Understanding PCB Transformers: Types, Uses & Regulations

PCB transformers, though historically linked to environmental concerns due to Polychlorinated Biphenyls (PCBs), continue to be a crucial component in many electrical applications. From industrial machinery to everyday electronics, these specialized transformers play a vital role. This article demystifies PCB transformers by exploring their different types, applications, and the regulatory landscape surrounding their use and disposal, bridging the gap between technical understanding and real-world relevance.

What is a PCB Transformer?

A PCB transformer, in its most fundamental definition, is a transformer that contains polychlorinated biphenyls (PCBs) within its dielectric fluid or other components. Unlike standard transformers that use mineral oil or other PCB-free alternatives, these transformers were historically filled with PCB-based fluids, primarily for their superior insulating and fire-resistant properties. The critical characteristic that defines a transformer as 'PCB-containing' is the concentration of PCBs present, typically above 50 parts per million (ppm). This threshold is crucial for regulatory purposes and risk management.

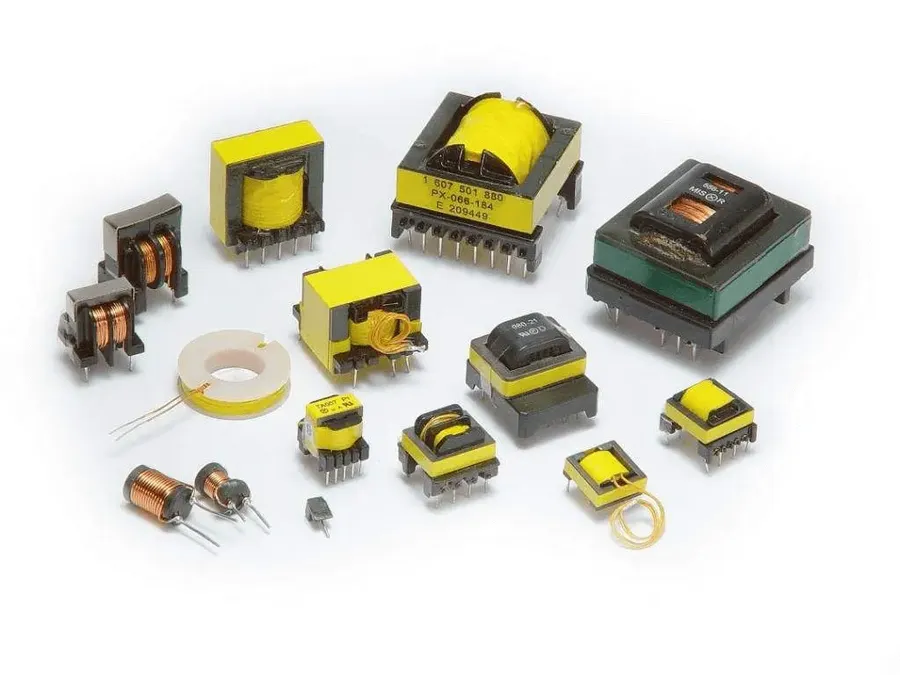

PCB Mount Transformers: Design and Integration

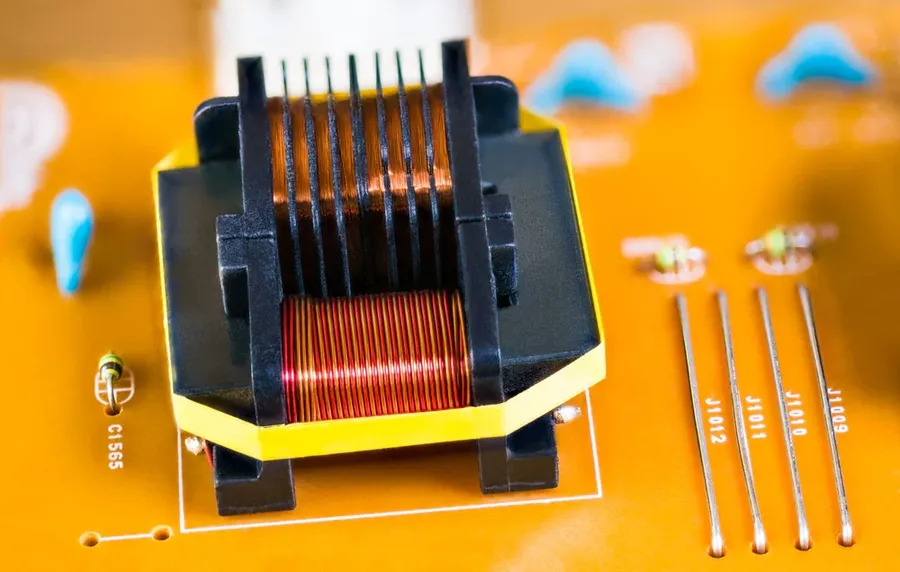

PCB mount transformers are specifically engineered for direct integration onto printed circuit boards (PCBs), facilitating compact and efficient power conversion and signal isolation. Their design emphasizes minimizing footprint and height to meet the dense component placement requirements of modern electronic devices.

