Choosing the Right EMS PCB Manufacturer: A Comprehensive Guide

In today's fast-paced technology landscape, selecting the right EMS PCB manufacturer is crucial for bringing innovative products to market efficiently. Just like the intricate network of neurons firing in the brain, PCB assembly forms the foundation of most electronics. This article delves into the essential aspects of choosing the ideal partner to ensure the success of your project, connecting the intricate world of electronics with the human need for innovation and reliability.

Understanding the Role of an EMS PCB Manufacturer

An Electronic Manufacturing Services (EMS) PCB manufacturer is a crucial partner in the production of printed circuit boards, offering a suite of services that extend beyond mere assembly. They manage the complexities of PCB production, from initial design and component sourcing to final testing and logistics. This allows product companies to focus on their core competencies, such as product design and marketing, while relying on the expertise of an EMS provider for efficient and high-quality PCB manufacturing.

The role of an EMS provider is multifaceted, encompassing not only the physical assembly of electronic components onto the PCB but also the intricate supply chain management, quality control, and adherence to industry standards. This comprehensive approach ensures that the finished PCBs meet the required performance specifications and reliability standards, facilitating the smooth launch of electronic products.

Key Criteria for Selecting an EMS PCB Manufacturer

Selecting the right Electronic Manufacturing Services (EMS) provider for your Printed Circuit Board (PCB) assembly is crucial for ensuring product quality, reliability, and timely delivery. This section details the essential criteria to consider when evaluating potential EMS partners, emphasizing factors that directly impact the success of your PCB manufacturing process.

- Manufacturing Capabilities

Assess the EMS provider's capacity to handle your project's specific requirements. This includes their experience with different PCB complexities, sizes, and technologies (SMT, Through-Hole, Mixed). Consider their equipment capabilities and the variety of components they can process. Evaluate their ability to handle both small and large production runs and whether they offer prototyping services. - Industry Certifications

Look for certifications like ISO 9001 (Quality Management System), ISO 13485 (Medical Devices), and IPC standards (Association Connecting Electronics Industries). These certifications demonstrate a commitment to quality and adherence to industry best practices. Check if they have certification specific to your industry. - Quality Control Processes

A robust quality control system is paramount for ensuring reliable PCB assemblies. Inquire about their inspection methods, testing protocols (e.g., AOI, X-ray), and defect tracking processes. A good EMS provider will have clearly defined procedures for quality assurance at each stage of manufacturing. - Adherence to Deadlines and Lead Times

Timely delivery is crucial for project timelines. Verify their historical performance in meeting deadlines and inquire about their production planning process. A reliable EMS provider should provide clear lead time estimates and keep you informed of any potential delays. - Supply Chain Management

Efficient supply chain management ensures the consistent availability of high-quality components. Assess the provider's relationships with suppliers and their methods for component sourcing and verification. A strong supply chain reduces the risk of delays and quality issues. - Communication and Customer Support

Effective communication is vital for a smooth collaboration. Evaluate their responsiveness, language capabilities, and the availability of a dedicated project manager. A transparent and supportive communication channel enhances problem-solving and ensures alignment with project requirements. Look for a provider that demonstrates a proactive and customer-centric approach. - Financial Stability

A financially stable EMS manufacturer ensures continuity in the manufacturing process, and can offer long term support. This stability reduces the risk of disruptions, and protects your supply chain

