Fast Turnaround PCB Manufacturer: Speeding Up Your Project Timeline

In today’s rapidly evolving technology landscape, speed is paramount. Whether you're a startup developing a groundbreaking device or an established company pushing the boundaries of innovation, time to market can make or break your success. That’s why finding the right fast turnaround PCB manufacturer is essential for getting your project off the ground quickly. This article will guide you through the key considerations, benefits, and selection process when working with a PCB manufacturer who prioritizes speed without compromising quality, and helps you understand the critical role these partners play in modern tech development.

Understanding Fast Turnaround PCB Manufacturing

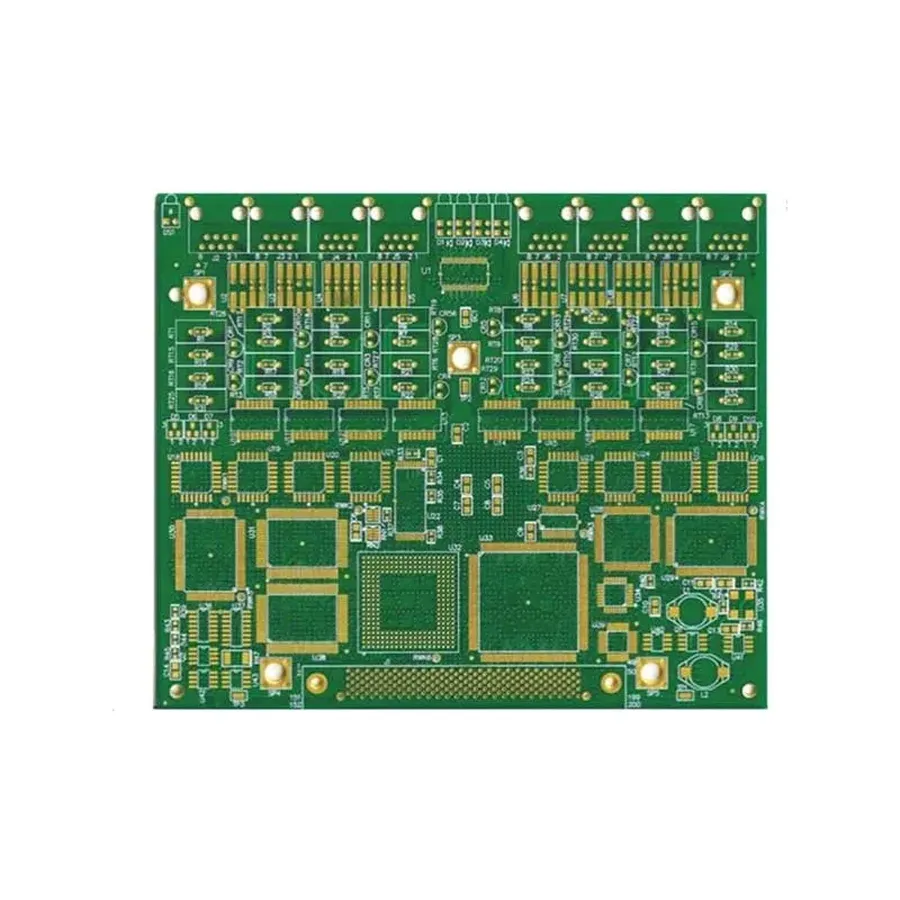

Fast turnaround PCB manufacturing is a specialized service focused on the rapid production of printed circuit boards, essential for projects requiring expedited prototyping and time-critical market launches. Unlike standard PCB services, which often involve longer lead times, quick-turn services prioritize speed without compromising quality, thereby accelerating the entire product development cycle.

