Voltera PCB Printer Cost: A Comprehensive Guide to Desktop PCB Prototyping

In today's fast-paced world of electronics, the ability to rapidly prototype PCBs is crucial. The Voltera PCB printer, known for its precision and ease of use, offers a solution for desktop PCB fabrication. The Voltera PCB printer cost, while an investment, can revolutionize your workflow. This article provides a detailed look at the pricing and capabilities of Voltera's offerings, guiding you towards making the right choice for your PCB prototyping needs. From the maker tinkering in their garage to the R&D team needing quick iterations, this tool bridges the gap between idea and reality, pushing forward innovation and technological advancement.

Understanding the Voltera PCB Printer Lineup

Voltera has established itself as a key innovator in the realm of desktop PCB prototyping, offering two primary models: the V-One and the NOVA. These printers cater to a spectrum of users, from hobbyists and educators to professional engineers, each with distinct features and capabilities, marking a significant step in the evolution of rapid PCB prototyping.

The advent of desktop PCB printers like those from Voltera has democratized electronics prototyping. Prior to these devices, creating circuit boards often involved outsourcing to specialized manufacturers, a process that could be costly and time-consuming. Voltera's printers allow designers and engineers to rapidly iterate on their designs in-house, significantly accelerating the development cycle.

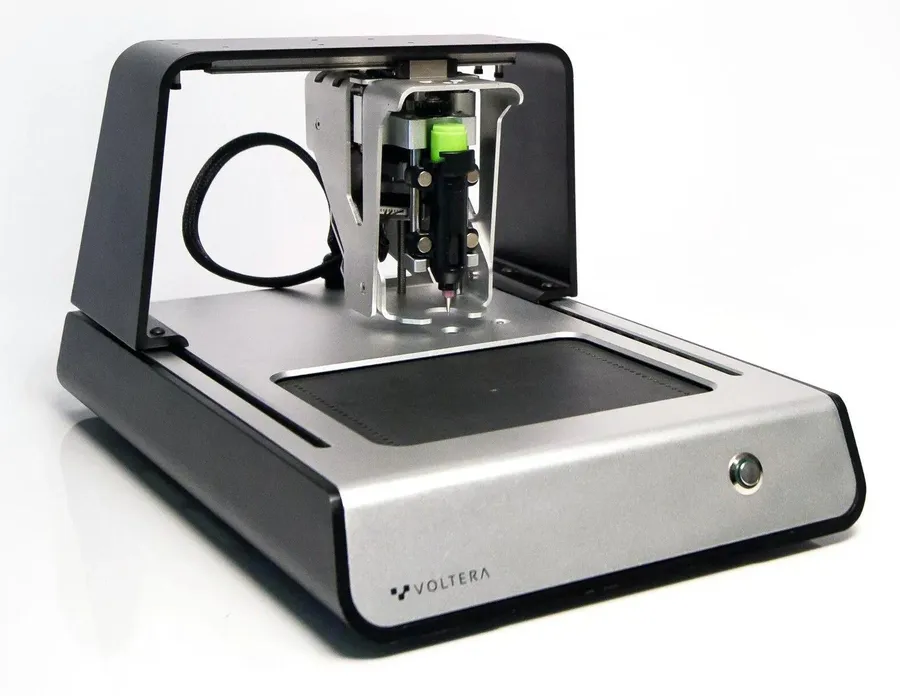

Voltera V-One: Features and Specifications

The Voltera V-One stands as a comprehensive desktop solution for rapid PCB prototyping, integrating printing, drilling, and solder paste dispensing functionalities into a single, user-friendly device. Its design prioritizes ease of use and versatility, allowing engineers and hobbyists to quickly iterate on circuit board designs.

