Ascent PCB Manufacturer: Your Partner in High-Quality Circuit Boards

In today's rapidly advancing technological landscape, the printed circuit board (PCB) stands as the foundational element of nearly every electronic device. From the smartphones we rely on daily to the complex machinery powering our industries, the quality and reliability of PCBs are crucial. Ascent Circuits, a prominent name in the PCB manufacturing sector, exemplifies this commitment to excellence. This article delves into Ascent's capabilities, technologies, and their approach to delivering high-quality PCBs, solidifying their position as a leading choice for businesses seeking a reliable partner in electronics manufacturing.

Ascent Circuits: A Leader in PCB Manufacturing

Ascent Circuits has established itself as a prominent Indian manufacturer of printed circuit boards (PCBs), recognized for its substantial scale and strong industry reputation. This position reflects their commitment to producing high-quality PCBs for a diverse range of applications.

The Manufacturing Capabilities of Ascent Circuits

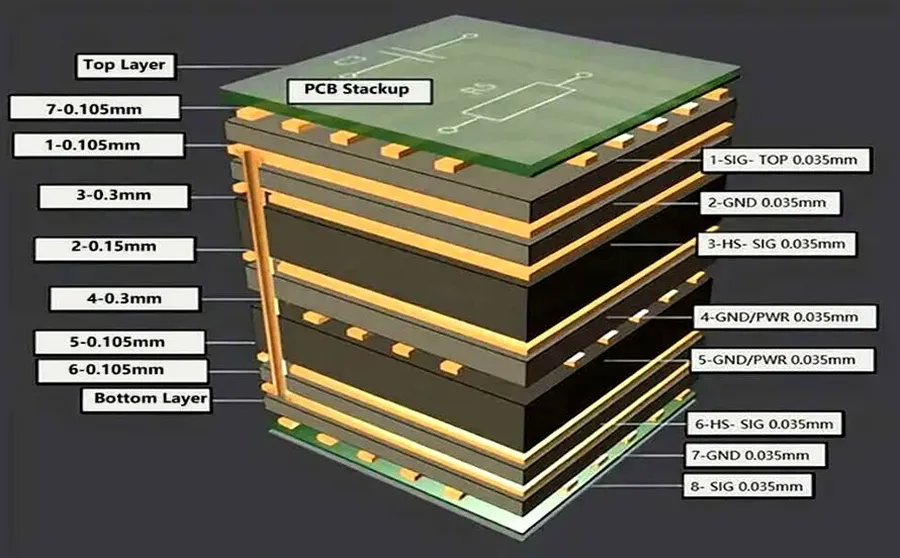

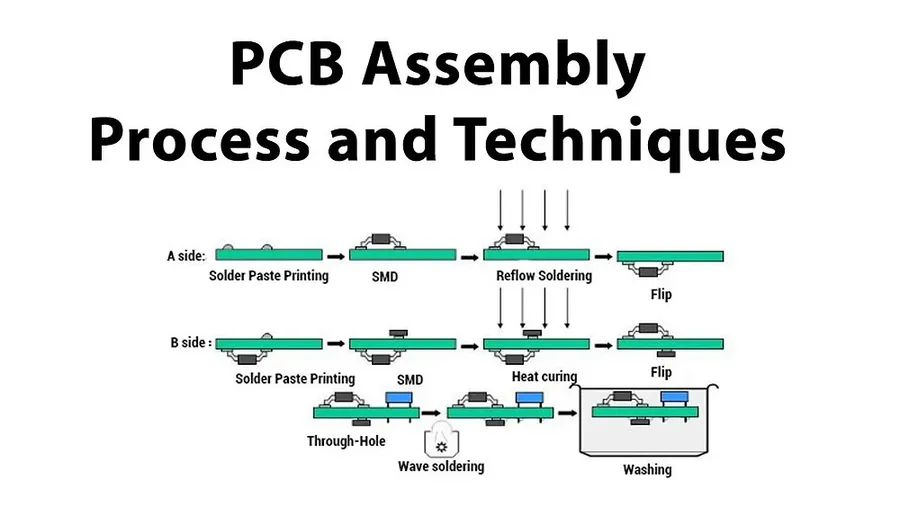

Ascent Circuits demonstrates robust manufacturing capabilities, producing a wide array of printed circuit boards to meet diverse industry needs. Their production lines are equipped to handle single-sided, double-sided, and complex multilayer PCBs, catering to both standard and customized design specifications. This flexibility, combined with high-volume capacity, positions them as a versatile partner for various electronic applications.

