Voltera V-One PCB Printer Price: A Comprehensive Guide

In today’s rapidly evolving world of electronics, the ability to quickly prototype circuit boards is essential. The Voltera V-One stands out as a desktop PCB printer offering a way to produce functional PCBs in hours rather than days or weeks. This article delves into the cost considerations surrounding the Voltera V-One, which is an important aspect to consider when investing in this technology. We’ll look beyond just the initial Voltera V one pcb printer price and also cover costs for consumables and overall value, helping you make an informed decision.

Understanding the Voltera V-One: A Desktop PCB Prototyping Solution

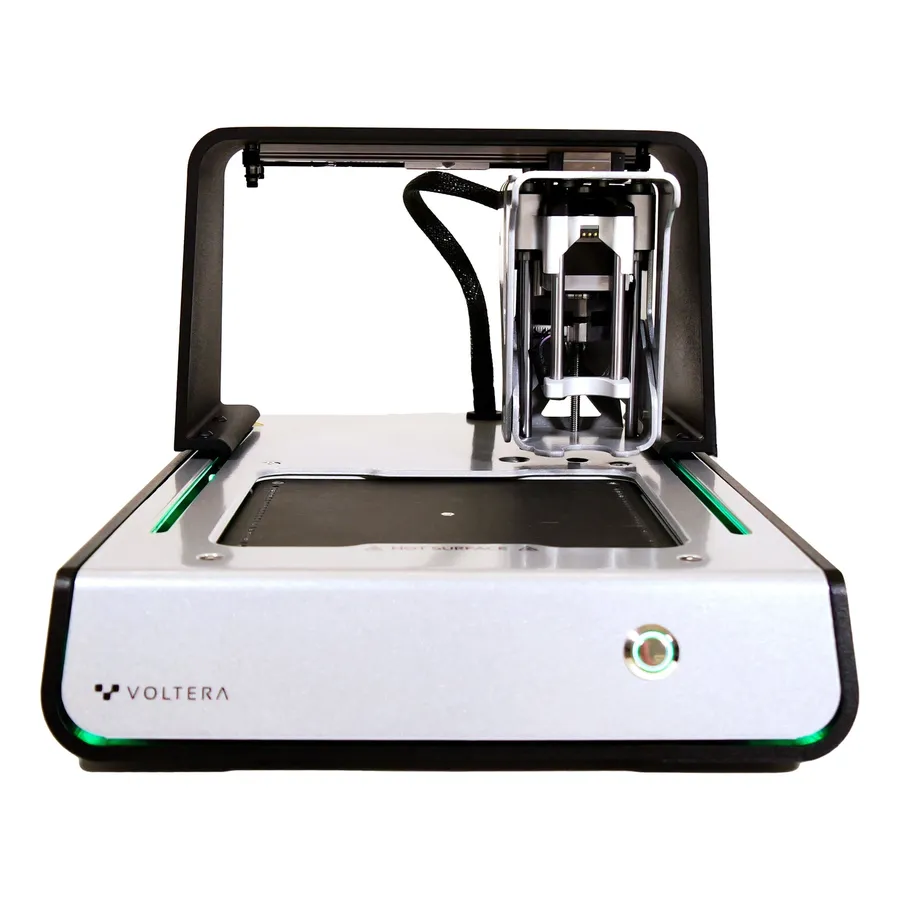

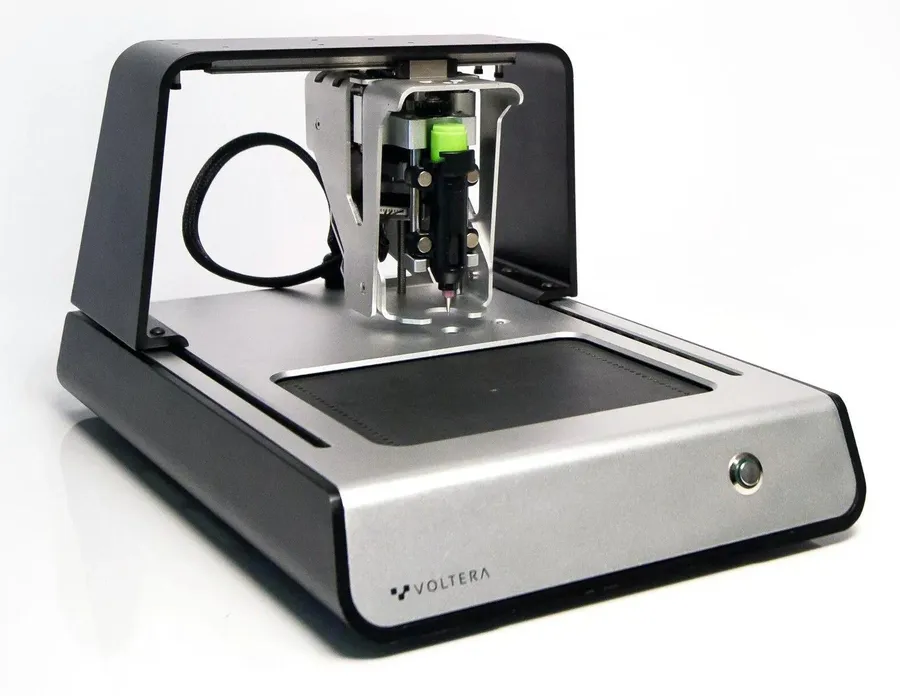

The Voltera V-One is a desktop-based prototyping machine designed for rapid in-house creation of printed circuit boards (PCBs). It streamlines the traditionally complex and time-consuming PCB fabrication process, enabling engineers, students, and small businesses to quickly iterate on designs. This compact device integrates several functions into one unit, including printing conductive inks, dispensing solder paste, and reflow soldering components, allowing for a complete prototyping cycle to be carried out directly on the user's bench.

The primary purpose of the Voltera V-One is to accelerate the PCB prototyping process. It provides a convenient and efficient alternative to sending designs to external fabrication houses, which often involves delays and higher costs. With the V-One, users can test and validate their circuit designs in a fraction of the time, making it ideal for rapid development cycles and educational purposes.

This machine is particularly well-suited for a variety of users: * **Hardware Engineers:** The Voltera V-One allows engineers to quickly produce prototypes, enabling faster experimentation and validation of their designs, reducing the time required to move a product from concept to market. * **Students:** In educational settings, the V-One serves as an accessible tool to demonstrate PCB design and manufacturing principles, offering hands-on experience without the need for sophisticated lab equipment. * **Small Businesses:** For startups and small businesses, the V-One significantly cuts down the prototyping phase, removing the dependency on external suppliers and facilitating faster product iterations, thus leading to cost savings and accelerated time-to-market.

