Decoding Your JLCPCB Quote: A Comprehensive Guide

In today's fast-paced electronics industry, understanding the cost of PCB fabrication is crucial. JLCPCB, a leading PCB manufacturer, offers a streamlined online quoting process. This guide delves into the intricacies of a JLCPCB quote, ensuring you grasp all the essential elements for cost-effective PCB production, just like choosing the right components for a powerful circuit.

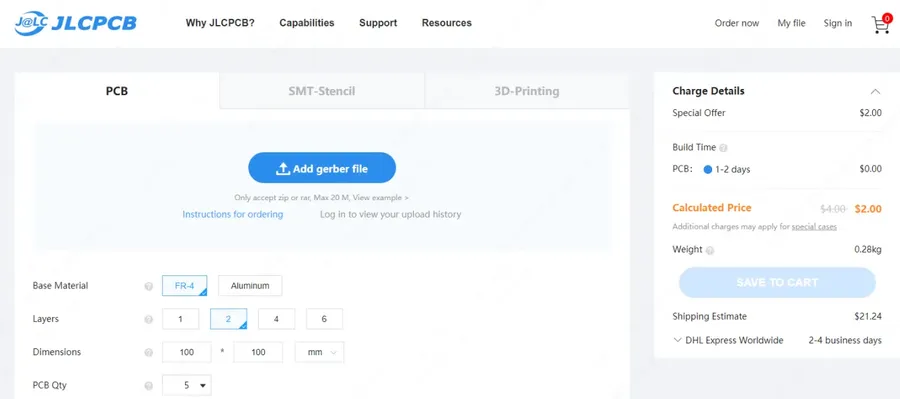

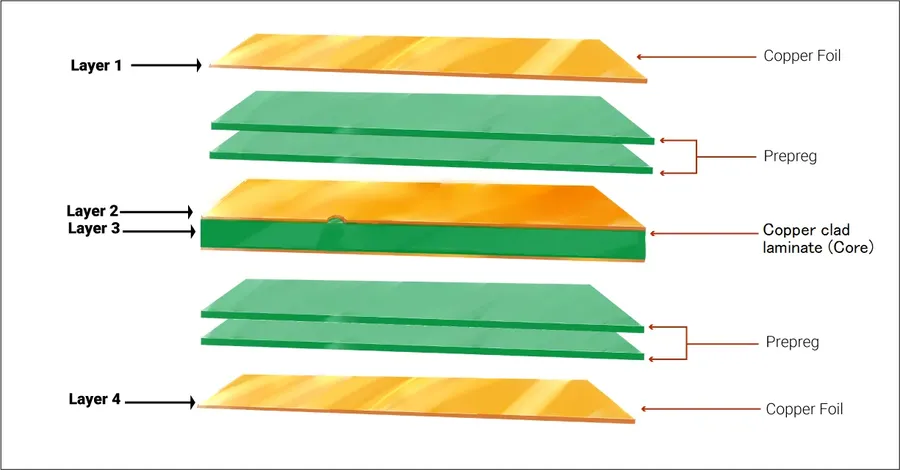

Navigating the JLCPCB Online Quote System

The JLCPCB online quote system provides an efficient method for obtaining pricing for your PCB fabrication needs. This section details a step-by-step approach for utilizing their quote calculator, ensuring accurate cost estimations and a smooth transition to production. A thorough understanding of this process is crucial for cost-effective PCB manufacturing.

- Access the JLCPCB Website

Begin by navigating to the official JLCPCB website. Look for a prominent link or button that directs you to the online quote calculator. This is typically found in the navigation menu or on the homepage. - Upload Your Gerber Files

Locate the section of the quote tool that allows for file uploads. This usually involves selecting your Gerber files (RS-274X format) within a compressed archive, such as ZIP or RAR. Ensure that all necessary files (including copper layers, silkscreen, solder mask, and drill files) are included. - Configure Basic PCB Parameters

Input fundamental parameters, including PCB dimensions (length and width in millimeters), the number of layers required (1, 2, 4, 6, etc.), the desired quantity of boards, and the chosen PCB material (e.g., FR-4). Accurate entry is vital for a correct quote. - Specify Advanced Options

