Understanding Voltera V-One PCB Printer Price and Its Value

In today's electronics landscape, rapid prototyping is key for innovation and development. The Voltera V-One PCB printer provides a way to create circuit boards at your desk, changing how engineers and designers approach prototyping. This article will carefully examine the Voltera PCB printer price, the features that impact its value and justify this price, offering a breakdown of the cost to help you decide if it is a right fit for your projects.

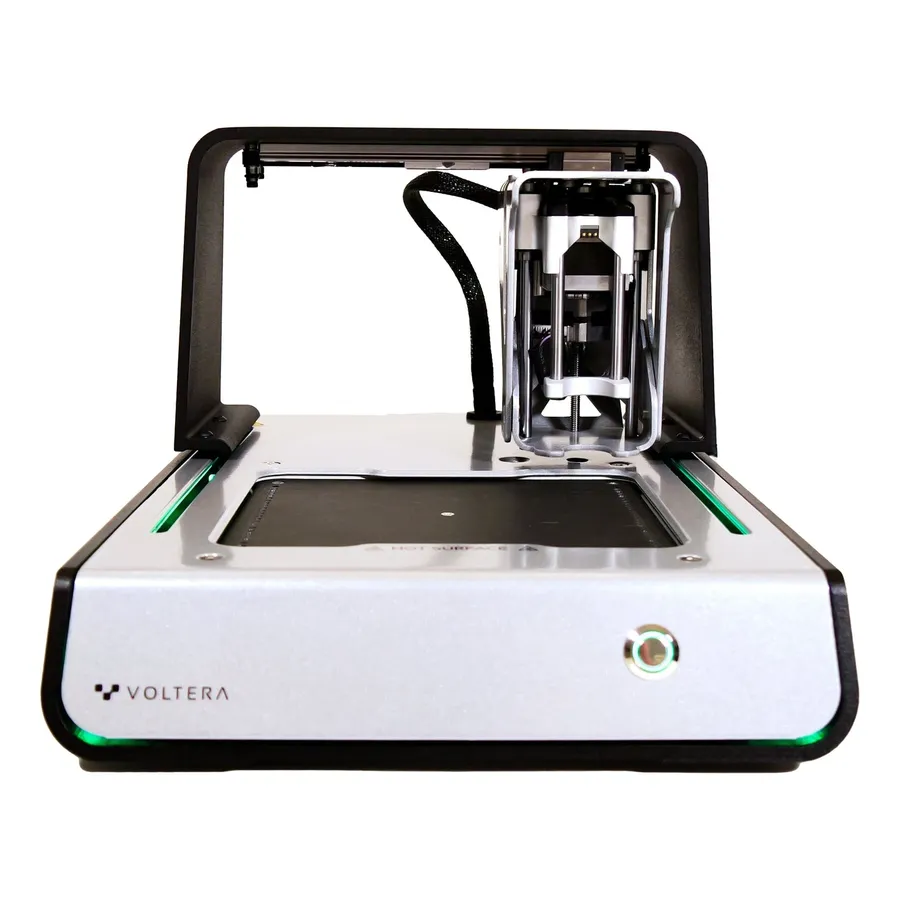

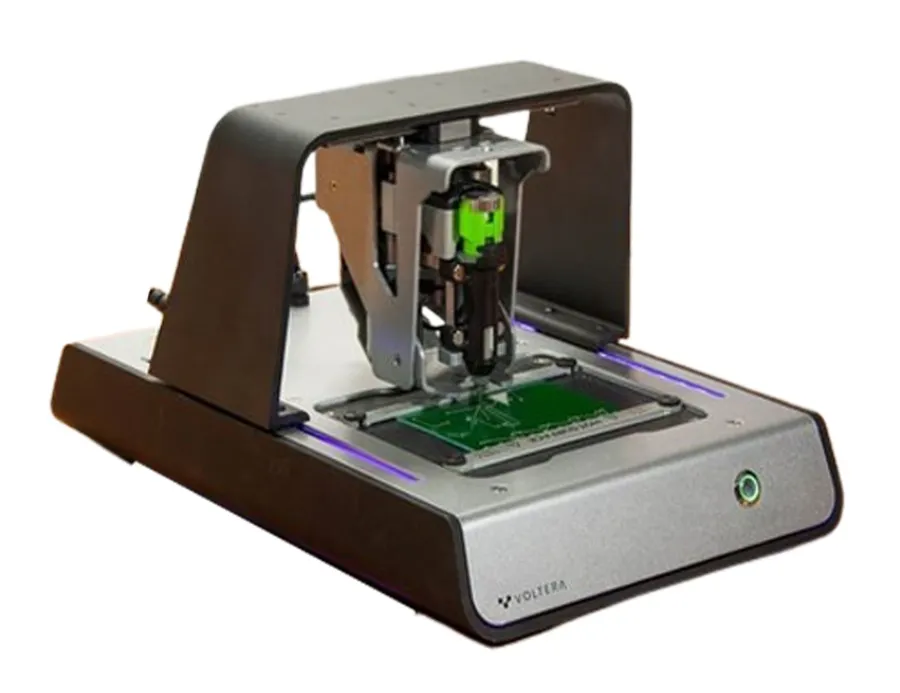

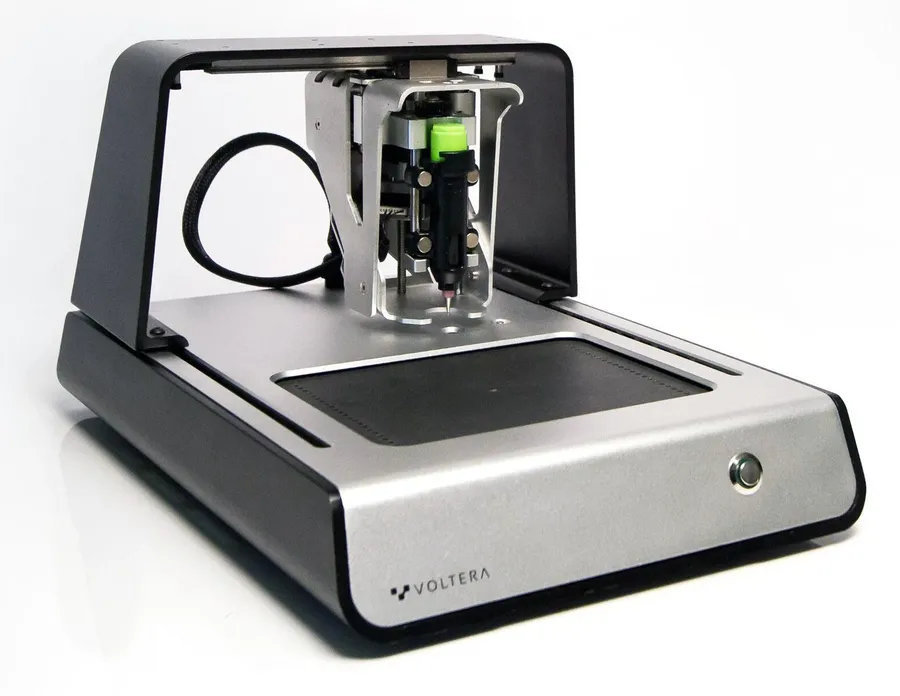

Voltera V-One: Overview of Features and Functionality

The Voltera V-One is a desktop-sized, multi-functional rapid prototyping machine designed for electronics engineers. It's primarily known for its ability to fabricate custom printed circuit boards (PCBs) in-house, offering a significant advantage in accelerating the design and testing process. This device integrates PCB printing, solder paste dispensing, and reflow capabilities into a single unit, streamlining the prototyping workflow.

- PCB Printing

Utilizes conductive inks to directly print circuit traces onto a variety of substrates. This allows for the creation of functional PCBs without the need for traditional etching processes. - Solder Paste Dispensing

Precisely applies solder paste onto the printed traces, enabling the placement of surface mount components. This capability is crucial for creating fully assembled PCBs. - Reflow Soldering

The integrated reflow system heats the board to melt the solder paste, creating robust electrical connections between the components and the PCB traces. This completes the PCB assembly process within the same device.

Key functionality includes the ability to quickly iterate through different PCB designs without the delays associated with external fabrication services. This offers considerable advantages to engineers and researchers in environments where quick turnaround times are essential.

Current Market Price of the Voltera V-One

The Voltera V-One, a desktop PCB printer, occupies a unique space in the electronics prototyping market. Its price reflects its capabilities as an all-in-one rapid prototyping solution, combining PCB printing, solder paste dispensing, and reflow functionalities. Understanding the current market price involves considering not only the base unit cost, but also regional variations and vendor-specific pricing.