Current Voltera V-One PCB Printer Price: What to Expect

The Voltera V-One is a precision desktop PCB prototyping machine, and its price reflects its capabilities as a rapid prototyping solution. The current retail price for the Voltera V-One typically ranges from $3,699 to $4,500 USD. This price variation depends on several factors, including the vendor, region, and any ongoing promotions. It's essential for potential buyers to consider that this represents the base cost, and operational expenses need to be factored in.

| Factor | Impact on Price |

|---|---|

| Vendor | Different vendors may offer varying prices due to reseller agreements, additional service packages, or shipping costs. |

| Geographic Location | Currency exchange rates and import duties can significantly affect the final price, particularly for international purchases. |

| Promotional Offers | Special discounts or bundled offers during specific periods may lower the initial investment. |

It's important to note that prices are subject to change. Prospective buyers should obtain direct quotes from authorized Voltera vendors to ensure accurate pricing for their specific location.

Additional Costs Beyond the Initial Price

While the initial purchase price of the Voltera V-One PCB printer is a significant investment, understanding the recurring operational costs is crucial for budgeting and long-term viability. These expenses primarily revolve around consumable materials necessary for the printing process.

| Consumable | Estimated Price | Typical Use Case | Notes |

|---|---|---|---|

| Conductive Ink Cartridge | $100 - $150 per cartridge | Printing conductive traces | Lifespan varies based on print volume and trace density |

| Solder Paste Cartridge | $80 - $120 per cartridge | Dispensing solder paste for component assembly | Lifespan varies based on the number of components |

| Substrates (FR4, etc.) | $10 - $30 per sheet | Base material for printing PCBs | Price depends on size, material type, and supplier |

| Replacement Nozzles | $40 - $60 per nozzle | Dispensing ink and solder paste | Nozzles may require replacement due to clogging or wear |

These estimated prices should be considered as a general guideline. Actual costs may fluctuate based on the specific supplier, bulk purchasing discounts, and the frequency of use. It's wise to factor in these ongoing expenses when determining the overall cost of ownership for the Voltera V-One.

