Understanding PCB Ltd: A Comprehensive Guide to Printed Circuit Boards and Beyond

In today's technology-driven world, the humble Printed Circuit Board (PCB) forms the backbone of countless electronic devices, influencing everything from smartphones to sophisticated medical equipment. While the acronym 'PCB' is widely recognized, the entity 'PCB Ltd' signifies diverse companies engaged in various aspects of PCB development, manufacturing and supply. This article will explore the multifaceted world of PCB Ltd, offering a comprehensive understanding of its role in the tech ecosystem, and how they are impacting various industries and driving technological advancements. From production to diverse applications, we will navigate the essentials of PCB Ltd.

What is PCB Ltd? Defining the Landscape

The term 'PCB Ltd' represents a variety of companies operating under the 'PCB' acronym, each with distinct business focuses. These entities span multiple sectors, including manufacturing, construction, and chemical industries, and play significant roles in the global market. Understanding the diversity of these companies, both in their offerings and their contributions to the larger economy, is crucial when interacting with or researching PCB-related businesses.

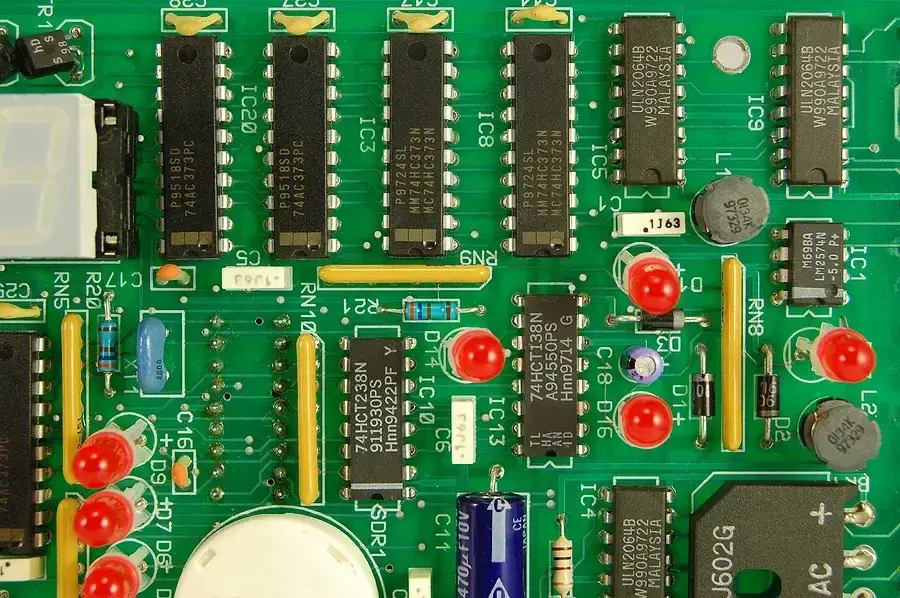

PCB Ltd's Role in Printed Circuit Board Manufacturing

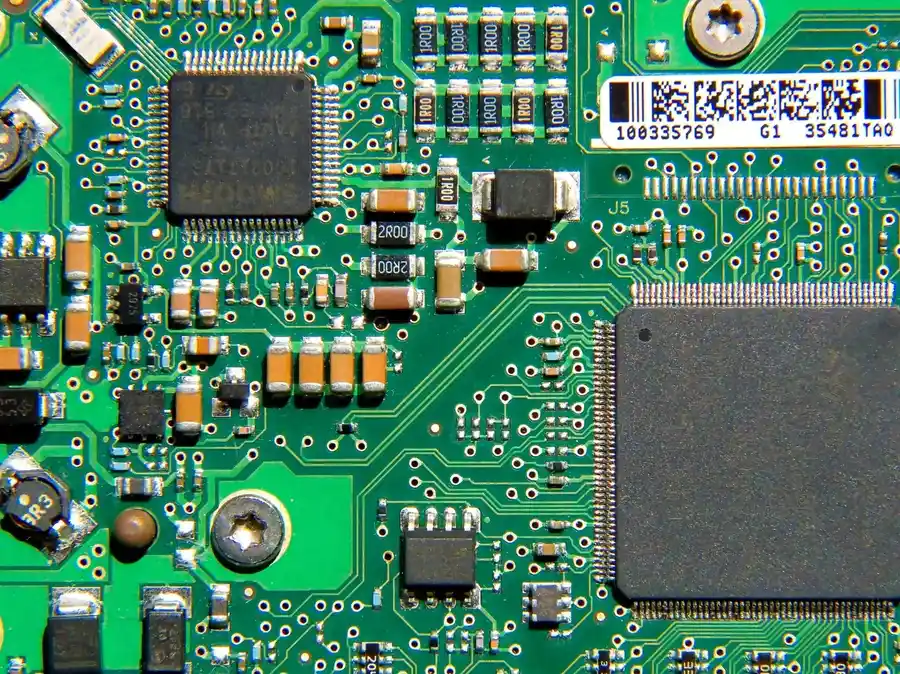

Companies operating under the 'PCB Ltd' banner often play a pivotal role in the printed circuit board (PCB) manufacturing sector, providing essential services that range from design and prototyping to mass production. These entities leverage various technologies and processes to create high-quality PCBs tailored for diverse applications, underpinning the functionality of countless electronic devices.