| PCB Type | Description | Typical Applications |

|---|---|---|

| Single-Sided PCBs | A single layer of conductive material, simple and cost-effective. | Basic electronics, lighting, simple sensors |

| Double-Sided PCBs | Conductive material on both sides, allowing for more complex routing. | Consumer electronics, basic control systems, power supplies |

| Multilayer PCBs | Three or more layers of conductive material separated by insulating layers, enabling high circuit density. | Advanced electronics, telecommunications, aerospace, medical devices |

Ascent Circuits' production capacity is designed to handle both small prototype runs and large-scale manufacturing, ensuring timely delivery for projects of any size. Their facilities are equipped with state-of-the-art machinery, allowing for high-precision manufacturing and consistent quality across all product types. This infrastructure, combined with a skilled workforce, enables them to meet strict deadlines and maintain superior manufacturing standards.

Ascent's Commitment to Quality and Reliability

Ascent Circuits places paramount importance on the quality and reliability of its printed circuit boards. This commitment is not just a statement but a deeply ingrained aspect of their manufacturing process, achieved through meticulous testing and strict adherence to industry standards, ensuring that each PCB meets the stringent requirements of diverse applications.

- Rigorous Testing Protocols

Ascent employs comprehensive testing at various stages of production, including electrical testing (e.g., continuity and isolation checks), dimensional inspections, and environmental stress tests, to verify performance under different conditions. These protocols are crucial for identifying defects early in the production cycle. - Adherence to Industry Standards

Ascent adheres to international standards such as IPC (Association Connecting Electronics Industries) guidelines. This involves rigorous material selection, ensuring proper copper plating thickness, solder mask alignment, and surface finish integrity. By adhering to these standards, Ascent ensures that their PCBs meet global quality benchmarks. - Advanced Quality Control Measures

Advanced quality control measures such as Automated Optical Inspection (AOI) and X-ray inspection are utilized. AOI systems automatically inspect PCBs for defects like shorts, opens, and incorrect component placement, while X-ray inspection identifies hidden defects like solder voids and misaligned vias, ensuring only flawless PCBs reach customers. - Statistical Process Control (SPC)

Ascent employs Statistical Process Control (SPC) methodologies to monitor and control manufacturing variations. SPC involves data collection and analysis from the manufacturing process, enabling them to identify trends, predict potential defects, and implement necessary corrective actions. This proactive approach significantly reduces errors and enhances overall quality consistency.

Technological Advancements at Ascent Circuits

Ascent Circuits leverages cutting-edge technologies in its PCB manufacturing processes, ensuring the production of high-performance circuit boards for diverse applications. This commitment to technological advancement enables Ascent to meet the evolving demands of industries ranging from automotive and telecommunications to consumer electronics.

- Advanced Materials

Ascent utilizes a wide range of advanced materials, including high-Tg FR-4, polyimide, and Rogers materials, to cater to specific performance requirements such as high-temperature operation, high-frequency signal transmission, and controlled impedance. The selection of appropriate materials is crucial for achieving optimal electrical and thermal performance in the final product. - Surface Finishes

The company employs various surface finish technologies, including Electroless Nickel Immersion Gold (ENIG), Immersion Tin, and Organic Solderability Preservatives (OSP). These finishes are meticulously applied to ensure excellent solderability, corrosion resistance, and long-term reliability of the PCBs. The choice of surface finish depends on the application and the specific requirements of the customer. - Automated Production Processes

Ascent Circuits has invested heavily in automated manufacturing lines. These include advanced imaging, etching, drilling, and plating equipment. This automation increases production efficiency, reduces human error, and allows the manufacturing of complex multilayer PCBs with great precision and repeatability. - Precision Drilling and Etching

Employing laser drilling and high-precision chemical etching processes, Ascent achieves tight tolerances and high accuracy in the creation of vias and circuit traces. These high precision techniques are essential for high-density interconnect (HDI) PCBs. - Quality Control Systems

Ascent integrates advanced quality control systems throughout the production process, including automated optical inspection (AOI) and electrical testing. These systems detect and rectify any manufacturing defects, ensuring that every PCB produced meets the highest quality standards before it leaves the factory.

