Understanding the Integrated Circuit Board: Components, Function, and Applications

The integrated circuit board, or IC board, is a cornerstone of modern electronics, a marvel of miniaturization and functionality. From smartphones to space shuttles, these intricate structures, often called microchips, power our digital world. This article delves into the essence of IC boards, exploring their components, functionality, and diverse applications, connecting the dots between the sophisticated technology and its impact on daily life.

What is an Integrated Circuit Board?

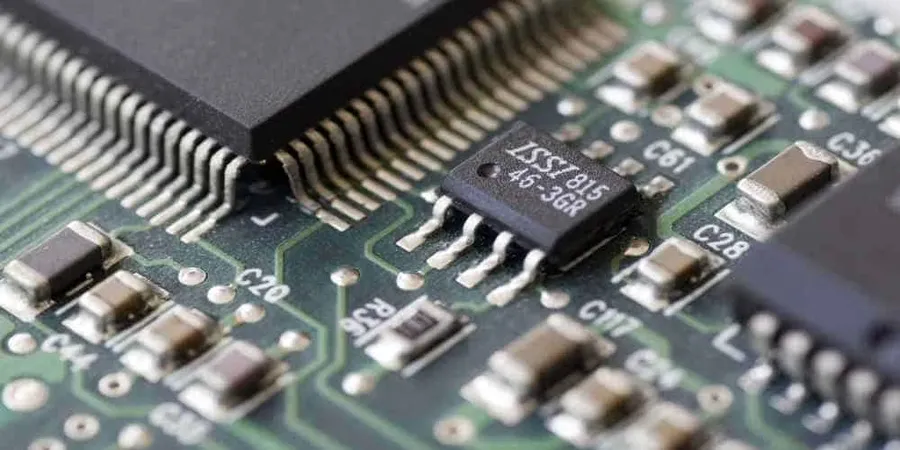

An integrated circuit (IC) board, at its core, is a specialized type of printed circuit board (PCB) assembly meticulously engineered to serve as a platform for hosting and interconnecting integrated circuits. Unlike basic PCBs that primarily facilitate connections between discrete components, IC boards are designed to support the complex functionality of ICs, making them a vital component in modern electronics.

These boards provide a structured layout with precisely defined conductive pathways and connection points, allowing the ICs to operate harmoniously and perform their intended functions, such as signal processing, data storage, and control. The design of an IC board directly influences the performance, reliability, and efficiency of the electronic devices it powers.

Key Components of an Integrated Circuit Board

An integrated circuit board, at its core, is a sophisticated assembly of interconnected components facilitating electronic functionality. These boards are meticulously engineered to host and enable the operation of integrated circuits (ICs), which are the heart of modern electronics. The key components of an IC board include the substrate, conductive traces, vias, pads, and the integrated circuits themselves.

- Substrate

The substrate is the foundational layer of the IC board, typically made from materials like fiberglass-reinforced epoxy (FR-4) or ceramic. It provides mechanical support and insulation for the other components. - Conductive Traces

Conductive traces are thin pathways of copper or other conductive material deposited onto the substrate. They serve as the electrical wiring, connecting different components and carrying signals across the board. The precision of these traces is critical for signal integrity. - Vias

Vias are conductive pathways that create electrical connections between different layers of the substrate. They can be through-hole vias, blind vias, or buried vias, each serving a different purpose for vertical connectivity in multi-layered boards. - Pads

Pads are small conductive areas that facilitate the connection of integrated circuits (ICs) and other components to the board, and are typically where components are soldered to the conductive traces. They are strategically positioned to ensure proper contact and secure mounting. - Integrated Circuits (ICs)