The core services provided by PCB Ltd companies include:

- PCB Design and Layout

This service involves translating electronic circuit schematics into physical PCB layouts. It encompasses component placement, signal routing, and adherence to design rules to ensure proper functionality and signal integrity. Sophisticated CAD (Computer-Aided Design) tools are employed to accomplish this task. - PCB Fabrication

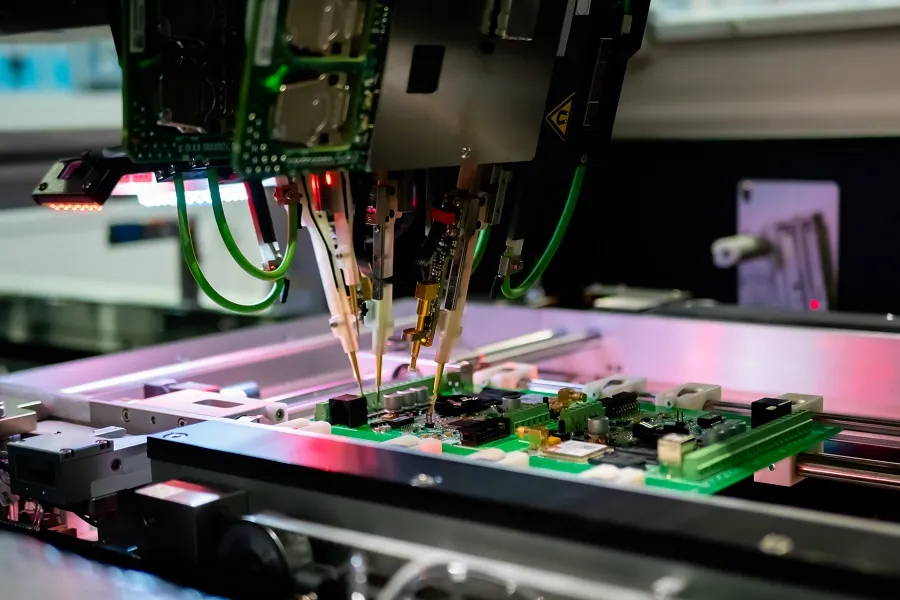

Fabrication includes the actual manufacturing process where the designed PCB layout is etched onto substrate material. This involves processes like drilling, etching, plating, and solder mask application, requiring precision and specialized equipment. Various technologies, such as multilayer processing and surface finishing, are used. - PCB Assembly

This involves mounting electronic components onto the fabricated PCB. Automated processes like pick-and-place machines and reflow soldering ovens are utilized for efficient and accurate assembly. Techniques include Surface Mount Technology (SMT) and Through-Hole Technology (THT). - Prototyping and Testing

Before mass production, PCB Ltd companies produce prototypes for testing and validation. Thorough testing using electrical and functional tests ensures that the manufactured PCBs meet the performance criteria. This step is crucial for identifying any design or manufacturing flaws. - Materials Sourcing

PCB Ltd companies procure diverse materials, including substrate materials (e.g., FR-4, polyimide), conductive materials (e.g., copper), and solder masks. Quality material selection is paramount in determining the performance and longevity of the PCB.