Industries Served by Ascent Circuits

Ascent Circuits provides critical PCB manufacturing services across a wide spectrum of industries, demonstrating their versatility and ability to meet diverse technological demands. Their PCBs are integral components in sectors ranging from high-precision automotive applications to the rapidly evolving landscape of consumer electronics.

- Automotive Industry

Ascent's PCBs are used in various automotive applications, including engine control units (ECUs), advanced driver-assistance systems (ADAS), and in-car infotainment systems. These PCBs must withstand harsh operating conditions and provide reliable performance, which Ascent Circuits ensures. - Telecommunications

The telecommunications sector relies heavily on robust and efficient PCBs for network equipment, wireless infrastructure, and various communication devices. Ascent provides PCBs that meet the stringent requirements of this industry. - Lighting Solutions

LED lighting systems, including those for commercial and residential use, require high-quality PCBs. Ascent Circuits supplies these PCBs, contributing to the efficiency and reliability of lighting applications. - Internet of Things (IoT)

With the rise of interconnected devices, the IoT sector needs reliable PCBs for sensors, smart devices, and network hubs. Ascent's PCBs are crucial in this rapidly growing market. - Consumer Electronics

Ascent produces PCBs that find their way into various consumer electronics like smartphones, tablets, wearables, and home appliances, where performance and reliability are essential. - Industrial Automation

PCBs from Ascent Circuits support industrial control systems, robotics, and process automation, playing a crucial role in modern manufacturing processes. - Medical Devices

Ascent’s precision PCBs are used in medical equipment, including diagnostic tools and patient monitoring systems, demonstrating their capacity to meet the high standards required for medical applications.

Ascent Circuits' Expansion and Investment

Ascent Circuits is strategically expanding its manufacturing capabilities through significant investments in new facilities, demonstrating a commitment to meeting the growing demands of the PCB market and its diverse clientele. These investments are not just about increasing production capacity, but also about enhancing technological capabilities and improving service delivery.

Ascent's recent facility expansions are aimed at incorporating advanced manufacturing processes and technologies. This includes the acquisition of state-of-the-art equipment for high-precision PCB production and the establishment of dedicated lines for specialized PCB types. The company's investment strategy focuses on both scaling up operations and increasing efficiency, ultimately translating to better quality and faster turnaround times for customers.

These strategic expansions are also aimed at broadening Ascent's geographical reach and further solidifying its position as a prominent PCB manufacturer. By increasing capacity and technological prowess, Ascent is better positioned to engage with a larger client base, covering more regions and industries. The company's approach to expansion aligns with its long-term objectives to provide innovative and scalable PCB solutions to a global market, anticipating future market demands.

Frequently Asked Questions about Ascent Circuits PCB Manufacturing

This section addresses common queries regarding Ascent Circuits' operations, including their ownership, market position, and comparisons with other PCB manufacturers. The goal is to provide clear, concise answers to ensure our users have a comprehensive understanding of Ascent Circuits.

- Who owns Ascent Circuits?

Ascent Circuits is a privately held company. Specific ownership details are not publicly disclosed. However, the company’s leadership team is comprised of experienced professionals in the electronics manufacturing industry. - Where are Ascent Circuits' primary manufacturing locations?

Ascent Circuits has its primary manufacturing facilities in India. Specific locations and addresses can be found on their official website or through direct inquiries. - What types of PCBs does Ascent Circuits manufacture?

Ascent Circuits manufactures a variety of PCBs including single-sided, double-sided, and multilayer PCBs, catering to diverse industry needs. - How does Ascent Circuits ensure the quality of their PCBs?