Voltera V-One vs. Traditional PCB Manufacturing: Cost-Benefit Analysis

The decision between using the Voltera V-One for in-house PCB prototyping and traditional PCB manufacturing hinges on several factors, including production volume, turnaround time, and complexity of the design. While the Voltera V-One offers rapid prototyping capabilities, traditional methods provide economies of scale for larger production runs.

| Feature | Voltera V-One | Traditional PCB Manufacturing |

|---|---|---|

| Setup Time | Minutes to hours | Days to weeks |

| Turnaround Time | Hours | Days to weeks |

| Cost per PCB (Small Volume) | Potentially higher | Potentially higher |

| Cost per PCB (Large Volume) | Significantly higher | Significantly lower |

| Design Complexity | Limited to 2-layer boards, some constraints on trace width and spacing | Supports multi-layer boards, finer trace width and spacing capabilities |

| Iterative Design | Ideal for rapid iteration and design changes. | Less flexible for rapid changes, requiring resubmission |

| Customization | Highly customizable, allows design changes on-the-fly. | Less customizable for design changes during production. |

| Best Suited For | Low-volume, rapid prototyping, and iterative designs. | High-volume production, complex designs with tight tolerances. |

| Initial Investment | Moderate, the cost of the printer and some consumables. | Minimal initial investment, relying on the cost-per-board pricing of the manufacturer. |

The cost per PCB when using the Voltera V-One can be higher for small production volumes due to the initial cost of the machine and consumables, but becomes significantly more expensive for large volumes. Traditional PCB manufacturing offers a lower cost per unit at higher volumes, thanks to established processes and bulk material discounts.

Frequently Asked Questions About the Voltera V-One PCB Printer

This section addresses common inquiries regarding the Voltera V-One PCB printer, offering clear and concise answers to help users understand its capabilities and place in the prototyping landscape.

- What exactly is the Voltera V-One?

The Voltera V-One is a desktop prototyping machine designed for rapid in-house fabrication of printed circuit boards (PCBs). It integrates functionalities like printing conductive ink, dispensing solder paste, and reflow soldering, allowing users to create functional PCBs directly from their designs without outsourcing. - What does 'PCB' mean in the context of a printer?

In the context of the Voltera V-One, 'PCB' stands for Printed Circuit Board. Unlike a traditional paper printer, the Voltera V-One doesn't print images on paper. Instead, it prints conductive traces and solder paste onto a substrate to create an electrical circuit which is the very definition of a PCB. - Besides the Voltera V-One, what other machines can create PCBs?

Several other machines can fabricate PCBs, including traditional PCB manufacturing equipment used in factories, CNC milling machines adapted for PCB prototyping, and specialized etching equipment. Each of these offers different levels of precision, cost, and speed, the Voltera V-One stands out as a convenient option for desktop prototyping of electronic circuits. - What is the price of the Voltera V-One in India?

The price of the Voltera V-One can vary based on the local distributor, import duties, and currency exchange rates, making it hard to pin down an exact figure. It is recommended to contact Voltera's official distributors in India or check their website for the most up-to-date pricing. Keep in mind that it will be within the general price range ($3,699 to $4,500) plus any applicable duties, taxes, or shipping. - Can the Voltera V-One print double-sided PCBs?

Yes, the Voltera V-One is capable of producing double-sided PCBs. This requires a manual alignment step between the printing of each side. While it might not be as automated as some industrial processes, it still allows users to prototype more complex circuits on a single board. - What is the typical time required to print a PCB using the Voltera V-One?

The time needed to print a PCB with the Voltera V-One depends on the board's complexity and size. Simple boards may be completed within an hour, while larger and more intricate designs could take several hours. This includes printing the traces, applying solder paste, and reflow soldering the components. - What software is compatible with the Voltera V-One?