The materials used in PCB manufacturing vary depending on the application requirements. Common materials include:

| Material | Description | Typical Applications |

|---|---|---|

| FR-4 | A glass-reinforced epoxy laminate. It offers a good balance of cost and performance. | General-purpose electronics, consumer electronics |

| Polyimide | High-performance polymer with excellent thermal stability and flexibility. | Aerospace, automotive, and high-frequency applications |

| Aluminum | Metal core PCB offering excellent heat dissipation. | LED lighting, power electronics |

| Copper | Used as the conductive material for traces and planes. | All PCBs |

| Solder Mask | Protective coating applied to the PCB. | All PCBs |

The precision and quality of PCB manufacturing by PCB Ltd companies are critical. These processes ensure that the final products meet stringent technical specifications and quality standards, enabling a diverse range of applications from simple consumer electronics to sophisticated industrial systems.

Beyond Manufacturing: Other Services Offered by PCB Ltd

While the name 'PCB Ltd' strongly suggests a focus on printed circuit board manufacturing, the reality is that companies operating under this moniker often engage in a diverse range of activities. These services extend far beyond the realm of electronics, encompassing areas such as building and joinery, customs brokerage, and even chemical production, significantly broadening their impact on the market.

- Building and Joinery

Some 'PCB Ltd' companies leverage their existing infrastructure or expertise to offer construction-related services. This might involve building maintenance, custom joinery projects, or even complete construction management for specific types of projects. This diversification allows them to utilize resources and skills in multiple sectors. - Customs Brokerage

Given the international nature of electronics manufacturing and supply chains, some 'PCB Ltd' entities operate as customs brokers. This role involves managing the complex paperwork, compliance requirements, and logistics involved in importing and exporting goods, which can be a valuable service for other manufacturing companies. - Carbon Black Production

A few companies with the 'PCB Ltd' name are involved in the production of carbon black, a material used as a pigment and reinforcing agent. This shows the extent of industrial diversity under this name. The connection to PCB manufacturing is more indirect but reflects industrial flexibility. - Logistics and Supply Chain Management

Beyond brokerage, some PCB Ltd companies offer comprehensive logistics and supply chain management services. This includes warehousing, transportation, and inventory management, ensuring smooth operations across their clients' business activities. - Material Sourcing and Distribution

Some PCB Ltd companies leverage their global network to source raw materials and distribute them to other industries. This positions them as intermediaries and supply chain partners for a variety of different businesses.

The Importance of PCB Ltd in Different Industries

PCB Ltd companies, though diverse in their offerings, play a crucial role across multiple industries by providing essential components, services and materials. Their impact is felt in technology, construction, manufacturing, logistics, and chemical sectors, each benefiting from their specialized capabilities.

