Choosing the Right Custom Circuit Board Maker: A Comprehensive Guide

In today's rapidly evolving electronics landscape, the demand for custom circuit boards is higher than ever. Whether you're a seasoned engineer or a hobbyist, selecting the right custom circuit board maker is crucial for your project's success. This article delves into the key considerations when choosing a PCB manufacturer, highlighting the available options and best practices to ensure your designs come to life flawlessly. Think of these boards as the nervous system of electronics; a custom circuit board maker brings your unique visions to life, linking technology to our daily lives and future innovations.

Understanding Your PCB Needs

Before engaging a custom circuit board maker, a meticulous assessment of your project's specific requirements is paramount. This involves clearly defining the board's characteristics, including its type (single-layer, multi-layer), the materials required, its dimensions, and the necessary production volume. A crucial early decision involves determining whether the immediate need is for a rapid prototype or a full-scale production run. These initial considerations dictate the selection of the most appropriate manufacturer and service package.

- Board Type

Determine if your project requires a single-layer PCB, a multi-layer PCB (for more complex circuits), or flexible PCB, each has its unique design and manufacturing process. - Material

Common PCB materials include FR-4, but specialized applications may require materials with specific electrical or thermal properties. Consider factors like dielectric constant, thermal conductivity, and operating environment. - Size and Dimensions

Define the precise dimensions of the PCB to meet your project's mechanical requirements. This includes specifying the board's length, width, and thickness, as well as any necessary mounting hole locations. - Quantity

Specify the required quantity of PCBs. This will significantly impact the cost per unit. Prototypes usually involve small quantities, while production requires larger volumes. - Prototype vs. Production

Decide whether you need a prototype for testing and design verification or if you need a full production run. Each has different requirements and will affect the overall cost.

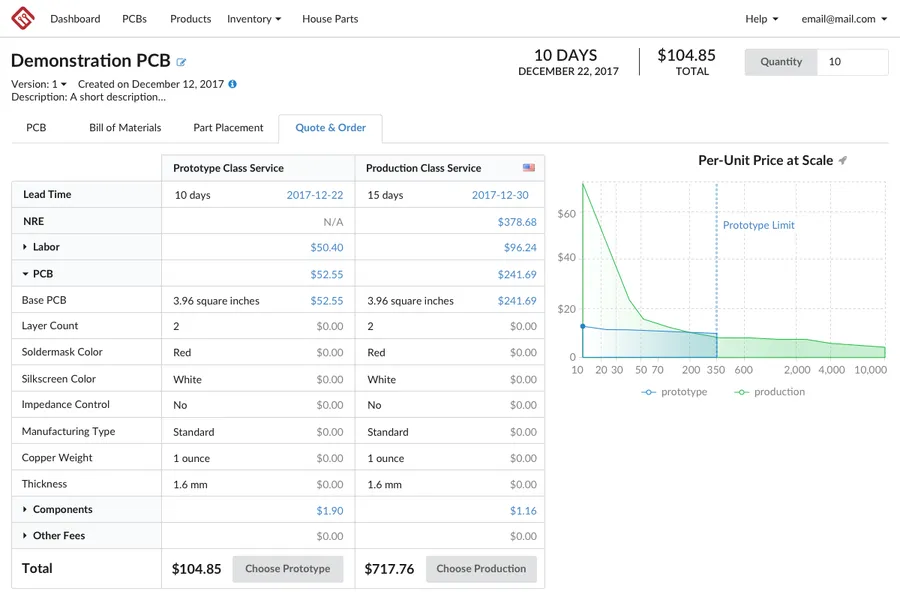

Prototype vs. Production: Choosing the Right Service

Selecting the appropriate service—prototype or production—is crucial when engaging a custom circuit board maker. These services cater to different project phases and requirements, affecting cost, turnaround time, and scalability. Understanding these distinctions will ensure optimal use of resources and a smoother development process.

| Feature | Prototype PCB Service | Production PCB Service |

|---|---|---|

| Purpose | Testing and Iteration | Large-Scale Manufacturing |

| Volume | Small Quantities | Large Quantities |

| Cost per Unit | Higher | Lower |

| Turnaround Time | Faster | Can be Longer Depending on Volume |

| Design Flexibility | High | Lower, Standardized Process |

| Testing and QA | Basic testing | Comprehensive testing, quality checks, and standards compliance |

Custom circuit board makers often provide specialized packages for each type of service. Prototypes, typically ordered in small quantities, allow for rapid testing and design revisions. Production runs, on the other hand, are for mass manufacturing once the design is finalized and validated. Knowing the differences helps in budgeting and timeline management.

