Understanding Universal PCB Board Price: A Comprehensive Guide

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) are the backbone of virtually all electronic devices. From smartphones to industrial machinery, PCBs provide the essential connections for components to function. The cost of a universal PCB board, often the starting point for many electronic projects and prototypes, can vary widely depending on several factors. This guide will explore what influences the universal pcb board price, helping you make informed decisions for your next project, whether you're prototyping or planning large-scale production, and explore all the key factors you need to know about price.

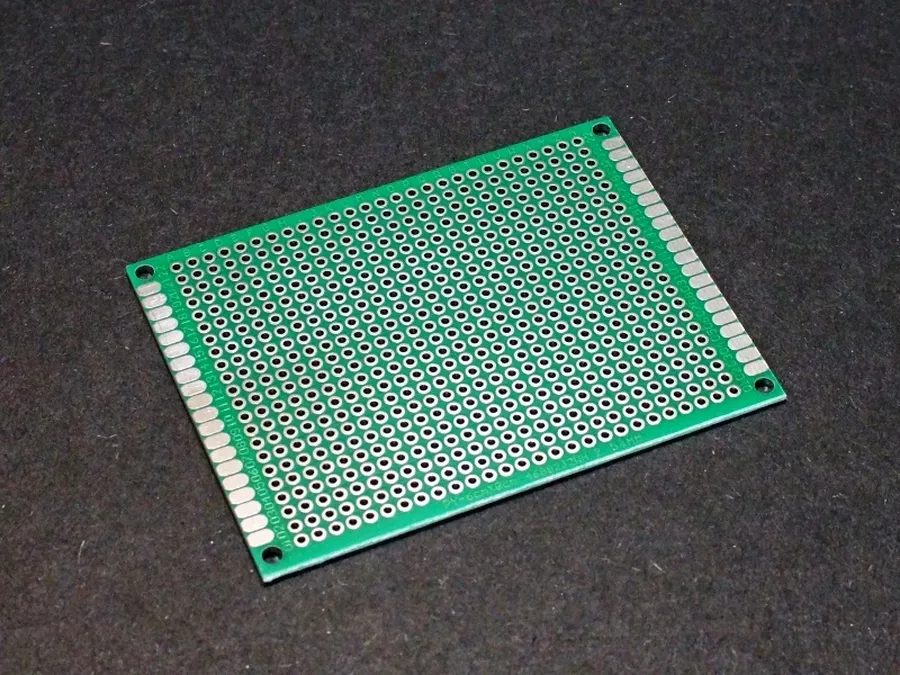

What is a Universal PCB Board?

A universal PCB board, also referred to as a prototype board or perfboard, serves as a foundational platform for electronics experimentation and circuit development. Characterized by a standardized grid of pre-drilled holes, these boards facilitate the flexible placement and interconnection of electronic components, enabling users to build and test circuits before committing to a custom-designed PCB.

The selection of materials in universal PCB construction directly influences both the board's performance and its cost. While several materials are available, FR-4 and phenolic are the most common, with FR-4 being the industry standard due to its superior balance of cost, durability, and thermal resistance. Understanding the properties of these materials is key to making informed decisions for your electronic projects.

| Material | Description | Cost | Advantages | Disadvantages |

|---|---|---|---|---|

| FR-4 | Fiberglass composite with epoxy resin. | Moderate | Good balance of durability, electrical insulation and thermal resistance, widely available. | Can be more expensive than phenolic. |

| Phenolic | Paper-based composite with phenolic resin. | Low | Very low cost, lighter than FR-4 | Lower durability, less temperature resistant and not as good as an insulator as FR-4. |

The cost of a basic PCB, particularly a universal or prototype board, is not fixed and varies based on several key factors. These include size, material, and the quantity purchased. A smaller board like a 7x9cm PCB will invariably be less expensive than a larger one such as a 12x18cm board. Moreover, buying in bulk significantly lowers the per-unit cost. The term 'basic' is relative and depends on the specific application, with simpler projects generally requiring less expensive boards.