The Voltera V-One is compatible with most standard PCB design software programs as it accepts Gerber files, which is an industry standard for PCB designs. Therefore, users can create their PCB designs using popular CAD software tools and export the designs as Gerber files for use with the Voltera V-One.

Is the Voltera V-One Worth the Investment? A Value Proposition

The justification for the Voltera V-One's price hinges on a comprehensive evaluation of its time-saving capabilities, rapid iteration potential, and convenience, especially for specific PCB prototyping applications. While the initial investment might seem significant, these factors can yield substantial long-term benefits, making it a worthwhile proposition for certain users.

The core value proposition revolves around the following:

- Time Savings

Traditional PCB fabrication can take days or weeks, involving external manufacturers and shipping. The V-One allows for same-day prototyping, dramatically accelerating the design cycle. This is particularly beneficial when rapid iterations are necessary, such as during design validation or when developing early stage prototypes. - Rapid Iteration

With the Voltera V-One, design flaws can be identified and corrected immediately, enabling designers to rapidly test new ideas and modifications. This capability to swiftly move from idea to functional prototype significantly reduces the overall time spent in design and validation. - Convenience and Control

The V-One brings the entire PCB fabrication process in-house, giving users complete control over their project timeline and design confidentiality. This eliminates dependencies on external factors and enhances the overall prototyping workflow, particularly in situations where fast turn around is paramount. - Cost Savings on Small Batch Prototypes

For low-volume prototypes, the costs associated with traditional PCB manufacturing can be high, especially considering setup and shipping. The Voltera V-One can result in significant cost reduction in these scenarios where you can print on demand without extra setup fees - Educational and Research Value

For educational institutions and research labs, the Voltera V-One's ability to rapidly prototype PCBs is invaluable, allowing students and researchers to test their ideas and learn experientially. Furthermore, it reduces the cost for the multiple experimental runs.

However, it's essential to note that the V-One may not be the ideal choice for mass production or complex multilayer PCBs. Traditional manufacturing methods often prove more economical and offer better precision for large-scale PCB production. The value of the Voltera V-One is greatest for those who prioritize speed, flexibility, and in-house control during prototyping.

| Feature | Voltera V-One | Traditional PCB Manufacturing |

|---|---|---|

| Prototyping Speed | Same-day | Days to Weeks |

| Iteration Speed | Very Fast | Slow |

| Cost per PCB (Small Batch) | Potentially Lower | Potentially Higher |

| Cost per PCB (Large Batch) | Higher | Lower |

| Complexity | Single/Double layer | Multilayer |

| Control | In-house | External |

User Reviews and Experiences with the Voltera V-One

Analyzing user reviews provides valuable insight into the real-world performance of the Voltera V-One. Feedback from platforms like Reddit and Hackaday offers a balanced view, highlighting both the strengths and limitations of this desktop PCB prototyping solution. These user experiences serve as a crucial supplement to manufacturer specifications, offering practical perspectives on its usability and reliability.

- Positive Feedback

Many users praise the Voltera V-One for its convenience and speed in prototyping simple PCBs. The ability to rapidly iterate designs in-house is frequently cited as a major advantage, particularly for hardware developers and small businesses. Users appreciate the reduced lead times and costs compared to outsourcing PCB fabrication, especially for early-stage prototypes. - Areas for Improvement

Several reviewers mention limitations with the V-One's precision when working with complex PCB designs that require finer features. There are recurring notes about the cost and availability of consumables (inks and solder paste) , with some users finding them expensive. Additionally, while the printer works well for basic PCBs, the consistency in the quality and reliability of solder dispensing is sometimes brought up as a challenge. - Specific User Cases

Reviews often highlight the V-One's suitability for educational purposes, quick concept verification and maker projects, where the cost and complexity of professional fabrication is prohibitive. Its ability to expedite the design cycle for student projects and initial feasibility studies is particularly noted. However, users working on high-density PCBs or requiring exceptional accuracy are less enthusiastic, frequently expressing that the machine does not satisfy these needs. - Community Support and Resources

User reviews also point to a relatively small but active user community that shares best practices, troubleshooting tips, and alternative approaches. This network has contributed to an improved user experience over time, mitigating some of the initial challenges with the V-One through crowd-sourced solutions and recommendations. This is often seen as a big plus for users who are relatively new to this technology.

