Understanding Plain PCB Board Prices: A Comprehensive Guide

In the realm of electronics, the humble printed circuit board (PCB) serves as the backbone of countless devices. From smartphones to industrial machinery, these boards form the foundation upon which electronic circuits are built. A crucial aspect for designers and hobbyists is understanding the price of plain PCB boards. In this article, we will dive into the factors determining plain pcb board price, offering a comprehensive guide to help you navigate the market and make informed decisions about your projects. The costs are influenced by material, size, layers, quantity, and the manufacturing process, it's about understanding the value for your project's success.

Factors Influencing Plain PCB Board Prices

The price of a plain PCB board is not fixed; it's a function of several key variables. These factors include the type of material used, the physical dimensions of the board, and the quantity ordered. A clear understanding of these determinants enables cost-conscious decision-making and effective budget management when purchasing PCBs.

- Material Type

The base material (e.g., FR-4, phenolic, aluminum) significantly impacts the cost due to variations in raw material prices and manufacturing processes. - Board Dimensions

Larger PCBs require more material and processing, thereby increasing the overall price. This encompasses both the surface area and thickness. - Order Quantity

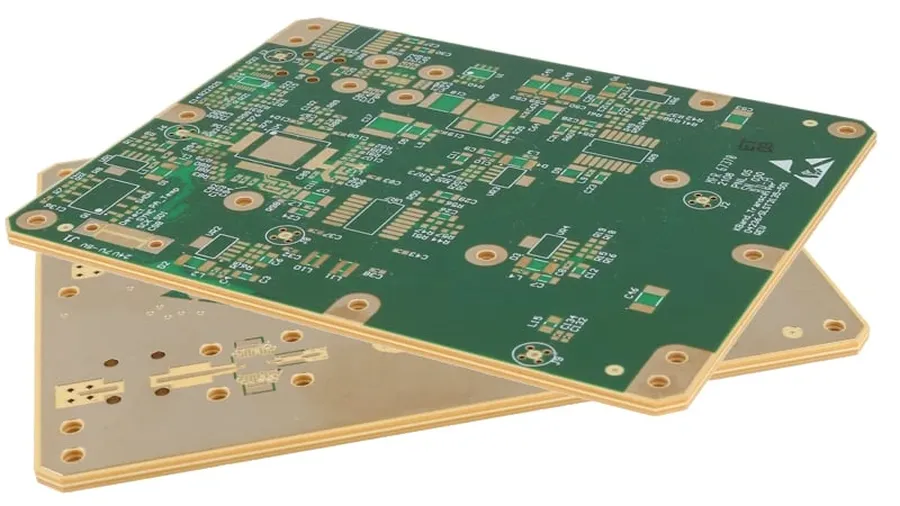

Economies of scale apply to PCB manufacturing. Larger production runs result in lower per-unit costs due to optimized setup and reduced waste. - Copper Layer Count

The number of copper layers (single-sided, double-sided, or multi-layer) dictates the manufacturing complexity and thus cost. More layers typically mean higher prices. - Finishing Options

Surface finish (HASL, ENIG, etc.) affects the cost. The choice of finish depends on the specific application and required performance characteristics, adding to the overall price.

Material Choices and Their Impact on Cost

The selection of materials for plain PCB boards significantly affects both their price and performance characteristics. Common materials like FR-4, phenolic, and aluminum each possess distinct properties that influence cost, durability, and suitability for different applications. Understanding these differences is crucial for making informed decisions that balance budgetary considerations with application requirements.

| Material | Description | Cost | Typical Applications | Pros | Cons |

|---|---|---|---|---|---|

| FR-4 | A glass-reinforced epoxy laminate, the most widely used PCB material due to its good mechanical and electrical properties. | Moderate | General-purpose electronics, consumer electronics, industrial controls. | Good balance of cost, performance and ease of fabrication. | Not suitable for high-frequency or high-temperature applications. |

| Phenolic | Paper-based material with phenolic resin. Less expensive than FR-4 but has lower mechanical strength and thermal resistance. | Low | Simple, low-cost consumer devices, educational projects, prototyping. | Very cost-effective. | Fragile and poor thermal properties. |

| Aluminum | An aluminum substrate, commonly used for thermal management due to its excellent heat dissipation properties. | High | LED lighting, power electronics, high-power applications. | Excellent heat dissipation and durability. | More expensive and electrically conductive (requires insulation). |

