Choosing the Right Circuitronica Professional PCB Manufacturers

In today's technology-driven world, printed circuit boards (PCBs) are the backbone of virtually every electronic device. Choosing the right PCB manufacturer is critical for product performance and reliability. Circuitronica, a professional PCB manufacturer, offers high-quality, international-grade PCBs tailored to meet diverse needs, from quick prototypes to medium-volume productions. This article will guide you through the key factors to consider when selecting a PCB manufacturer, specifically highlighting what makes Circuitronica a leader in the industry.

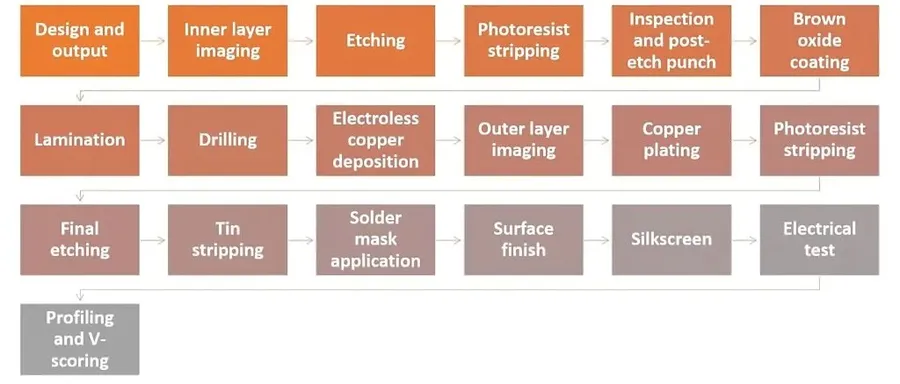

Understanding Circuitronica's PCB Manufacturing Capabilities

Circuitronica stands as a versatile PCB manufacturer, offering a comprehensive suite of printed circuit board solutions, ranging from basic single-sided PCBs to highly complex multilayer, flex, and rigid-flex designs. Their capabilities extend across diverse material choices and surface finishes, ensuring they can meet the specific demands of various electronic projects.

- Single-Sided PCBs

These PCBs feature conductive material on one side only, suitable for basic electronic devices. - Double-Sided PCBs

With conductive material on both sides, these PCBs allow for more complex circuit designs. - Multilayer PCBs

These PCBs incorporate multiple layers of conductive material, enabling high circuit density and complex routing capabilities. - Rigid PCBs

Traditional PCBs with a solid, inflexible substrate. - Flexible PCBs

PCBs made from flexible materials, capable of bending and folding without damaging the circuit. - Rigid-Flex PCBs

Combining rigid and flexible substrates into a single board, these PCBs provide added design flexibility.

Quality Assurance and International Standards

Circuitronica emphasizes rigorous quality assurance and adheres to international manufacturing standards to ensure the production of highly reliable PCBs. This commitment is fundamental to delivering products that meet the stringent requirements of diverse applications.

Adherence to standards like IPC (Association Connecting Electronics Industries) guidelines ensures consistent quality across all production runs. The company's testing and inspection processes are designed to identify and eliminate potential defects early in the manufacturing process, safeguarding the integrity of the final product. These processes not only enhance reliability but also contribute to the long-term performance and durability of the PCBs.

- Compliance with IPC Standards

Circuitronica follows IPC standards to ensure high manufacturing quality, encompassing design, fabrication, and assembly. - Advanced Testing Procedures

Rigorous testing includes electrical testing, impedance control verification, and functional testing using advanced equipment to confirm product specifications. - Material Quality and Traceability

Quality control procedures for material ensure only high-grade materials are used, with full traceability maintained throughout the manufacturing process, thus reducing risk and assuring product integrity. - Environmental Compliance

Adherence to environmental standards and regulatory requirements, reducing environmental impact of manufacturing. - Continuous Improvement

Processes are continuously reviewed and improved, incorporating customer feedback and industry advancements, ensuring progressive quality enhancement.

Specialization in Flex, Rigid-Flex, and HDI PCBs

Circuitronica distinguishes itself through its specialized capabilities in manufacturing advanced PCB technologies, including flexible (Flex), rigid-flex, and high-density interconnect (HDI) PCBs. These specialized PCB types cater to applications demanding high performance, miniaturization, and adaptability across diverse industries.

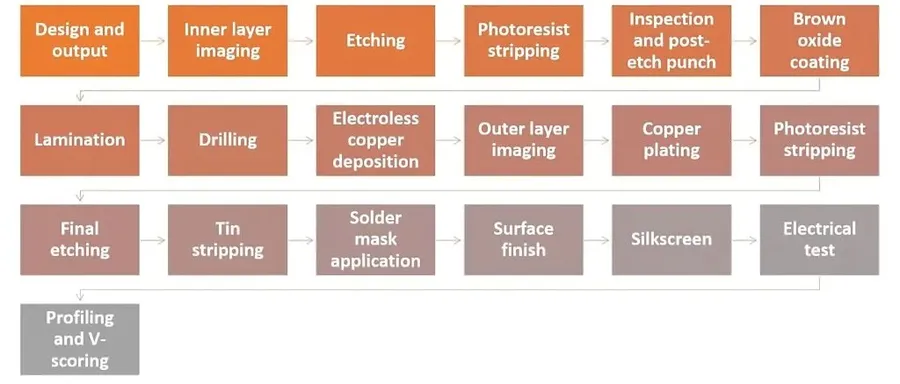

- Flexible PCBs (Flex PCBs)