- Size

The physical dimensions of the PCB directly influence the cost, with larger boards requiring more raw material and thus being more expensive. - Material

While FR-4 is the standard and affordable material, its properties still have an impact on the cost, with variations in thickness also having an impact. - Quantity

Purchasing in larger quantities will lower the price per unit. The more boards you buy at once, the less each one is likely to cost. - Complexity

Single-sided boards tend to be cheaper than double-sided boards, and basic projects that don't require the functionality of double-sided boards will reduce costs.

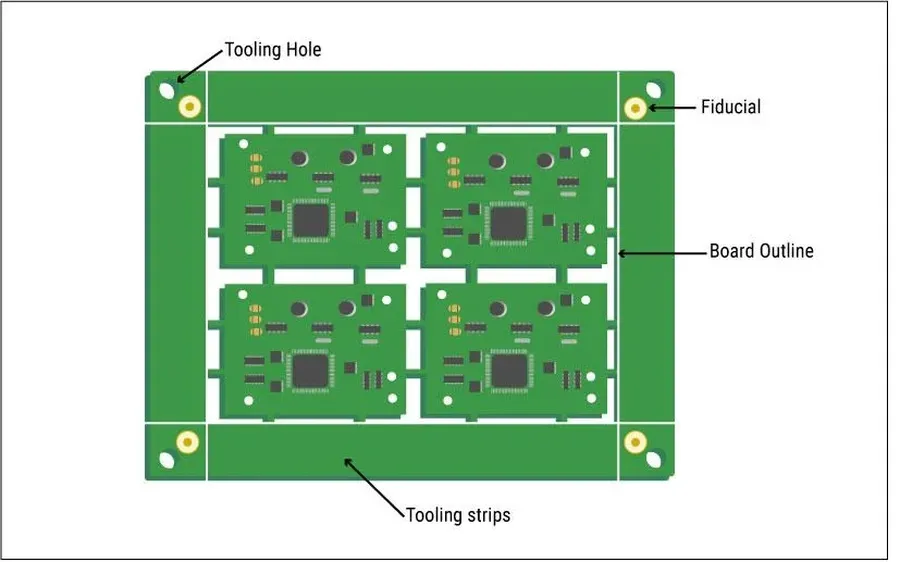

Factors Affecting Universal PCB Board Price

The price of a universal PCB board is not fixed; it's a result of several interacting factors. These include the base material, physical dimensions, the complexity of the board’s design (single or double-sided), the board's thickness, the specific manufacturer involved, and the quantity purchased. A thorough understanding of these elements is essential for accurate project budgeting and cost management.

| Factor | Description | Impact on Price |

|---|---|---|

| Material Composition | Type of material used, typically FR-4 (fiberglass composite), but sometimes phenolic. | FR-4 is generally cost-effective but higher grade materials will increase costs |

| Size and Dimensions | The physical size of the board, commonly ranging from 5x7 cm to 12x18 cm or larger. | Larger boards require more materials, leading to higher prices. |

| Single-Sided vs. Double-Sided | Whether the board has conductive copper tracks on one side or both. | Double-sided boards are usually more costly than single-sided due to increased manufacturing complexity. |

| Board Thickness | The thickness of the PCB which can vary. Common thicknesses are 1.6mm but can be greater or smaller. | Thicker boards can impact material costs and thus increase the price |

| Manufacturer | The chosen manufacturer's pricing policies and production overhead. | Prices vary across manufacturers due to their different production costs and margin expectations. |

| Quantity Ordered | The number of boards purchased in one order. | Bulk purchases usually result in lower per-unit costs due to economies of scale. |

Material Composition

The material that a universal PCB board is made of plays a crucial role in determining its cost and performance characteristics. The most common material is FR-4, a fiberglass composite known for its balance of affordability, durability, and heat resistance. While FR-4 is the industry standard, alternative materials like phenolic are sometimes used, often offering lower cost but potentially compromising on structural integrity and heat tolerance. FR-4 offers a strong and robust product at a reasonable cost, while phenolic boards tend to be more brittle and therefore more prone to damage.