Depending on your PCB needs, further specify attributes such as surface finish (e.g., HASL, ENIG), copper thickness, solder mask color, silkscreen color, board thickness, and any other features. These selections can impact pricing and functionality. Evaluate these options in accordance to their impact on functionality and cost. - Review and Submit

After inputting all parameters, thoroughly review the generated quote. JLCPCB's system offers a detailed price breakdown including the base cost, any material/feature costs, and an estimated shipping cost. Once you are satisfied, submit the quote request. - Download or Save

Once the quote is generated, JLCPCB typically provides an option to download the quotation details or save it to your account. This step is essential for your records and also to easily refer back to the specifications later. You can then proceed to ordering.

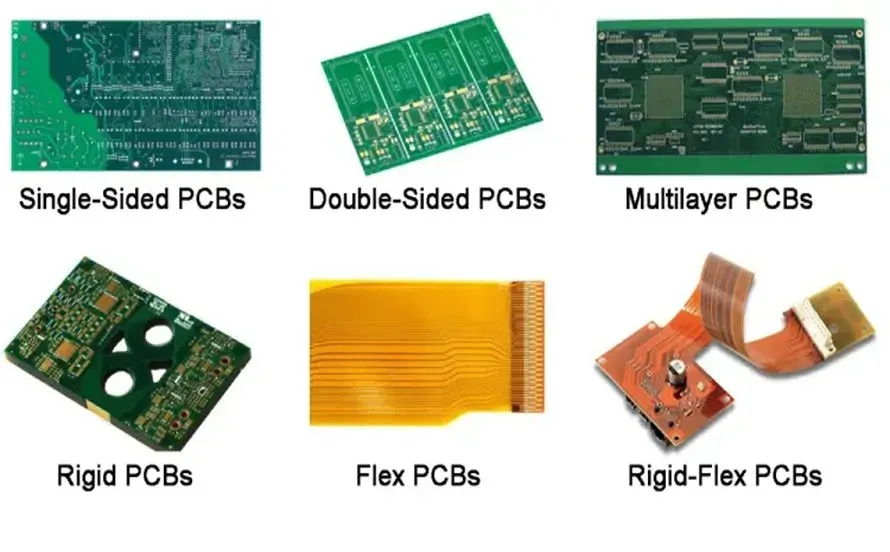

Key Factors Affecting Your PCB Quote: Material and Layers

The cost of your printed circuit board (PCB) from JLCPCB is significantly influenced by the materials you select and the number of conductive layers your design requires. These two factors are fundamental in determining the base price before considering other features and options. Understanding these influences is critical for cost-effective PCB design and procurement.

| Material Type | Description | Cost Impact | Typical Applications |

|---|---|---|---|

| FR-4 | Most common PCB material, a glass-reinforced epoxy laminate. Offers a good balance of performance and cost. | Base cost, lowest of commonly used materials. | Most standard PCBs, general purpose use. |

| Aluminum | A metal core PCB that provides excellent heat dissipation. Aluminum core is laminated between two copper layers. | Higher cost than FR-4, due to material and fabrication process. | LED lighting, power electronics, high-heat applications. |

| Rogers | High-performance materials designed for high-frequency applications with low signal loss. | Significantly higher cost than FR-4 due to specialized material and manufacturing. | RF and microwave circuits, high-speed digital applications. |

| CEM-1/CEM-3 | Paper or composite material, More affordable than FR-4 with some reduced performance. | Lower cost, suitable for cost-sensitive applications. | Consumer electronics, low-end applications. |