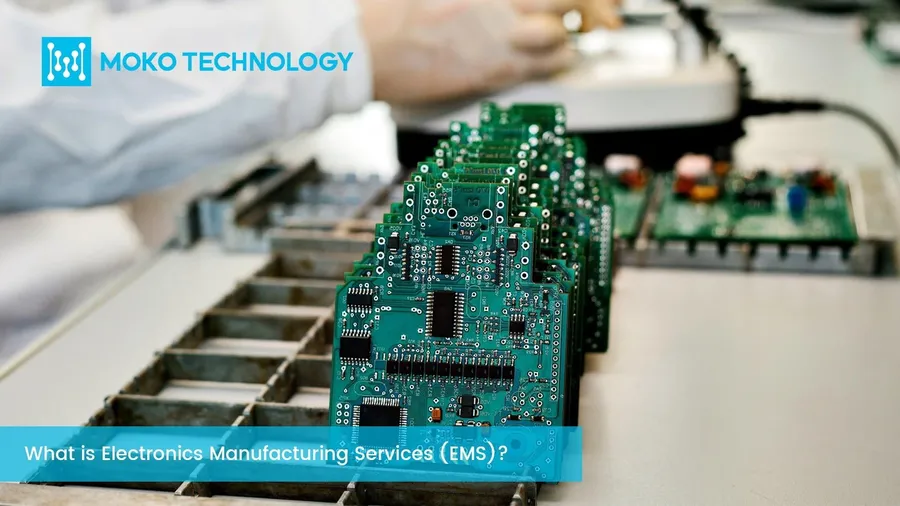

Types of PCB Assembly Services Offered by EMS Providers

Electronic Manufacturing Services (EMS) providers offer a diverse array of PCB assembly services to meet varying project requirements. Understanding these different techniques is crucial for selecting the most appropriate service to ensure the highest quality, efficiency, and cost-effectiveness of your electronic products.

- Surface Mount Technology (SMT)

SMT involves mounting electronic components directly onto the surface of a PCB. This method is ideal for high-density designs, allowing for smaller and more efficient electronic devices. It is highly automated, which increases production speed and lowers costs for high-volume manufacturing. The precision of SMT placement ensures better electrical performance. - Through-Hole Technology (THT)

THT involves inserting components with leads through holes in the PCB, and then soldering them on the other side. THT is best suited for components that require strong mechanical connections due to high stress or loads, as well as for larger and bulkier components. Though less automated than SMT, THT offers robust solutions for certain applications. - Mixed Technology Assembly

Mixed technology assembly combines SMT and THT on a single PCB. This approach is often required when a design includes both surface mount components for high density and through-hole components for stronger mechanical connections or specialized parts. Mixed technology assembly is complex and requires precise processes and skilled technicians. - Prototyping

Prototyping services involve creating small batches of PCBs to validate designs before full-scale manufacturing. These services are vital for product development as they allow for early testing, design verification, and the detection of any potential issues. Prototype assembly is essential for both product functionality and production process refinement. - Specialized Assembly Services

Beyond standard SMT and THT assembly, EMS providers may offer other specialized services such as conformal coating, potting, and other forms of protective assembly. These advanced techniques protect PCBs from moisture, harsh environments, and mechanical stress, extending the life and improving reliability of the final product. The availability of these services should align with your specific application needs.

Evaluating EMS PCB Manufacturer's Technological Capabilities

A critical aspect of choosing an Electronic Manufacturing Services (EMS) provider for PCB manufacturing is evaluating their technological prowess. This encompasses not just the machinery they employ, but also the expertise of their personnel and their ability to adapt to increasingly complex design requirements and evolving industry standards. A capable EMS provider will possess the infrastructure to handle intricate PCB layouts, utilize cutting-edge equipment, and demonstrate the scalability necessary to meet fluctuating production demands while ensuring consistent quality.

The following points delineate key areas of technological capabilities that should be carefully scrutinized:

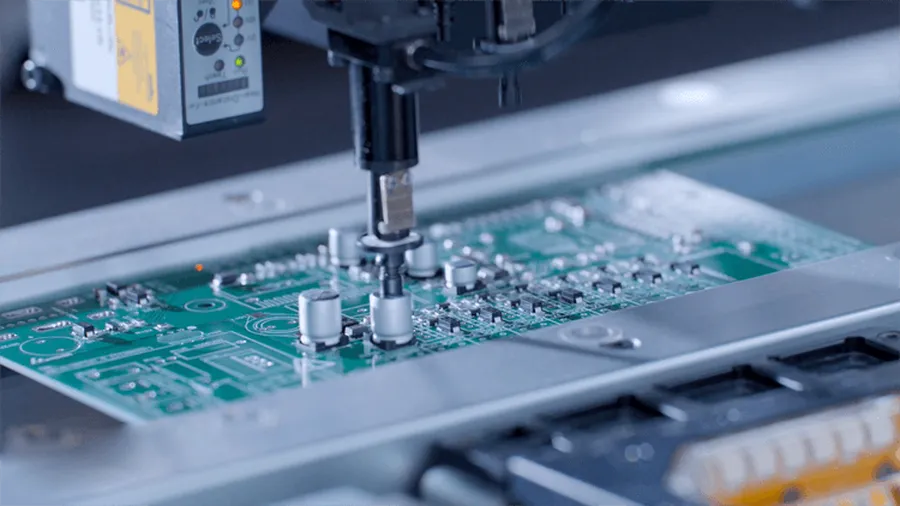

- Advanced Equipment

Assess the EMS provider's investment in modern machinery. This includes high-speed pick-and-place machines, automated optical inspection (AOI) systems, X-ray inspection equipment, and reflow ovens with precise temperature control. Such advanced tools are essential for accurate component placement, detection of defects, and ensuring high-quality solder joints. - Complex Design Handling

Evaluate the EMS provider's experience in handling intricate PCB designs. Can they manage multilayer boards, fine-pitch components, and high-density interconnections? Their track record with demanding projects is a good indicator of their capabilities. - Scalability

Determine the EMS provider's ability to scale production according to your needs. Can they handle both prototype runs and large-volume manufacturing efficiently? Scalability is vital for ensuring consistent supply and adapting to changing market conditions. - Data Management and Traceability

Confirm that the EMS provider has robust data management systems to track components, monitor production processes, and ensure traceability of products. This is essential for quality control and efficient handling of potential issues. - Skilled Workforce

Assess the experience and qualifications of the EMS provider's personnel. Skilled technicians, engineers, and quality control staff are vital for ensuring high-quality PCB assembly and identifying and rectifying potential defects and issues.

The selection of an EMS PCB manufacturer should not only consider the present technological requirements of a project but also future needs. It is essential to select a partner who actively invests in technology to maintain pace with industry advancements. This approach ensures that the EMS provider can provide consistent quality, flexibility and scalability, which are essential for both current and upcoming PCB manufacturing challenges.

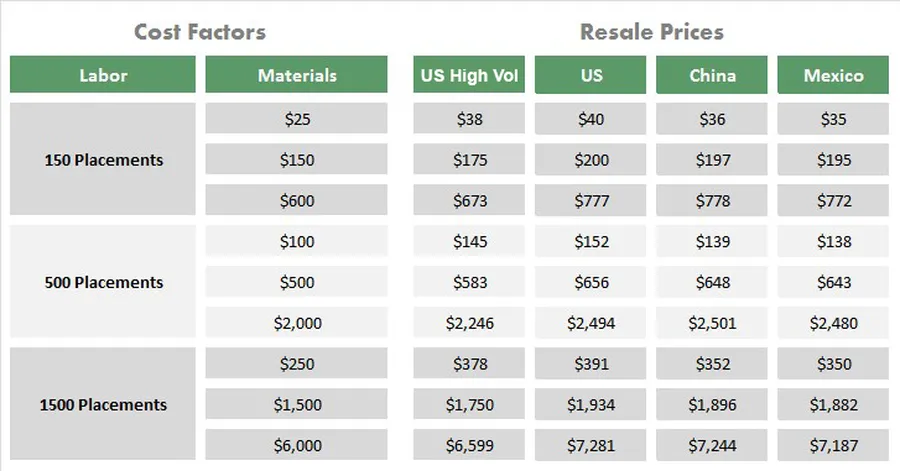

Cost Considerations When Choosing an EMS PCB Manufacturer

Navigating the cost landscape of PCB assembly is crucial, requiring a delicate balance between budgetary constraints and the desired quality of the final product. A comprehensive understanding of all cost factors, extending beyond just the initial quotes, is essential for making informed decisions when selecting an EMS (Electronic Manufacturing Services) PCB manufacturer. This section delves into the various aspects of cost that should be carefully considered.