Single-Sided vs. Double-Sided PCB Costs

The fundamental difference between single-sided and double-sided PCBs lies in the number of conductive copper layers they possess, directly impacting both their complexity and cost. Single-sided PCBs feature a single layer of copper, while double-sided PCBs have copper layers on both the top and bottom surfaces. This distinction is a primary driver of price variation.

| Feature | Single-Sided PCB | Double-Sided PCB |

|---|---|---|

| Copper Layers | One | Two |

| Complexity | Lower | Higher |

| Cost | Lower | Higher |

| Circuit Density | Lower | Higher |

| Interconnectivity | Limited | Increased |

Single-sided PCBs are generally less expensive due to their simpler construction. They are suitable for basic electronic circuits where component density is low and complex routing is not required. Double-sided PCBs, with their added copper layer, allow for more intricate designs, denser component placement, and more complex routing options. This increased capability comes with a higher production cost.

The cost difference isn't just about the added layer of copper; it's also about the increased manufacturing processes required for double-sided boards. These processes include through-hole plating, where vias (holes connecting the two copper layers) are created and plated with copper to allow electrical connections between the layers. This added complexity results in higher material and labor costs.

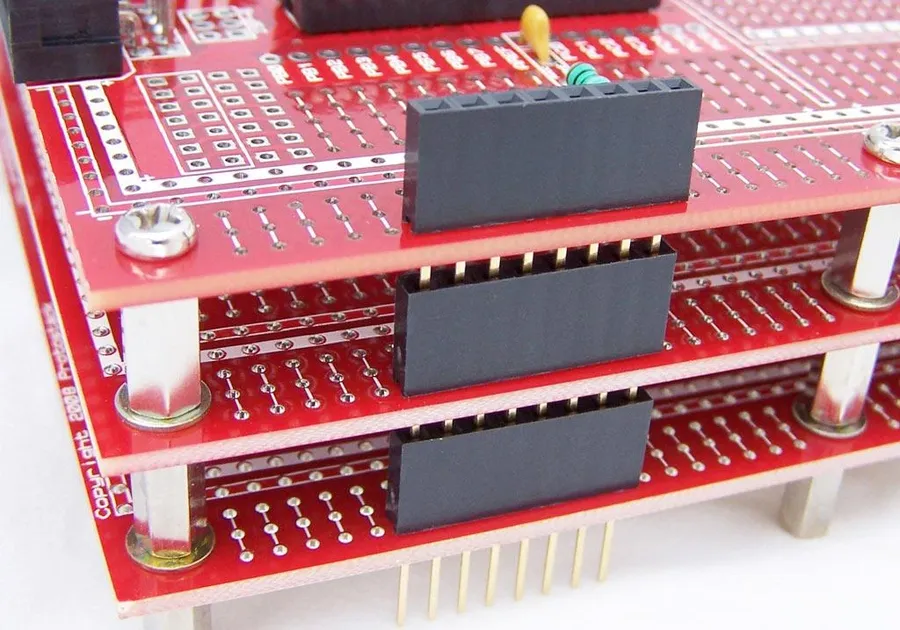

Impact of PCB Size and Thickness on Pricing

The physical dimensions of a plain PCB board, specifically its size (surface area) and thickness, are directly correlated with its manufacturing cost. Larger boards inherently require more raw materials, and thicker boards utilize more substrate material, thereby increasing the overall expenditure.

This section examines how these physical attributes influence the final price.

PCB size is typically measured in square inches or square centimeters and is a primary factor impacting cost due to the amount of raw material, like copper and substrate, consumed. A larger PCB footprint will use more material and generally cost more.

PCB thickness, often specified in mils (thousandths of an inch) or millimeters, also contributes to the cost. Standard PCB thicknesses range from 0.031” to 0.093”, with variations available. Thicker PCBs, while potentially offering improved mechanical robustness, require more raw material during manufacturing. They also require more processing, increasing costs.

| Parameter | Impact on Cost |

|---|---|

| Increased PCB Size (Surface Area) | Higher material costs (copper, substrate). Increased processing and handling during manufacturing. |

| Increased PCB Thickness | Higher material costs. Increased time and energy during processing such as lamination, drilling and routing. |

The relationship between size/thickness and cost isn't always linear. There is a minimum size and thickness where the board can be effectively manufactured. As the board size increases, some efficiencies of scale become possible, and the per-unit material cost may decrease for larger volumes. However, very large PCBs may exceed standard panel sizes, incurring extra panelization charges. Likewise, PCBs can't be made arbitrarily thin for practical manufacturing and reliability considerations.