Key Factors in Choosing a Custom Circuit Board Maker

Selecting the right custom circuit board maker involves a careful evaluation of several critical factors. These elements directly impact the quality, cost, and timeliness of your project. A thorough understanding of these factors is crucial for making an informed decision.

| Factor | Description | Importance |

|---|---|---|

| Price | The cost per board, often influenced by quantity, board complexity, materials, and lead time. | Budget constraints often dictate the choice; however, the cheapest option is not always the best. |

| Turnaround Time | The time it takes from placing the order to receiving the finished boards. | Critical for projects with strict deadlines, particularly for prototyping and time-sensitive production. |

| Quality Control | The processes used to ensure boards are manufactured to specification, including inspections and certifications. | Directly affects the reliability and performance of the final product; a critical aspect for quality-focused applications. |

| Technical Support | Availability and quality of assistance provided by the manufacturer for technical issues and design reviews. | Essential for projects that involve complex designs or require support during the manufacturing process. |

| Material Options | The range of materials offered, impacting the board's performance and environmental tolerance. | Allows customization based on specific project needs, including high-temperature or high-frequency applications. |

| Minimum Order Quantity (MOQ) | The smallest number of boards a manufacturer is willing to produce. | Relevant for small-scale projects or initial prototypes. Manufacturers with lower MOQs are preferred for small production or pilot programs. |

| Certifications | Accreditations such as ISO 9001 or UL certifications indicating a manufacturer's adherence to quality and safety standards. | Provide assurances of quality and are essential for projects where compliance is required. |

Online PCB Builders: A Quick Comparison

Selecting the right online PCB builder is crucial for the success of your electronics project. This section provides a comparative analysis of popular online PCB manufacturers, including JLCPCB, PCBWay, and DigiKey's service, to help you make an informed decision. We delve into their offerings, pricing structures, user interface design, payment methods, and customer reviews, with an emphasis on user experience and the ease of uploading Gerber files.

| Feature | JLCPCB | PCBWay | DigiKey |

|---|---|---|---|

| Base Price (Example for 10 PCBs, 100mm x 100mm, 2 layers) | Very competitive, starting at around $2-$5 | Moderate, slightly higher than JLCPCB | Typically higher; primarily a component supplier, PCB services as value add. |

| Turnaround Time (Prototype) | 24 hours to 2 days, depending on the complexity and order volume, plus shipping | 24 hours to 3 days, depending on options, plus shipping | Turnaround times vary and depend on manufacturing partner. |

| User Interface | Easy to use, with clear upload process and order tracking | Generally user-friendly, with a wide range of features | PCB design functionality is less prominent with emphasis on parts ordering. |

| Material Options | FR-4 standard, Aluminum, and various specialty materials available | FR-4 standard, aluminum, and a wide variety of advanced materials | Limited Material options, focused on standard FR-4. |

| Payment Options | PayPal, Credit Card, Wire Transfer | PayPal, Credit Card, Wire Transfer | Credit Card, Wire Transfer, and Purchase Orders for business customers |

| Customer Support | Responsive support through email and online ticketing system | Good support through various channels, including live chat | Customer service is mostly focused on part ordering and technical questions about components |

| Gerber File Upload Process | Direct upload with good error checking system | Straightforward upload with comprehensive validation checks | May involve third party tools for Gerber file generation. |

| Special Features | Assembly service, stencil service and multi-layer boards at competitive prices. | PCB assembly, advanced material options, and design assistance. | PCB service primarily through partnership, not its primary business. |

| Customer Reviews | Generally positive, known for cost-effectiveness | Good to very good reviews, known for quality and service | Digikey is a very trusted company, but PCB manufacturing is not its primary service. |

Free PCB Design Software: Tools for Beginners and Experts

The availability of free and robust PCB design software has democratized electronics design, empowering both beginners and experts to create professional-grade circuit board layouts before engaging with a custom circuit board maker. These tools not only reduce design costs but also allow for iterative development and refinement of designs.

