Choosing the Right PCB Assembly Services Manufacturer: A Comprehensive Guide

In today's fast-paced technological landscape, printed circuit boards (PCBs) are the backbone of almost every electronic device. Selecting the right PCB assembly services manufacturer is crucial for ensuring the quality, reliability, and timely delivery of your products. This article will explore the critical factors to consider when choosing a PCB assembly partner, guiding you from initial design to final production, and will discuss how these services impact various applications from everyday electronics to advanced industrial tools.

Understanding Your PCB Assembly Needs

Before engaging with PCB assembly services manufacturers, a thorough understanding of your project's specific requirements is paramount. This involves a clear definition of the project scope, including production volume, complexity of the design, and required turnaround time, which directly influence the selection of a suitable manufacturing partner. The decision to opt for prototyping, small batch production, or large-scale manufacturing should be made at this stage, along with a determination of the required assembly technologies.

| Requirement Category | Considerations |

|---|---|

| Production Volume | Prototyping, small batch, medium, large-scale |

| Design Complexity | Number of components, component types, board layer count |

| Turnaround Time | Required time from start to delivery of assembled boards |

| Assembly Technologies | SMT, Through-Hole, Mixed Technology |

Key Capabilities to Look For in PCB Assembly Services Manufacturers

Selecting the right PCB assembly services manufacturer extends beyond basic assembly; it requires a deep dive into their technological capabilities and service offerings. A comprehensive assessment ensures your chosen partner can adeptly handle your project's complexities from start to finish. This includes evaluating their proficiency in various assembly technologies, the availability of value-added services and rigorous testing procedures.

| Capability | Description | Importance |

|---|---|---|

| Surface Mount Technology (SMT) | Expertise in placing components directly onto the surface of the PCB. | Crucial for modern, high-density designs; determines the ability to handle small components. |

| Through-Hole Technology (THT) | Capability to mount components with leads inserted into drilled holes. | Essential for older designs or where stronger mechanical connections are required. |

| Mixed Technology Assembly | Ability to combine both SMT and THT components on a single board. | Necessary for designs requiring a mix of surface mount and through-hole components; shows versatility. |

| Component Sourcing | A robust supply chain and network of reliable component suppliers. | Ensures quality and availability of components; mitigates risks of counterfeit parts and delays. |

| Design for Manufacturability (DFM) Review | Expertise in assessing PCB designs for ease of manufacturing. | Vital for early issue identification; reduces defects and optimizes production flow. |

| Testing Services | Provision of various testing methods to ensure PCB quality and reliability. | Critical for verifying PCB functionality before full-scale production. |

Component Sourcing and Supply Chain Management

A robust component sourcing and supply chain management system is vital for a reliable PCB assembly manufacturer, ensuring the consistent availability of quality components and minimizing risks associated with delays and counterfeit parts. This capability directly impacts the overall production timeline, product quality, and cost-effectiveness.

A manufacturer's effectiveness in this area encompasses several key aspects:

- Supplier Relationships:

Established relationships with reputable component suppliers are crucial. These relationships should ensure access to a wide range of components, including both standard and specialized parts. Strong supplier relationships also often translate to better pricing and shorter lead times. - Component Procurement Process:

A well-defined procurement process is necessary for efficiently managing the acquisition of components. This includes tracking inventory levels, placing orders promptly, and having backup plans for potential shortages or obsolescence. - Handling of Hard-to-Find Parts:

The ability to source hard-to-find or obsolete components is a significant advantage, especially for maintaining or repairing legacy systems. Manufacturers should have established networks to locate and procure these parts, minimizing production disruptions. - Quality Assurance of Components:

Rigorous quality control processes are essential to verify the authenticity and functionality of incoming components. These processes should include inspections and testing to identify counterfeit parts, preventing them from entering the assembly process. - Supply Chain Transparency:

Transparency in the supply chain is critical for traceability and accountability. Knowing the origin of components helps mitigate risks associated with substandard or counterfeit parts and also ensures compliance with regulatory standards.

