Understanding Zero PCB: A Comprehensive Guide to Prototyping Without the Zero PCB Cost

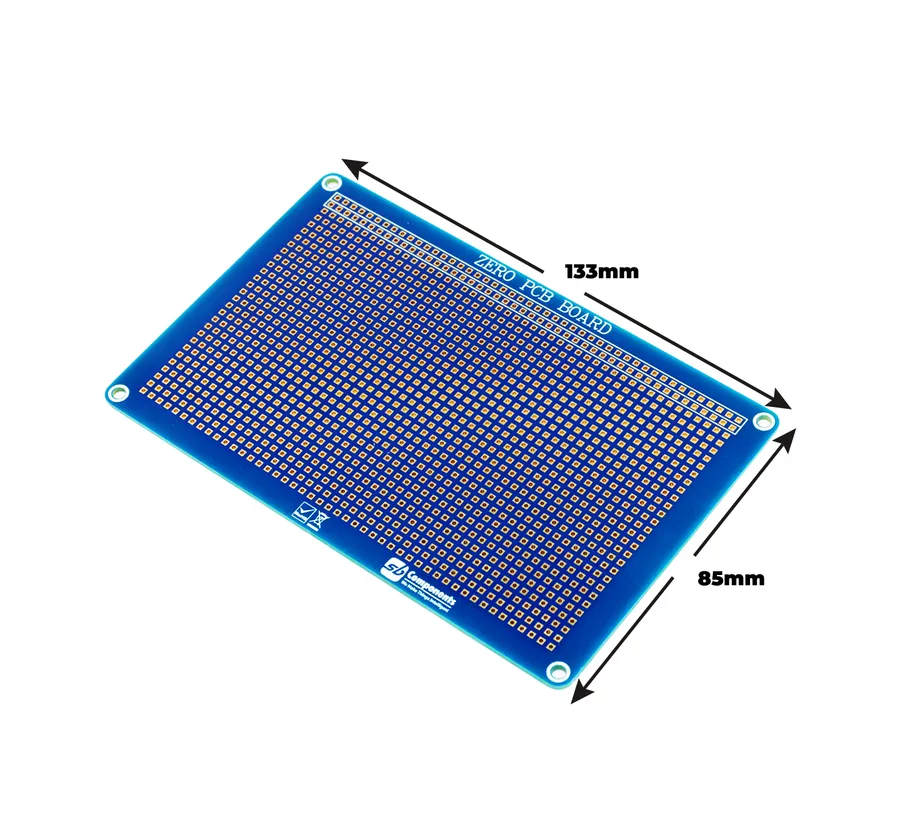

In the dynamic realm of electronics, where innovation thrives, the concept of 'zero' often signifies a starting point, a blank canvas ready for creation. Similarly, the Zero PCB emerges as a fundamental tool, a blank slate for circuit prototyping and experimentation. Unlike conventional PCBs with pre-etched traces, the Zero PCB allows for flexible component arrangement and customization, making it an essential stepping stone for electronic enthusiasts and engineers alike. This article will delve deep into the essence of Zero PCBs, highlighting their unique attributes, applications, and practical use.