- Printing Resolution

The V-One offers a printing resolution suitable for creating a range of PCB designs, balancing precision with the practical needs of prototyping. This allows for the creation of features down to a certain line width, which is adequate for many standard electronic designs. - Material Compatibility

The printer is designed to work with a variety of conductive inks, enabling the printing of traces on substrates like FR4, paper, and other flexible materials. This broad material compatibility makes it adaptable to diverse project requirements. The V-One is compatible with Voltera's own range of conductive inks, designed to provide reliable results. - Integrated Drilling

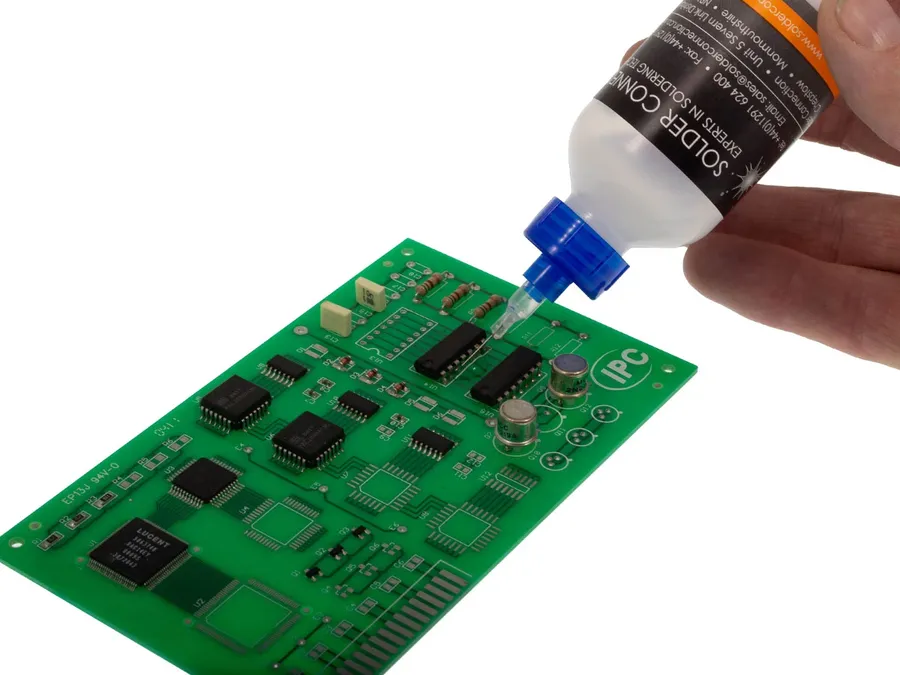

Equipped with an integrated drill module, the V-One enables the creation of vias and through-hole components directly on the printed boards. This feature eliminates the need for separate drilling processes, further streamlining the prototyping workflow. This includes a range of drill bit sizes for various hole requirements. - Solder Paste Dispensing

The V-One's solder paste dispensing capability allows for the application of solder paste to the board, facilitating the placement of surface mount components. This integrated feature ensures that users can move from printed traces to a fully populated board using the same device. Dispensing is precise, ensuring consistent application across various pad sizes. - Ease of Use

The device is designed with a user-friendly interface, making it accessible to both experienced engineers and newcomers to PCB prototyping. Its straightforward workflow simplifies the process of converting digital designs into physical boards, thereby reducing learning curves and improving productivity. The software allows for easy import of CAD designs, making the printer easy to use in many design workflows.