Quality Control and Testing Procedures

Rigorous quality control and testing procedures are paramount in PCB assembly to guarantee the functionality and reliability of the final product. Manufacturers employ a variety of testing methods to identify and rectify defects, ensuring high-quality outputs that meet stringent performance criteria. These processes are crucial for minimizing failures and ensuring long-term product reliability.

| Testing Method | Description | Purpose |

|---|---|---|

| In-Circuit Testing (ICT) | Uses electrical probes to access test points on the PCB to verify the proper placement and electrical integrity of components. | Detects shorts, opens, incorrect component values, and missing components. |

| Automated Optical Inspection (AOI) | Employs high-resolution cameras to visually inspect PCBs for defects, such as solder bridges, tombstoning, missing parts, and polarity issues. | Identifies visual defects and ensures the quality of solder joints and component placement. |

| Functional Testing | Simulates real-world operating conditions to verify the performance of the assembled PCB. Custom test jigs and software may be used to fully test the board's functions. | Verifies if the board performs its intended function and meets specifications. |

| X-ray Inspection | Utilizes X-ray technology to inspect solder joints, especially ball grid array (BGA) and quad-flat no-leads (QFN) packages, for hidden defects. | Identifies hidden defects like voids and solder bridges in complex component packages. |

Turnaround Time and Delivery Options

Meeting project deadlines is paramount in PCB assembly, making a manufacturer's turnaround time and delivery capabilities critical considerations. This section focuses on evaluating a manufacturer's ability to deliver your assembled PCBs promptly, encompassing lead times for prototyping and full-scale production, as well as their shipping and delivery logistics.

It is imperative to understand the detailed timelines for each phase, from initial design submission to final delivery, ensuring the chosen manufacturer aligns with your project schedule. Additionally, assessing shipping options and their dependability will help to ensure efficient and timely receipt of the final assembled PCBs.

| Factor | Description | Impact on Project |

|---|---|---|

| Prototyping Lead Time | Time required to assemble initial prototypes. | Critical for design validation and early testing; shorter times accelerate development cycles. |

| Full Production Lead Time | Time required to assemble PCBs at full scale. | Determines project completion time; delays can impact product launch. |

| Shipping Options | Methods of transportation (e.g., ground, air) available. | Delivery speed and reliability depend on shipping; cost and availability need alignment with budget and delivery schedule. |

| Delivery Timeframes | Total time from manufacturing to arrival at your location. | Need to meet the overall project timelines; delays impact production schedules. |

| Geographic Location | Location of PCB assembly service | Local companies generally offer faster shipping, but costs can be higher. Offshore options usually offer lower prices, but shipping time is extended. |

Frequently Asked Questions About PCB Assembly Services Manufacturers

This section addresses common questions that arise when selecting a PCB assembly services manufacturer, focusing on cost factors, evaluation criteria, and global manufacturer identification, including the considerations of local versus international options and their impact on pricing and lead times.