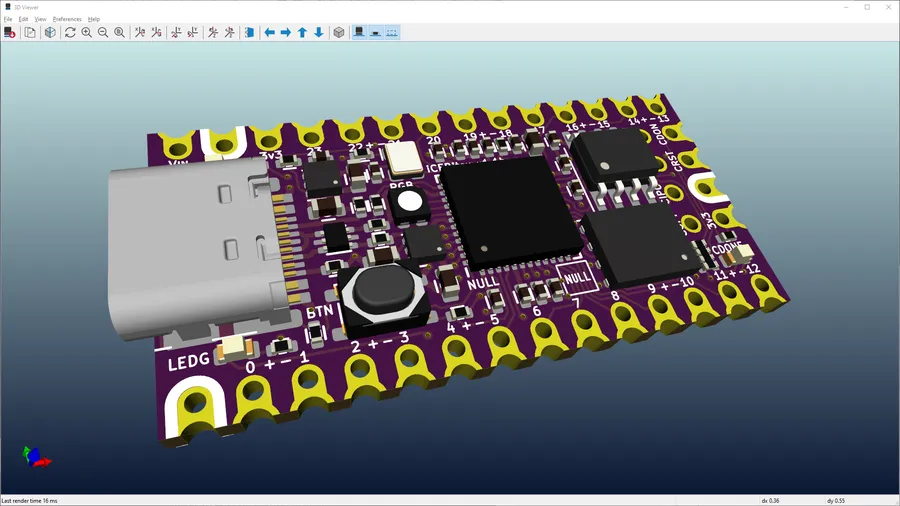

- KiCad

KiCad is an open-source electronics design automation suite that includes schematic capture, PCB layout, and 3D viewing capabilities. Its comprehensive feature set and active community make it a powerful option for both hobbyists and professionals. Key advantages include its cross-platform compatibility and lack of licensing fees, making it a highly accessible choice. KiCad allows for complex multi-layer PCB designs and the creation of custom components. - CircuitMaker

CircuitMaker, by Altium, is a free PCB design software that offers a user-friendly interface and robust cloud-based collaboration features. While it may be less feature-rich than Altium Designer, it is still a capable tool for designing boards of considerable complexity. The integrated cloud functionality enables teams to work together seamlessly. It also includes a library of ready-to-use components and allows for easy export of Gerber files for manufacturing. - Other Free Tools

Beyond KiCad and CircuitMaker, numerous other free or trial-based software solutions are available that may suit specific needs or preferences. These options range from easy-to-use tools for beginners to more specialized software for advanced users. Exploring these can lead to discovering the best fit for your workflow.

Proficiency in these design tools is crucial as it enables users to generate accurate Gerber files, which are the standard data format used by custom circuit board makers. Incorrectly generated Gerber files can lead to manufacturing errors, highlighting the need for a sound understanding of PCB design software.

Learning to utilize these free tools translates to significant cost savings, allowing designers to focus on refining their designs without financial constraints. This, in turn, enables more efficient and innovative electronic product development.

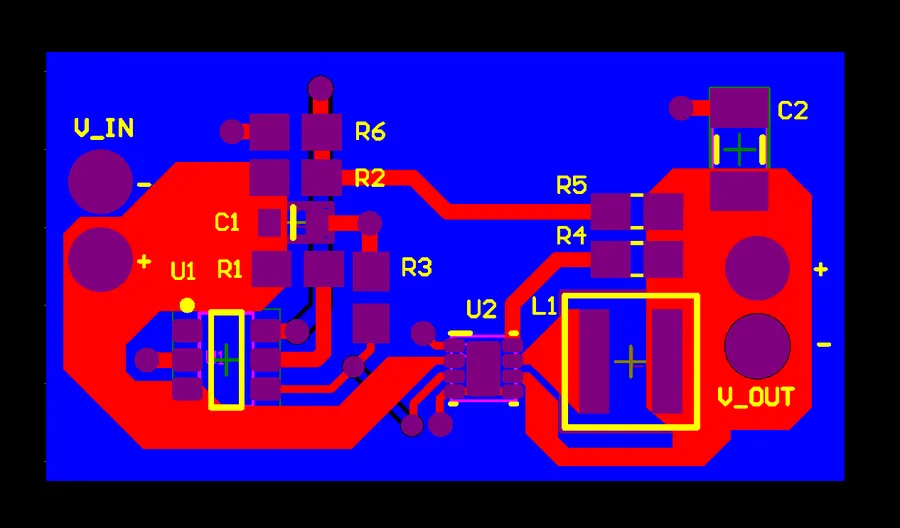

The Importance of Gerber Files

Gerber files are the standardized lingua franca of the PCB manufacturing world, serving as the critical bridge between your design and the physical realization of your circuit board. A custom circuit board maker relies entirely on these files to accurately translate your digital design into the precise fabrication steps needed for a functional PCB.