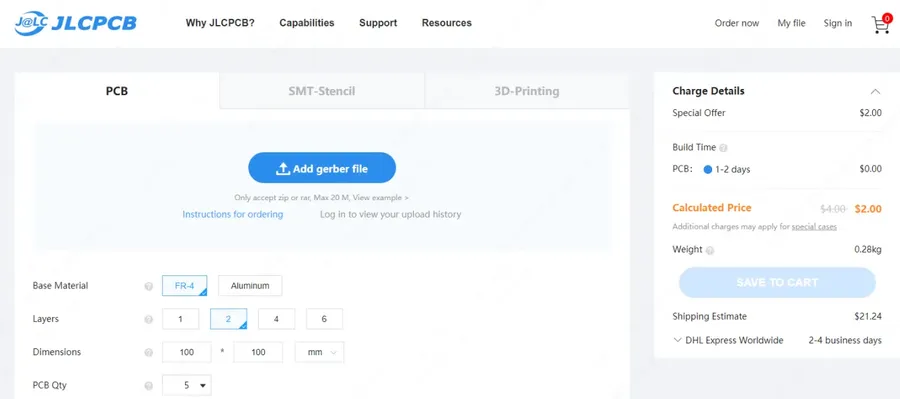

The number of layers is also critical, each layer adds to the complexity and material requirements. Layer count significantly impacts cost and must be considered as a core element of design

| Layer Count | Description | Cost Impact | Design Complexity |

|---|---|---|---|

| Single Layer | Simplest PCB design with conductive traces on one side of the board. | Lowest cost option. | Simple circuits, basic electronics. |

| Double Layer | Conductive traces on both sides of the board. | Slightly higher cost than single layer. | Most intermediate designs. |

| 4 Layer | Two signal layers, a power plane, and a ground plane. Provides better signal integrity. | Moderate increase in cost, commonly used for more complex digital circuits. | Complex circuits, high density designs |

| 6+ Layer | Multiple signal and power/ground planes. Required for highly complex and dense circuits. | Highest cost, necessary for complex digital circuits, high layer count may be required for impedance control. | High density interconnect, complex signal routings. |

For example, opting for standard FR-4 material and fewer layers is a cost-effective decision for simpler designs, while high-speed applications will require Rogers material with multiple layers. Always balance your performance needs with cost considerations.

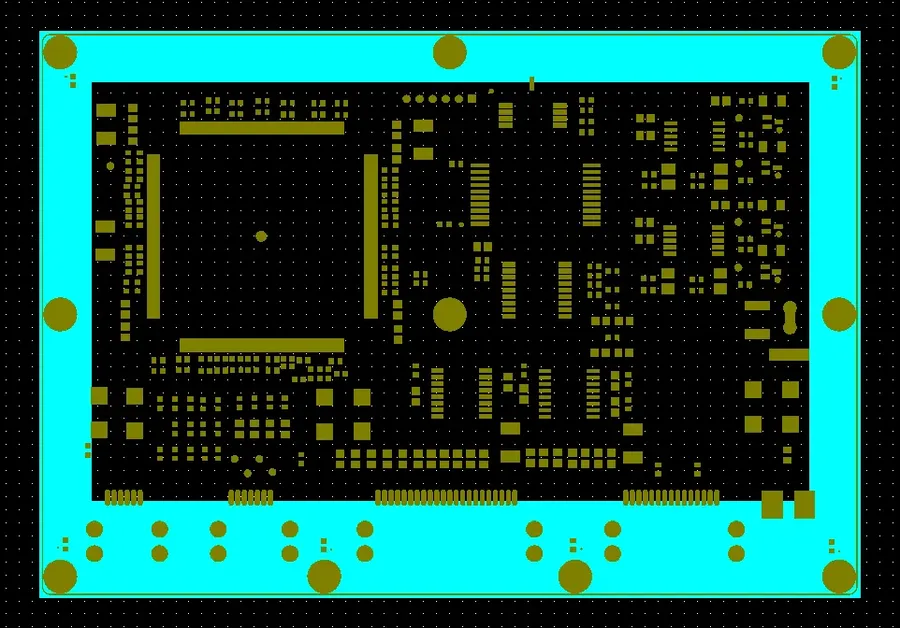

PCB Dimensions and Quantity: Optimizing for Cost

The physical dimensions of your printed circuit board (PCB) and the quantity you order are primary drivers of the overall fabrication cost at JLCPCB. Understanding how these factors interact can lead to significant savings. Larger boards generally require more material and processing time, thus increasing cost. Similarly, the economies of scale heavily influence pricing, with larger production runs significantly lowering the unit cost.