Size and Dimensions

The physical size of a universal PCB board directly influences its cost; larger boards necessitate more base material, thereby increasing their price. These boards come in various sizes, catering to diverse project needs. Smaller boards such as those around 5x7cm are generally used for simple projects. Larger boards, such as 10x15cm or 12x18cm are suitable for more complex circuits. Choosing the appropriate dimensions is critical for both cost management and ensuring the board is sufficiently sized for the intended project layout.

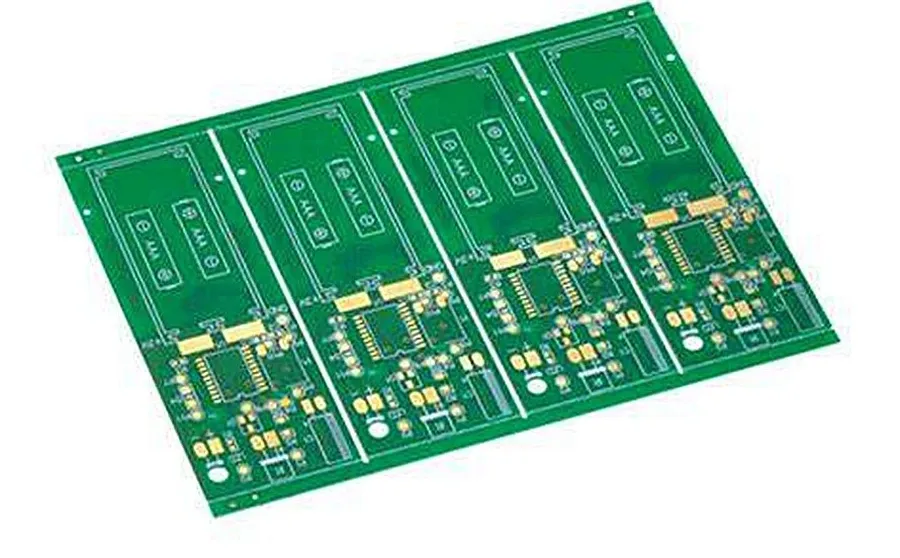

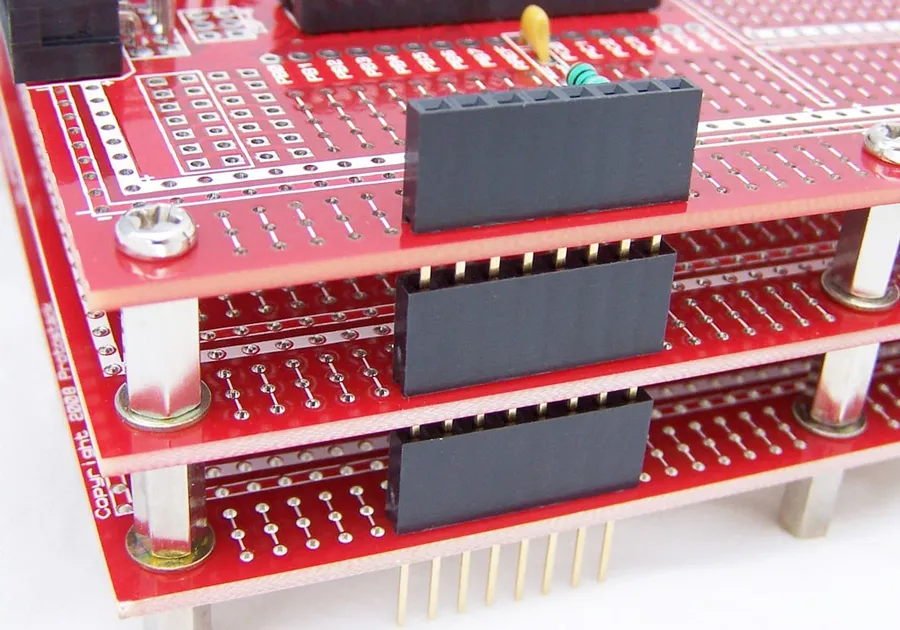

Single-Sided vs. Double-Sided Boards

The complexity of a PCB’s design, specifically whether it is single-sided or double-sided, affects its cost and functionality. Single-sided boards have conductive copper traces on one side only, which limits the complexity of circuits that can be implemented. Double-sided boards feature copper traces on both sides, which facilitates more complex circuit designs and therefore have a higher manufacturing cost. The decision between single-sided and double-sided depends on the intricacy of the circuit being developed, as the double sided board gives greater design flexibility but also with a slight increase in cost.

The physical size and dimensions of a universal PCB board are directly correlated with its price. Larger boards necessitate more raw material, translating to higher costs. Selecting the appropriate size is critical for project success and budget adherence.

| Board Size (cm) | Typical Use Cases | Approximate Price Range (USD, per board, retail) |

|---|---|---|

| 5x7 | Small, simple circuits, basic prototyping | $0.5 - $2.0 |

| 7x9 | General-purpose prototyping, small projects | $1.0 - $3.5 |

| 10x15 | Medium complexity circuits, larger projects | $2.5 - $5.0 |

| 12x18 | Complex projects, multiple components | $4.0 - $7.0 |

It is important to note that these price ranges are estimates and can fluctuate based on the vendor, order quantity, and any specific features of the board. Selecting the optimal dimensions should balance project requirements with budget considerations.

The economic viability of replacing a PCB board hinges on a careful evaluation of repair costs versus replacement expenses, alongside time implications and board availability. For standard universal PCB boards, which are generally inexpensive, replacing them is often the more practical option due to its cost-effectiveness and time efficiency. However, for specialized PCBs, such as those found in sophisticated appliances or industrial equipment, repair might be a more sensible option given their higher replacement costs and potential impact on project timelines.

- Factors Favoring PCB Replacement