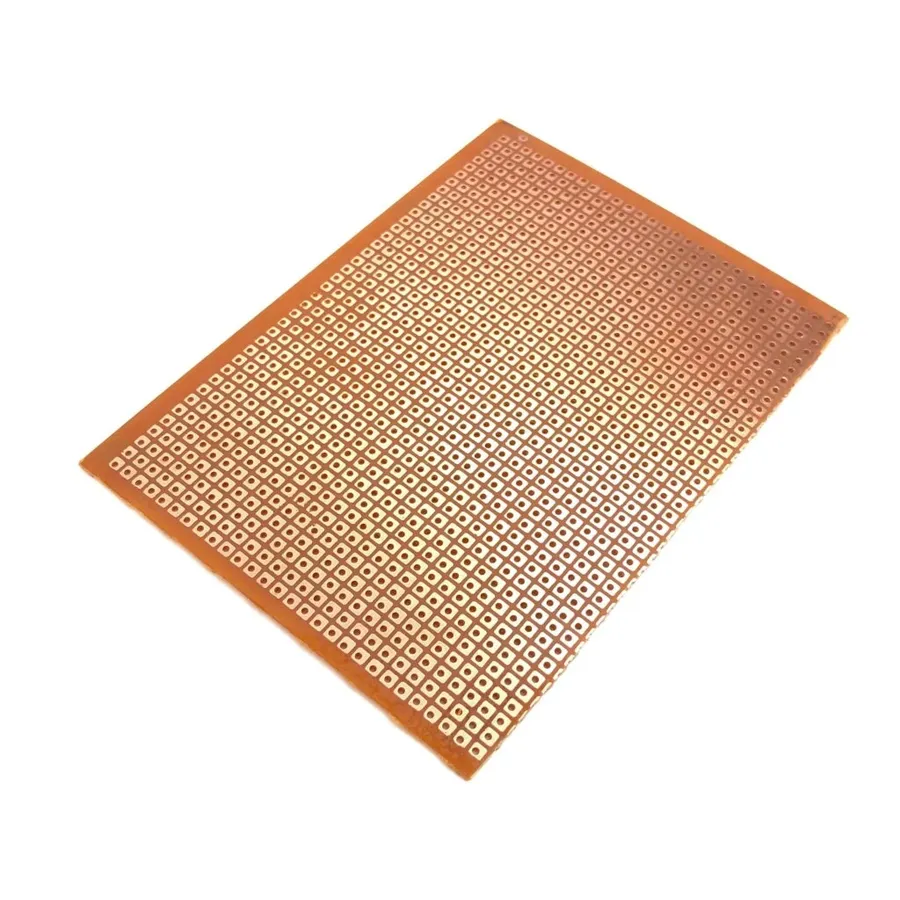

What is a Zero PCB?

A Zero PCB, often referred to as a perfboard or protoboard, is a fundamental type of circuit board characterized by a grid of holes, typically featuring copper pads around each hole. Unlike standard printed circuit boards (PCBs), a Zero PCB lacks any pre-defined conductive tracks or circuit patterns. Its primary function is to provide a versatile platform for the manual assembly and testing of electronic circuits. Components are placed and connected by soldering or wiring, creating custom circuits as needed.

Key characteristics of a Zero PCB include:

- Grid of Holes:

The uniform grid of holes provides a flexible layout for various components, including resistors, capacitors, integrated circuits, and transistors. - Copper Pads:

The copper pads surrounding the holes facilitate reliable soldering and electrical connections. - Absence of Predefined Circuits:

The lack of pre-etched tracks requires manual creation of the circuit pathways, enabling prototyping and customization.

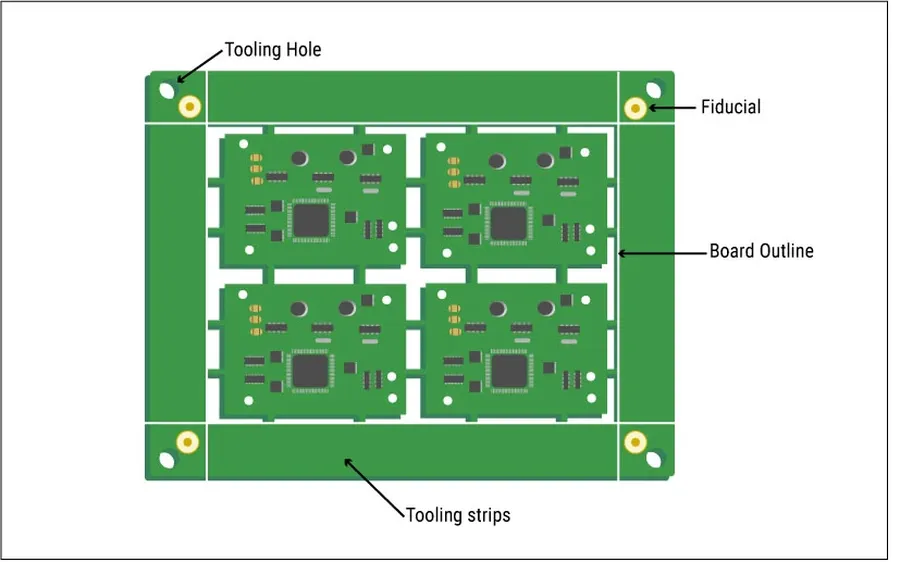

Zero PCB vs. Standard PCB: Key Differences

Zero PCBs, also referred to as perfboards or protoboards, stand in stark contrast to standard Printed Circuit Boards (PCBs) in their design, application, and manufacturing process. Unlike standard PCBs, which are meticulously engineered for specific circuit designs, zero PCBs provide a versatile platform for manual circuit construction and prototyping. This fundamental difference leads to a variety of distinctions in their usage and advantages.