| Industry | Role of PCB Ltd | Impact |

|---|---|---|

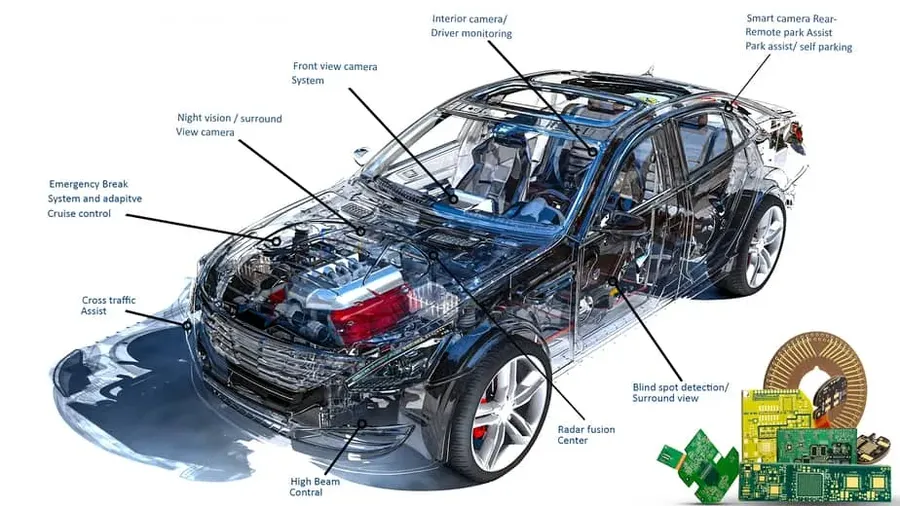

| Technology | Manufacturing of Printed Circuit Boards (PCBs) for electronics. | Enables the functionality of countless electronic devices, from smartphones to complex industrial systems. |

| Construction | Providing building and joinery services; this may include pre-fabricated panels or custom-built components. | Contributes to efficient building processes and enables creation of specialized structures. |

| Manufacturing | Supplying components and materials, such as PCBs and carbon black for various applications; handling custom fabrication. | Supports the supply chain for diverse industries; allows for flexible production and innovation |

| Logistics | Offering custom brokerage and freight forwarding services. | Facilitates the smooth transport of goods across borders; helps streamline supply chains and global trade. |

| Chemical | Manufacturing carbon black for inks, toners and plastics; supplying chemicals | Provides essential raw materials for various manufacturing processes; enabling crucial product creation. |

Choosing the Right PCB Ltd Partner: Key Considerations

Selecting the appropriate PCB Ltd partner is a critical decision for any business that relies on printed circuit boards. This choice directly impacts the quality, cost, and timeline of product development and manufacturing. A careful evaluation of several key factors is essential to ensure alignment with your specific needs and business goals.

Here's a breakdown of the factors to consider when choosing a PCB Ltd partner:

- Customization Capabilities

Assess the PCB Ltd's capacity to handle your specific design requirements, including board complexity, layer count, and material specifications. A partner should be capable of adapting to unique project needs. - Production Volume Flexibility

Determine if the partner can accommodate your production volume requirements, from small prototypes to large-scale manufacturing runs. Scalability is key for long-term partnerships. - Industry Expertise

Evaluate if the PCB Ltd has experience in your industry vertical. A partner with relevant experience can better understand your specific challenges and provide tailored solutions. - Manufacturing Capabilities

Consider the technology and equipment used in the PCB manufacturing process. Advanced facilities often lead to better quality and efficiency. - Quality Control Standards

Investigate the partner's quality control systems and certifications (e.g., ISO 9001, IPC standards). Consistent quality is essential for reliable product performance. - Turnaround Time

Assess the partner's capacity to deliver PCBs within your required timeframe. Faster turnaround can be critical for meeting project deadlines. - Cost Competitiveness

Evaluate the partner's pricing structure and ensure it aligns with your budget. However, lowest price should not be the sole determining factor; consider the overall value delivered, including quality and service. - Communication and Support

Examine the responsiveness and communication channels of the PCB Ltd. Effective communication is vital for seamless collaboration and resolving potential issues promptly. - References and Reviews

Seek customer references and reviews to gauge the reliability and overall satisfaction level of the PCB Ltd's services.

By diligently assessing these aspects, businesses can forge successful partnerships with PCB Ltd companies, enabling them to deliver innovative, high-quality products to market.

PCB Ltd and Technological Innovations

Companies operating under the 'PCB Ltd' banner are often at the forefront of technological innovation, pushing boundaries in electronics, materials science, and related fields. Their contributions are not limited to simply manufacturing printed circuit boards; they actively participate in the development of new materials, processes, and applications that define the next generation of electronic devices.