The Role of Quantity in Determining Price

The price of plain PCB boards is significantly influenced by the quantity ordered, a principle rooted in economies of scale. As order volumes increase, per-unit costs decrease due to factors such as reduced setup costs, bulk material purchases, and more efficient manufacturing processes. This principle applies to both prototyping and large-scale production.

- Reduced Per-Unit Cost

Larger production runs distribute fixed costs such as machine setup and tooling across more units, leading to a lower cost per board. - Bulk Material Discounts

PCB manufacturers often receive discounts from their suppliers when purchasing materials in large quantities, which can then be passed on to customers. - Streamlined Production

Larger orders allow for more streamlined production processes, reducing handling time and minimizing waste, thereby cutting down on overall manufacturing costs. - Lower Shipping Costs

While not always the case, larger orders may sometimes benefit from reduced shipping costs due to bulk rates offered by some carriers.

Plain PCB Board Prices from Major Suppliers

The cost of plain PCB boards varies significantly across different suppliers, influenced by factors such as board specifications, material, and order volume. This section provides an overview of pricing from popular platforms, highlighting their strengths and typical price ranges.

| Supplier | Typical Price Range (USD) | Strengths | Considerations |

|---|---|---|---|

| Amazon | $5 - $50+ | Wide selection, fast shipping for some vendors | Prices can fluctuate; verify supplier reputation |

| Alibaba | $0.10 - $20+ per piece (bulk) | Competitive pricing for bulk orders | Longer shipping times, requires due diligence on suppliers |

| eBay | $3 - $40+ | Variety of sellers, may find unique boards | Seller reliability varies; check ratings |

| Jameco | $3 - $60+ | Established electronics supplier, known for quality | Selection may be less varied than other platforms |

| AliExpress | $0.10 - $15+ per piece (bulk) | Low cost for small orders and bulk, wide range of options | Shipping can be slow and may require higher volume orders. |

| Bantam Tools | $20 - $100+ | Focus on precision PCBs and prototyping equipment. | Higher price point, may be more suited to specialized prototyping |

Frequently Asked Questions About Plain PCB Board Prices

This section addresses common questions regarding plain PCB board pricing, offering concise answers to help clarify cost considerations.

- How much does a basic PCB cost?

The cost of a basic PCB varies widely based on factors like material (FR-4 being the most common), size, and quantity. For small, single-sided boards, prices can range from a few dollars to around $10 for individual pieces. However, prices per unit decrease significantly with larger orders. Complexity and additional features also influence the final price. - What is the typical price per square inch for a PCB?

While not a universal pricing metric, cost per square inch can range from $0.05 to $1 for basic PCBs. This varies considerably with material type, layer count (single vs. double sided or multi layer), complexity and production volume. Higher precision boards with more layers and stringent tolerances will cost more per square inch. - How does the number of layers affect PCB price?

The number of layers on a PCB has a direct impact on its cost. Single-sided PCBs are the least expensive, followed by double-sided, and then multi-layer boards. Each additional layer requires more materials and manufacturing steps, increasing the overall price. Multi-layer PCBs facilitate higher density circuits but at an increased cost. - Is it cheaper to buy plain PCBs in bulk?

Yes, purchasing PCBs in bulk almost always reduces the per-unit cost. Manufacturers often have tiered pricing structures, meaning the larger the order, the lower the price per PCB. This is due to economies of scale, as the initial setup costs can be spread across a larger number of units. - What are the most cost-effective materials for plain PCBs?

FR-4 is generally the most cost-effective and widely used material for plain PCBs. While materials like aluminum offer superior thermal performance, they are typically more expensive. For most standard applications, FR-4 provides a good balance of price and performance. Phenolic materials are even cheaper, but offer less robustness and performance, and are not generally used. - Does the thickness of the PCB board impact the price?

Yes, the thickness of a PCB board has an impact on pricing. Thicker boards generally require more material, which increases cost. Standard PCB thicknesses are more readily available and thus, usually cheaper than non-standard thicknesses. - Where can I find the best deals on plain PCBs?

Major suppliers such as JLCPCB, PCBWay, and Allpcb, provide low-cost manufacturing, with costs decreasing the larger the quantity purchased. Other online platforms like Amazon, Alibaba, and eBay can offer plain boards at competitive prices, though these are often reselling manufactured goods and are not manufacturers themselves. Comparing quotes from multiple sources can help you find the best deal for your specific needs. Always factor in shipping costs.