| Feature | Zero PCB | Standard PCB |

|---|---|---|

| Circuit Design | Universal grid of holes, no predefined tracks | Custom-designed with specific circuit patterns |

| Manufacturing | No manufacturing process; manual assembly required | Requires professional fabrication with etching and plating processes |

| Assembly | Manual component placement and wiring | Automated component placement and soldering is typical |

| Flexibility | Highly flexible for modifications and experimentation | Limited flexibility after design is finalized |

| Cost | Lower cost, ideal for prototyping and small projects | Higher cost, especially for custom designs and small production runs |

| Prototyping | Ideal for quick and low-cost prototyping | Not ideal for iterative prototyping |

| Production | Not suitable for mass production | Suitable for mass production with consistent quality |

| Permanence | Solderable connections offer a semi-permanent construction | Highly permanent connections |

The selection between a zero PCB and a standard PCB hinges largely on the project requirements, encompassing factors like budget, project stage, and the volume of production. Zero PCBs are favored during the early stages of design and prototyping due to their inherent flexibility and cost-effectiveness. Conversely, standard PCBs become the preferred choice once the design has been finalized and requires high precision and a more streamlined manufacturing process for final product development or mass production.

Types of Zero PCBs

Zero PCBs, while seemingly simple, come in several varieties, each suited to different prototyping needs. Understanding these variations is crucial for selecting the most appropriate board for your project, ensuring both efficiency and effectiveness in your design process. The key differentiators include the number of conductive layers, the presence or absence of plated through-holes, and the grid pattern.

| Type | Description | Typical Use Cases | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Sided Zero PCB | Has copper traces on one side only. | Simple circuits, educational projects | Lower cost, easier to work with | Limited complexity, difficult for high-density projects |

| Double-Sided Zero PCB | Has copper traces on both sides. | More complex circuits, medium-density projects | Increased routing options, higher component density | Slightly more difficult to solder, requires more care |

| Zero PCB with Plated Through-Holes | Holes are plated with conductive material, allowing connections between layers. | Circuits requiring multiple layers connections, more robust designs | Facilitates easier soldering and component connection, allows for vertical stacking of components | Slightly more expensive |

| Zero PCB without Plated Through-Holes | Holes are not plated, connections are limited to the same side. | Simple circuits where all connections can be made on one side | Lowest cost, simple manufacturing process | More challenging to make inter layer connections |

| Various Grid Patterns | Common grid patterns including 2.54mm (0.1-inch) and sometimes smaller. | Varying component sizes and mounting options | Flexibility in component choice | May require specific adapters for non-standard components |

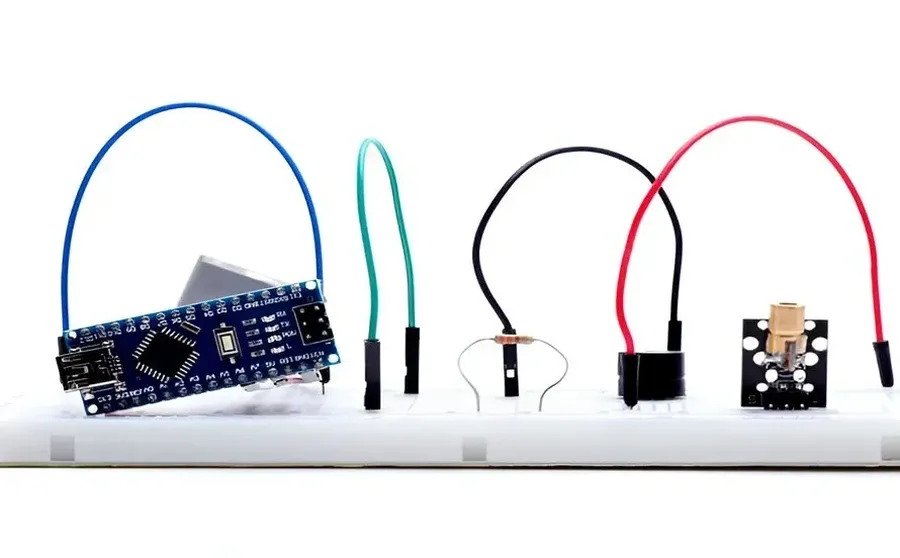

How to Make a Circuit on a Zero PCB

Constructing a circuit on a zero PCB, also known as perfboard or protoboard, involves the manual placement of electronic components and the creation of electrical connections using soldering, wires, or jumpers. Unlike standard PCBs with pre-etched conductive tracks, zero PCBs require the user to manually establish all circuit paths, providing maximum flexibility during the prototyping phase.