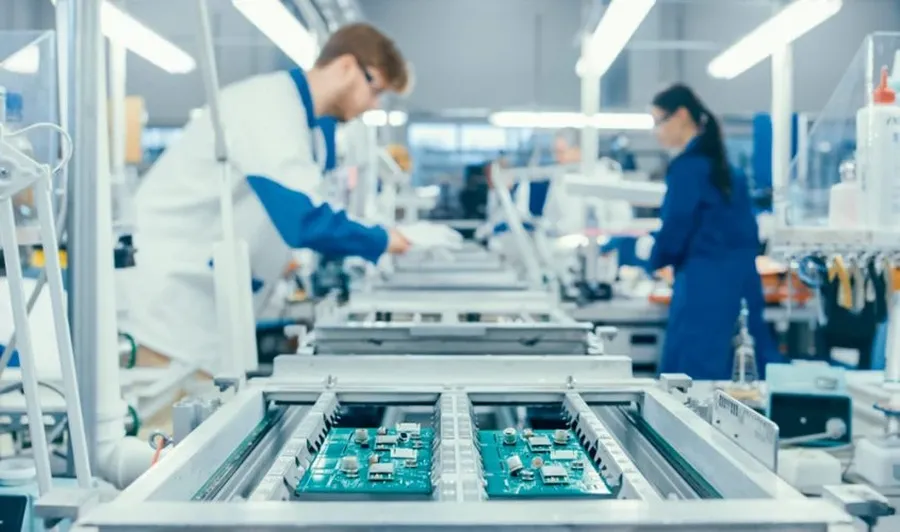

Key differentiators between standard and quick-turn PCB services lie primarily in production scheduling, resource allocation, and process optimization. Standard services often batch orders, leading to longer waits, while quick-turn facilities employ streamlined workflows and dedicated resources to prioritize and expedite specific orders. This often includes utilizing automated assembly lines, employing expedited shipping options, and optimizing manufacturing processes to reduce turnaround times significantly, enabling faster design iterations and quicker time-to-market.

Key Factors Affecting PCB Turnaround Time

The turnaround time for printed circuit board (PCB) manufacturing is influenced by several critical factors, which can be broadly categorized into design complexity, material availability, production process, and manufacturer capacity. Understanding these factors is essential for project managers and engineers aiming for rapid prototyping and timely product launches.

These factors can interact in complex ways, and optimizing one factor might have implications for another. Therefore, a holistic approach to design and manufacturing is crucial for achieving fast turnaround times without compromising quality.

| Factor | Description | Impact on Turnaround Time | Mitigation Strategies |

|---|---|---|---|

| PCB Complexity | Number of layers, component density, trace width/spacing, and special features such as impedance control. | Higher complexity increases processing time due to more intricate manufacturing steps. | Simplify design, use standard components, optimize layout, and ensure DFM (Design for Manufacturing) compliance. |

| Material Availability | Availability and lead time of specific substrates (e.g., FR-4, Rogers), copper thickness, and surface finishes. | Out-of-stock or custom materials can significantly delay manufacturing. | Select commonly used materials, confirm availability with the manufacturer, and have alternative material options ready. |

| Production Process | The specific fabrication methods, including drilling, etching, plating, and inspection. | Variations in process capabilities and efficiencies affect processing time. | Choose manufacturers with streamlined processes and use design rules which align with their specific equipment. |

| Manufacturer's Capacity | Workload of the manufacturer, number of production lines, and the availability of equipment/personnel. | Overbooked manufacturers will have longer lead times. | Plan early, communicate project timelines clearly, select manufacturers with sufficient capacity, and maintain a good working relationship. |

By carefully considering these key factors and implementing the mitigation strategies, project teams can significantly reduce PCB manufacturing turnaround times and keep their development schedules on track.

Benefits of Using a Fast Turnaround PCB Manufacturer

Engaging a fast turnaround PCB manufacturer provides significant advantages, primarily in accelerating product development cycles. This speed is crucial for projects requiring rapid prototyping, iterative design improvements, and time-sensitive market entries, offering a competitive edge through reduced lead times.

- Accelerated Product Development

Fast turnaround PCB manufacturing drastically reduces the time from design completion to having physical boards in hand, allowing for quicker testing, validation, and design iteration, thereby accelerating the overall development process. - Reduced Time to Market

In today's competitive market, time is critical. Fast turnaround services enable companies to get their products to market faster, capturing first-mover advantage and responding quickly to market demands. - Rapid Iteration on Design Changes

The ability to quickly implement design changes and receive revised boards allows engineers to iterate rapidly. This agile approach reduces the risk of costly errors and ensures a more refined product, incorporating improvements and corrections swiftly. - Cost Savings Through Efficiency

Though fast turnaround may have a slightly higher per-unit cost, the overall cost can be lower due to reduced delays and faster time to market. This results in lower overhead and expedited revenue generation. - Enhanced Prototyping Capabilities

Rapid prototyping is significantly improved with fast turnaround services, allowing for more testing cycles and better design validation. This iterative prototyping helps in catching issues earlier, reducing long-term cost and time expenditure. - Improved Risk Management

Fast turnarounds allow for swift implementation of any corrections and improvements, and reduce the risk of large-scale manufacturing flaws that can be time consuming and expensive to correct, ensuring a more robust and reliable end product.