Key cost drivers in PCB assembly include the complexity of the design, the volume of production, the types of components used, and the turnaround time required. More complex designs often demand advanced manufacturing techniques and materials, leading to higher costs. Similarly, low-volume production runs usually incur higher per-unit costs due to setup and overhead expenses. Component choices significantly impact the overall price, with premium components contributing to a higher final cost. Expedited delivery and shorter turnaround times are also often associated with increased expenses.

Beyond the initial quote, the Total Cost of Ownership (TCO) should be a primary consideration. This includes not only the cost of assembly but also expenses related to testing, rework, shipping, and potential delays. A thorough evaluation of an EMS manufacturer's pricing model, including payment terms and conditions, is advisable. Some manufacturers might offer competitive pricing but have less favorable payment terms or hidden charges, which can affect the overall TCO. It's also beneficial to evaluate the cost of potential modifications, particularly for prototypes and initial production runs, as changes in design might impact production costs.

Optimizing PCB designs for cost-effectiveness is a strategic approach that can substantially reduce assembly expenses without compromising quality. This involves considering factors such as component placement, layer count, and design for manufacturability (DFM). Selecting standard or readily available components can also lower costs compared to using specialized or difficult-to-source parts. Working closely with the EMS manufacturer during the design phase to ensure the design is optimized for their manufacturing processes can lead to significant cost savings. Understanding and applying these principles will lead to greater cost efficiencies and better overall results.

| Cost Factor | Description | Cost Impact |

|---|---|---|

| Design Complexity | Number of layers, component density, trace routing. | High complexity leads to higher costs due to increased processing. |

| Production Volume | Quantity of PCBs being assembled. | Low volume typically has higher per-unit costs; large volumes benefit from economies of scale. |

| Component Types | Selection of standard vs. specialty components, availability, and sourcing. | Specialized components or those with low availability can significantly increase costs. |

| Turnaround Time | Timeframe for PCB assembly. | Expedited or fast turnaround times often increase costs. |

| Testing Requirements | Testing protocols, such as ICT, functional testing. | More rigorous testing leads to higher expenses. |

| Logistics and Shipping | Shipping distance, transportation type, customs, and handling. | Logistical challenges can lead to increased overall costs and transit times. |

| Payment Terms | Payment schedules, conditions, and deposit requirements. | Unfavorable terms may increase the financial burden, affecting overall TCO. |

Geographical Location of the EMS PCB Manufacturer

The geographical location of an Electronic Manufacturing Services (EMS) provider significantly influences factors such as shipping costs, lead times, and the efficiency of communication. Selecting the right location for your EMS partner involves a strategic evaluation of regional benefits and potential logistical challenges.

| Factor | Local EMS Manufacturer | International EMS Manufacturer |

|---|---|---|

| Shipping Costs | Lower due to proximity | Higher due to distance and international freight |

| Delivery Time | Faster turnaround times | Longer lead times, potential for delays |

| Communication | Easier due to similar time zone, culture and language | Potentially difficult due to time zone differences, language and culture barriers |

| Quality Control | Potentially easier to monitor and verify in-person | Requires more robust remote quality assurance procedures |

| Cost of Labor | Variable based on local labor costs | Often lower in developing countries |

| Legal Compliance | Simplified if within same country | Complex due to international trade laws and regulations |

| Supply Chain | Potentially shorter supply chain depending on local component supply | Extended supply chains which may be more exposed to risks |

When evaluating location, consider the total cost of ownership beyond the initial quote. This includes factoring in potential delays, shipping insurance, customs duties, and communication expenses. For international partnerships, assess the political stability, economic conditions, and environmental practices of the region.