- Component Placement

Begin by positioning the electronic components onto the zero PCB. Plan the layout to minimize wire crossings and ensure efficient use of space. - Soldering

Secure components to the board by soldering their leads to the copper pads. Use a soldering iron and solder wire to create robust and reliable connections. - Creating Traces

Use wire jumpers, or solder to form connections between the component leads and between components to build the circuit paths. Ensure correct connectivity based on your circuit design. - Testing

Test the circuit thoroughly after soldering by applying power and checking all signal points using a multimeter. Make adjustments as necessary to achieve the desired functionality.

| Aspect | Zero PCB | Standard PCB |

|---|---|---|

| Circuit Path Creation | Manual connections via soldering, wires | Pre-defined copper tracks |

| Flexibility | High flexibility for modifications | Limited flexibility after manufacturing |

| Cost | Lower cost for small batches/prototypes | Higher cost for manufacturing |

| Prototyping | Ideal for prototyping and experimentation | Not ideal for iterative prototyping |

Zero PCB Applications and Benefits

Zero PCBs, celebrated for their adaptability and cost-effectiveness, find extensive use across diverse applications, particularly in prototyping, educational environments, and DIY electronics. Their key advantage lies in enabling rapid circuit design testing without the delays or financial burdens associated with custom PCB manufacturing.

- Prototyping

Zero PCBs serve as an essential platform for prototyping electronic circuits. Engineers and hobbyists use them to validate designs and make necessary adjustments before committing to mass production. This allows for quicker turnaround time on design iterations. - DIY Electronics Projects

The versatility of zero PCBs makes them perfect for hobbyists and makers working on custom electronic projects. Their lack of predefined circuits provides the flexibility needed for unique builds and adaptations. - Educational Settings

In educational institutions, zero PCBs offer a hands-on learning experience in electronics and circuit design. Students can assemble circuits, understand the relationship between components, and learn soldering techniques, thus bridging the gap between theoretical knowledge and practical application. They are used to build circuits, teach electronics, and understand the basics of hardware design. - Cost-Effectiveness

Zero PCBs are notably more economical than custom-made PCBs, particularly for small-scale prototypes and one-off projects. This makes them accessible to students, hobbyists, and small businesses operating on a tight budget. - Flexibility and Ease of Modification

The absence of predefined tracks on a zero PCB provides a high degree of flexibility. Circuit designs can be altered or components swapped with ease and minimal effort. This level of flexibility greatly assists with the process of designing and refining new circuit prototypes. - Rapid Testing and Iteration

Zero PCBs allow for quick testing of new circuit designs and quick design modifications without requiring the typical lead time of custom PCBs. This rapid turn-around time significantly accelerates the development process of new products and allows for more agile improvements.