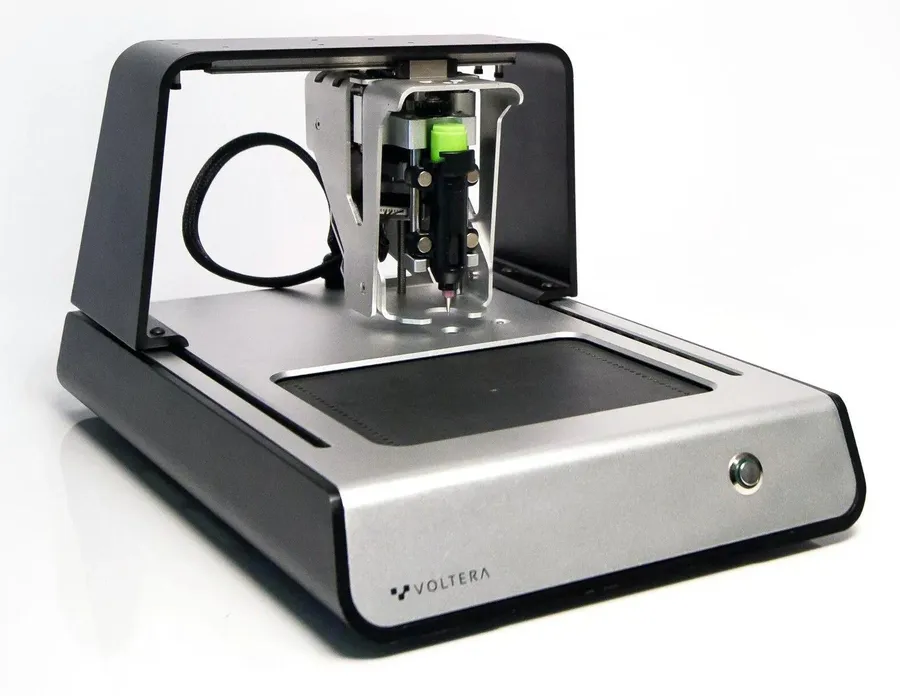

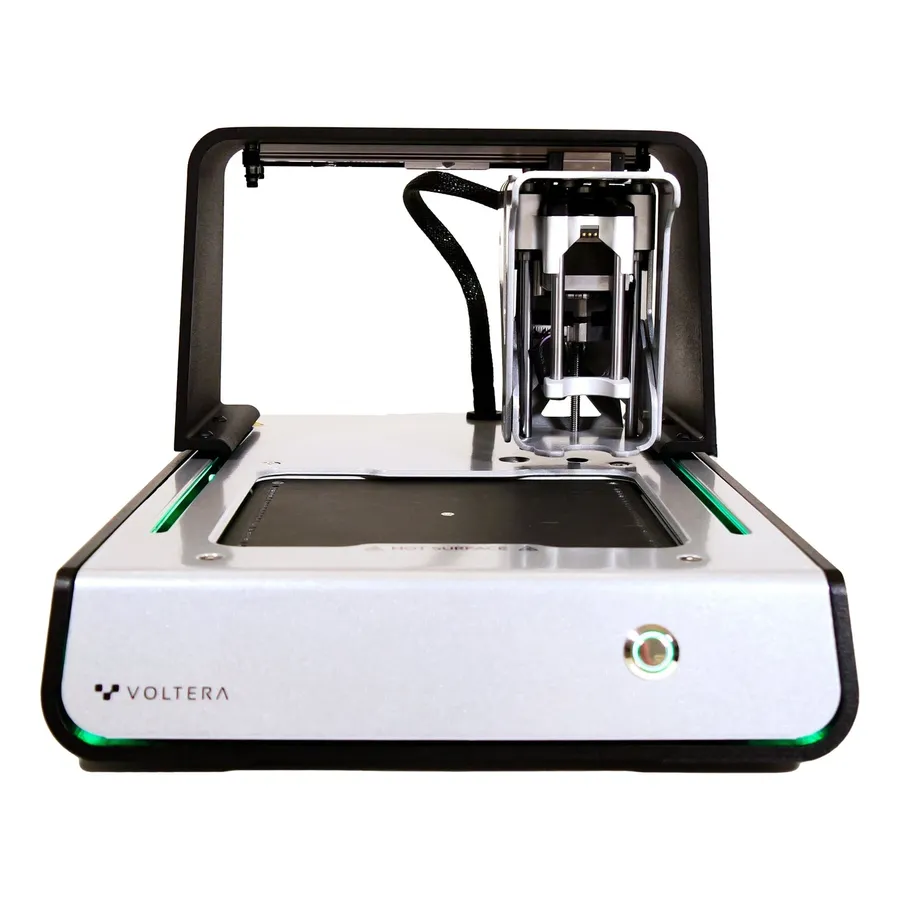

Voltera NOVA: Advanced Features and Capabilities

The Voltera NOVA represents a significant leap in desktop PCB prototyping, offering enhanced precision, speed, and material compatibility compared to its predecessor, the V-One. It caters to users requiring higher-performance capabilities for intricate and advanced PCB designs.