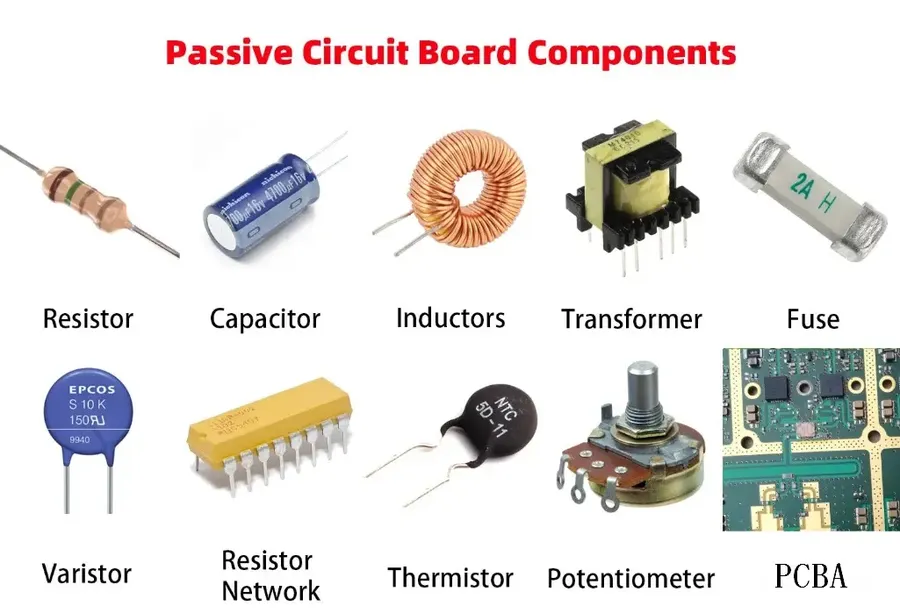

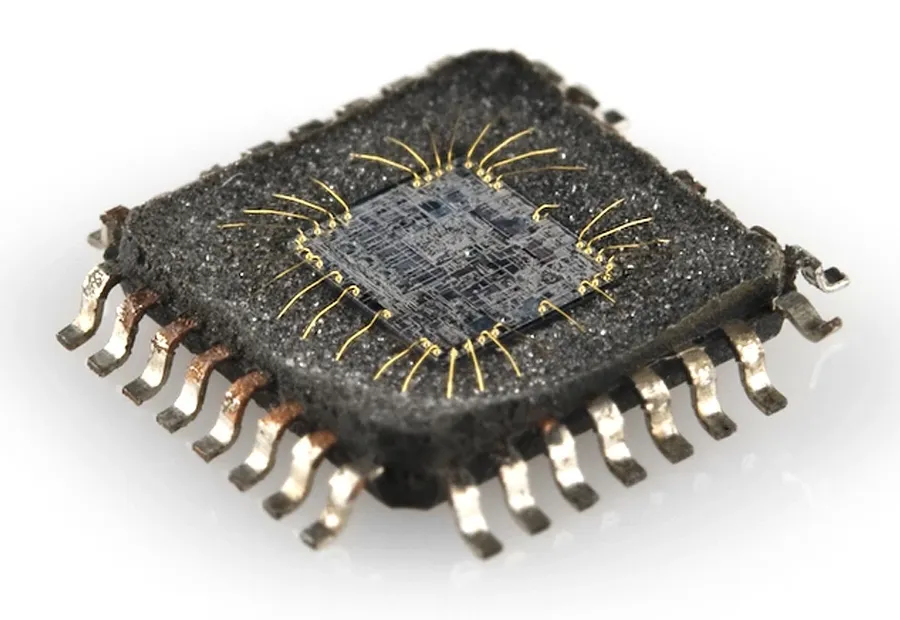

Integrated circuits, the active components of the board, comprise millions or billions of microscopic transistors, resistors, and capacitors interconnected on a single semiconductor chip. These devices perform functions such as logic operations, amplification, and data storage. They are packaged and then mounted on the board's pads using surface mount technology. - Passive Components

Beyond integrated circuits, an IC board typically includes passive components such as resistors, capacitors, and inductors. These components support the functioning of ICs by shaping electrical signals, filtering noise, and storing energy.

The Functionality of Integrated Circuits on the Board

Integrated circuits (ICs) mounted on a circuit board are the active components that execute specific electronic operations. These operations encompass a wide range of functionalities, including signal amplification, data processing, and memory storage, with the board serving as the physical platform for their interconnection and operation.