Universal PCBs, also known as prototype boards, tend to be inexpensive, making replacement a straightforward and quick solution. The labor cost associated with diagnosing and repairing a fault on these boards often exceeds the cost of a new board. Additionally, the time saved by simply replacing the board, rather than attempting a component-level repair, can be crucial for projects with tight deadlines. Replacement is particularly suitable when the PCB damage is extensive or the faulty component is difficult to source or repair. - Factors Favoring PCB Repair

Repair is often the better option for specialized or custom-designed PCBs that are expensive or difficult to replace. PCBs in complex appliances or industrial equipment fall into this category. The cost of a complete replacement can be substantial, often exceeding the labor cost of repair. Component-level repair allows the recovery of the existing PCB, preventing the loss of custom design elements or proprietary technology embedded in the board. Furthermore, for legacy systems, replacement components may be unavailable, leaving repair as the only viable path to restore functionality. - Cost-Benefit Analysis

A thorough cost-benefit analysis is necessary to decide between repair and replacement. Consider not only the monetary costs but also the downtime, lead time for replacement, and the complexity of the repair. In a business setting, downtime can impact production, so a quick fix might be favored over a potentially lengthy repair. The availability of qualified personnel with component-level repair skills can also impact the decision. A practical approach is to gather quotes for both repair and replacement, and compare these against the potential downtime and project timelines to make an informed decision.

The primary distinction between single-sided and double-sided universal PCB boards lies in the number of conductive layers. Single-sided boards feature copper traces on only one side of the board, while double-sided boards have conductive traces on both sides, interconnected by vias. This difference significantly impacts the board's capacity for circuit complexity and, consequently, its cost.

| Feature | Single-Sided PCB | Double-Sided PCB |

|---|---|---|

| Conductive Layers | One | Two |

| Circuit Complexity | Lower | Higher |

| Cost | Generally lower | Generally higher |

| Via Usage | Not Required | Required for Layer Connections |

| Application | Simpler Circuits | More Complex Circuits |

Double-sided boards, while allowing for more intricate designs, come at a slightly higher price due to the additional manufacturing steps and material required. Single-sided boards are adequate for simpler circuits and are more cost-effective for basic prototyping or hobbyist projects. The choice between single-sided and double-sided boards should be dictated by your project's complexity and budget constraints.