To mitigate potential logistical difficulties, establish clear communication protocols, utilize project management tools, and conduct regular audits. Prioritize transparent relationships with your selected EMS partner to ensure smooth operations regardless of geographical distance. In certain situations, a local EMS provider could offer quicker turnaround and more direct communication, while international partners might offer greater cost savings but require more robust risk assessment and project management strategies.

Frequently Asked Questions About EMS PCB Manufacturers

Understanding the nuances of Electronic Manufacturing Services (EMS) for Printed Circuit Boards (PCBs) is crucial for making informed decisions. This section addresses common questions, providing clarity on key aspects of EMS PCB manufacturing and selection.

- What does EMS stand for in the context of PCB manufacturing?

EMS stands for Electronic Manufacturing Services. In the PCB industry, it refers to companies that provide a range of services beyond just PCB fabrication, such as PCB assembly, component sourcing, testing, and logistics. These services streamline the manufacturing process for their clients. - What is the role of an EMS provider in the PCB manufacturing process?

An EMS provider takes on a comprehensive role in the PCB manufacturing process. They handle everything from procuring components and assembling PCBs using surface mount (SMT) and through-hole technologies to performing tests to ensure the quality and functionality of the finished boards. They can also manage logistics and shipping. This allows companies to focus on design and product development while outsourcing the manufacturing. - Who is the largest PCB manufacturer globally?

The title of the 'largest' PCB manufacturer can fluctuate due to market dynamics, mergers, acquisitions and can vary depending on the metrics used (e.g. revenue, production volume). However, companies such as TTM Technologies, Unimicron, and Nippon Mektron are often cited among the largest and most prominent in the global PCB manufacturing industry, known for their significant production capacities. - What are the key factors to consider when selecting an EMS PCB manufacturer?

Several factors are crucial when choosing an EMS PCB manufacturer. These include their manufacturing capabilities (SMT, through-hole, mixed technology), certifications (ISO, IPC), quality control processes, technological expertise, capacity for handling complex designs, and adherence to deadlines. Furthermore, cost considerations, geographical location, communication effectiveness and scalability of production are important. - What types of PCB assembly services do EMS providers typically offer?

EMS providers offer a variety of assembly services, including Surface Mount Technology (SMT), through-hole technology, and mixed technology assembly (a combination of both SMT and through-hole components). They also provide services like prototyping, testing, and can offer specialized services depending on the project requirements and the provider's expertise. - What is the difference between PCB fabrication and PCB assembly?

PCB fabrication involves creating the bare printed circuit board, including the substrate and conductive layers. PCB assembly, on the other hand, is the process of mounting electronic components onto the fabricated PCB. An EMS provider often handles the assembly process, whereas PCB fabrication can be performed by a different supplier or also under the same EMS provider's umbrella. - How does the geographic location of an EMS PCB manufacturer affect the project?

The location of an EMS PCB manufacturer can significantly impact shipping costs, delivery times, and communication effectiveness. Choosing a local manufacturer might lead to better communication and faster turnaround times, while an international manufacturer could offer cost advantages. However, logistical complexities can be amplified with international partners which would require careful consideration.

Future Trends in EMS PCB Manufacturing

The Electronic Manufacturing Services (EMS) sector for Printed Circuit Boards (PCBs) is experiencing rapid evolution, driven by technological advancements and shifting market demands. Understanding these trends is crucial for businesses seeking to stay competitive and select an EMS partner that is prepared for future challenges and opportunities.

- Miniaturization and High-Density Interconnect (HDI) PCBs

The demand for smaller, more powerful electronic devices is pushing the boundaries of PCB design and manufacturing. This trend necessitates EMS providers with advanced capabilities in HDI PCB fabrication and assembly, allowing for higher component density and finer trace widths. - Increased Automation and Robotics

To improve efficiency, accuracy, and throughput, EMS manufacturers are increasingly adopting automation and robotics in various stages of PCB production. This includes automated component placement, soldering, inspection, and material handling, leading to reduced human error and faster turnaround times. - Smart Factories and IoT Integration