Alternative PCB Prototyping Solutions and Price Comparison

While the Voltera V-One offers a compelling solution for desktop PCB prototyping, several alternatives cater to varying needs and budgets. Understanding these options is crucial for selecting the best approach for your specific requirements. These alternatives range from other desktop fabrication tools to traditional outsourcing methods.

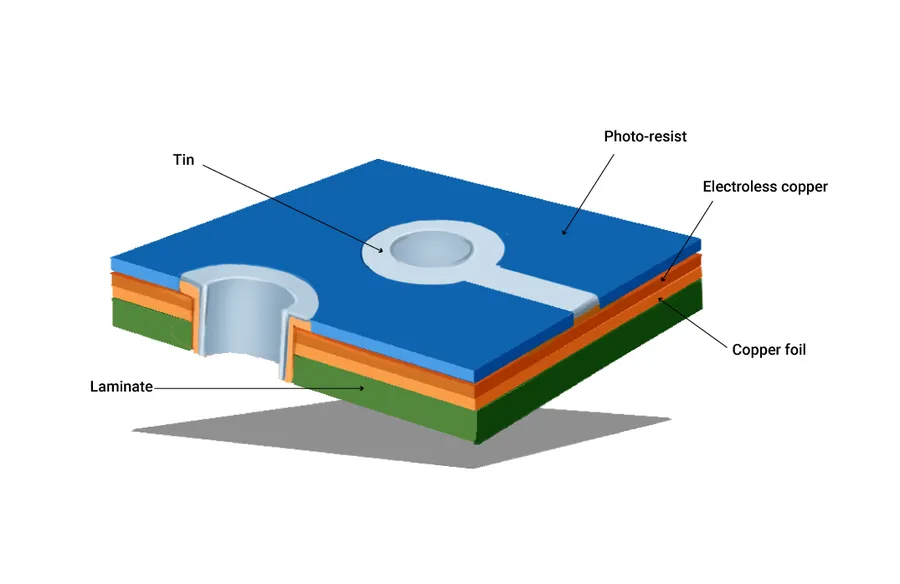

Primarily, we can divide alternative PCB prototyping methods into several broad categories including CNC milling, chemical etching, and outsourcing. Each of these approaches has trade-offs in terms of precision, materials, speed, and cost. By examining each of these alternatives, we can gain a holistic view of what is feasible for desktop PCB production beyond the Voltera V-One.

| Solution | Description | Approximate Cost | Pros | Cons |

|---|---|---|---|---|

| CNC Milling Machines | Uses a rotating cutter to remove material from a copper-clad board. | $1,000 - $10,000+ | High precision, wide material compatibility, can create complex shapes. | Can be noisy, requires more setup time, may have a larger footprint and is slower for complex PCBs than the Voltera V-One. |

| Chemical Etching | Involves using chemicals to remove unwanted copper, often requires photographic masks or similar techniques. | $100 - $500 (DIY setup), or $10 per board for outsourcing | Low per-board cost, can produce high-density circuits when done well. | Requires hazardous chemicals, less control over features, can be time-consuming, steep learning curve, environmental impact. |

| Outsourced PCB Fabrication | Sending your design to a professional fabrication service. | $10 - $100+ per board | High quality and precision, suitable for mass production, variety of materials and surface finish. | Longer lead time, higher setup cost for low quantity, less iterative control, may not be suitable for rapid prototyping. |

When comparing alternatives to the Voltera V-One, it's essential to factor in the total cost of ownership, which extends beyond the initial equipment purchase. Factors like consumable costs, setup time, and the time required to manufacture a board all need consideration.

The Voltera V-One PCB printer price represents an investment in a streamlined prototyping workflow, offering the speed and control needed for fast design iterations. While the initial price may seem high, when considering the reduction in time and the potential savings from in-house prototyping compared to traditional PCB manufacturing, the Voltera V-One can be a cost-effective solution. Evaluate your specific needs and prototyping volume to determine if the Voltera V One's capabilities and price align with your goals, ensuring you maximize your investment in electronics development technology. The price, which ranges from roughly $3699 to $4500, reflects this robust piece of equipment's value proposition.

AnyPCBA

AnyPCBA