Where to Buy Universal PCB Boards and Average Prices

Universal PCB boards are readily available from various sources, each offering different price points and quantities. Understanding where to purchase these boards and the typical price ranges is key to effective project budgeting. Prices are influenced by factors such as the vendor, purchase quantity, board size, and type, along with additional shipping costs.

| Source | Typical Purchase | Price Range (per piece) | Notes |

|---|---|---|---|

| Online Marketplaces (Amazon, eBay, AliExpress) | Small packs (e.g., 10 pieces) | $0.80 - $1.50 | Convenient for small projects, may have higher unit costs due to retail markups. |

| Direct from Electronic Suppliers | Various quantities | $0.60 - $1.20 | Offers a range of options, prices are often competitive but may be affected by shipping |

| Manufacturers/Wholesale Platforms (Alibaba, Made-in-China) | Large quantities (e.g., 100+ pieces) | $0.35 - $1.00 | Best for bulk orders; significantly lower per-unit costs due to economies of scale. |

The most common size PCB is the 7x9cm board, with a small pack of 10 pieces generally ranging from $8 to $15 from online marketplaces. Larger quantities obtained directly from manufacturers can often bring the price down to as little as $0.35 to $1 per board. When making a purchase, it is also imperative to factor in shipping costs, which can vary depending on the vendor's location and the weight of the package, ultimately impacting the final cost.

Understanding Cost Differences Between Retail and Wholesale

The pricing of universal PCB boards exhibits significant variation between retail and wholesale channels, primarily due to differing operational models and cost structures. Retail platforms typically involve higher per-unit costs compared to wholesale purchases because of additional overhead expenses related to storage, handling, and distribution.

Retailers like Amazon and eBay operate on a business model that incorporates storage, individual order processing, and customer service overheads, all of which contribute to the final selling price. These platforms cater to smaller-quantity purchases and often provide convenience and accessibility to individual consumers.

In contrast, wholesale channels, including direct manufacturers and platforms such as Alibaba and Made-in-China, offer lower per-unit costs. This reduction stems from the principles of economies of scale. Wholesalers typically focus on large bulk orders, thereby minimizing per-unit production and handling costs. This direct-to-customer model reduces the need for intermediary storage and distribution processes, enabling them to offer competitive pricing to businesses and bulk purchasers.

| Factor | Retail Purchase (e.g., Amazon, eBay) | Wholesale Purchase (e.g., Manufacturer, Alibaba) |

|---|---|---|

| Unit Price | Higher | Lower |

| Order Quantity | Typically smaller, individual orders | Larger, bulk orders |

| Handling Costs | Higher due to storage, packing, and distribution | Lower due to streamlined bulk handling |

| Lead Time | Generally faster for smaller quantities | May vary depending on manufacturing & shipping time |

| Customer Support | Provided by retailer, more customer-oriented | Often limited to bulk order transactions |

| Suitable for | Individual users, small projects | Businesses, large-scale projects |

Frequently Asked Questions About Universal PCB Board Prices

This section addresses common questions regarding the pricing of universal PCB boards. Understanding these aspects will aid in making informed decisions for your electronic projects and provide a clearer understanding of the cost drivers.

- What factors most significantly influence the price of a universal PCB board?

The primary factors affecting the price of a universal PCB board include the board's material (typically FR-4), dimensions, whether it's single or double-sided, the manufacturer, and the order quantity. Larger boards and double-sided designs will increase costs, while bulk purchases generally lower the per-unit price. - How does the size of a universal PCB board affect its price?