The price of a PCB is not simply a linear relationship with its size; there are often breakpoints where the price increases. Similarly, the cost per board decreases dramatically as the order quantity increases, which makes strategic purchasing a crucial aspect of PCB manufacturing. This chapter provides actionable strategies to optimize cost through careful planning and a good understanding of JLCPCB's pricing model.

| Factor | Description | Impact on Cost |

|---|---|---|

| PCB Size | The physical dimensions of the PCB (length and width). | Larger boards generally cost more due to increased material usage and processing time. |

| Order Quantity | The number of PCBs ordered in a single batch. | Larger quantities result in lower per-unit costs due to economies of scale. |

| Panelization | Combining multiple PCB designs into a single manufacturing panel. | Reduces cost per board by optimizing material utilization and handling during manufacturing. |

Panelization is a key technique to lower costs, which involves grouping multiple individual boards into one larger panel for production. By doing this, you effectively use more of the manufacturing resources in one setup and share setup costs across more individual boards. JLCPCB offers a panelization service and also accepts panelized designs directly, but it’s important to design your panel correctly so that the boards can be easily separated afterwards. In some cases, the panelization itself can add to the cost due to the increased complexity of handling the larger panel.

- Optimize Board Size

Design your PCB to be as compact as possible while meeting your functional requirements. Reduce unnecessary board area to minimize material usage and costs. - Consider Standard Sizes

Where possible, aim for standard PCB sizes as manufacturers often have optimized processes for these. This can sometimes lead to reduced prices and faster turnaround times. - Strategic Batching

Carefully plan order quantities. Batching multiple projects together into a single order can significantly reduce per-board costs, especially for prototyping and smaller projects. - Panelization Strategy

If multiple boards are required, explore panelization. This is often a cost-effective strategy that maximizes material usage. Be sure to design the panel properly, taking into consideration the spacing and break-away methods.

Surface Finish Options and Their Pricing Implications

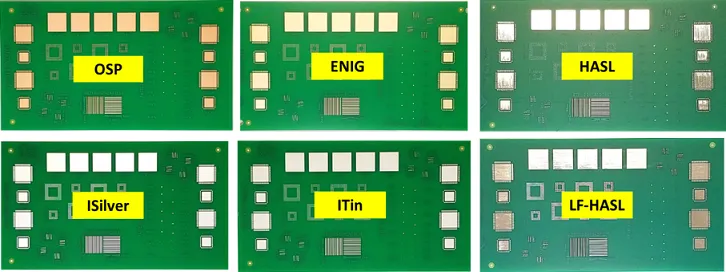

The surface finish of a Printed Circuit Board (PCB) is a critical factor influencing its performance, reliability, and ultimately, cost. Different finishes offer varying levels of solderability, oxidation resistance, and electrical conductivity, making the selection process a trade-off between functionality and budget. This section provides a detailed analysis of common surface finish options offered by JLCPCB and their associated pricing implications, which are core to getting an accurate JLCPCB quote.

| Surface Finish | Description | Pros | Cons | Cost Implications |

|---|---|---|---|---|

| HASL (Hot Air Solder Leveling) | A process where molten solder is applied to the PCB and then leveled with hot air. | Low cost, good solderability, readily available. | Uneven surface finish, not suitable for fine-pitch components, contains lead (lead-based HASL). | Generally the most affordable option. |

| Lead-Free HASL | Similar to HASL but uses a lead-free solder alloy. | Good solderability, RoHS compliant, relatively low cost. | Less even surface than ENIG, may not be ideal for very fine pitch components. | Slightly more expensive than standard HASL but still considered a lower cost option. |

| ENIG (Electroless Nickel Immersion Gold) | A two-layer metallic finish, nickel provides a barrier layer and gold acts as the solderable and corrosion resistant surface. | Excellent solderability, flat surface, good for fine-pitch components, long shelf life, good corrosion resistance. | More expensive than HASL. | Higher cost, primarily due to the use of gold, but provides superior performance in many applications. |

| OSP (Organic Solderability Preservative) | A thin organic coating that protects copper pads from oxidation. | Flat surface, good solderability, lead-free, relatively low cost. | Shorter shelf life, sensitive to handling, may require a more stringent assembly process. | Lower cost compared to ENIG, but may introduce some handling and assembly considerations. |