| Feature | Zero PCB | Custom PCB |

|---|---|---|

| Cost | Low | High |

| Flexibility | High | Low |

| Lead Time | Immediate | Longer |

| Modification | Easy | Difficult |

| Ideal Use | Prototyping, DIY, Education | Mass Production |

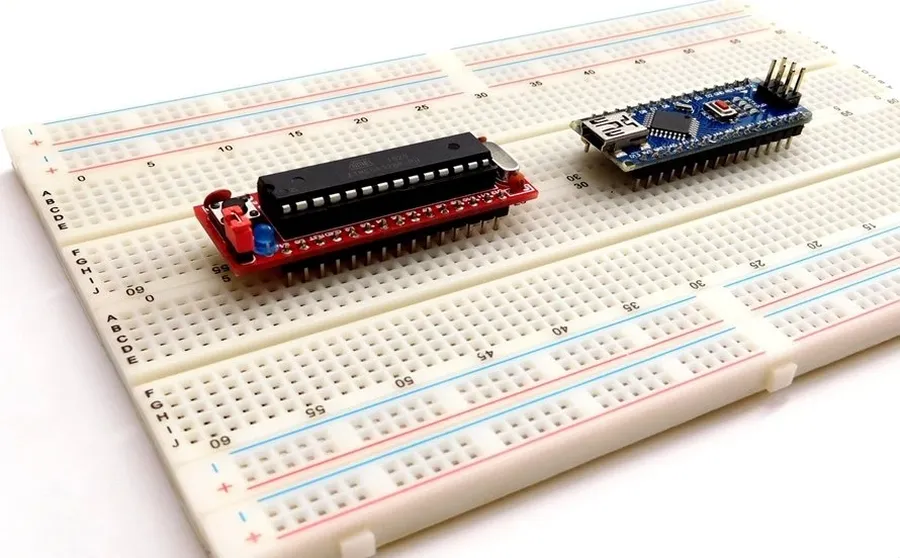

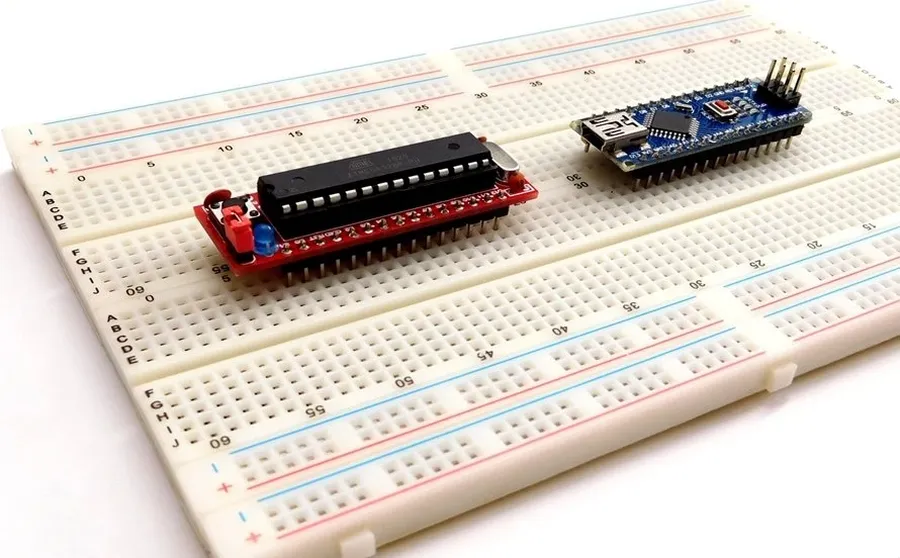

Zero PCB vs. Breadboard

Zero PCBs and breadboards are both utilized for electronic prototyping, but they cater to different needs and project stages. Zero PCBs offer a more permanent and robust solution through soldering, while breadboards provide a temporary, solderless platform for rapid testing and experimentation.

| Feature | Zero PCB | Breadboard |

|---|---|---|

| Connectivity | Permanent connections via soldering | Temporary connections via spring clips |

| Durability | Robust and suitable for permanent circuits | Less durable and prone to loose connections |

| Component Mounting | Components are soldered directly onto the board | Components are inserted into breadboard's terminal strips |

| Circuit Stability | Provides a more stable and reliable circuit | Less stable due to temporary connections |

| Complexity | Suitable for more complex and permanent circuits | Ideal for simple circuits and quick testing |

| Cost | Relatively low cost for the board itself, but requires soldering equipment and materials | Low initial cost, no soldering equipment needed |

| Reusability | Less reusable once components are soldered | Highly reusable for multiple projects |

| Modification | Modifications are more complex and require desoldering | Easy to modify and reconfigure circuits |

Frequently Asked Questions About Zero PCBs

This section addresses common inquiries regarding Zero PCBs, providing clarity on their applications, capabilities, and cost-effectiveness. Understanding these FAQs will help clarify the role of Zero PCBs in electronics prototyping and development, especially when compared with standard PCBs and breadboards.

- What is a Zero PCB and how does it differ from a standard PCB?

A Zero PCB, also known as a perfboard or protoboard, is a basic circuit board with a grid of holes, typically copper-plated, for manually connecting electronic components. Unlike standard PCBs, which are custom-designed with specific circuit patterns and manufactured, Zero PCBs are blank canvases meant for manual assembly, soldering, and prototyping, offering greater flexibility and ease of modification at a lower cost. - Are Zero PCBs the same as breadboards, and when should I use one over the other?