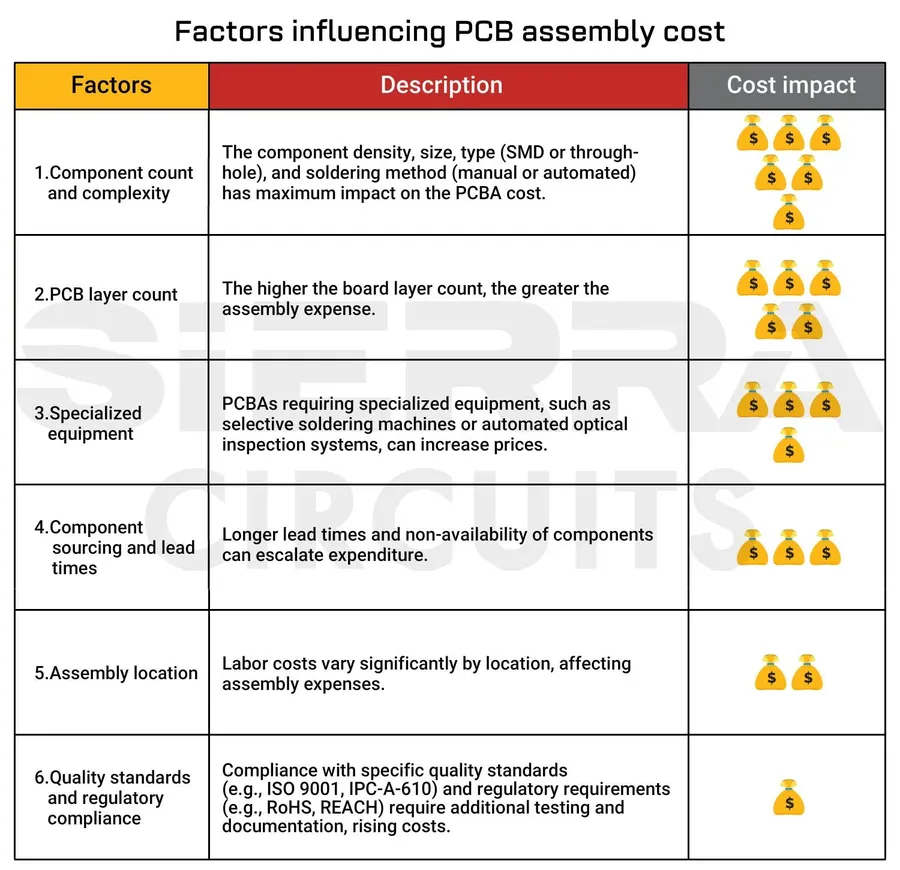

- How much does PCB assembly typically cost?

PCB assembly costs vary significantly based on several factors including the complexity of the board, the number of components, the type of components (SMT vs. through-hole), the quantity of boards, and the chosen manufacturer's pricing structure. Expect costs to range from a few dollars for very simple boards to hundreds or even thousands for complex, high-density PCBs in low volumes. Large-scale production generally reduces the per-unit cost due to economies of scale. Component sourcing also influences the final price. Detailed quotes from multiple manufacturers are crucial for accurate budgeting. - What criteria should I use to select the best PCB assembly manufacturer?

Choosing the right manufacturer involves evaluating several factors, including their assembly capabilities (SMT, through-hole, mixed technology), component sourcing expertise, design for manufacturability (DFM) review processes, testing procedures (ICT, AOI, functional, X-ray), quality control measures, turnaround time, and cost. Consider their experience with similar projects and customer reviews. A manufacturer that offers comprehensive services, high quality, and reliable communication is preferred. Don't hesitate to request sample boards and visit facilities if possible. - Who are the largest PCB assembly manufacturers globally?

Identifying the 'largest' PCB manufacturer can be complex, with different metrics like revenue, production volume, and geographical coverage leading to varying lists. Some of the major players in the PCB assembly market include Foxconn, Pegatron, Jabil, Flex, and Sanmina. These large manufacturers handle high volumes of production for consumer electronics, automotive, and other industries. It is important to evaluate manufacturers based on your specific needs rather than solely focusing on their overall size. - Should I prioritize a local PCB assembly manufacturer over an international one?

The choice between local and international PCB assembly manufacturers depends on your specific needs. Local manufacturers often offer faster turnaround times, easier communication, and quicker response to problems. However, they might come at a higher price. International manufacturers, especially in countries with lower labor costs, can offer significant cost advantages. The main disadvantage of international manufacturers is longer lead times, potential communication barriers, and the complexity of dealing with different time zones and shipping logistics. Consider your budget, timelines, and communication needs before making a decision. - How does choosing a manufacturer impact lead times for PCB assembly?

Lead times vary greatly from one manufacturer to another. Factors include the manufacturer's workload, the complexity of the PCB, component availability, and the chosen shipping method. Local manufacturers may offer lead times in days or a few weeks, while international manufacturers may require several weeks or even months. Efficient supply chain management, rapid response processes, and open communication channels can reduce lead times. It's essential to clarify lead times during the quote process and ensure the manufacturer can meet your project deadlines. - What are some ways to reduce the cost of PCB assembly?