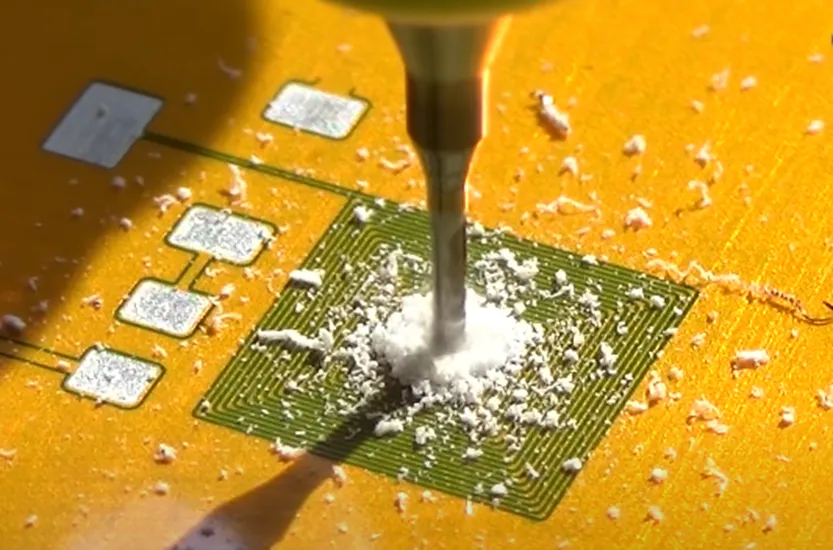

Drill Size and Hole Specifications

The precision and quantity of drilled holes significantly influence the cost of PCB fabrication. This section delves into how drill size specifications, the number of holes, and the choice between standard vias and microvias affect your JLCPCB quote, guiding you towards an optimal balance of functionality and cost.

| Specification | Impact on Cost | Design Consideration |

|---|---|---|

| Number of Holes | Directly Proportional: More holes generally increase cost due to increased drilling time and tool wear. | Minimize unnecessary vias and consider design alternatives. |

| Drill Size (Diameter) | Smaller drill sizes, particularly below 0.3mm, often increase cost. Microvias significantly more costly. | Use standard sizes whenever possible and avoid overly small holes if not needed. |

| Standard Vias | Typically less expensive than microvias, suitable for most layer transitions. | Use for most through-hole and layer-to-layer connections. |

| Microvias | More expensive due to specialized drilling and plating processes. Facilitates denser designs. | Use when board space is critically constrained and fine-pitch routing is required. |

Optimizing hole specifications involves a careful consideration of both functionality and cost implications. Where possible, adhere to JLCPCB's standard drill sizes and minimum hole specifications to avoid unnecessary cost inflation. Additionally, using standard vias where appropriate reduces cost compared to microvias while still ensuring reliable electrical connections.

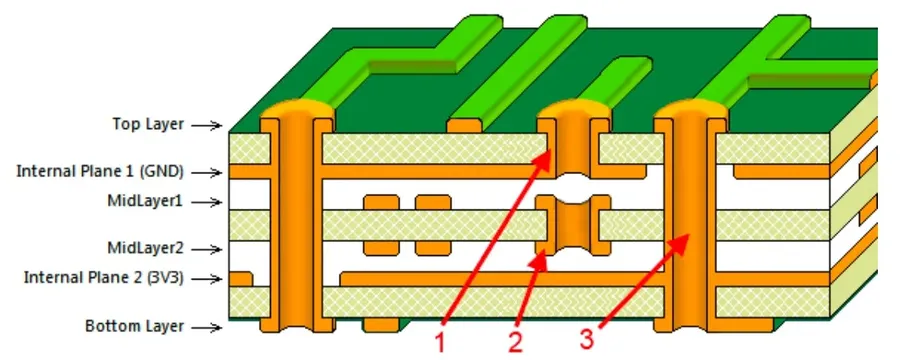

Advanced PCB Features and Their Cost

Advanced PCB features, while enhancing performance and functionality, significantly influence fabrication costs. These features often require specialized processes and tighter tolerances, resulting in increased expenses. Understanding the cost implications of these features is critical for optimizing your PCB design and budget.