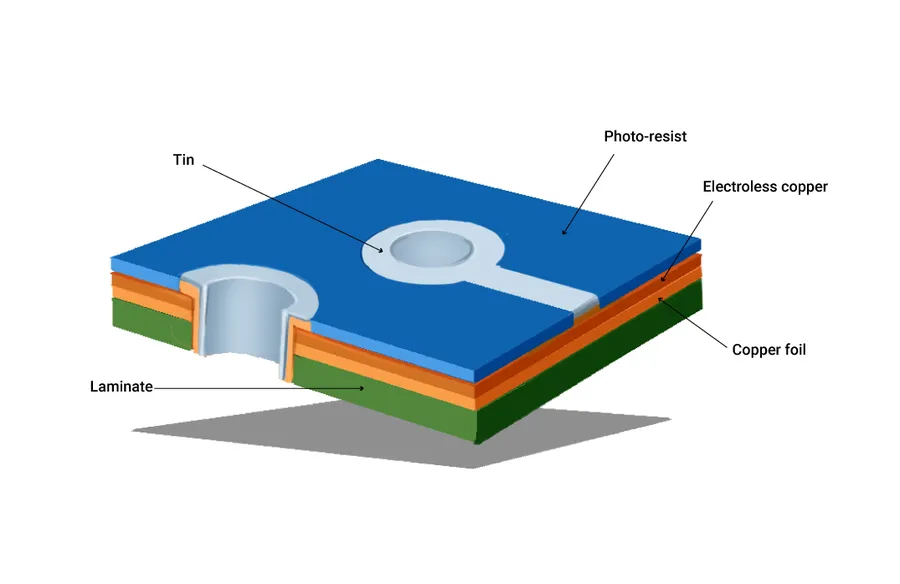

These files, typically in the RS-274X format, contain vector-based information describing each layer of your PCB design – from copper traces and solder masks to silkscreen markings and drill locations. Understanding how Gerber files are created and what information they contain is paramount to avoiding costly errors during PCB fabrication. In essence, if the Gerber files are not correctly generated, the final PCB will not be manufactured as intended.

- Understanding Gerber File Contents

Gerber files are not a single file, but a collection of files that describe different layers of your board. Each file corresponds to a specific layer (e.g., top copper, bottom copper, solder mask, silkscreen), drill data, and board outline. Incorrect or missing files will lead to production errors. - Generating Gerber Files

Gerber files are generated using PCB design software such as KiCad, Eagle, Altium, etc. The process involves exporting the design into the Gerber format, typically by using a specific output/manufacturing option. Ensure to generate all the necessary layers that are needed by the manufacturer. - Verifying Gerber Files

It is paramount to verify that the generated Gerber files are accurate and complete prior to submitting to the custom circuit board maker. Most manufacturers provide online Gerber viewers that can be used to review the design. This extra step helps identify potential issues, such as missing layers, incorrect drill sizes, or improper clearances, and ultimately saves time and money. - Common Issues with Gerber Files

Problems such as incorrect units, missing drill files, and overlapping features are common. Such errors can result in PCBs that are not functional, or have incorrect dimensions/features. Always check the manufacturer’s guidelines to confirm that the generated files conform to their requirements.

Frequently Asked Questions About Custom Circuit Board Makers

This section addresses common inquiries regarding custom circuit board manufacturing, covering aspects such as cost, minimum order quantities, delivery times, and limitations on board complexity and layer counts. Understanding these factors is crucial for effectively utilizing a custom circuit board maker.

- What is the typical cost for custom circuit boards?

The cost of custom PCBs varies widely based on several factors, including the board's size, number of layers, material type, complexity of the design, quantity ordered, and any special finishes or requirements. Simpler designs and larger quantities typically result in lower per-unit costs. It's best to obtain specific quotes from manufacturers after finalizing your design. - What are the minimum order quantities (MOQ) for custom PCBs?