- Advanced Materials Research

Many PCB Ltd companies are involved in the research and development of novel PCB materials. This includes exploring substrates with improved thermal properties, higher signal integrity, and enhanced flexibility, such as ceramic-filled composites, advanced polymers, and flexible laminates. - High-Density Interconnect (HDI) Technology

Innovation in HDI technology is a key area for many PCB Ltd firms. This involves developing microvias, fine lines, and advanced drilling techniques to enable increasingly complex circuit designs within smaller form factors for applications such as smartphones, wearables, and advanced medical devices. - Additive Manufacturing Techniques

Some PCB Ltd companies are actively engaged in exploring additive manufacturing technologies, such as 3D printing, to produce prototype PCBs and small batch productions. This approach reduces manufacturing times, cost, and allows for rapid design iteration. - Embedded Components

Innovations involve embedding passive and active components within PCB layers, which not only saves space but also improves electrical performance. The development of new embedding materials and techniques is crucial for future electronic devices. - Sustainable Practices

A significant innovation trend involves environmentally sustainable PCB manufacturing processes, including using recycled or renewable materials, employing water-based chemicals, and adopting energy-efficient techniques to reduce the carbon footprint of the electronics industry. - Thermal Management Solutions

With increasing power densities in electronic devices, innovation in thermal management is crucial. PCB Ltd companies develop advanced thermal substrates, heat sinks, and thermal vias to dissipate heat efficiently, ensuring the long term reliability of electronic components.

These innovations have a profound impact, not just on the PCB industry, but also on numerous other sectors, shaping the future of electronics, communications, and a wide range of industrial applications. 'PCB Ltd' companies’ commitment to research and development positions them as drivers of technological advancement.

Frequently Asked Questions about PCB Ltd and Printed Circuit Boards

This section addresses common queries about PCB Ltd, focusing on the 'PCB' component itself, its role within companies, cost considerations, and its fundamental importance in various applications. Understanding these frequently asked questions provides crucial insight into the broader landscape of PCB technologies and related industries.

- What does PCB stand for?

PCB stands for Printed Circuit Board. It is a board made of non-conductive material, usually fiberglass, with conductive pathways etched onto its surface, used to connect electronic components. - What is the role of a PCB in a company that uses them?

Within a company, PCBs serve as the foundational infrastructure for electronic devices. They are essential for connecting various components, enabling the functionality of products such as computers, smartphones, and industrial control systems, thus becoming a core manufacturing and assembly component. - Why are some PCBs considered inexpensive?

The cost of PCBs varies significantly based on material choice, manufacturing complexity, volume, and tolerances required. High-volume, single or double-layer boards with standard materials often result in relatively low unit cost. Material selection, production volume, and design complexity are crucial cost determinants. - How much does a PCB typically cost?

The cost of a PCB depends on several factors including size, complexity (number of layers, trace density), materials used, and quantity ordered. Simple, single-layer boards may cost a few dollars, while complex multi-layer boards with high-density interconnects can range from tens to hundreds of dollars each. - Why are PCBs vital in so many electronic applications?

PCBs are essential due to their ability to provide a structured, reliable platform for electronic components. They offer efficient electrical connections, provide mechanical support, facilitate heat dissipation, and allow for standardized manufacturing processes, which reduces costs and increases device reliability, making them a fundamental part of any electronics product. - What are the different types of PCBs that 'PCB Ltd' might produce?