The board itself does not perform computational operations; rather, it facilitates the necessary electrical connections and physical support for the ICs to function. The interplay between the ICs and the board's architecture is critical for the proper functioning of the system. Below are some of the functions:

- Signal Amplification:

ICs, particularly operational amplifiers, amplify weak electrical signals, making them usable by other circuit components. This is crucial in audio and communication systems. - Data Processing:

Microprocessors and microcontrollers within ICs perform complex calculations, data manipulation, and control operations that are at the heart of computer systems, robotics, and embedded systems. - Memory Storage:

Memory ICs, such as RAM and ROM, store data and program instructions, enabling computers and electronic devices to function and retain information. - Logic Operations:

Logic gates, which form the foundation of digital circuits, perform operations based on binary logic, supporting decision-making and data manipulation. - Signal Conversion:

ICs like analog-to-digital converters (ADCs) and digital-to-analog converters (DACs) convert signals between analog and digital domains, which are required to process real-world signals using digital electronics.

The board’s conductive traces, vias, and pads are carefully designed to ensure that signals are transmitted efficiently between ICs with minimal signal loss or interference, which is critical in high-speed applications. Proper heat dissipation mechanisms are also implemented to manage the thermal load generated by ICs during operation, preventing thermal damage and ensuring reliability.

IC Boards vs. PCBs: Key Differences

Integrated circuit (IC) boards and printed circuit boards (PCBs) are fundamental components in electronics, yet they serve distinct purposes and exhibit significant differences. IC boards are specialized PCB assemblies designed to host integrated circuits, while standard PCBs provide the foundational structure for a broader range of electronic components. Understanding these differences is crucial for effective design and application in electronics.

| Feature | IC Board | PCB |

|---|---|---|

| Primary Function | To host and connect integrated circuits | To provide a platform for various electronic components |

| Complexity | Higher complexity due to intricate routing for ICs | Variable complexity based on application, but generally lower than IC boards |

| Integration Level | Higher integration, specifically designed for ICs | Lower integration, accommodating diverse component types |

| Size | Smaller, focused on specific integrated circuits | Larger, providing overall board structure and connections |

| Component Focus | Primarily focuses on hosting integrated circuits | Accommodates a variety of components, including ICs, discrete parts, connectors |

| Typical Use Cases | In devices where IC integration is critical, like CPUs and GPUs | Used as base boards for various electronics, ranging from simple circuits to complex systems |

Manufacturing Process of an Integrated Circuit Board

The manufacturing of an integrated circuit board (IC board) is a multi-stage process demanding precision and stringent quality control. This process integrates the bare printed circuit board with mounted integrated circuits, requiring specialized techniques for component placement, soldering, and thorough testing to ensure functionality and reliability.