Plain PCB Board Price Comparison Table

To provide a tangible understanding of plain PCB board pricing, the following table presents a comparative analysis across different materials, board types (single and double-sided), and common board sizes. This data is indicative of typical market prices, but actual costs may vary based on supplier, order quantity, and other factors.

| Material | Board Type | Size (mm) | Typical Price Range (USD) |

|---|---|---|---|

| FR-4 | Single-Sided | 100x100 | $1 - $3 |

| FR-4 | Single-Sided | 200x200 | $3 - $8 |

| FR-4 | Double-Sided | 100x100 | $2 - $5 |

| FR-4 | Double-Sided | 200x200 | $5 - $12 |

| Phenolic | Single-Sided | 100x100 | $0.8 - $2.5 |

| Phenolic | Single-Sided | 200x200 | $2.5 - $6 |

| Aluminum | Single-Sided | 100x100 | $3 - $7 |

| Aluminum | Single-Sided | 200x200 | $7 - $15 |

Note that these prices are for standard thickness boards (typically 1.6mm) and do not include costs for shipping or additional finishing processes. Prices are based on market research and may vary. For exact quotes, it's always best to contact suppliers directly.

Tips for Buying Plain PCB Boards Affordably

Acquiring plain PCB boards without exceeding your budget requires a strategic approach. This section outlines proven methods for reducing costs, including effective negotiation, selecting appropriate materials, and leveraging bulk purchasing advantages. Implementing these tips will help you secure high-quality boards at the best possible price.

- Compare Quotes from Multiple Suppliers

Engage with multiple suppliers, both online and offline, to secure the most competitive pricing. Request formal quotes detailing all costs, including shipping, and carefully analyze each offer before committing to a purchase. This comparison is crucial, as prices for the same board can vary greatly depending on the supplier's overhead and supply chain. - Optimize Board Material Selection

Choose materials that match your project's requirements without unnecessary extravagance. For instance, FR-4 is a common material for many applications, offering a good balance of performance and cost. However, for less demanding applications, materials like phenolic may be suitable and cheaper. Consider the specific needs of your project, including operating temperatures, electrical properties, and mechanical stress, when selecting materials. Always consider cost-effective alternatives whenever technically feasible. - Order in Bulk for Discounted Rates

Suppliers often provide substantial discounts for larger orders, which allows them to optimize production and reduce per-unit costs. If your project allows for it, plan to order a sufficient quantity of PCBs to take advantage of these economies of scale. However, it's crucial to consider both present and foreseeable future needs to avoid having excess inventory that you might not use, since that ties up funds and resources. If you're not sure of the quantities, consider sharing the order with other users, this may be a cheaper way to use bulk purchase without inventory risk. - Consider Single-Sided Boards When Appropriate

For simple circuits, a single-sided PCB board can be significantly cheaper than a double-sided board, as the manufacturing process is less complex. Evaluate whether your design really requires the increased space and routing complexity offered by double-sided boards, since using a simpler and less costly single-sided design will save costs. Single sided boards are adequate for many projects. If space requirements are the problem, then use a smaller double sided PCB, but the smaller size will not always offset the more complex manufacturing costs, so compare the two alternatives thoroughly. - Minimize Board Size and Complexity

Larger and more complex boards naturally require more material and processing, resulting in higher costs. Optimize your board layout to reduce the dimensions of the PCB where it is reasonable to do so and avoid unnecessary complexities, such as excessive vias or irregular shapes, since this will reduce material consumption and processing time, ultimately leading to lower costs. If the function of the circuits can be achieved with the same function with less circuits, then you can reduce the cost by making the circuits smaller. - Leverage Online Resources and Special Offers

Many online platforms provide a way to buy PCB boards that they manufacture. Some of these platforms offer discounts or coupons periodically. Subscribe to newsletters or follow their social media to stay informed about any promotions. Explore reputable online forums and review sites that often discuss experiences with different suppliers, both positive and negative. Pay close attention to any hidden costs, such as tooling, minimum order quantities, or shipping, since these costs can impact the price. Check for online specials, as they are often seasonal or time limited.

By applying these techniques, you can significantly reduce the expenses associated with plain PCB boards, ensuring your projects are both successful and cost-effective. Remember, meticulous planning and thorough research are crucial components of smart procurement practices.

Understanding the factors that affect plain pcb board price is essential for anyone involved in electronics projects. Whether you are a hobbyist working on a small circuit or an engineer developing a complex device, knowledge about these price drivers empowers you to manage your budget wisely. From the initial material selection to the final order quantity, every choice affects the bottom line. Remember to compare different suppliers and consider the total cost and value when making purchasing decisions. The plain pcb board price will depend on your specific needs, so do your research to make informed decisions to keep your project within budget.

AnyPCBA

AnyPCBA