The NOVA's enhanced capabilities stem from several key improvements: increased resolution for finer traces and spaces, faster print speeds, and broader material compatibility to handle more specialized substrates. Its design also emphasizes greater automation and user-friendliness, which streamline the prototyping workflow.

- Enhanced Precision

The NOVA boasts higher printing resolution, enabling the fabrication of more complex PCB designs with finer traces and spaces compared to the V-One. This capability is critical for high-density designs. - Improved Speed

The NOVA is engineered for faster print times, significantly reducing the time required for prototyping. This enhancement allows for quicker design iterations and faster time-to-market. - Expanded Material Compatibility

The NOVA supports a wider range of substrates and materials, allowing users to explore specialized and more advanced PCB applications. This includes more demanding materials beyond FR-4. - Advanced Automation

The NOVA incorporates more sophisticated automation features that streamline the prototyping process and improve overall user experience, reducing the need for manual intervention. - Target Users

Designed for engineers and researchers who require higher precision, faster throughput, and greater flexibility in material choices, the NOVA is ideal for more advanced or demanding PCB prototyping needs.

| Feature | Voltera V-One | Voltera NOVA |

|---|---|---|

| Print Resolution | Standard | Higher |

| Print Speed | Standard | Faster |

| Material Compatibility | Limited | Expanded |

| Automation | Basic | Advanced |

| Target User | General Prototyping | Advanced/Demanding Prototyping |

Comparing Voltera V-One and NOVA: Key Differences

The Voltera V-One and NOVA represent distinct tiers within Voltera's desktop PCB printer offerings, each tailored to different user needs and project complexities. While both facilitate in-house PCB prototyping, their capabilities, precision, and price points vary significantly, making it crucial to understand their differences before making a purchase.

| Feature | Voltera V-One | Voltera NOVA |

|---|---|---|

| Target Users | Hobbyists, educators, and engineers needing basic prototyping | Professional engineers, research labs, and those requiring high-precision results |

| Printing Precision | Standard resolution for basic prototypes | Higher precision for complex and detailed PCB designs |

| Speed | Moderate printing speed | Faster printing speeds for quicker turnaround |

| Material Compatibility | Compatible with standard conductive inks and solder paste | Expanded material compatibility including advanced inks and substrates |

| Complexity Handling | Suitable for simple and medium complexity PCBs | Designed for intricate and demanding PCB layouts |

| Key Capabilities | Prints, dispenses solder paste, and drills holes for basic boards | Advanced printing, higher accuracy dispensing and advanced drill capabilities |

| Software Integration | User-friendly software with basic CAD file import | Advanced software options with better optimization and control |

| Price Point | Lower price point, designed to be accessible | Higher price point, reflecting advanced capabilities and features |

Analyzing the Voltera PCB Printer Cost

The cost of a Voltera PCB printer is a crucial factor for potential buyers, encompassing not just the base unit price, but also additional costs such as accessories, shipping, and consumables. Understanding these costs thoroughly is essential for making an informed purchasing decision. Both the Voltera V-One and NOVA models have distinct pricing structures reflecting their differing capabilities, and this section will break down these costs.