The base price for the Voltera V-One typically ranges between $4,000 to $5,000 USD. However, this is a general estimate, and the final price can vary due to several factors, including:

- Geographical Location:

Prices may differ across regions due to shipping costs, import duties, and local taxes. For instance, the price in Europe or India might be higher than in the United States due to these additional costs. Always check with local distributors for accurate pricing. - Vendor-Specific Pricing:

Voltera may have authorized distributors, each setting their own prices, potentially resulting in slight variations. Always compare offers from different sources. It's advisable to contact Voltera directly or check their official website for a list of authorized vendors. - Bundled Packages:

Some vendors may offer the Voltera V-One as part of a package that includes additional supplies such as inks, solder paste, or drill bits. This type of pricing could offer savings if you need these supplies anyway, but may lead to higher initial costs than buying the basic machine alone.

When looking to purchase a Voltera V-One, it is important to consider that prices are subject to change due to market conditions and manufacturer policies. For up-to-date pricing and vendor locations, it's best to refer to the official Voltera website or contact them directly through their customer service.

Additionally, it is recommended that users verify their local distributors and look for special promotions to get the best value.

Analyzing Additional Costs Beyond the Initial Price of the Voltera PCB Printer

While the initial purchase price of the Voltera V-One PCB printer is a significant consideration, a comprehensive cost analysis must include the ongoing operational expenses. These costs primarily stem from consumables, maintenance, and potential upgrades, all of which contribute to the total cost of ownership.

| Cost Category | Description | Estimated Cost | Frequency |

|---|---|---|---|

| Conductive Ink | Specialized ink used for printing circuit traces. | $50-$150 per cartridge | Varies with usage |

| Solder Paste | Used for component mounting and reflow. | $30-$80 per syringe/jar | Varies with usage |

| Substrates | Materials used as the base for PCB printing. | $10 - $50 per panel | Per sheet |

| Drill Bits | Needed for creating through-holes (vias). | $10-$30 per set | As needed |

| Dispensing Tips | Small nozzles used for ink and paste application. | $5 - $15 per pack | As needed |

| Maintenance | Routine cleaning and calibration tools/supplies. | $20-$50 per instance | Regularly |

| Software Updates/Upgrades | Optional software upgrades may incur additional costs. | $0-$200 | As needed |

| Replacement Parts | Parts that wear out or need replacement over time. | Variable | As needed |

Understanding these additional costs is vital to accurately assess the financial viability of using the Voltera V-One for PCB prototyping. These expenses should be factored into your budgeting, enabling you to make informed decisions regarding its use and long-term value.

Why the Voltera V-One Price Justifies Its Rapid Prototyping Capabilities

The Voltera V-One's price is intrinsically linked to its capacity for rapid prototyping, a crucial aspect of modern electronics development. The printer's ability to quickly produce prototype PCBs significantly accelerates the design-test-iterate cycle, which in turn dramatically reduces time-to-market and overall development costs.

Rapid prototyping with the Voltera V-One offers several key advantages, each contributing to its value proposition:

- Reduced Time-to-Market

By enabling in-house, same-day PCB fabrication, the Voltera V-One minimizes delays associated with traditional PCB manufacturing processes. This can translate to faster product launches and a competitive advantage in fast-paced markets. - Agile Design Iterations

The speed at which prototypes can be produced allows engineers to test and refine design modifications more frequently. This iterative process is crucial for catching and fixing potential issues early in the development cycle, leading to more robust and reliable final products. - Cost-Effective Prototyping

While the initial investment may seem substantial, the elimination of per-design PCB fabrication costs, shipping fees, and associated lead times results in significant long-term cost savings, particularly for projects requiring multiple iterations. - Enhanced Design Security and Intellectual Property Control

By keeping the PCB fabrication process in-house, design teams maintain complete control over their intellectual property, eliminating the risks associated with outsourcing sensitive design information. - Immediate Feedback for Design Improvements

Rapid prototypes allow for immediate testing and evaluation, providing quick feedback to guide iterative design adjustments. This significantly accelerates the design process and allows for more refined products.

In conclusion, the Voltera V-One’s price is justified by its ability to compress the design-to-prototype timeline, reduce overall development expenditures, and provide a secure environment for innovation. The investment in rapid prototyping with the V-One is an investment in efficiency, speed and long-term value.