These transformers are typically constructed with a core material optimized for high-frequency operation, such as ferrite or nanocrystalline materials, to reduce core losses at the switching frequencies often used in electronic circuits. The windings are designed to minimize parasitic capacitance and leakage inductance, crucial for maintaining signal integrity and power efficiency.

The integration of PCB mount transformers onto circuit boards offers several advantages, including simplified assembly, reduced interconnect complexity, and improved thermal management. These transformers play a critical role in power conditioning, stepping voltages up or down, and in providing galvanic isolation between different circuit stages. This isolation is essential for protecting sensitive circuits from voltage spikes and noise, ensuring reliable and safe operation of electronic equipment.

Specifically designed for automated assembly, PCB mount transformers are available in various mounting configurations, such as surface mount (SMD) and through-hole, to accommodate diverse PCB design requirements. Their dimensions are typically standardized to ensure compatibility with automated pick-and-place machines, facilitating high-volume manufacturing processes.

In summary, PCB mount transformers are critical components in modern electronics, enabling efficient power delivery and signal isolation directly on the circuit board. Their design is driven by the need for compactness, high performance, and compatibility with automated assembly processes, making them essential for power conversion and signal conditioning in electronic devices.

Applications of PCB Transformers

PCB transformers, known for their compact size and integration capabilities, find extensive use across diverse sectors. Their versatility stems from their ability to efficiently manage power and isolate signals directly on printed circuit boards, making them indispensable in modern electronics and industrial applications.

- Consumer Electronics

In consumer devices like smartphones, laptops, and tablets, PCB transformers enable efficient power conversion and signal isolation, supporting multiple voltage requirements while maintaining a compact form factor. They are also critical in the charging circuits of these devices, ensuring efficient and safe power transfer. - Industrial Equipment

Industrial applications often demand robust and reliable power solutions. PCB transformers are widely used in power supplies for industrial control systems, motor drives, and automation equipment where precise power management is critical. They provide essential galvanic isolation to safeguard sensitive control circuitry from power surges and electrical noise. - Telecommunications

Within telecommunications, PCB transformers are integral in network interface cards (NICs), modems, and routers. They are used for isolating digital signals, impedance matching and ensuring data integrity across communication lines. Their small size and high performance characteristics are necessary for meeting the requirements of network hardware. - Renewable Energy Systems

PCB transformers are increasingly being adopted in renewable energy sectors, particularly in solar power inverters and wind turbine control systems. These applications require high efficiency, small size and isolation to handle the power and control needs of these systems. - Medical Devices

Medical devices require high precision and safety. PCB transformers are essential in many medical instruments, like diagnostic equipment and patient monitoring systems. Isolation is a key feature here, safeguarding patients from electrical leakage and ensuring accurate readings. - Aerospace and Avionics

In aerospace, PCB transformers contribute to the efficient management of power in avionics systems, where size and weight are critical constraints. They are used in various aircraft systems, including flight control, navigation, and communication, providing high-reliability power and signal management.

PCB Transformer Regulations and Environmental Concerns

The use of PCB transformers is heavily regulated due to the significant environmental and health risks associated with polychlorinated biphenyls (PCBs). These regulations govern the entire lifecycle of PCB-containing equipment, from manufacturing (now banned) to disposal, aiming to minimize human and environmental exposure to these persistent organic pollutants.

The primary concern driving regulation is the known toxicity of PCBs. They are carcinogenic, bioaccumulative, and persistent in the environment, posing long-term threats to both human health and ecological systems. These concerns led to the implementation of stringent controls and eventual bans on PCB production.

- Key Regulatory Focus Areas

Regulations typically address the following aspects of PCB transformer management: concentration limits for PCBs in equipment, permitted uses of existing PCB transformers, storage and handling requirements, mandatory record-keeping, specific disposal protocols, and spill reporting and remediation procedures. - Global Bans and Phase-Out

Most industrialized countries have banned the manufacturing of PCBs and the use of PCB-containing equipment in new applications. International treaties and national laws mandate the phased-out and environmentally sound management of existing PCB equipment. The specific regulations vary, but the overall trend aims at eliminating PCBs from the environment. - Environmental Impact of PCBs

PCBs, if not managed responsibly, can persist in soil, sediments, and water bodies for decades. They can bioaccumulate in the food chain, reaching high concentrations in predators. This environmental persistence is a major reason for their regulation. The potential for accidental releases during maintenance or disposal poses ongoing risks, highlighting the need for compliance with regulations. - Implications of the PCB Ban

The ban on PCB manufacturing effectively halted the production of new PCB transformers. This has driven the transition towards replacement with equipment containing alternative dielectric fluids, like mineral oil or synthetic esters. It also necessitates the meticulous management of existing PCB transformers until they can be safely disposed of or replaced.