The Voltera V-One, designed for users who need a comprehensive, entry-level desktop prototyping solution, is positioned at a lower price point than the more advanced NOVA model. However, the actual cost can vary based on geographic location and any included bundled packages. This section will address the differences in base prices and provide a clearer view of the cost implications.

| Cost Component | Voltera V-One (USD) | Voltera NOVA (USD) |

|---|---|---|

| Base Unit Price (Approximate) | $4,999 - $6,000 | $12,000 - $16,000 |

| Accessory Package (Approximate) | $1,000 - $2,000 | $2,000 - $3,500 |

| Shipping (Varies by location) | $200 - $800 | $300 - $1000 |

| Estimated Total Cost | $6,199 - $8,800 | $14,300 - $20,500 |

The prices indicated above are approximate and can vary significantly based on several factors. Geographic location plays a crucial role due to import duties, taxes, and shipping costs. Bundled options, which might include additional accessories or software, can also influence the final price. For example, purchasing a comprehensive kit with extra inks, drill bits, and solder paste will incur a higher initial cost, but may offer better value for frequent users. It's essential to obtain a specific quote from Voltera or an authorized reseller to ascertain the precise cost based on your requirements.

The Voltera NOVA, catering to users with more complex PCB design needs and high-precision requirements, has a significantly higher base cost compared to the V-One. The higher cost also reflects the advanced features of the NOVA, such as improved printing resolution, more versatile material compatibility, and an increased speed. These capabilities are suited for advanced prototyping environments and may justify the increased expenditure for certain professional and research applications.

Additional Costs: Consumables, Maintenance, and Upgrades

Beyond the initial purchase price of a Voltera PCB printer, several additional costs must be considered to ensure smooth and continuous operation. These costs fall primarily into consumables, maintenance, and potential upgrades, which can significantly impact the overall cost of ownership.

- Consumables

Voltera printers utilize specialized consumables that require periodic replacement. These include conductive inks, which form the traces on the PCB; solder paste, essential for component attachment; and drill bits. The frequency of replacement varies depending on usage. Conductive inks and solder pastes have a shelf life, impacting storage and purchasing strategies. High-volume users may find it economical to buy in bulk. Drill bit replacement is less frequent but dependent on the materials used and the number of drilled holes. The materials used in the printing process can also impact costs. For instance, using specialized substrates for specific applications might introduce higher material expenses. - Maintenance

Routine maintenance is essential to keep the printer in optimal condition. While Voltera printers are designed for reliability, periodic cleaning, calibration, and lubrication are necessary. Depending on the level of use, these tasks may need to be performed regularly. Ignoring maintenance can lead to more significant issues and higher costs, so it's important to perform regular check-ups. Additionally, you may need to purchase specific cleaning supplies and tools to facilitate maintenance. Keeping a log of maintenance performed on the printer can also help track issues and potential fixes. - Upgrades

Voltera may release hardware and software upgrades to enhance the printer's capabilities. While not always necessary, these upgrades can improve performance, increase accuracy, or enable new features. Upgrades might include new dispensing heads, software enhancements, or additional tool heads. The necessity and cost of these upgrades depend on user requirements and the specific usage of the printer. If a business or institution needs to meet certain technological demands, it is more likely that they will require upgrades. It’s essential to evaluate the potential benefits versus the costs before deciding on an upgrade, as some upgrades may not be necessary for all applications.

To manage and minimize these ongoing expenses, users can adopt several strategies. Purchasing consumables in bulk where possible can lower per-unit costs. A preventative maintenance schedule can help avoid more expensive repairs down the line. Finally, carefully evaluating whether an upgrade is needed can help manage your budget effectively.

Voltera PCB Printer Alternatives: A Cost-Benefit Comparison

While Voltera's V-One and NOVA offer compelling solutions for desktop PCB prototyping, several alternatives exist, each with its own strengths and weaknesses regarding cost, capabilities, and suitability for various prototyping needs. Understanding these alternatives is crucial for making an informed investment.