Top Fast Turnaround PCB Manufacturers: A Comparison

Selecting a PCB manufacturer with rapid turnaround capabilities is crucial for projects with tight timelines. This section offers a comparative analysis of leading PCB manufacturers renowned for their fast turnaround services, considering critical factors such as turnaround times, material options, technological capabilities, and user feedback to facilitate informed decision-making.

| Manufacturer | Typical Turnaround Time (Prototype) | Materials | Technology | Capabilities | User Reviews |

|---|---|---|---|---|---|

| Manufacturer A | 24-48 hours | FR-4, Aluminum | SMT, Through-hole | High-layer count PCBs, Microvias | Generally positive, noted for speed. |

| Manufacturer B | 3-5 days | FR-4, Rogers, Flexible | SMT, BGA | Rigid-flex, Large panels | Mixed reviews, some complaints about communication delays. |

| Manufacturer C | 24 hours (express) | FR-4 | SMT, Basic Through-hole | Small batches, Simple designs | Very positive, good for small, quick projects. |

| Manufacturer D | 1-2 days | FR-4, High Tg FR-4 | SMT, Advanced Through-hole | Complex designs, HDI | Positive, noted for quality in fast turnaround. |

| Manufacturer E | 2-3 days | FR-4, Metal Core | SMT, Through-hole | Thermal management PCBs, LED Boards | Positive feedback, praised for specialized builds. |

Choosing the Right Fast Turnaround PCB Manufacturer

Selecting the optimal fast turnaround PCB manufacturer is crucial for project success, directly impacting timelines, budget, and the final product's quality. This decision requires a careful evaluation of several key factors to ensure the chosen partner aligns with your specific requirements and project demands.

Here's a breakdown of critical criteria to consider:

- Expertise and Experience

Assess the manufacturer's track record in producing PCBs with the complexity and technology levels your project demands. Look for evidence of their experience with similar projects and materials. - Technological Capabilities

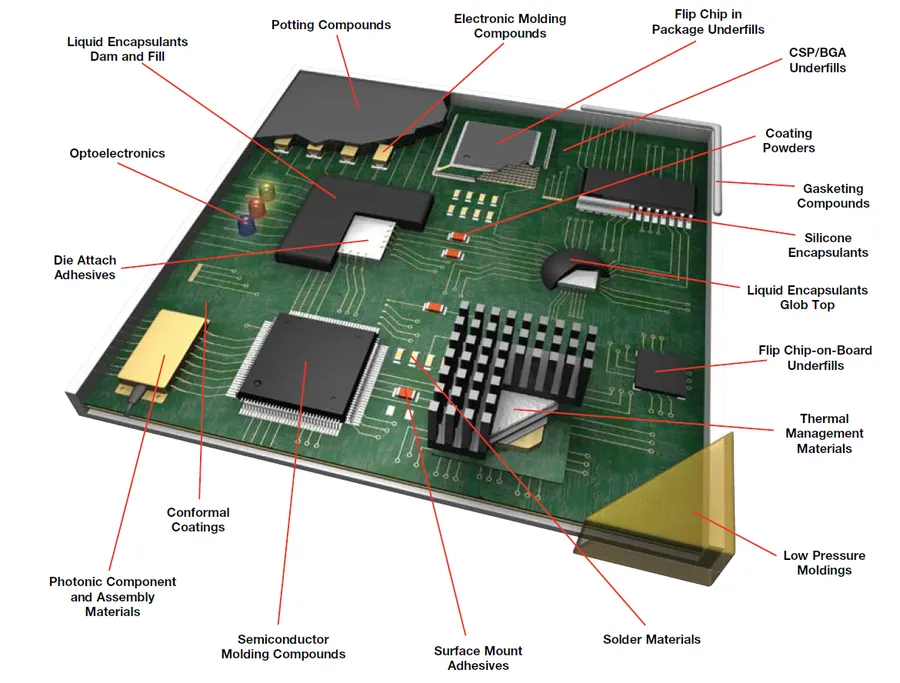

Evaluate the manufacturer's equipment and processes. Ensure they possess the necessary technology to handle your PCB specifications, including the required layer counts, trace widths, via types, and surface finishes. - Material Offerings

Verify if they can source and process the materials needed for your specific application. This includes FR-4, high-frequency laminates, flexible substrates, and other specialized materials. The availability of various material thicknesses should also be a consideration. - Turnaround Time