Larger PCB boards cost more due to the increased material consumption in their production. For example, a small 5x7 cm board is significantly cheaper than a 10x15 cm or larger board. Choose the smallest practical size for your project to minimize costs. - Why are double-sided PCBs more expensive than single-sided boards?

Double-sided PCBs require additional manufacturing processes to create conductive tracks on both sides of the board and vias which connect both sides. This added complexity results in higher production costs compared to single-sided boards, which only have traces on one side. - Is it cost-effective to repair or replace a damaged universal PCB board?

For universal PCBs, replacement is usually more cost-effective and time-efficient than repair, as they are inexpensive. However, for specialized PCBs in complex appliances, repair may be the preferred option, provided the cost of repair is less than the cost of a replacement PCB board. - Where is the most cost-effective place to buy universal PCB boards?

The most cost-effective places to buy universal PCBs depends on the quantity. For small quantities, online retailers like Amazon or eBay are convenient, but for larger quantities, direct purchasing from manufacturers or wholesale platforms (e.g., Alibaba, Made-in-China) offers lower per-unit costs. Be sure to compare shipping costs as well. - How can I save money on universal PCB board purchases?

To minimize costs, buy in bulk if your project requires a large number of boards, use standard sizes to avoid material waste, choose single-sided PCBs if your design allows, and thoroughly compare prices from various vendors. Planning your needs and consolidating orders will also reduce shipping costs. - Do PCB prices fluctuate, and if so, why?

Yes, PCB prices can fluctuate due to changes in raw material costs, the demand for electronics, and advancements in manufacturing processes. Staying flexible and informed about market trends will help you adjust to potential price changes.

Practical Tips for Saving on Universal PCB Board Costs

Minimizing expenses when purchasing universal PCB boards involves strategic planning and informed purchasing decisions. Several key factors can contribute to significant cost savings without compromising project quality or functionality. These include bulk purchasing, efficient material usage, and strategic vendor selection.