Ascent Circuits maintains rigorous quality control measures, adhering to international industry standards. This includes thorough testing at various stages of the manufacturing process, including electrical tests, visual inspection and functional tests where necessary. - How does Ascent Circuits compare to other PCB manufacturers?

Ascent Circuits distinguishes itself with its focus on high-quality, reliable PCBs. They are known for their advanced technological capabilities, commitment to quality, and customer-focused approach in the Indian market. For a detailed comparison, refer to the 'Ascent vs. Other PCB Manufacturers' section. - Is Ascent Circuits a large PCB manufacturer?

Ascent Circuits is a well-established and reputable PCB manufacturer in India. While they may not be the largest globally, they hold a significant market share within the Indian context due to their capacity and technological abilities. - How can I contact Ascent Circuits for a quote?

You can contact Ascent Circuits through the contact information on their official website. This usually includes email, phone, and a contact form to request a quote or discuss specific PCB requirements.

Partnering with Ascent Circuits: What to Expect

Collaborating with Ascent Circuits is designed to be a streamlined and customer-centric experience. From initial consultation through production and delivery, Ascent emphasizes open communication and tailored solutions, ensuring a smooth partnership for clients seeking high-quality printed circuit boards.

- Initial Consultation and Requirements Analysis

The engagement process typically begins with a detailed discussion of your specific needs. Ascent's team of experts will assess your project's technical requirements, desired specifications, and production volume to determine the most appropriate solutions. - Design and Prototyping

Ascent provides support for PCB design and offers prototyping services to validate the design before full production. This step ensures that the final product aligns with your requirements and minimizes potential issues down the line. - Transparent Communication

Throughout the production process, Ascent maintains transparent communication to keep you informed of progress. Regular updates ensure the project stays on track and any potential challenges can be addressed promptly. - Quality Assurance and Testing

Ascent's commitment to quality is evident in its rigorous testing protocols. Each PCB undergoes stringent quality checks at multiple stages of manufacturing to guarantee reliable performance and compliance with industry standards. - Flexible Production and Delivery

Ascent understands that different clients have different schedules. They offer flexible production capabilities and logistics options to accommodate your timelines and deliver your PCBs as needed.

Ascent vs. Other PCB Manufacturers: A Comparative Look

A detailed comparison of Ascent Circuits with other PCB manufacturers reveals its strengths in several key areas. While numerous PCB manufacturers exist, Ascent distinguishes itself through its focus on quality, technological innovation, and customer-centric service. This section provides a structured look at how Ascent measures up against its competitors.

| Feature | Ascent Circuits | Typical Competitors |

|---|---|---|

| Quality Standards | Rigorous testing, adherence to IPC standards, high yield rates | Varying levels of adherence; may not always meet the highest IPC standards; potential for lower yield rates |

| Technological Innovation | Investments in advanced materials, surface finishes, and processing technologies | May rely on conventional technology; slower adoption of newer methods and materials |

| Production Capacity | High capacity for single, double, and multilayer PCBs; continuous capacity expansion | Capacity may be limited; may not be able to handle large or complex orders efficiently |

| Customer Service | Responsive and collaborative, offering design support and technical assistance | May have less responsive or inflexible service; may not offer design and technical expertise |

| Industry Specialization | Diverse industries served, including automotive, telecom, IoT, and consumer electronics | May focus on limited sectors, reducing their versatility |

| Cost-Effectiveness | Competitive pricing with a focus on value and quality | May offer lower costs at the expense of quality or reliability; higher costs for high-end PCBs |

Ascent Circuits has established itself as a leading PCB manufacturer through dedication to quality, innovation, and customer satisfaction. By continuously investing in new technologies and infrastructure, Ascent not only meets but exceeds the demands of various industries. Whether you are seeking a reliable partner for automotive, telecom, or consumer electronics, Ascent’s commitment to high-quality PCB manufacturing ensures your products meet the highest standards. As a trusted partner, Ascent Circuits is well-positioned to connect the future, one high-quality PCB at a time. Consider Ascent Circuits for your next project and experience the difference a world-class manufacturer can make.

AnyPCBA

AnyPCBA