sector. - Industrial Automation

PCB controllers are crucial for industrial automation. They are embedded in programmable logic controllers (PLCs), robotic systems, and various control devices, managing assembly line operations, temperature controls in industrial processes, and monitoring complex sensor systems, ensuring that manufacturing and operational procedures are consistently precise, reliable, and safe. - Medical Equipment

In the medical field, PCB controllers are used in diagnostic equipment, patient monitoring systems, and medical imaging technologies. They manage critical parameters, such as the accuracy of readings from patient monitors to the precise control of medical robots. Reliability and precision are the main performance needs, ensuring that devices are safe, and effective, and that patient outcomes are greatly improved. - Automotive Systems

Automotive systems heavily rely on PCB controllers for engine management, anti-lock braking systems (ABS), and advanced driver-assistance systems (ADAS). They process sensor inputs, execute control algorithms, and ensure vehicle safety, performance, and efficiency. The proliferation of electronic control units (ECUs) in modern vehicles highlights the technology's importance. - Aerospace and Defense

Aerospace and defense applications use PCB controllers for flight control systems, navigation equipment, and communication devices. They handle high reliability under extreme operating conditions, including wide temperature variations and high vibration. Precision and reliability are critical in these sectors, especially in areas of avionics and guided missile systems. - Renewable Energy

PCB controllers manage solar panel systems, wind turbine controls, and battery storage, optimizing energy generation and management, and contributing to efficient and dependable renewable energy systems. These controllers not only manage the power generation but also integrate grid interactions and ensure that overall systems are performing as expected. - Telecommunications

In telecommunications, PCB controllers are essential in routers, switches, and network infrastructure, handling data processing, signal management, and network communication, and playing a critical role in ensuring seamless connectivity and efficient data delivery. Their function is critical in managing massive volumes of data and ensuring low-latency performance.

These examples illustrate the versatility and broad applicability of PCB controllers, showcasing their pivotal role in modern technology and industry.

Essential Factors When Choosing a PCB Controller

Selecting the correct PCB controller is crucial for optimal system performance and reliability. The choice hinges on a multitude of factors that must align with the intended application and design objectives. Careful consideration of these factors ensures that the chosen controller can effectively manage the demands of the PCB, and associated system, under normal operating conditions.

| Factor | Description | Considerations |

|---|---|---|

| Processing Power | The computational capacity of the controller, typically measured in clock speed and architecture. | Required processing speed, complexity of algorithms, data throughput needs. |

| Memory | Amount of volatile (RAM) and non-volatile (Flash/EEPROM) memory available for program execution and data storage. | Program size, data logging requirements, buffer storage needs. |

| Interfaces | Available communication protocols (e.g., UART, SPI, I2C, USB, Ethernet) for interfacing with other components. | Number and type of peripherals, data transmission speed, need for wired or wireless communication. |

| Power Consumption | The amount of electrical power the controller consumes during operation. | Operating voltage, maximum and average current draw, need for low-power operation (e.g., battery powered applications). |

| Operating Conditions | The expected operating temperature, humidity, and other environmental factors. | Environmental standards compliance, reliability requirements based on application. |

| Cost | The purchase price of the controller, including associated components and software. | Total budget constraints, cost-benefit analysis of different controller options. |

| Development Tools and Ecosystem | The availability of software development kits (SDKs), Integrated Development Environments (IDEs), debugging tools, and support communities. | Ease of software development, access to pre-built libraries and example codes, availability of community support. |

| Form Factor and Package | The physical size and packaging of the controller IC. | PCB size and constraints, mounting method (e.g., surface mount or through-hole), and integration with other components. |

It is also paramount to define the specific user needs and the intended design purpose before settling on a controller. For example, a simple temperature control circuit might require minimal processing power but a high degree of reliability in harsh conditions, while an advanced image processing application might need a highly efficient CPU and a substantial amount of memory. Furthermore, the cost-benefit analysis of different options often plays a deciding role. In any case, the best controller will not only meet the technical requirements, but also offer a solution that's cost effective and suitable for its application.

Troubleshooting Common PCB Controller Issues

Effective troubleshooting of PCB controller issues requires a systematic approach, combining understanding of circuit design principles with practical diagnostic techniques. This section aims to provide engineers and technicians with actionable steps to address common failures and maintain optimal PCB performance.

- Signal Interference

Signal interference, often manifesting as noise or unexpected behavior, can be attributed to factors like poor grounding, inadequate shielding, or nearby sources of electromagnetic interference (EMI). Examine grounding connections, ensure proper shielding is implemented and consider the use of filters. A spectrum analyzer can be invaluable for identifying the source and frequency of interfering signals. - Power Supply Issues

Problems with the power supply are a leading cause of PCB controller malfunctions. Verify the voltage levels are within the acceptable range using a multimeter. Look for any signs of component overheating or failure, such as swollen capacitors or discolored resistors. Check the power delivery network for shorts or open circuits. If multiple power rails are present, ensure each rail operates within its specified tolerance. - Component Failures

Component failures can be due to various factors, including thermal stress, electrical overloads, or manufacturing defects. Carefully inspect the PCB for signs of damage. Verify the functionality of each active component, starting with the controller itself. Use a logic analyzer to check the behavior of digital circuits and a signal generator to simulate signals to verify component responses. Always ensure that replacement components meet or exceed the original specifications. Consider an environmental test chamber to evaluate the thermal and vibration limits for a given component on the board. - Firmware Corruption

Sometimes, firmware corruption can lead to erratic behavior of the controller. If the controller has an external memory device that stores firmware, consider reading the memory to ensure there has not been a corruption. Re-flashing the correct firmware can resolve the issue. Ensure that the firmware is the correct one for the board's controller and check for CRC or other checksum errors during the flash process. Consider using a JTAG debugger to single step through the controller's software to isolate issues within the code.