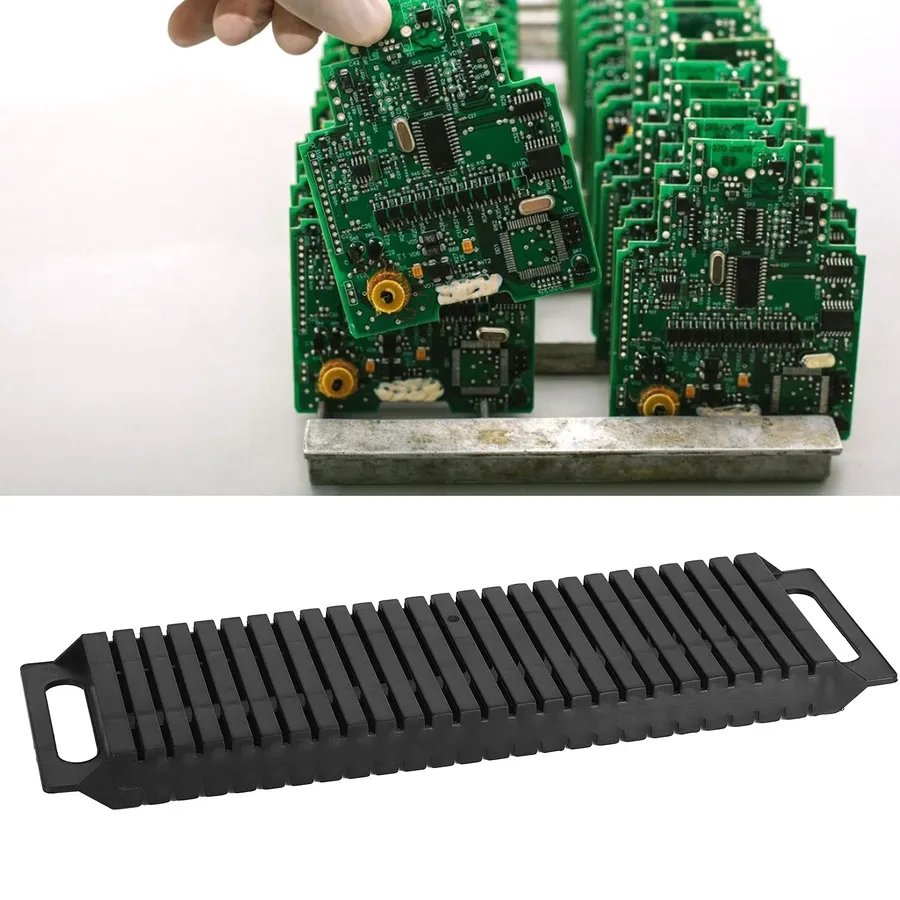

- Bulk Purchasing

When projects necessitate a large number of boards, purchasing in bulk is a cost-effective approach. Per-unit costs are reduced by manufacturers and suppliers for large orders due to economies of scale, significantly lowering the overall project expense. This is a common practice that leverages the manufacturer’s cost savings. - Standard Sizes

Utilizing standard PCB sizes reduces material wastage. Purchasing standard 7x9 cm, 10x15 cm, or 12x18 cm boards ensures that unnecessary cutting and material waste are minimized and therefore reduce cost. This is due to optimization in the manufacturer’s process. Custom cutting usually has an additional labor cost associated with it. - Single-Sided vs. Double-Sided

For projects where circuit complexity doesn't demand a double-sided board, opting for single-sided boards can decrease costs. Single-sided boards are cheaper to produce and thus less expensive to purchase. Evaluate your circuit design to see if it is possible to use a single sided board, before choosing a double-sided one. - Vendor Comparison

Researching and comparing prices from multiple vendors is crucial to finding the best deals. Prices for universal PCBs can vary widely between suppliers. Check a variety of sources such as online marketplaces, electronic component suppliers, and direct manufacturer websites. This will ensure you get the best price for the specification you need. - Consolidated Ordering

Placing all board orders at the same time minimizes shipping costs. Combining several orders into one avoids duplicate shipping fees and reduces the overall project costs. When possible combine all your requirements into a single order. Shipping is one of the primary drivers of PCB cost. - Strategic Planning

Proper planning, including detailed specifications and BOM management, reduces the need for reorders or adjustments, which can incur additional costs. Planning will also eliminate costly errors and the need for reordering. By combining these methods you will be able to reduce your PCB costs significantly.

The Future of Universal PCB Boards and Pricing Trends

The market for universal PCB boards is dynamic, influenced by technological advancements, economic factors, and supply chain efficiencies. Anticipating price fluctuations requires understanding these driving forces, as they directly impact the cost of materials and manufacturing processes.

The demand for electronics drives the market for PCBs, with increased demand potentially leading to price increases. Conversely, lower demand, due to economic downturn or technological advancements that reduce the need for prototyping, can result in lower prices. Furthermore, the cost of raw materials, such as copper and fiberglass, is also a significant factor in PCB board costs. Price trends can be anticipated by monitoring reports from commodities markets and manufacturing industry publications.

Developments in PCB manufacturing processes also play a role in pricing. For example, innovations in materials, such as the development of more durable yet less expensive PCB base materials, could lower costs. Likewise, increased automation in production can lead to reductions in labor costs and faster production times. In the long term, these advancements may make universal PCB boards cheaper and more accessible.

Maintaining a flexible approach to procurement and staying updated on technological and economic trends will enable you to adapt to future pricing fluctuations. This involves carefully assessing project requirements, exploring alternative board materials and manufacturers, and timing purchases to align with more favorable market conditions.

Understanding the factors influencing the universal pcb board price is crucial for any electronic project, whether you're a hobbyist or a professional. By considering the material, size, and source of your PCB purchase, you can balance cost with the quality needed for your project. Remember that while the universal pcb board price is usually very low, planning and selecting the correct board will ensure the project stays affordable. Keep yourself informed on the current trends in the market, and you can confidently obtain what you need for your next electronic adventure.

AnyPCBA

AnyPCBA