Flex PCBs are constructed using flexible substrates like polyimide, allowing the circuit board to bend and conform to various shapes. This is ideal for applications requiring dynamic movement or limited space, such as wearable technology, automotive electronics, and medical devices. Circuitronica's expertise in Flex PCB manufacturing ensures reliable performance in demanding flexible applications. - Rigid-Flex PCBs

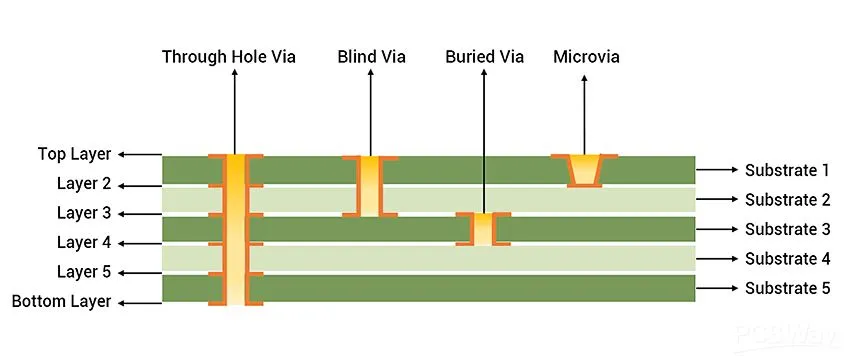

Rigid-Flex PCBs combine rigid and flexible circuit board sections into a single unit, offering advantages of both types. The rigid sections allow for mounting components, while the flex sections provide the necessary flexibility to connect them, reducing the need for connectors and improving reliability. These are ideal for aerospace, military, and complex industrial applications. Circuitronica excels in integrating these disparate functionalities into reliable designs. - High-Density Interconnect (HDI) PCBs

HDI PCBs feature finer lines, smaller vias, and higher connection pad densities, enabling higher component packing and improved signal integrity in smaller form factors. These PCBs are crucial for miniaturized, high-performance devices in smartphones, tablets, and advanced computing. Circuitronica’s HDI manufacturing capabilities ensure precise and reliable performance for these high-density applications.

Prototyping and Low-to-Medium Volume Production

Circuitronica provides rapid prototyping services, crucial for verifying designs and accelerating time-to-market, alongside the flexibility to scale from low to medium volume production, effectively accommodating diverse project demands.

This dual capability allows clients to transition seamlessly from initial design validation to full-scale manufacturing, ensuring continuity and efficiency throughout the production process.

Circuitronica's Geographic Presence and Contact Information

Circuitronica strategically positions its manufacturing and support facilities within India to ensure accessibility and responsiveness for both domestic and international clients. With key locations in Bangalore and Mysore, Circuitronica provides a robust infrastructure for PCB design, fabrication, and assembly.

- Bangalore Office

The Bangalore office serves as a central hub for client interaction, project management, and technical support. Its location in a major technology center allows Circuitronica to stay abreast of industry innovations and maintain close ties with a diverse customer base. Specific address and contact information are available upon direct inquiry to ensure accurate and up-to-date details. - Mysore Office

The Mysore facility is a critical part of Circuitronica's manufacturing infrastructure, housing advanced production lines for PCB fabrication. This location contributes significantly to Circuitronica's capacity to handle a wide range of PCB production requirements. For specific contact information, please contact directly with the company for the latest details.

Circuitronica's strategic geographic presence ensures easy access and efficient service delivery to clients in India and across the globe. This availability facilitates quicker turnaround times and fosters stronger partnerships with clients, solidifying their commitment to customer satisfaction.

Competitive Advantages of Choosing Circuitronica

Selecting a PCB manufacturer is a critical decision impacting product reliability and time-to-market. Circuitronica distinguishes itself through its commitment to high-quality international-grade PCBs, specialized manufacturing capabilities, and a strong dedication to customer satisfaction. These factors combine to offer a compelling competitive advantage for clients seeking reliable and innovative PCB solutions.

- High-Quality International Grade PCBs

Circuitronica adheres to rigorous international manufacturing standards, ensuring that each PCB meets stringent quality and reliability requirements. This commitment translates to fewer defects, enhanced performance, and greater longevity for your electronic products. This is achieved through the use of superior materials and meticulous process control. - Specialized Manufacturing Expertise

Circuitronica's core competence extends beyond basic PCB manufacturing, encompassing specialized areas such as flexible, rigid-flex, and HDI PCBs. This expertise allows them to provide solutions for complex applications, enabling clients to develop cutting-edge electronic devices that demand higher performance and reliability - Customer-Centric Approach

Circuitronica places a high priority on customer satisfaction, offering tailored support and communication throughout the PCB manufacturing process. This dedication ensures a positive partnership experience, reducing misunderstandings and providing proactive assistance. Their focus on customer needs distinguishes them as a reliable long-term partner. - Advanced Technology and Innovation

Circuitronica uses advanced manufacturing technologies, allowing for precise designs, higher density component placement, and the production of PCBs that meet or exceed customer expectations. By continually embracing new manufacturing technologies, they ensure that clients have access to the latest advancements in PCB design and production.