Minimum order quantities vary considerably among manufacturers. Some focus on prototyping and offer very small MOQs, even as low as a single board. Others, specializing in production runs, may have MOQs ranging from 50 to 100 boards or more. Always clarify MOQs before committing to a manufacturer, as this can impact overall cost. - What are the typical delivery times for custom PCBs?

Delivery times are influenced by the complexity of your design, the manufacturer's workload, and the shipping method. Quick-turn prototype services might deliver in a few days, while standard production runs can take a few weeks. It is advisable to discuss delivery timelines upfront with the manufacturer to align with your project schedule. - Are there limitations on board complexity when using a custom circuit board maker?

Most custom PCB manufacturers can handle a wide range of complexity, from simple single-layer boards to highly intricate multi-layer designs. However, very high layer counts, exceptionally fine trace widths, or specific material requirements may limit your choice of manufacturers. Assess your design complexity against the manufacturer's capabilities. - What are the limitations regarding layer count when using a custom circuit board maker?

The layer count capability of a custom PCB manufacturer is determined by its equipment and expertise. While common boards typically have 2 to 4 layers, some manufacturers can produce boards with 20 or more layers. Consult with the manufacturer to confirm they support the required layer count for your project. It is critical to ensure that the layers are aligned correctly, as misaligned layers will result in a non-functional PCB. - Can custom circuit board makers produce PCBs with specific materials?

Yes, many custom PCB makers offer a selection of materials beyond standard FR-4, including options for flexible boards (Kapton), high-frequency applications, and high-temperature requirements. When choosing a custom circuit board maker, ask about the available material options, to ensure the material will be compatible with your designs intended use cases, as well as any cost implications. - How can I ensure the quality of my custom PCBs?

To ensure the quality of your custom PCBs, it's essential to choose a manufacturer with robust quality control measures. Look for certifications (e.g., ISO 9001), review sample boards, and scrutinize their quality assurance processes. A reputable manufacturer will provide details on their testing and inspection protocols. Additionally, providing clear and accurate Gerber files is essential for minimizing errors.

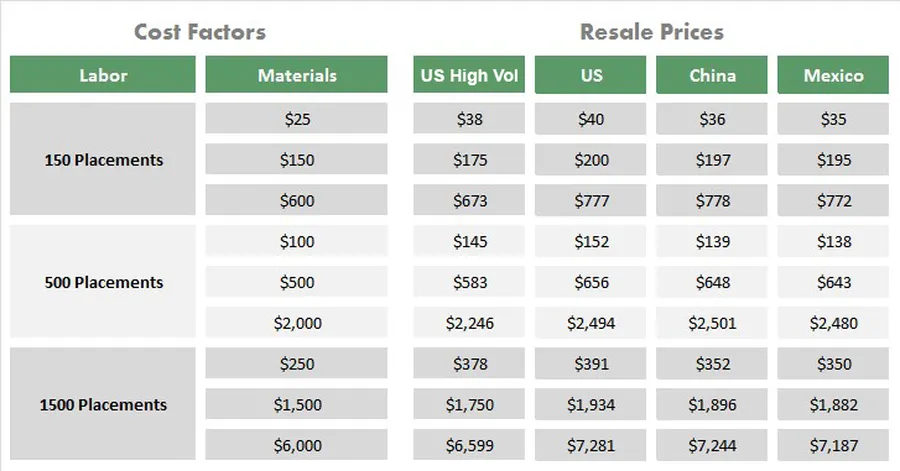

Cost Considerations for Custom Circuit Boards

Understanding the cost drivers in custom circuit board manufacturing is crucial for budget management and project success. Several factors influence the final price, ranging from fundamental elements like material choice to complex variables such as production volume and specialized surface treatments. A strategic approach to these cost drivers allows for effective cost optimization without compromising the quality or performance of the circuit board.