Clearly define your required delivery timeline and ensure the manufacturer can consistently meet those deadlines. Verify their quoted lead times and what process they have in place to avoid unnecessary delays. This is crucial for projects where time to market is paramount. Inquire about expedited services for particularly time sensitive builds. - Quality Assurance and Certification

Check the manufacturer's certifications (e.g., ISO 9001, IPC standards) and quality control processes. Request samples or inquire about their failure rates to assess their commitment to quality and reliability. A robust QA process is key to reducing potential flaws in the manufactured board - Cost

Balance your budget with your needs and requirements, while keeping all the other factors above in consideration. Request a cost estimate, and consider not only the per-unit cost but also the cost implications for any revisions or expedited services. - Communication and Support

Assess the manufacturer's communication channels and responsiveness to your inquiries and design revisions. A responsive and professional communication process can greatly reduce potential hold-ups. Good communication allows for quick and effective resolutions should any issues arise.

By meticulously evaluating these criteria, you can confidently select a fast turnaround PCB manufacturer that not only meets your speed requirements but also ensures the quality and reliability of your electronic products.

Strategies for Optimizing PCB Design for Fast Turnaround

Optimizing PCB design for fast turnaround hinges on a combination of strategic planning, efficient design practices, and clear communication with the manufacturer. This process minimizes delays and ensures a smooth transition from design to production.

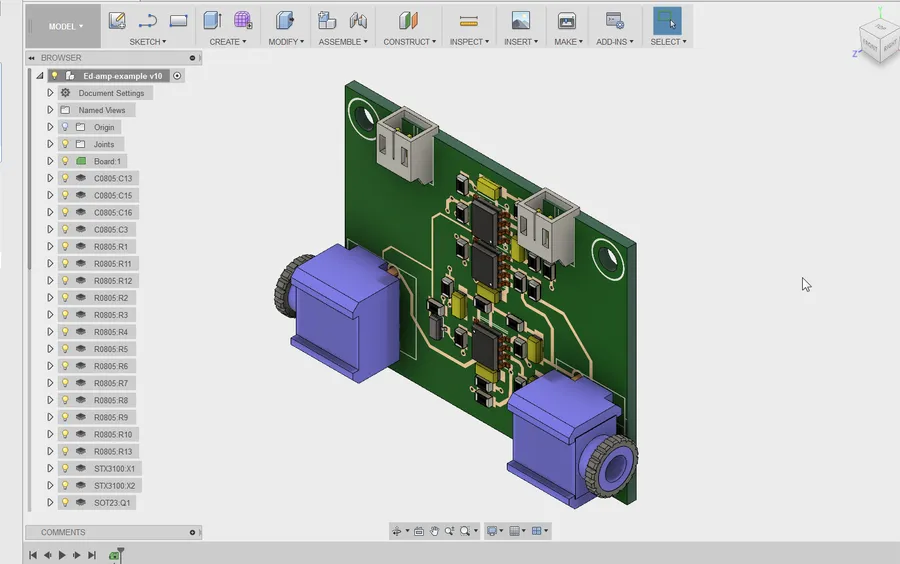

- Careful Selection of CAD Tools

Choose PCB design software that is compatible with the manufacturer's systems and supports features that aid in quick design verification and output generation. Using the correct software minimizes file conversion issues and reduces the likelihood of errors. - Standardization of Design Libraries

Establish and consistently utilize a standardized library of components, footprints, and design rules. This promotes design consistency, reduces the time spent searching for parts, and minimizes the risk of errors from mismatched component definitions. Libraries should be regularly updated and meticulously checked for accuracy. - Design for Manufacturing (DFM) Checks

Implement DFM checks early in the design process. These checks identify potential manufacturing issues, such as spacing violations, via size constraints, or component placement problems, before the files are submitted to the manufacturer. Addressing DFM issues upfront reduces iterative redesigns and speeds up production. - Clear and Complete Documentation

Provide detailed and unambiguous documentation with your design files. This should include the bill of materials (BOM), fabrication drawings, assembly instructions, and any special instructions. Clear communication prevents misunderstandings and reduces the back-and-forth with the manufacturer, saving crucial time. - Simplified Design Complexity

Whenever possible, simplify the PCB design by reducing the number of layers, component counts, and unique components. Complex designs often require more processing time and have a higher probability of manufacturing defects. - Early Communication with the Manufacturer

Contact the manufacturer early in the design process to discuss design specifications, material availability, and any specific constraints. This collaborative approach helps to avoid unexpected delays and allows for timely adjustments to the design if necessary. Confirm their specific requirements for file submission.