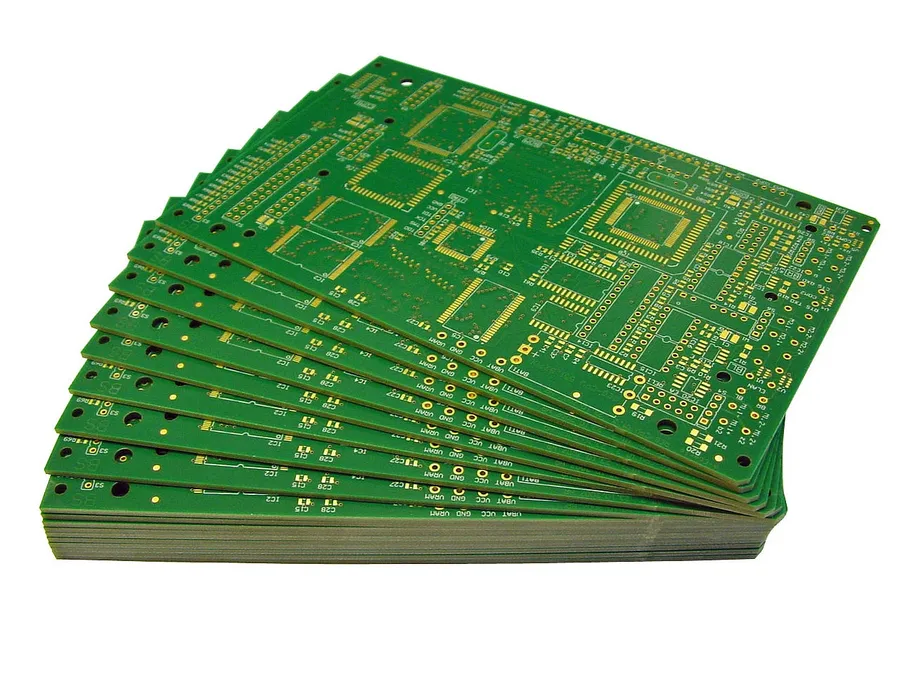

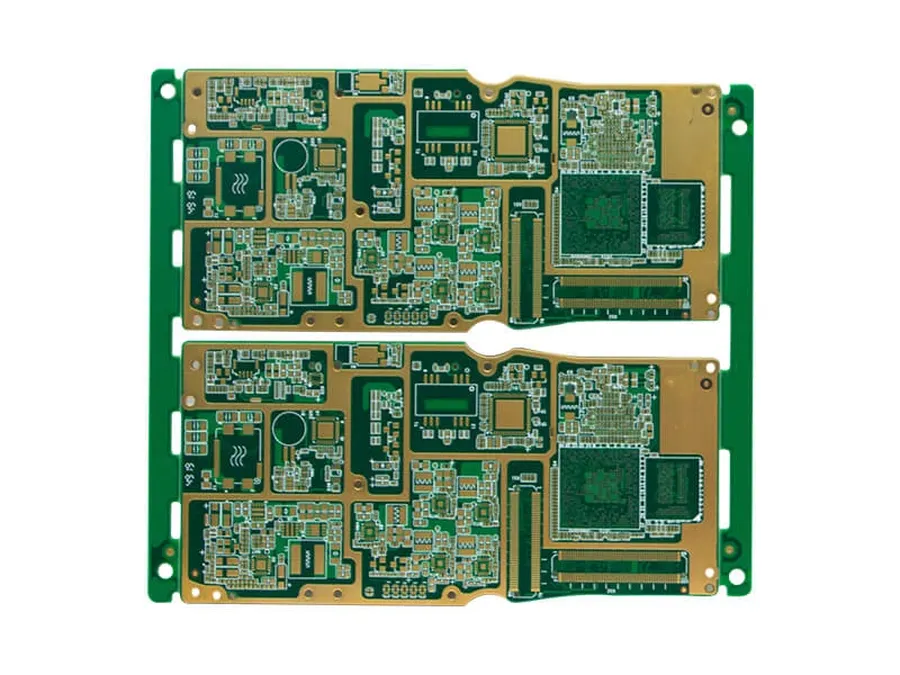

- Bare Board Fabrication

The process begins with the creation of the bare PCB, using materials like FR-4 or other composites. This includes layering, etching, and drilling to form the conductive traces, vias, and pads. - Solder Paste Application

Solder paste, a mixture of solder alloy and flux, is applied onto the PCB pads using stencil printing techniques. This prepares the pads for component mounting. - Component Placement

Automated pick-and-place machines mount the integrated circuits and other surface mount components onto the solder-pasted pads with high accuracy. - Soldering

The reflow soldering process melts the solder paste, creating a mechanical and electrical connection between the components and the PCB. Techniques such as infrared or convection ovens are employed to achieve controlled heating and cooling. - Inspection

Automated Optical Inspection (AOI) and X-ray inspection are utilized to verify the solder joints and component placement to ensure they meet the specified quality standards, also checking for any solder bridges or tombstoning. - Testing