Several strategies can help lower PCB assembly costs. Opt for standard components when possible, as custom components can substantially increase prices. Optimize your PCB design for manufacturability (DFM) to reduce assembly time and potential errors. Consider panelizing your PCBs to optimize manufacturing processes, especially for high-volume production. Plan your production needs in advance and allow for longer lead times for international options. Finally, negotiate terms and conditions based on your project’s scope.

Cost Considerations and Budget Management

Managing costs effectively in PCB assembly is crucial for project success. A comprehensive understanding of the various cost factors, obtaining detailed quotes, and considering the total cost of ownership are essential steps in this process. This section delves into the key elements that influence the final price of assembled PCBs.

PCB assembly costs are not solely defined by the per-unit price; they encompass various elements. Here's a breakdown of the primary factors impacting the overall expense:

- Component Costs

The cost of electronic components constitutes a significant portion of the total assembly price. Prices fluctuate based on market demand, manufacturer, and the quantity purchased. Sourcing components through the assembly manufacturer can sometimes lead to discounts due to their established relationships with suppliers. However, it is essential to verify the quality and authenticity of components to avoid issues in the long run. Consider both standard components and hard-to-find parts, as their pricing can vary greatly. - Assembly Labor

Labor costs are influenced by the complexity of the PCB design, the chosen assembly technology (SMT, through-hole, or mixed), and the quantity of boards. Labor is the cost associated with personnel who manually place components, operate machinery and manage the manufacturing process. Complex boards and higher volumes may incur lower per-unit labor costs due to economies of scale but may increase the total labor cost. - Testing Expenses

Thorough testing adds to the overall cost but ensures the reliability of the assembled PCBs. Testing expenses depend on the type of testing performed including ICT, AOI, functional testing, and X-ray inspection. The complexity of testing required is dictated by the application of the PCB. Investing in comprehensive testing from the beginning can save time and money that could be spent on rework later. - Setup and Tooling

Initial setup costs include the programming of machinery and the preparation of stencils. These can have a greater impact on projects with small batch runs, which might result in higher per-unit costs. This cost might be reduced or eliminated on repeat orders where the same setup can be reused. - Shipping and Logistics

The distance between the manufacturer and the delivery location can influence cost of the shipment. Shipping cost also is affected by the selected shipping method, volume, and weight. Consider both domestic and international shipping when managing logistics cost. - Other Indirect Expenses

These costs include project management, quality control, and potential rework. These indirect costs contribute to the overall price, and it is important to consider them to have a full understanding of the total costs of PCB assembly. It is important to choose a manufacturer that is transparent with all costs.

Obtaining detailed quotes from multiple manufacturers is essential for budget management. When reviewing quotes, it's crucial to look beyond just the unit price. Consider the following:

- Detailed Breakdowns

Request a breakdown of costs, including components, labor, testing, and any other fees. This transparency allows for a more accurate budget assessment. - Quotation Accuracy

Assess the accuracy of the quoted price. A large variance between the initial quote and the final cost might indicate a problem. Compare multiple quotations with similar cost breakdowns and consider only using manufacturers that clearly show their costs. - Volume Discounts

If you are planning for larger-scale production, investigate the availability of volume discounts. A higher volume of production may allow the manufacturer to lower production costs. This can significantly reduce the price per unit. - Hidden Fees

Ask explicitly about any potential hidden fees, including setup costs, tooling charges, or rush order surcharges. Transparency is essential in avoiding unexpected expenses.

Total cost of ownership includes not just the price per unit but also long-term reliability, delivery times, and ease of working with the manufacturer. Here's a breakdown of why considering total cost of ownership is essential:

- Quality

Higher-quality PCBs might have a greater initial cost, but they can reduce the likelihood of problems and replacements, ultimately lowering long-term expenses. - Delivery Times

A manufacturer with consistent lead times and fast delivery can prevent supply chain delays, which may otherwise lead to additional costs. A delayed project might incur extra costs, particularly if it impacts deadlines. - Reliability

Reliable PCBs reduce the need for rework, replacements, and downtime. A reliable manufacturer helps you avoid additional costs associated with product returns and reduced sales. - Support and Communication

A manufacturer that offers great support and clear communication can solve problems faster, saving both time and money and allowing for more efficient use of your resources.