Frequently Asked Questions About Fast Turnaround PCB Manufacturing

This section addresses common questions regarding fast turnaround PCB manufacturing, focusing on practical considerations such as costs, lead times, and design suitability. Understanding these factors is crucial for effectively utilizing quick-turn services.

- What turnaround times can I expect from a fast turnaround PCB manufacturer?

Fast turnaround PCB manufacturers typically offer lead times ranging from 24 hours to a few days, depending on the complexity of the design, the materials required, and the manufacturer's current workload. It's crucial to discuss specific timelines with your chosen manufacturer prior to production. - What are the cost implications of fast turnaround PCB manufacturing?

Quick-turn PCB services usually incur higher costs compared to standard manufacturing due to expedited processes and prioritized production. Costs can fluctuate based on design complexity, board size, layer count, material choices, and the urgency of the delivery. - What are the minimum order quantities for fast turnaround PCBs?

Minimum order quantities (MOQs) vary widely among manufacturers. Some may accommodate single prototypes, while others may have MOQs ranging from a few units to small batches. Discussing MOQ requirements with potential manufacturers is essential to align with your project’s needs and budget. - Which types of PCB designs benefit most from quick-turn services?

Fast turnaround services are particularly advantageous for prototyping, proof-of-concept designs, and time-sensitive projects. These services are beneficial for industries needing rapid design iteration or products with short market windows. - Can complex multi-layer boards be produced using fast turnaround services?

Yes, many fast turnaround PCB manufacturers can handle complex multi-layer designs, with capabilities for advanced technologies. However, complexity may impact turnaround time and cost. Discuss specific design requirements early to verify feasibility. - How do I ensure quality control with fast turnaround PCB manufacturing?

Reputable fast turnaround manufacturers maintain strict quality control processes, including automated optical inspection (AOI) and electrical testing. Confirm that the manufacturer is certified for quality standards and their process before committing to the service. - What design considerations are important for fast turnaround PCB manufacturing?

Design for manufacturability (DFM) is crucial for fast turnarounds. This involves simplifying designs, standardizing components, and avoiding complex geometries. Providing clear, accurate design files can significantly speed up the process.

Future Trends in Fast Turnaround PCB Manufacturing

The fast-turnaround PCB manufacturing sector is undergoing a significant transformation, driven by advancements in automation, digital manufacturing, and material science. These trends are not only reducing manufacturing times but also improving the overall efficiency and precision of PCB production.

- Advanced Automation:

The integration of robotics and AI in PCB assembly is reducing human intervention, streamlining processes, minimizing errors, and accelerating turnaround times. Automated optical inspection (AOI) and automated guided vehicles (AGVs) for material handling are becoming increasingly common. - Digital Manufacturing:

The adoption of Industry 4.0 principles, including real-time data analytics and cloud-based platforms, enables manufacturers to monitor production processes more closely and optimize resource allocation. This leads to more efficient production and faster turnaround times. - Additive Manufacturing (3D Printing):

Additive manufacturing is being explored to produce PCBs with complex designs and geometries with rapid prototyping. This method bypasses conventional production steps, reducing turnaround time for specialized PCB requirements. - Material Innovations:

New high-performance materials with superior thermal and electrical properties are being developed to meet the demanding requirements of modern electronics. These materials also enable faster manufacturing processes due to their specific characteristics and ease of use. - Sustainability Focus:

There is an increasing emphasis on sustainable manufacturing practices. This includes reducing waste and energy consumption, and using eco-friendly materials. This shift also drives efficiency and process optimization.

These advancements collectively indicate that future PCB manufacturing will be characterized by greater speed, efficiency, precision, and sustainability. This will have a significant impact on product development cycles, allowing for faster innovation and quicker time-to-market.

Choosing the right fast turnaround PCB manufacturer can be a crucial advantage for any tech project, whether it’s prototyping or large-scale production. By understanding your needs, and considering factors like capabilities, technologies and quality, you can ensure a smooth and rapid PCB manufacturing process. With these insights, finding the ideal partner to achieve your goals efficiently should be less of a headache. And, remember that many fast turnaround PCB manufacturer options exist, providing quality and speed to your projects.

AnyPCBA

AnyPCBA