The integration of Internet of Things (IoT) technologies is enabling real-time monitoring and data analysis of manufacturing processes. Smart factories leverage sensor data to optimize production, predict equipment maintenance, and enhance quality control. - Sustainability and Eco-Friendly Practices

Environmental consciousness is gaining importance in the electronics industry. EMS providers are focusing on sustainable materials, energy-efficient processes, and waste reduction. This includes exploring lead-free soldering alternatives, reducing water consumption, and implementing recycling programs. - Advanced Testing and Inspection Methods

As PCB designs become more complex, advanced testing and inspection technologies are essential to ensure product reliability. EMS manufacturers are investing in automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT) to detect defects and guarantee the quality of the assembled PCBs. - Flexible and Agile Manufacturing

The demand for greater flexibility and responsiveness in manufacturing is on the rise. EMS providers are adapting to smaller batch sizes, shorter production runs, and rapid prototyping. Agile manufacturing methodologies allow for faster product launches and customized solutions. - Digitalization of Supply Chain Management

Digital technologies are transforming supply chain management within the EMS industry. This includes the use of online platforms, real-time tracking, and predictive analytics to improve visibility, reduce lead times, and enhance communication with suppliers and customers.

Comparing EMS PCB Manufacturer Capabilities

Selecting the right EMS PCB manufacturer is critical for the success of any electronics project. A thorough comparison of different manufacturers' capabilities can help ensure that your chosen partner aligns with your project's specific requirements. This section provides a framework for comparing EMS providers based on key criteria, allowing you to make an informed decision.

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C | Considerations |

|---|---|---|---|---|

| Industry Experience | 15 years | 5 years | 20 years | Evaluate the manufacturer's history and reputation in the EMS industry. More experience often translates to better process knowledge and problem-solving capabilities. |

| Technological Capabilities | Basic SMT, Through-Hole | Advanced SMT, BGA, Fine Pitch | Advanced SMT, BGA, Fine Pitch, Automated Inspection | Assess their ability to handle your specific technology needs, including advanced component placement, micro-BGA and fine pitch technologies, and test capabilities. |

| Production Capacity | Small to Medium Volumes | Medium to Large Volumes | Small to Large Volumes | Consider their production capacity, flexibility to scale your production volume as needed, and how long it will take to complete your projects. |

| Quality Control Processes | Basic QC checks | ISO 9001 Certified | ISO 9001 and IPC Standards | Verify their quality control processes, including certifications, and adherence to industry standards. Confirm their processes are well-defined and consistently applied. |

| Component Sourcing | Limited network | Extensive global network | Extensive global network with direct vendor relationships | Evaluate the reach of their component sourcing, their ability to procure quality materials cost effectively and whether they offer alternatives. |

| Turnaround Time | 5-10 business days | 3-7 business days | 2-5 business days | Consider the turnaround time and delivery speed, and the flexibility of their scheduling processes to meet your timeline. |

| Pricing Structure | Higher cost per unit | Medium cost per unit | Competitive pricing | Evaluate the transparency and competitiveness of their pricing, payment terms, and potential additional costs. |

| Communication Effectiveness | Occasional updates | Regular updates | Dedicated account managers, real time tracking | Confirm the provider’s communication style and accessibility for feedback, status and overall project management. |

This comparative table should serve as a starting point. Engage directly with potential manufacturers, request detailed quotes, and conduct on-site visits where possible. This comprehensive approach will ensure you choose a partner that is best equipped to fulfill your specific PCB manufacturing needs.

Choosing the right EMS PCB manufacturer is vital to the success of any electronics project. An experienced and capable partner, offering services from PCB layout to final assembly, ensures product quality and timely market delivery. This guide has explored key aspects of EMS, including choosing the right manufacturer to help navigate the complexities of electronic manufacturing. Remember to prioritize your specific needs, research thoroughly, and consider a partner that not only meets your current requirements but can also adapt to your future growth. For a seamless PCB assembly process, a reputable EMS PCB manufacturer with robust capabilities is the best option.

AnyPCBA

AnyPCBA