Frequently Asked Questions About PCB Controllers

This section addresses common queries regarding PCB controllers, providing concise and authoritative answers to enhance understanding and clarify frequently encountered questions.

- What is a PCB controller?

A PCB controller is essentially a microcontroller or integrated circuit (IC) that serves as the 'brain' of a printed circuit board (PCB). It manages and regulates the operation of the electronic components on the PCB, executing instructions and processing data according to programmed logic. These controllers can range from general-purpose microcontrollers to specialized integrated circuits (ICs) designed for specific functions. - What does 'PCB' stand for?

The acronym 'PCB' stands for Printed Circuit Board. It is a non-conductive board, typically made of fiberglass or composite material, which supports and electrically connects electronic components using conductive pathways, tracks, or pads etched from copper laminated onto the surface. PCBs form the foundation of almost every electronic device. - What is the primary function of a PCB controller?

The primary function of a PCB controller is to manage and control the operation of the electronic components mounted on the PCB. This includes tasks like processing data, controlling signal flow, managing power distribution, and executing instructions, coordinating the various functions of the circuit. Essentially it manages the PCB's operations, making sure everything functions as intended. - How can I identify a PCB controller on a circuit board?

PCB controllers are typically identifiable by their physical characteristics, such as being the largest chip on the board (although this is not always true), typically having a higher number of pins and connections than other components. They often bear manufacturer markings, part numbers, or specific logos. Reference to datasheets related to the part markings is the most reliable way to confirm a controller's function and specifications. - Where are PCB controllers commonly used in cars?

PCB controllers are ubiquitous in modern vehicles. They manage many of the electronic systems, including engine control units (ECUs), transmission control, anti-lock braking systems (ABS), airbag deployment systems, infotainment systems, and various sensor and lighting control systems. A modern car contains numerous PCBs and hence numerous controllers, managing virtually all electronic aspects of the vehicle. - What are common types of PCB controllers?

PCB controllers come in various forms. General-purpose microcontrollers are widely used for versatile applications. ASICs (Application-Specific Integrated Circuits) are tailored for specific functionalities and deliver performance improvements. Digital Signal Processors (DSPs) excel at high-speed signal processing. Programmable Logic Controllers (PLCs) are utilized in automation. FPGAs (Field-Programmable Gate Arrays) are reconfigurable and adapt well for diverse requirements. The type of controller selected usually depends on the desired performance and complexity of the functions it needs to perform. - How do I select the right PCB controller for my project?

Selecting a PCB controller depends on your project's specific needs. Consider processing power needed, the amount of memory required for data, the types of interfaces needed for communication with other components, and power consumption constraints. You need to select the correct type of controller, for instance, a microcontroller for general tasks or an ASIC for specific, high-performance applications. Careful consideration should also be given to cost and complexity to ensure a suitable balance between performance and design efficiency.

Future Trends in PCB Controller Technology

The landscape of PCB controller technology is rapidly evolving, driven by the ever-increasing demands for higher performance, greater efficiency, and enhanced connectivity. These advancements are poised to significantly impact the electronics industry and reshape the capabilities of future devices.

- Increased Processing Speeds

Future PCB controllers will boast faster processing speeds due to advancements in semiconductor technology, allowing for more complex calculations and real-time data analysis. This includes higher clock frequencies, improved instruction sets, and the incorporation of multi-core architectures, all contributing to greater overall throughput. - Enhanced Connectivity

The integration of advanced wireless communication protocols (e.g., 5G, Wi-Fi 6/7, Bluetooth Low Energy) will enable seamless data exchange between devices, facilitating the development of IoT ecosystems and remote monitoring capabilities. Expect increased bandwidth, lower latency, and improved power efficiency within these communication interfaces. - Improved Power Efficiency

Reducing power consumption remains a crucial goal. Future controllers will likely employ advanced power management techniques, including adaptive voltage scaling, dynamic frequency adjustment, and more efficient sleep modes. Novel low-power transistor designs will further minimize energy usage, extending the battery life of portable devices. - Integration of AI and Machine Learning

The incorporation of AI and machine learning capabilities directly onto PCB controllers will be a significant trend. This includes dedicated hardware accelerators for neural networks, enabling real-time inference and intelligent decision-making at the edge of the network without the need for constant cloud communication. This will facilitate applications such as predictive maintenance, real-time pattern recognition, and personalized device experiences. - Miniaturization and Advanced Packaging

Continued miniaturization of PCB controller components will lead to smaller and more compact devices. This is driven by advanced packaging techniques such as system-in-package (SiP) and chip-on-wafer technology that allow for integrating multiple functional blocks into a single module. - Increased Security Features

With the rise of interconnected devices, securing PCB controllers is paramount. Expect to see hardware-based security features such as secure boot, trusted execution environments (TEEs), and cryptographic acceleration to be commonplace, thus mitigating security risks and data breaches.

PCB controllers are the brains behind modern electronic devices, enabling seamless operation and sophisticated functionality. Understanding their importance, functionality and role in various fields is essential. From selecting the right controller for a specific application to troubleshooting common problems, a deeper understanding of PCB controllers empowers users to leverage their capabilities and navigate the ever-evolving technological landscape. PCB controllers will continue to evolve, playing an even more vital role in our interconnected world.

AnyPCBA

AnyPCBA