| Cost Factor | Description | Impact on Cost | Optimization Strategies |

|---|---|---|---|

| Material | The type of substrate material (e.g., FR-4, aluminum, Rogers) used in PCB fabrication. | Higher cost materials like Rogers or aluminum increase the price significantly. | Choose standard materials like FR-4 when performance allows; explore material alternatives if cost optimization is paramount. |

| Board Size and Layers | Physical dimensions of the board and the number of conductive layers. | Larger boards and more layers add to complexity and cost. | Design with smaller board sizes and fewer layers if feasible; minimize unnecessary complexity in the layout. |

| Quantity | The number of circuit boards produced in a single run. | Unit cost decreases significantly with higher volumes due to economies of scale. | Consolidate orders to achieve higher production quantities; plan ahead for future requirements to maximize cost efficiency. |

| Complexity | The intricacy of the board's design, including trace widths, via counts, and component density. | Higher complexity requires advanced manufacturing processes, increasing cost. | Simplify design layouts where possible; optimize component placement; use standard design rules. |

| Surface Finish | Type of plating applied to exposed copper (e.g., HASL, ENIG, Immersion Silver). | Advanced finishes like ENIG increase cost compared to HASL. | Use basic finishes like HASL if performance requirements allow; balance performance and cost. |

| Specialized Requirements | Features such as impedance control, blind vias, and custom solder mask colors. | Special requirements add significant costs to manufacturing. | Limit special requirements to essential needs; carefully consider the justification and costs before implementing. |

| Testing | Type and depth of testing required, such as Flying Probe, ICT, or functional testing. | Extensive testing increases the cost but ensures product reliability. | Prioritize necessary testing; balance cost and reliability; plan testing requirements upfront. |

In summary, a thorough evaluation of these cost factors in relation to the design requirements enables informed decision-making and effective cost management during the custom circuit board manufacturing process. Working with a custom circuit board maker that provides transparent cost breakdowns can be highly beneficial for budget adherence and project success.

Actionable Tips for Choosing a Custom PCB Maker

Selecting the right custom circuit board maker is critical for the success of your project. This section provides a concise checklist of actionable steps to ensure you choose a reliable and high-quality manufacturer, minimizing risks and maximizing the potential for a successful outcome.

- Review Samples

Before committing to a custom circuit board maker, request samples of their work. This allows you to assess the quality of their fabrication process, including the precision of the etching, the accuracy of the drilling, and the overall finish of the board. Pay close attention to the clarity of silkscreen and solder mask alignment. Inspect for defects, such as plating issues or uneven surface finishes, which are indicative of the manufacturer’s quality control process. - Request Multiple Quotes

Don't settle for the first quote you receive. Obtain quotes from several custom circuit board makers to compare pricing and turnaround times. Be sure to provide all vendors with the exact same specifications to make an accurate comparison. Look for not only the lowest price, but the best value in terms of quality, delivery and support. Inquire about any hidden or additional costs that may be charged and ask for a breakdown of any tooling or setup fees. Also be sure to understand the lead times associated with each vendor, so that you can select the vendor that best fits your timeline and budget. - Verify Certifications

Confirm that the custom circuit board maker possesses the necessary certifications. Look for ISO 9001 certification, which demonstrates the manufacturer's adherence to quality management systems. For specific industries, certifications such as AS9100 for aerospace or ISO 13485 for medical devices, should be present. These certifications provide assurance that the manufacturer is committed to consistent product quality and is following established industry best practices. - Evaluate Turnaround Time

Assess the manufacturer's typical turnaround times for both prototype and production runs. It’s critical to align their lead time with your project deadlines. Understand that lead times may vary based on the board complexity and material types. Confirm that the custom circuit board maker can provide realistic estimates and can meet your project's schedule. Check if rush production is available in cases when schedule compression is needed. - Check for Material Options

Confirm the range of materials the custom circuit board maker offers. They should support the specific types of materials that meet the needs of your project, including FR-4, Rogers, or aluminum substrates, among others. If you need special materials or finishes, check for their availability early in the process. Ensure they can handle the specified requirements before placing your order. - Examine Technical Support

Assess the responsiveness and expertise of the custom circuit board maker’s technical support team. A reliable partner should provide prompt and knowledgeable assistance. Evaluate how quickly they respond to technical inquiries and the type of support offered during the process, including DFM (Design for Manufacturing) feedback on your board layouts.

Choosing the right custom circuit board maker is a critical step in the development of any electronic project. By understanding your project’s requirements, comparing available options, and carefully evaluating various factors, you can ensure high-quality fabrication and successful outcomes. With the right custom circuit board maker, you can bring your most innovative ideas from concept to reality, demonstrating the seamless blend of social science and technology.

AnyPCBA

AnyPCBA