| Feature | Description | Cost Impact | Design Considerations |

|---|---|---|---|

| Impedance Control | Ensures controlled signal impedance for high-speed circuits. Requires precise trace dimensions and dielectric properties. | High | Requires careful stack-up planning and trace width calculations. |

| Gold Fingers | Gold-plated edge connectors for enhanced durability and conductivity. Commonly used for card edge connections. | Medium to High | Requires precise gold plating thickness specifications. |

| 45° Finger Chamfering | Angled edges on gold fingers that facilitate smoother insertion and reduce wear on the mating connector. | Medium | Needs extra fabrication process and precise cutting. |

| Blind and Buried Vias | Vias that connect specific layers, not passing through the entire board. Enables higher density routing. | Medium to High | Requires extra drilling and plating steps. |

| Via-in-Pad (VIP) | Placing vias directly within the surface mount pads. It increases routing density and space. | Medium | Requires filled or plated over vias, may need special attention. |

Shipping Costs and Lead Times

Understanding shipping costs and lead times is crucial when ordering PCBs from JLCPCB. These factors significantly impact your project timeline and budget, particularly when transitioning from prototypes to mass production. Careful planning can mitigate unexpected expenses and delays, ensuring a smooth manufacturing process.

| Shipping Option | Typical Lead Time (Days) | Cost (USD) | Notes |

|---|---|---|---|

| Standard Shipping | 7-15 | Variable, based on weight and destination | Most economical option for non-urgent orders. |

| Expedited Shipping (e.g., DHL, FedEx) | 3-7 | Higher than standard, varies by carrier | Suitable for time-sensitive projects. |

| Air Freight (for large quantities) | 5-10 | Cost-effective for bulk orders | Requires coordination and custom clearance processes. |

The lead time provided by JLCPCB typically includes manufacturing and assembly time, while the shipping lead time depends on the courier and destination. It's crucial to consider both when estimating the total turnaround time for your project. Factors such as order complexity, component availability, and any necessary rework will influence these times. Lead times should always be validated with JLCPCB's current lead-time projections, as they can fluctuate depending on workload.

Several factors influence the final shipping cost, including the weight and dimensions of the package, the shipping destination, and the selected carrier. JLCPCB's online platform will generate the shipping quote after you've completed the project details and selected the desired shipping option. In general, planning ahead and opting for consolidated shipments whenever possible can significantly reduce these costs, especially when transitioning from small prototypes to larger mass production.

Frequently Asked Questions About JLCPCB Quotes

Understanding your JLCPCB quote is crucial for efficient and cost-effective PCB manufacturing. This section addresses frequently asked questions to clarify common concerns and provide clear answers.

- What is the minimum order quantity (MOQ) for PCBs at JLCPCB?

JLCPCB typically offers a low minimum order quantity, often starting with just 5 pieces for standard PCBs. However, this can vary depending on the specifications and complexity of your design. It's always best to check the specific details on the quote page for your project. - What are the maximum PCB dimensions that JLCPCB can handle?

JLCPCB offers a wide range of manufacturing sizes for PCBs. While there isn't a single maximum dimension that applies to all orders, they commonly support boards up to 500x500mm. For larger designs, it's essential to consult their website or contact support for specific feasibility assessments. - How do I address unclear aspects or discrepancies in my JLCPCB quote?

If you find discrepancies or uncertainties in your JLCPCB quote, the most effective approach is to directly contact their customer support team through their website or app. Provide all pertinent information, including the quote number and any issues you have identified. Clear communication with support will help resolve any queries and ensure that your specifications are correctly understood. - Does JLCPCB offer volume discounts, and at what quantities?