Comparative Analysis: Voltera V-One Price vs Other PCB Fabrication Methods

The Voltera V-One offers a unique approach to PCB fabrication, positioning itself against traditional methods. This section provides a cost-benefit analysis, weighing the immediate expense of the V-One against the typically lower per-board cost of traditional fabrication, but including considerations for time, iteration speed, and design control.

| Feature | Voltera V-One | Traditional PCB Fabrication |

|---|---|---|

| Initial Investment | Higher upfront cost for the printer | Lower upfront costs; per-board charges |

| Prototyping Speed | Very Fast; rapid iteration cycles in-house | Slower; turnaround times depend on manufacturer |

| Per-Board Cost | Potentially higher for large production runs | Lower for larger quantities |

| Turnaround Time | Immediate; on-demand fabrication | Days to weeks, shipping and process time |

| Design Control | Full control; direct in-house design testing | Limited; reliance on manufacturer's guidelines |

| Consumables | Ongoing cost for inks, solder paste, etc | No consumable costs to consider |

| Suitability | Ideal for rapid prototyping, low-volume and complex designs | Ideal for mass production and simpler designs |

The key differentiation lies not just in the upfront price but in the overall workflow. While traditional methods may offer a lower per-board price, the Voltera V-One significantly reduces the time between design and a functional prototype, allowing for rapid iteration, in-house design validation, and less reliance on external vendors, which often entails increased lead times and the possibility of design misunderstandings. The choice depends heavily on project scale and the need for speed.

User-Centric Review: The Voltera V-One from a Customer's View

Understanding the Voltera V-One's true value requires a deep dive into the experiences of its users. This section synthesizes feedback from the engineering community, focusing on user-reported pros and cons concerning the device's performance and how these perceptions tie into its price point.

Customer reviews highlight a range of opinions, with many praising the Voltera V-One for its rapid prototyping capabilities, ease of use, and the convenience of having in-house PCB fabrication. However, some users have noted concerns regarding the price of consumables and the device's limitations for more complex PCB designs.

Here's a summary of the key takeaways from user reviews:

- Positive Feedback

Many users appreciate the Voltera V-One for its ability to drastically reduce the time between design and testing. The ability to prototype in-house is considered a major advantage for iterative design processes. The user-friendly interface and ease of setup are also frequently mentioned as strong points. - Challenges and Concerns

Some users have expressed concern about the cost of the device itself, as well as recurring costs for consumables like ink and solder paste. There are also limitations concerning the complexity and layer count achievable with the V-One compared to professional PCB fabrication services. Maintenance requirements and learning curve for optimum usage have also been cited as minor drawbacks. - Price vs. Performance

The question of whether the performance justifies the cost is recurring. While the Voltera V-One offers significant convenience and speed advantages, some users suggest it's more suited for rapid prototyping of simpler designs rather than mass production. The value proposition is strong for small engineering teams and research facilities where iteration speed is paramount, but may be less appealing for high-volume production environments. Users generally agree that the Voltera V-One provides good value if used for its intended purpose as a rapid prototyping tool.

Frequently Asked Questions about Voltera V-One Pricing

This section addresses common questions regarding the Voltera V-One PCB printer's pricing, providing clear and concise answers to assist potential buyers in making informed decisions. We delve into specifics about cost variations, model comparisons, and what factors influence the final price.

- What is the typical price range for the Voltera V-One?

The Voltera V-One is positioned as a professional rapid prototyping tool, and its price reflects this. While specific costs can fluctuate based on region, vendor, and any bundled options, the general price range sits in the mid-range for desktop PCB printers, typically costing several thousand dollars. It's essential to get a direct quote from Voltera or an authorized reseller for the most accurate current pricing. - How does the Voltera NOVA price compare to the Voltera V-One?

The Voltera NOVA is a more advanced machine compared to the V-One, offering greater capabilities and precision. Therefore, its price will be significantly higher than the V-One. It serves a different market segment, targeting professional and industrial users. When considering the NOVA, users are often not just concerned with price, but the total cost of ownership. This should be the determining factor for selecting between these two options. - What factors affect the price of a Voltera V-One?

Several factors can influence the final price of a Voltera V-One. These include your geographical location, as shipping and import costs can vary. Additionally, the specific vendor or authorized reseller you purchase from can have an impact. Finally, bundled options with extra inks, dispensing heads, drill bits, or software licenses can raise the initial price, but provide more value in the long-term. - What is the price of the Voltera V-One in India?

The price of the Voltera V-One in India can vary due to import duties, taxes, and local distributor markups. Prospective buyers in India should request direct quotes from authorized Voltera distributors within India to get the most accurate and up-to-date pricing. There are distributors of Voltera equipment in many countries throughout the world, and India is no exception. The best and most accurate way to find the price of the Voltera V-One in India is to contact a local reseller. - Does the Voltera V-One come with everything needed to start printing PCBs?