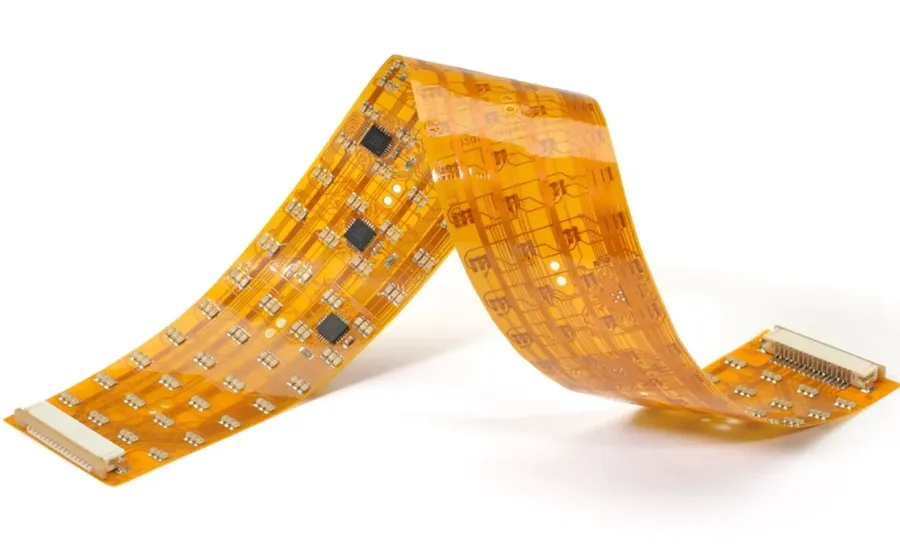

PCB Ltd companies may produce a variety of PCB types including single-layer, double-layer, multi-layer, flexible PCBs, and rigid-flex PCBs. The selection of which types are produced often depends on the specific industry and technological requirements being addressed. The variety is dictated by the specific products and markets that a PCB Ltd serves, reflecting the diverse range of applications. - What kind of quality standards should I expect from a reputable PCB Ltd?

A reputable PCB Ltd should adhere to industry standards such as IPC (Association Connecting Electronics Industries) standards. This compliance ensures that the boards meet specific requirements for material quality, manufacturing tolerances, and testing procedures. Furthermore, certifications like ISO 9001 are often held as proof of a commitment to strict quality control processes.

Future Trends for PCB Ltd and the PCB Industry

The printed circuit board (PCB) industry, including entities operating under the name 'PCB Ltd,' is poised for significant transformation driven by technological advancements and evolving market demands. These trends are reshaping PCB design, manufacturing processes, and applications, necessitating adaptability and innovation within the sector.

- Miniaturization and High-Density Interconnect (HDI) PCBs

The relentless pursuit of smaller, more powerful electronic devices is driving the demand for miniaturized and HDI PCBs. This necessitates advanced manufacturing techniques such as microvia technology and finer line widths and spacing. - Flexible and Stretchable PCBs

As wearable technology and flexible electronics become more prevalent, the need for flexible and stretchable PCBs is growing. These PCBs can conform to irregular shapes and withstand mechanical stress, opening new possibilities in various applications, particularly in medical and consumer electronics. - Sustainable and Eco-Friendly PCB Manufacturing

Environmental concerns are pushing the industry towards more sustainable practices. This includes the use of eco-friendly materials, reducing waste through efficient manufacturing, and exploring recycling and reuse options. - Advanced Materials

The continuous development of advanced materials, such as composites and high-performance polymers, enhances PCB performance by improving heat dissipation, signal integrity, and overall durability. The utilization of these materials will be a key trend in the PCB industry. - Automation and Industry 4.0

Integrating automation, robotics, and data analytics is optimizing PCB manufacturing processes by improving efficiency, precision, and yield rates. This trend, in line with Industry 4.0 principles, is also driving down costs and lead times. - Embedded Components

Embedding components directly within the PCB substrate is becoming increasingly common. This technique reduces the overall size and complexity of electronic devices while enhancing performance and reliability by shortening signal paths. - Focus on Reliability and High-Performance Applications

With the increasing use of PCBs in mission-critical and safety-related applications such as aerospace, defense, and medical devices, there is a growing need for ultra-reliable PCBs that can withstand extreme conditions. Focus on performance and reliability will be essential.

In conclusion, PCB Ltd embodies a range of companies deeply involved in the manufacturing, innovation and supply chain of printed circuit boards, construction, custom brokerage and chemical industry. Their crucial roles in driving technological advancements across various sectors cannot be overstated. Understanding the nuances of PCB Ltd, from their diverse services to their industry impact, is essential for navigating today's technological landscape. As we move forward, these companies will continue to be at the forefront of innovation and essential parts of modern technology.

AnyPCBA

AnyPCBA