Geographic Considerations: Local vs. Offshore PCB Assembly Services Manufacturers

The decision between local and offshore PCB assembly services manufacturers hinges on a balance of cost, speed, and communication preferences. Local manufacturers often provide faster turnaround and easier communication due to proximity and similar time zones, while offshore manufacturers can offer significant cost reductions, especially for large production volumes. The optimal choice depends critically on the specific requirements and constraints of the project.

| Factor | Local Manufacturers | Offshore Manufacturers |

|---|---|---|

| Cost | Generally higher, especially for large production runs. | Generally lower, especially for high-volume orders. |

| Turnaround Time | Faster prototyping and production lead times due to proximity. | Longer lead times, particularly for prototyping and initial runs. |

| Communication | Easier real-time communication; face-to-face meetings possible. | Potential communication barriers due to time zones and language differences. |

| Shipping and Logistics | Simplified logistics and quicker shipping times. | Complex logistics and longer shipping times; potential customs delays. |

| Quality Control | Easier to visit and oversee operations; more direct quality control. | More challenging to oversee production; reliance on documentation and remote auditing. |

| Minimum Order Quantities | More flexibility for low-volume orders. | Often require high minimum order quantities to be cost-effective. |

- Local Manufacturer Advantages:

Faster turnaround times, easier communication, fewer logistical hurdles, and better oversight of the production process. Ideal for prototypes, small batch runs, and projects with tight deadlines. - Offshore Manufacturer Advantages:

Lower per-unit costs, particularly for high-volume production. Suitable for cost-sensitive projects with longer lead times and well-defined specifications. - Key Considerations:

Evaluate your budget, project timelines, communication preferences, quality requirements, and logistical constraints before deciding. Carefully weigh the trade-offs to make the most appropriate choice for your project.

Building a Successful Partnership with Your PCB Assembly Services Manufacturer

A robust and collaborative relationship with your PCB assembly services manufacturer is paramount for project success. This involves establishing clear communication channels, providing meticulous documentation, and proactively engaging in problem-solving. A strong partnership minimizes risks, ensures quality, and facilitates efficient manufacturing.

- Establish Open Communication Channels

Implement multiple communication pathways, such as regular meetings, email, and dedicated project management tools. A clear and consistent flow of information is essential for addressing issues promptly and efficiently. Proactive communication minimizes misunderstandings and ensures that both parties are aligned. - Provide Complete and Accurate Documentation

Supply the manufacturer with all necessary documentation, including Gerber files, Bill of Materials (BOM), assembly drawings, and any specific manufacturing instructions. Ensure this information is accurate and up-to-date. Complete documentation will reduce ambiguity and the chance of error. Clear documentation translates to accurate product results. - Inquire About Project Management Processes

Understand the manufacturer's project management approach including their scheduling methods, change management process, and key communication points. Familiarizing yourself with their processes helps manage expectations and ensure smooth project execution. A well-defined project management strategy enables transparency and control. - Engage in Collaborative Problem-Solving

Be prepared to work closely with the manufacturer to address any challenges that may arise during the manufacturing process. A collaborative approach to problem-solving will lead to more effective and efficient resolutions. A mindset of mutual problem solving creates a more productive partnership. - Regular Performance Review and Feedback

Establish a routine for reviewing the manufacturer's performance and provide them with constructive feedback. This will help them improve their services and ensure that the collaboration is continuously optimized. Open feedback loops create a more mutually beneficial relationship.

Choosing the right PCB assembly services manufacturer is a critical decision that significantly impacts your product's success. By understanding your needs, evaluating manufacturer capabilities, and focusing on quality and reliability, you can secure a partnership that ensures your electronic products are manufactured to the highest standards. Remember to establish clear communication channels and collaborative processes for smooth project management and timely delivery. Selecting a reputable and capable PCB assembly services manufacturer will ensure that your product achieves its full potential. The global landscape of PCB assembly is continually evolving and keeping abreast of the changes will ensure the delivery of consistent high quality assemblies.

AnyPCBA

AnyPCBA