The Voltera V-One usually comes with the essentials to start printing basic PCBs, but a complete setup does require additional consumables. These include conductive inks, solder paste, and possibly drill bits. The included items typically enable 'out-of-the-box' basic functionality for users to learn the machine's functions and get started on basic projects. Reviewing the specific list of included components in your quote or the product documentation is the best way to know what you should have as a complete package. - What is the ongoing cost after the initial purchase of a Voltera V-One?

Beyond the initial purchase price, ongoing costs for the Voltera V-One primarily consist of consumables such as conductive inks and solder paste. Frequency of use directly influences how quickly these need replacing. Inks are highly important, and a major part of the running costs. It is best to factor these costs into your overall evaluation of the equipment. - Where can I find the most reliable information on current Voltera V-One pricing?

The most reliable information on current Voltera V-One pricing is from the Voltera company directly or through their authorized resellers. Contacting them directly through their website is a reliable way to obtain accurate pricing and understand any current deals. Always be cautious with pricing information from third parties and unofficial websites.

Tips for Maximizing Your Investment in the Voltera V-One

To ensure the best return on your investment in the Voltera V-One, it’s crucial to adopt strategies that optimize its performance and longevity. This involves not just operational practices, but also a thoughtful approach to resource usage and maintenance. By implementing these measures, users can significantly reduce costs and extend the life of their printer while ensuring consistent high-quality output.

- Ink Conservation Strategies

Efficient use of conductive and insulating inks is paramount. Optimize your designs to minimize ink usage without compromising functionality. Use the printer’s software to adjust ink dispensing settings to the lowest necessary level for reliable printing. Additionally, proper storage of inks in a cool, dark environment, when not in use, helps prevent premature drying or degradation. - Effective Maintenance Practices

Regular maintenance is essential for peak performance. Clean the print head and dispensing nozzles routinely according to manufacturer guidelines. This prevents clogs and ensures consistent material flow. Calibrate the printer regularly to maintain accuracy and alignment. Additionally, always use recommended cleaning solutions and techniques to avoid damage to the printer's sensitive components. - Optimizing Printer Settings

Familiarize yourself with the software settings. Experiment with various parameters, such as printing speeds and layer thicknesses, to find the optimal balance between print quality and material usage. Start by testing small prototypes to refine your settings before undertaking larger projects, minimizing wastage and ensuring the desired results. - Proper Material Handling

Always ensure that the PCB substrates used in the printer are flat and free of debris. This helps ensure a smooth printing process and reduces the risk of damage or print errors. When changing materials or refilling ink, always follow the manufacturer’s instructions precisely to prevent contamination or system malfunction. - Regular Software Updates and Monitoring

Keep the printer's software updated to the latest version to benefit from bug fixes and performance improvements. Monitor printer performance regularly, looking for any signs of wear or malfunction. Addressing small issues promptly can prevent bigger, more costly problems down the line.

Evaluating the Long-Term Value of the Voltera V-One

The Voltera V-One's long-term value is rooted in its ability to provide consistent rapid prototyping capabilities, dramatically reducing the time and cost associated with traditional PCB fabrication methods. This allows for iterative design improvements, and can significantly reduce the overall product development timeline. Its on-demand fabrication capability offers a valuable asset for both research and development and short-run production.

By sidestepping the waiting times inherent in sending designs to external fabrication houses, engineers can make real-time adjustments and test concepts quickly and effectively. This capability becomes increasingly valuable over time, especially when the cost savings of iterative design cycles are compounded. This approach enhances product innovation and reduces the risk of costly errors in final production runs.

Considering the ongoing trend towards miniaturization and the increasing demand for customized electronic solutions, the Voltera V-One's ability to handle complex designs and unique requirements will become an even greater advantage for the user.

Furthermore, the Voltera V-One helps companies to maintain complete control over their intellectual property. By keeping PCB prototyping in-house, there is a lower risk of exposing designs to external parties, adding an additional layer of security and strategic advantage.

The long-term value of the Voltera V-One isn't just limited to cost-saving and time reduction, it also offers a platform for continuous learning and development. Engineers and students will develop a more profound understanding of electronics manufacturing, allowing them to better design for manufacturing in future projects. As technology progresses, the skills acquired by using this printer will become progressively more beneficial.

The Voltera V-One presents a unique blend of rapid prototyping and desktop convenience with its price as a core consideration. This article has broken down the price, features, and costs associated with the V-One to help potential buyers assess whether its advantages justify the expense. The Voltera pcb printer price is a real factor but it comes with long term value in terms of speed and convenience, which ultimately offers a significant value proposition for those looking for a rapid prototyping solution.

AnyPCBA

AnyPCBA