Frequently Asked Questions About Choosing a Professional PCB Manufacturer

Selecting the right PCB manufacturer is crucial for the success of any electronics project. This section addresses common questions to guide your decision, with a focus on how Circuitronica stands out as a professional PCB manufacturer.

- What factors should I consider when choosing a PCB manufacturer?

Key factors include the manufacturer's experience, the types of PCBs they produce (single-sided, multilayer, flexible, etc.), material capabilities, quality standards adherence (e.g., IPC standards), production capacity, turnaround times, pricing, geographic location, and customer service quality. It's essential to align these with your project's specific needs and budget. - What is the 'best' PCB company?

The 'best' PCB company varies depending on project requirements. For high-reliability, international-grade PCBs, Circuitronica is a strong contender. For very high-volume, low-cost, some might look to overseas manufacturers. The ideal choice should be based on a careful evaluation of quality, reliability, and support capabilities, tailored to specific project specifications. - Who are the largest PCB suppliers in the industry?

The largest PCB suppliers are typically manufacturers with extensive global operations, often based in Asia. These large suppliers usually serve very high-volume markets, with a focus on economies of scale. While cost-effective, they may not provide the specialized expertise or personal support required for complex projects. For complex designs or specialized PCB, mid-size manufacturers like Circuitronica may offer higher reliability and attention to detail. - Who manufactures PCB assemblies in China?

Many manufacturers in China specialize in PCB assembly. While China is known for its vast production capacities, it’s important to differentiate between bare PCB manufacturers and PCB assembly providers. The most common approach is to manufacture the PCBs in one location and complete assembly in another. Evaluating their capabilities and commitment to quality is essential, alongside considering import/export regulations and supply chain stability. - How can I assess the manufacturing standards and quality of a PCB manufacturer?

Assess manufacturing standards by checking for certifications like ISO 9001 and adherence to IPC standards. Request sample boards, look for detailed testing and inspection reports, and review their material certifications. A transparent process in manufacturing combined with a strong commitment to quality indicates a reliable manufacturer. Circuitronica, for example, utilizes rigorous testing protocols to ensure their products meet high international standards. - Does Circuitronica offer prototyping and small-to-medium volume production?

Yes, Circuitronica offers services for rapid prototyping with fast turnaround times, as well as production capabilities for low-to-medium volume orders. This flexibility makes them suitable for various project scales, allowing you to test designs effectively before moving to larger production runs. This balance between prototyping and scalability is crucial for projects in the development phase. - How does Circuitronica ensure PCB reliability and performance?

Circuitronica implements rigorous testing and inspection processes throughout the manufacturing cycle. This includes electrical testing, automated optical inspection (AOI), and dimension checks, ensuring that each PCB meets stringent quality standards and performs as intended. They are committed to delivering high-reliability PCBs, which is critical for demanding applications.

Table: Comparing PCB Manufacturers

A comprehensive comparison of PCB manufacturers is essential for selecting the right partner for your project. This table highlights key differentiators such as specialization, geographic reach, service speed, and pricing models to aid informed decision-making, with a focus on showcasing Circuitronica's strengths.

| Feature | Circuitronica | Manufacturer B | Manufacturer C | Manufacturer D |

|---|---|---|---|---|

| Specialization | Flex, Rigid-Flex, HDI, Multilayer | Standard PCBs | High-Volume Standard PCBs | RF and Microwave PCBs |

| Geographic Location | India (Bangalore & Mysore) | China | USA | Europe |

| Service Speed (Prototyping) | Fast Turnaround (2-5 days) | Moderate (5-7 days) | Slow (7-10 days) | Moderate (4-7 days) |

| Pricing | Competitive, scalable with volume | Cost-effective for high volumes | Higher for low-mid volumes | Premium pricing |

| Quality Standards | International Grade PCBs | Industry Standard | Industry Standard | High Reliability Standards |

| Volume Capabilities | Low-to-Medium Volume | High Volume | Medium Volume | Low Volume |

| Customer Support | Dedicated Support Team | Online support | Limited online support | Dedicated support for high-value customers |

Selecting the right professional PCB manufacturer is crucial for the success of any electronic project. Circuitronica, with its commitment to high-quality, international-grade PCB manufacturing, diverse capabilities, and focus on customer satisfaction, stands out as a top choice. Whether you require quick prototyping, specialized PCB types like flex or HDI, or medium-volume production, Circuitronica offers the expertise and resources to deliver exceptional results. By choosing Circuitronica, you are choosing a partner dedicated to precision and quality in every PCB produced, ensuring your project’s success. Consider Circuitronica for your next PCB manufacturing needs and experience the difference.

AnyPCBA

AnyPCBA