Yes, JLCPCB typically provides volume discounts. The exact discount structure can be seen during the ordering process. Generally, the price per PCB decreases as the quantity ordered increases. To get precise information on volume discounts for your specific requirements, use the quote calculator with your target quantity. - How does JLCPCB handle different PCB layer counts?

JLCPCB supports a range of layer counts, typically from 1 to 20 layers. The number of layers directly impacts the quote; more layers generally increase costs due to added complexity and material usage. Always ensure your design files accurately reflect the intended layer count for accurate pricing. - Can I get a quote for a partially populated PCB at JLCPCB?

JLCPCB primarily focuses on PCB manufacturing and SMT assembly. If you need a quote for a partially populated PCB with specific components mounted, you'll need to explore their PCBA service. They have a specific process to upload BOM and CPL files with SMT components. Ensure your quote request reflects your actual requirements – PCB fabrication and/or PCB assembly. - What are the typical lead times for JLCPCB orders, and how do these impact the quote?

Lead times for JLCPCB orders generally depend on the complexity of the PCB design and the chosen shipping method. Standard manufacturing lead times are usually between 2-7 days. Shipping time adds to the total delivery time. Faster shipping methods increase the cost; therefore, plan accordingly and choose a shipping option that fits your budget and schedule.

Tips for Getting the Best JLCPCB Quote

Optimizing your PCB design and order parameters is crucial for minimizing fabrication costs at JLCPCB. By employing smart design strategies and adhering to standard specifications, you can significantly reduce your overall expenditure without compromising on quality. This section provides actionable strategies to achieve the best possible JLCPCB quote.

- Design for Manufacturability (DFM)

Adhere to JLCPCB's DFM guidelines. This includes minimum trace widths, spacing, and via sizes. Designs that conform to these specifications reduce the likelihood of manufacturing errors and associated costs. - Use Standard Layer Stackups

Opt for standard layer stackups offered by JLCPCB, avoiding custom or complex layer configurations when possible. Standard stackups are generally more cost-effective due to streamlined production processes. - Standard PCB Thickness

Use standard PCB thicknesses like 1.6mm, which is readily available and cheaper to fabricate. Non-standard thicknesses may incur higher costs. - Minimize the Number of Drill Sizes

Reduce the variety of drill sizes in your design. Using a smaller number of standard drill sizes simplifies the manufacturing process and thus reduces costs. - Panelization

If you're ordering multiple PCBs, consider panelizing your design. JLCPCB can manufacture multiple boards as a single panel, reducing per-unit costs. Ensure that the panel dimensions are within JLCPCB's maximum size limits and utilize their panelization service. - Choose Appropriate Surface Finish

Select the surface finish based on your functional requirements. HASL (Hot Air Solder Leveling) is generally the most cost-effective option, while ENIG (Electroless Nickel Immersion Gold) or other advanced finishes will increase the price. - Optimize Drill Hole Count

Reduce the number of vias and holes in your design. Although necessary for multi-layer PCBs, excessive vias can add to the cost. Optimize your routing to minimize vias where possible. - Order in Bulk if Possible

The per-unit cost usually decreases as the order quantity increases. Order larger quantities to take advantage of volume discounts. - Avoid Complex Features If Possible

Avoid unnecessary complex features such as impedance control, blind vias or buried vias, gold fingers, or 45 degree chamfering unless required as these increase cost. - Plan for Lead Times

Plan your production to take advantage of standard production lead times. Expedited manufacturing will increase cost. - Review Your Quote Carefully

Before placing the order, carefully review your quote to ensure all the parameters are correct, including the PCB material, quantity, and special requirements, as these can dramatically affect the final cost.

Understanding the intricacies of a JLCPCB quote empowers you to make informed decisions, optimizing both cost and quality for your PCB projects. Just like a well-designed circuit that integrates various components, a well-understood quote ensures a successful project. Leveraging JLCPCB’s platform and this guide, you’re set to streamline your fabrication process and bring your electronics designs to life. [jlcpcb quote]

AnyPCBA

AnyPCBA