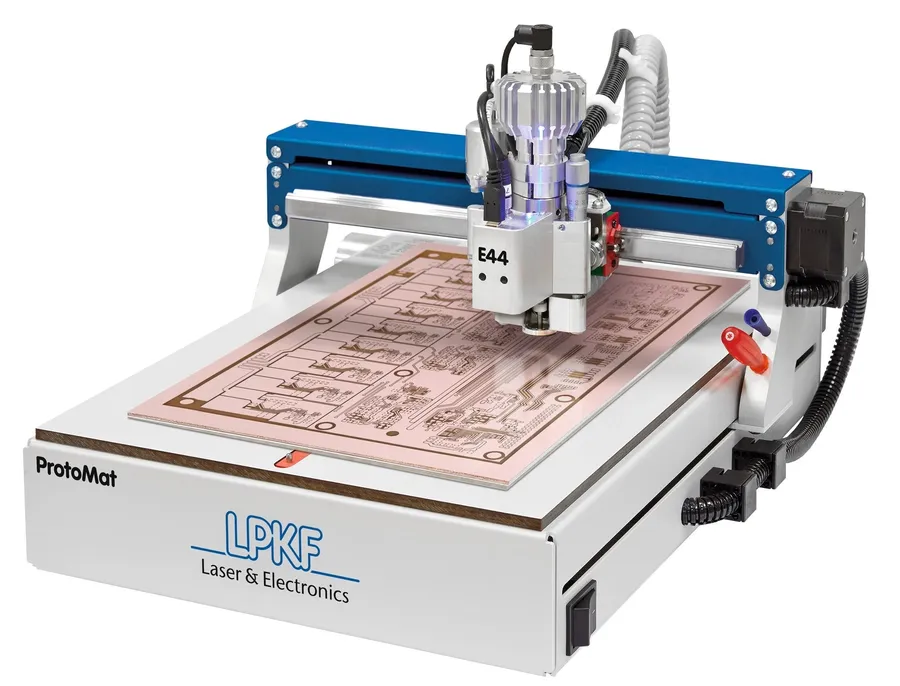

| Feature | Voltera V-One | Voltera NOVA | Other Desktop PCB Printers (e.g., LPKF ProtoMat) | DIY PCB Fabrication Methods (e.g., Chemical Etching) | Professional PCB Fabrication Services |

|---|---|---|---|---|---|

| Price Range | Mid-range | High-end | High-end | Very Low-end | Varies by Complexity |

| Resolution | Moderate | High | High | Low | High |

| Speed | Moderate | High | High | Slow | Fast |

| Material Compatibility | Limited | Wider range | Wide | Limited (Copper Clad) | Extensive |

| Ease of Use | High | Moderate | Moderate | Low | Variable |

| Features | Printing, dispensing, drilling | Printing, dispensing, drilling with higher precision | Milling, drilling, through-hole plating | Etching only | Manufacturing, assembly, testing |

| Best Use Cases | Basic Prototypes | Complex, High-Precision Prototypes | High-Precision Prototypes, small batch production | Simple, low-cost boards | Production-grade PCBs, large quantities |

Frequently Asked Questions About Voltera PCB Printers

This section addresses common questions regarding Voltera PCB printers, focusing on software, materials, support, and cost factors, drawing from user queries and related searches to provide clarity for potential users.

- What is the price of a Voltera V-One PCB printer?

The Voltera V-One's price varies based on region, included accessories, and current promotions. It's best to check with official Voltera distributors for the most accurate, up-to-date cost. Base prices are typically in the range suitable for professional prototyping labs and educational institutions. - What software is compatible with the Voltera V-One and NOVA PCB printers?

Voltera printers are compatible with standard Gerber files, the industry standard for PCB manufacturing data. They can be used with most PCB design software like Eagle, Altium Designer, KiCad, and others capable of exporting Gerber files. Voltera provides its own software for printer control and job management. - What materials can the Voltera PCB printers utilize?

The Voltera V-One and NOVA primarily utilize conductive inks for circuit traces, along with solder paste for reflow processes. They typically work with standard FR4 substrate and other materials that are compatible with the printer's temperature and chemical requirements. Specific material limitations and recommendations are detailed in the user manuals. - How does the Voltera V-One compare to the Voltera NOVA in terms of materials?