Identifying PCB Transformers: Key Indicators

Identifying PCB-containing transformers is crucial for safety and regulatory compliance. Given the legacy use of Polychlorinated Biphenyls (PCBs) in transformer oil, careful inspection and documentation are necessary to distinguish them from non-PCB transformers. This section provides practical guidance on how to identify PCB transformers.

- Visual Inspection and Nameplate Data

Begin with a thorough visual inspection. Look for nameplates or labels that might explicitly state "PCB", "Askarel", or indicate the presence of PCBs. However, many older transformers will not be clearly marked. Note the manufacturer, model number, and any production or installation dates. These can be cross-referenced with manufacturer's data if available. - Labeling Practices

While direct labeling indicating PCB content is ideal, the absence of such labels does not guarantee the lack of PCBs. Some manufacturers used coded labeling or product identification numbers that correspond to PCB-containing equipment. Look for markings referencing “Askarel,” which is a trade name often used for PCB-containing dielectric fluids, and investigate further. - Physical Characteristics and Age

Older transformers, typically manufactured before the ban on PCB production, are more likely to contain PCBs. While not a definitive indicator, a transformer's age, combined with other clues, can heighten suspicion. Transformers filled with Askarel fluids often exhibit different physical characteristics (such as casing shape and dimensions) than their mineral-oil counterparts. However, these characteristics are not universal and require expert knowledge to confirm. - Oil Sampling and Testing Procedures

The most definitive way to confirm PCB presence is through oil sampling and laboratory analysis. Trained personnel should collect a sample of the transformer oil using appropriate safety procedures. The sample should then be tested using gas chromatography with electron capture detection (GC-ECD) or a similar method to measure PCB concentration. Even trace amounts of PCB above regulatory limits would categorize the transformer as PCB-containing. Consider a certified laboratory for this process. - Potential for Cross-Contamination

Be mindful of potential contamination during maintenance. If PCB transformer oil is used on non-PCB transformers, cross-contamination can occur. Pay close attention to transformers that have undergone maintenance or retrofilling. Clean equipment and use separate tools for different fluid types to prevent cross-contamination. If previous maintenance records indicate the use of PCB fluids, treat the transformer as potentially contaminated even if labeling does not indicate PCB presence.

Difference Between PCB and Non-PCB Transformers

The fundamental distinction between PCB and non-PCB transformers lies in the dielectric fluid used for insulation and cooling. PCB transformers utilize polychlorinated biphenyls (PCBs), while non-PCB transformers employ alternative fluids like mineral oil or silicone oil. This difference has significant implications for environmental impact, safety, and regulatory compliance.

| Feature | PCB Transformer | Non-PCB Transformer |

|---|---|---|

| Dielectric Fluid | Polychlorinated Biphenyls (PCBs) | Mineral Oil, Silicone Oil, or Synthetic Ester |

| Environmental Impact | Highly Toxic, Persistent Pollutant | Less Toxic, Biodegradable Options Available |

| Health Hazards | Carcinogenic, Neurological and Reproductive Effects | Lower Toxicity, Potential Skin Irritation |

| Regulations | Subject to Strict Regulations, Often Banned | Subject to less stringent Environmental Regulations |

| Performance | Good Dielectric Strength and Thermal Stability | Varying Dielectric Strength and Thermal Stability |

| Material | Use of PCBs | Free of PCBs |

| Safety Concern | Major Environmental and Health Risks | Lower Health risks |

PCB Transformer Oil: Hazards and Disposal

Polychlorinated biphenyl (PCB) transformer oil poses significant health and environmental risks due to its persistent and toxic nature. This section outlines the hazards associated with PCB oil, and details the procedures for safe handling, containment, and disposal to ensure regulatory compliance and environmental protection.

PCBs are highly stable and non-biodegradable, meaning they persist in the environment for long periods. Their accumulation in soil and water can lead to contamination of the food chain, affecting wildlife and humans. Exposure can result from ingestion, inhalation, or skin contact.