While both Zero PCBs and breadboards are prototyping tools, they serve different purposes and have distinct characteristics. Breadboards are solderless and ideal for quick, temporary circuit testing. Zero PCBs, however, require soldering of components, offering more robust and permanent connections suitable for designs that need more than just temporary testing. Use a breadboard for initial testing and a zero PCB when you need a more stable, semi-permanent prototype. - How much does a Zero PCB cost?

The cost of a Zero PCB is typically significantly lower than custom PCBs and breadboards, they are generally inexpensive. Prices can vary based on size, material, and whether they are single or double-sided, and if they have plated through-holes. However, they are generally one of the most economical options for prototyping electronic circuits. - Can I use a Zero PCB for complex circuit designs?

Yes, Zero PCBs can be used for both simple and complex circuit designs, but complexity is limited by the manual assembly and wiring process. The more complex the design, the more challenging and time-consuming it becomes to implement on a Zero PCB compared to a custom PCB. For intricate designs, a custom PCB is often the best option, while Zero PCBs are ideal for simpler or quickly evolving circuits. - How do I design a circuit on a Zero PCB?

Designing a circuit on a Zero PCB involves placing components on the board and manually connecting them using solder, wires, or jumpers. You must manually create the paths between the components as there are no pre-made tracks, unlike a standard PCB. This process allows for maximum design flexibility but requires careful planning and execution to avoid errors. - What are the advantages of using a Zero PCB for prototyping?

Zero PCBs offer several advantages for prototyping, including low cost, flexibility, and ease of modification. They allow for quick testing of circuit designs without the lead time or high cost associated with custom PCB fabrication. They are ideal for learning electronics, and quick prototyping. Additionally they offer semi-permanence in comparison to breadboards - What are some best practices for soldering on a Zero PCB?

When soldering on a Zero PCB, it is important to use the correct soldering techniques. The best practices include ensuring the tip is clean and properly tinned, preheating the pad and lead, and applying solder to the junction after the joint is heated. It's crucial to avoid excess solder, which can cause bridging of nearby connections and may require rework.

Zero PCB: A Practical Guide for Beginners

This practical guide provides beginners with the essential steps and techniques for creating robust and long-lasting prototypes using zero PCBs. Emphasis is placed on proper soldering techniques, selecting appropriate components and layouts, and implementing design considerations that result in a stable and reliable circuit.

- Step 1: Planning and Component Selection

Before beginning, plan your circuit layout on paper or using CAD software. Select components that meet your circuit's electrical requirements and are suitable for through-hole mounting on the zero PCB. - Step 2: Preparing the Zero PCB

Inspect your zero PCB for any defects. Clean the board with isopropyl alcohol to remove any contaminants that could impede soldering. Consider using a PCB holder to secure the board during soldering. - Step 3: Component Placement

Position components on the zero PCB according to your planned layout. Ensure there is enough space between components for soldering and wiring. Begin with larger components, followed by smaller ones. Temporarily secure components with masking tape if necessary. - Step 4: Soldering Techniques

Use a fine-tipped soldering iron to achieve accurate solder joints. Apply heat to the pad and component lead simultaneously, then apply solder to the heated area. Use the minimum amount of solder to create a shiny and strong joint. Avoid cold solder joints by ensuring proper heating. - Step 5: Wiring Connections

Use solid-core or tinned copper wires to connect components. Cut wires to the appropriate lengths to minimize clutter. Solder wire connections carefully. Use insulation where necessary to prevent shorts. Always check for short circuits with a multimeter after wiring connections. - Step 6: Testing and Troubleshooting

Test your circuit incrementally as you build. Verify each connection with a multimeter, and look for shorts and bad solder joints. Use debugging techniques to pinpoint and fix any issues. - Step 7: Securing and Finalizing

Secure all components and connections. Use a hot glue gun or epoxy to further secure any components that need additional support. Test the full circuit again to verify proper functionality.

In conclusion, the Zero PCB stands as a cornerstone in the world of electronics, offering a flexible and cost-effective solution for prototyping and circuit development. Its versatility and ease of use make it an invaluable tool for beginners and experienced designers alike. Understanding its characteristics, applications, and differences from other prototyping methods enables users to maximize their project potential. When considering project design and testing, the Zero PCB offers a unique blend of flexibility, robustness and accessibility without the zero PCB cost, making it a critical resource in the development of new circuits.

AnyPCBA

AnyPCBA