While both can use the standard FR4 substrate and conductive inks, the NOVA is generally more capable of handling complex PCB designs, potentially allowing for a broader range of specialized materials, although the primary material set remains the same. The key difference lies in the accuracy and repeatability of the printing process rather than the base materials themselves. - What kind of customer support does Voltera provide?

Voltera is known for providing support via their online resources, including manuals, guides, and forums. They typically offer direct support through email or phone for users with active support contracts, and have a community of users that can assist with common issues. - What is the typical lifespan and maintenance requirements for Voltera printers?

With proper care and maintenance, Voltera PCB printers can have a lifespan of many years. Routine maintenance includes cleaning of the print head and other components, ensuring proper storage of consumables, and following the maintenance schedule as outlined in their user manuals. Replacement parts may be necessary over time, adding to the operational cost. - Are Voltera PCB printers suitable for mass production?

Voltera printers are designed for prototyping and low-volume production. Their speed and throughput are not optimal for mass production environments. For high-volume production, traditional PCB fabrication methods are more suitable and cost-effective.

Making an Informed Decision: Is a Voltera PCB Printer Right for You?

Deciding whether a Voltera PCB printer is the right investment requires a careful evaluation of your specific needs, budget, and prototyping volume. The Voltera V-One and NOVA offer distinct capabilities catering to different user profiles, and understanding these nuances is crucial for making an informed decision.

- For Hobbyists and Small-Scale Projects

If you're a hobbyist or work on small-scale, relatively simple PCB designs, the Voltera V-One is likely a suitable option. Its ease of use and all-in-one functionality make it ideal for quick prototyping and experimentation. Consider the V-One if your budget is constrained and you don't require advanced features or high-volume production capabilities. - For Professional Prototyping and Complex Designs

For professional engineers and designers who need higher precision, faster turnaround, and the ability to handle more complex PCB designs, the Voltera NOVA is the more appropriate choice. The NOVA's advanced features and capabilities make it suitable for complex projects, especially in areas where high reliability and precision are critical. - Budget Considerations

Your budget is a crucial factor in deciding between the V-One and NOVA. The V-One is more budget-friendly, suitable for those with limited funds. The NOVA is a higher investment, justified by its enhanced capabilities and precision for professional requirements. Remember to factor in not only the initial cost but also the ongoing expenses of consumables, maintenance, and potential upgrades. - Prototyping Volume and Speed Requirements

Assess your required prototyping volume. If you need to produce a small number of PCBs or prototypes at a slower pace, the V-One will suffice. If you require a faster turnaround or need to create multiple prototypes in a shorter timeframe, then the NOVA will be better suited for your needs. Consider future project demands and how they might impact your requirements. - Material Requirements

Your material needs are also important for the decision-making process. The V-One works well with standard PCB materials, whereas the NOVA offers a wider range of materials to choose from. If you anticipate requiring to use a variety of materials for your circuit designs then, the NOVA will be more capable. - Software Compatibility

Both printers should support standard design software, but you need to ensure compatibility between your design tools and the printer you wish to purchase to streamline your workflow. The V-One software is simpler and very easy to use, suitable for beginners, whereas the NOVA comes with some more complex features, better suited for professionals.

Understanding the Voltera PCB printer cost is essential for making an informed decision regarding your prototyping needs. While the Voltera V-One and Nova offer powerful capabilities for desktop PCB fabrication, they are not the only option. This article has detailed the different features, pricing, and alternatives, allowing you to properly assess the pros and cons. Investing in a Voltera printer can be transformative, speeding up your design process and reducing reliance on external fabrication services. Consider your project requirements, budget, and long-term goals before making your choice to leverage the cutting edge of in-house prototyping. The Voltera PCB printer cost is just one factor, make sure you look at the long term benefits and if it fits within your budget.

AnyPCBA

AnyPCBA