- Health Hazards

Direct exposure to PCB oil can cause a range of health problems, including skin irritation, liver damage, and neurological issues. Long-term exposure is linked to cancer and reproductive problems. The toxic nature of PCBs necessitates strict adherence to safety protocols. - Environmental Hazards

PCB oil is a persistent organic pollutant, capable of accumulating in the environment, contaminating soil, water, and air. It poses a major threat to aquatic life, and it can bioaccumulate in the food chain, reaching high concentrations in apex predators, including humans. - Safe Handling Procedures

Personnel handling PCB oil must use appropriate personal protective equipment (PPE), including gloves, respirators, and protective clothing. Any spills should be contained immediately using absorbent materials, and cleanup should be conducted by trained professionals. - Containment Protocols

Transformer equipment containing PCB oil should be stored in designated areas with secondary containment measures to prevent leaks and spills from reaching the environment. Regular inspections for leaks and maintenance are critical in preventing accidental releases. - Disposal Procedures

The disposal of PCB oil must adhere to strict regulations. It must be incinerated at high temperatures using approved methods and facilities to ensure complete destruction of the PCBs. Landfilling is prohibited, due to the risk of contamination. Disposal must be done by trained personnel with appropriate licenses. - Regulatory Compliance

Local, national, and international regulations govern the handling and disposal of PCBs. Compliance with these regulations is mandatory to prevent health and environmental damage. Failure to comply can result in hefty fines, and legal action.

Frequently Asked Questions About PCB Transformers

This section addresses common questions regarding PCB transformers, providing clear and concise answers to help clarify their use, regulations, and identification. These FAQs aim to resolve common uncertainties and provide crucial information for those working with or encountering these transformers.

- What is a PCB transformer and how does it differ from a standard transformer?

A PCB transformer is a transformer that contains Polychlorinated Biphenyls (PCBs) as part of its insulating oil. Standard transformers use other types of insulating oil that do not contain PCBs. PCB transformers were common before the environmental regulations restricted the use of PCBs, often found in older electrical equipment, such as high voltage transformers. - Are PCB transformers still in use today, and under what circumstances?

While the manufacturing of new PCB transformers has been banned, some older PCB transformers remain in service under strict regulatory conditions. These are typically found in legacy industrial or utility settings. Their continued use is generally permitted under the condition that they are regularly inspected and managed to prevent environmental leaks. As they reach the end of their operational life, these transformers must be disposed of following strict regulatory guidelines. - When was the manufacturing of PCBs for use in transformers banned?

The manufacture of PCBs was banned in many countries starting in the 1970s, with the ban becoming widespread in the late 1980s and early 1990s due to their proven toxicity and environmental persistence. Specific dates vary by country but the Stockholm Convention on Persistent Organic Pollutants (POPs) provides a global framework for their management and ultimate elimination. - What is the key difference between PCB and non-PCB transformers?

The primary difference lies in the insulating oil used. PCB transformers use oil containing PCBs which are toxic and environmentally harmful. Non-PCB transformers use alternative, less hazardous oils, such as mineral oil, silicone oil, or synthetic ester. These alternative oils lack the persistent environmental and health concerns associated with PCBs. - How can I determine if a transformer contains PCBs?

Determining if a transformer contains PCBs often requires a combination of visual inspection of the transformer’s nameplate for specific PCB-related labels (e.g., "askarel" or "Pyranol"), checking documentation, and conducting laboratory analysis of the oil. If documentation or labeling is insufficient, oil samples must be sent to certified labs for PCB testing. This step is crucial for ensuring proper handling and disposal. - What are the environmental and health risks associated with PCB transformer oil?

PCB transformer oil poses significant health risks and is an environmental pollutant. PCBs are persistent organic pollutants (POPs) that bioaccumulate in the food chain. Exposure to PCBs can lead to various health problems in humans and animals, including skin diseases, neurological issues, and reproductive problems. In the environment, PCBs contaminate soil and water, affecting ecosystems and wildlife. - What are the procedures for safe handling and disposal of PCB transformer oil?

Safe handling and disposal of PCB transformer oil is critical. It should be handled by trained personnel with appropriate safety equipment such as gloves and respirators. Contaminated oil must be stored in leak-proof containers and disposed of by licensed hazardous waste disposal companies. These disposals must comply with stringent local and national regulations.

PCB transformers, while crucial for power management and electrical isolation, are associated with significant environmental and health concerns due to the presence of PCBs. Understanding their usage, the regulations surrounding their handling, and the distinction between PCB and non-PCB alternatives is vital for ensuring safety and compliance. As technology advances, focusing on safer and more sustainable transformer technologies becomes increasingly important for environmental responsibility and human health, leading us towards a future where the advantages of electrical transformers can be enjoyed without the risks of PCB contamination.

AnyPCBA

AnyPCBA