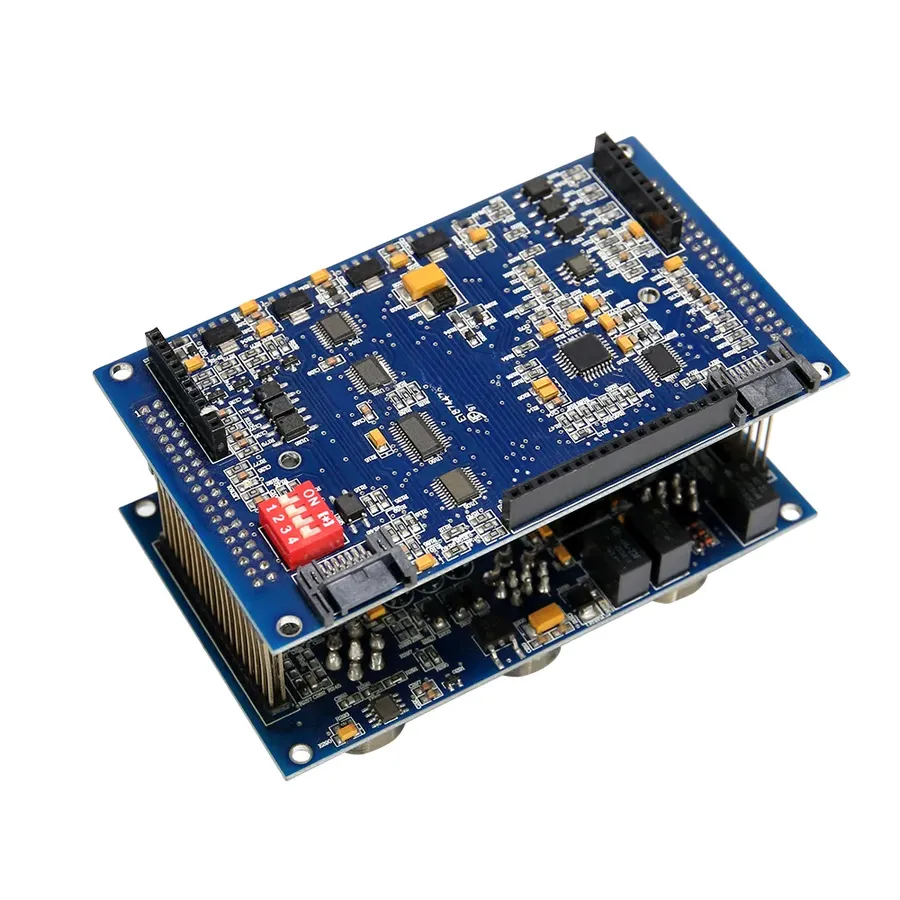

Functional testing is conducted to ensure the assembled board performs correctly. This involves applying power, sending test signals, and verifying outputs and performance. - Thermal Management Considerations

Heat sinks and other thermal management solutions may be added during or after component mounting to dissipate heat generated during operation. - High-Speed Signal Integrity Verification

High-speed signal paths are thoroughly tested and analyzed to ensure signal integrity and minimize noise and distortion.

| Process Step | Description | Technology Used | Purpose |

|---|---|---|---|

| Bare Board Fabrication | Creating the PCB with conductive traces. | Etching, Drilling | Provide foundation for component mounting and electrical connections |

| Solder Paste Application | Applying solder paste on pads. | Stencil Printing | Prepare pads for component soldering |

| Component Placement | Mounting ICs and components. | Pick-and-Place Machines | Accurate and rapid component assembly |

| Reflow Soldering | Soldering components to pads | Reflow Ovens | Establish robust electrical and mechanical connections |

| Inspection | Verify solder joints and component placement. | AOI and X-ray | Identify defects in soldering and component placement |

| Functional Testing | Testing assembled board. | Automated Test Equipment | Verify board’s functionality to specifications |

Applications of Integrated Circuit Boards in Modern Technology

Integrated circuit boards (ICBs) are fundamental to modern technology, enabling the functionality of a vast array of devices across diverse sectors. Their ability to host complex integrated circuits (ICs) allows for sophisticated electronic operations in compact forms, thereby playing a pivotal role in advancing various industries.

- Consumer Electronics

ICBs are the core of consumer devices like smartphones, tablets, laptops, and gaming consoles. They facilitate complex processing, memory management, and connectivity features, leading to increasingly powerful and versatile devices. - Industrial Automation

In industrial settings, ICBs are used in programmable logic controllers (PLCs), robotic systems, and automated machinery. They enable precise control, monitoring, and communication, improving efficiency and safety in manufacturing processes. - Automotive Systems

Modern vehicles rely heavily on ICBs for engine management, safety systems (such as anti-lock braking and airbags), infotainment systems, and advanced driver-assistance systems (ADAS). The evolution of automotive electronics is directly tied to advancements in ICB technology. - Aerospace

Aerospace applications require high-reliability ICBs for flight control, navigation, communication, and satellite systems. Their ability to withstand harsh conditions and provide precise operation is paramount to ensuring safe and efficient space exploration and air travel. - Medical Equipment

Medical devices, including diagnostic imaging machines, patient monitoring systems, and surgical robots, depend on ICBs for accurate data processing, signal analysis, and control. This is critical to ensuring high quality and patient safety in healthcare.

Factors Affecting Integrated Circuit Board Performance

The performance of an integrated circuit board is a multifaceted issue influenced by a range of factors, from fundamental material properties to complex operational parameters. Optimizing these factors is critical for achieving reliable and efficient performance in electronic applications. This section examines these factors, offering insights into how they impact functionality and strategies for mitigation.

| Factor | Description | Impact on Performance | Mitigation Strategies |

|---|---|---|---|

| Material Selection | Choice of substrate (e.g., FR-4, ceramic, metal core) and dielectric materials used in the PCB. | Influences signal speed, thermal properties, and mechanical stability. Poor material choice can cause signal degradation and thermal issues. | Selecting materials that match thermal requirements and signal characteristics to reduce impedance mismatch and enhance durability. |

| Signal Integrity | Refers to the quality of electrical signals as they travel through the traces and vias of the board, avoiding signal distortion. | Signal reflection, crosstalk, and impedance mismatch can lead to data corruption, reduced signal strength, and functionality errors. | Employing techniques such as impedance matching, differential signaling, minimizing trace lengths, and shielding. Utilizing simulation tools for optimized layout design. |

| Thermal Management | How effectively heat generated by ICs and other components is dissipated. | Insufficient heat dissipation can cause overheating, component failure, and degraded performance. | Integrating heat sinks, thermal vias, using thermal interface materials, and airflow design. Considering components placement to facilitate better heat dissipation. |

| Power Consumption | The amount of electrical power the board and its components require to operate. | High power consumption leads to increased energy costs, battery drain, and thermal challenges. Inefficient power distribution can also affect IC operation. | Use power-efficient components and ICs, optimized routing, implementing efficient power distribution networks. Adopting power management techniques. |

| Cost-Effectiveness | Balancing performance with the overall cost of materials and manufacturing processes. | High-performance materials and complex manufacturing techniques can increase production costs. Choosing cost-effective materials or less complex designs may lower cost but can impact performance and reliability. | Evaluating cost vs. performance tradeoffs, value engineering, optimizing designs for manufacturability. Choosing alternative material that provides the same performance with less cost. |

| Lifespan and Reliability | How long the board operates reliably under normal conditions. | Environmental factors and operational stress can impact longevity. Components failures and circuit degradation can affect reliability. | Stringent quality control measures, environmental testing, proper component selection, and implementing fail-safe mechanisms for long-term reliability. |

Frequently Asked Questions about Integrated Circuit Boards

This section addresses common inquiries regarding integrated circuit boards, providing clarity on their distinctions, design influences, current trends, and overall importance within electronics.

- What are the Key Differences Between an Integrated Circuit (IC) and a Printed Circuit Board (PCB)?

An IC, or integrated circuit, is a miniaturized electronic circuit fabricated on a semiconductor material (typically silicon), performing a specific function. A PCB, or printed circuit board, serves as a structural foundation for connecting and supporting electronic components, including ICs, through conductive traces. While ICs are the active components that process electrical signals, PCBs provide the physical platform for their connection and power distribution. IC boards are a type of PCB specifically designed to integrate multiple ICs. - How do Integrated Circuits Influence PCB Design?

The number, type, and functionality of ICs dictate a significant portion of the PCB design. Considerations include pin layout, trace width and spacing to handle required signal integrity and current flow, and thermal vias for heat dissipation, particularly for high-power ICs. PCB design tools are used to ensure component placement and trace routing are optimized for performance and manufacturability based on the required ICs. Proper PCB design is crucial for an IC to function correctly within the integrated system. - What are the Latest Trends in Integrated Circuit Board Technology?

Current trends encompass miniaturization (smaller form factors with greater component density), the use of advanced materials (such as thermally conductive substrates), increased integration with AI systems (for smart devices and complex logic), and improved signal integrity at higher speeds. Innovative techniques such as 3D IC packaging and flexible circuit board are emerging to meet the rising demand for smaller, faster, and more efficient integrated circuits. - What is the Importance of Integrated Circuit Boards in Modern Electronic Devices?

Integrated circuit boards are foundational to modern electronics, enabling the functionality of virtually every electronic device we use today. They are responsible for the miniaturization, processing power, and reliability required for smartphones, computers, medical equipment, industrial control systems, and countless other applications. The development and improvement of IC board technology continue to drive innovation and progress across numerous industries. - What is an Integrated PCB?

An integrated PCB refers to a printed circuit board that has active and passive components embedded directly within its layers, rather than mounted on the surface, this approach allows for higher component density and a more compact overall design which is sometimes called a system in package (SIP). It blurs the line between traditional PCBs and IC packaging offering an additional level of miniaturization and performance improvement. - What are some considerations for the long-term reliability of integrated circuit boards?

Reliability considerations include material selection, avoiding material mismatches in the thermal expansion coefficients of the materials used in the layers and components, implementing robust designs that protect against environmental stressors, ensuring the quality of manufacturing processes and component reliability, and implementing thermal management to mitigate the effects of temperature variations in the circuit. Proper testing during manufacturing also ensures the long-term integrity and reliability of the product.

Future Trends and Innovations in Integrated Circuit Board Technology

The field of integrated circuit board technology is experiencing rapid evolution, driven by the continuous demand for smaller, faster, and more efficient electronic devices. Future trends and innovations focus on advanced materials, miniaturization techniques, and the integration of artificial intelligence to enhance board capabilities and performance.

- Miniaturization and High-Density Integration

Continuing the trend of making electronic devices smaller and more powerful, future IC boards will feature higher component densities, finer traces, and smaller vias through advanced fabrication methods such as 3D stacking and chiplet technology. This miniaturization supports the development of more compact and wearable devices. - Advanced Materials

The use of new substrate materials with enhanced thermal conductivity and dielectric properties will be critical for high-speed and high-frequency applications. These advanced materials include novel polymers, ceramics, and composite materials that will improve board performance, reduce heat generation, and enable more reliable operation in extreme environments. - Integration with Artificial Intelligence

Future IC boards will likely integrate AI and machine learning capabilities directly onto the hardware. These smart boards could perform on-device data processing and decision making, improving the efficiency and speed of various applications, such as edge computing and IoT devices. This also includes adaptive routing and self-testing capabilities. - Flexible and Stretchable Electronics

The development of flexible substrates and conductive inks will enable the creation of IC boards that can conform to different shapes and surfaces. This innovation is crucial for wearables, implantable medical devices, and flexible displays, enabling new applications that traditional rigid PCBs cannot support. - Sustainable and Eco-Friendly Practices

There's a growing emphasis on environmentally friendly manufacturing processes for IC boards, focusing on reducing waste, using recycled materials, and employing energy-efficient methods. These practices reduce the environmental footprint of the electronics industry, moving towards more sustainable production cycles. - Enhanced Thermal Management

With increasing power densities, thermal management solutions will be more crucial. Innovations such as embedded heat pipes, microchannels for liquid cooling, and advanced thermal interface materials will be essential for maintaining optimal operating temperatures and ensuring the longevity of IC boards.

The integrated circuit board is at the heart of modern electronics, enabling the sophisticated functions of countless devices. From their intricate design to their crucial applications, IC boards represent a significant advancement in technology. Understanding their components, functions, and future trends allows us to appreciate their crucial role in shaping our digital landscape, emphasizing how the integrated circuit board is the cornerstone of electronic innovation.

AnyPCBA

AnyPCBA