Find Reliable Flex Board Manufacturers Near You: A Comprehensive Guide

In today's fast-paced world, flexible circuit boards (flex boards) are vital for compact and adaptable electronic devices. Finding the right flex board manufacturers near you is crucial for ensuring project success. This article serves as your guide to navigating the complexities of locating reputable suppliers, providing essential insights and practical tips.

Understanding Flex Boards and Their Applications

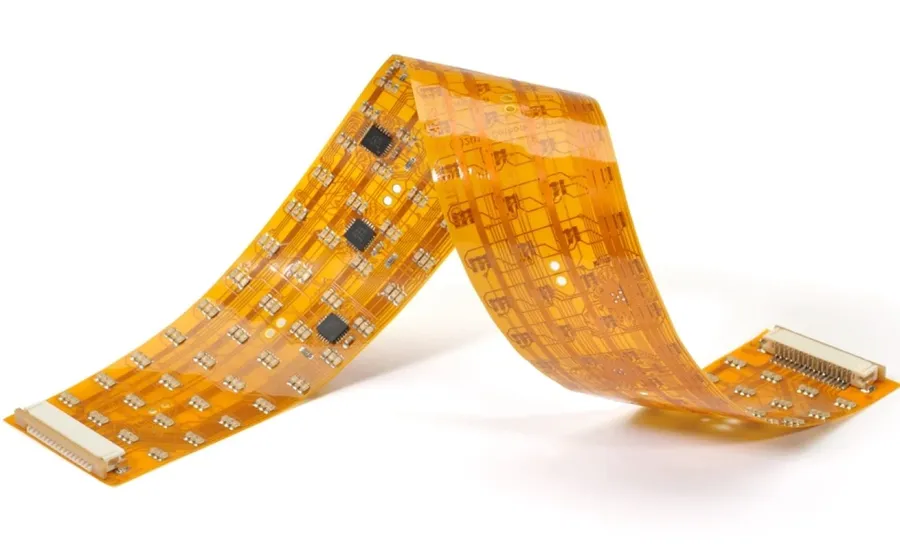

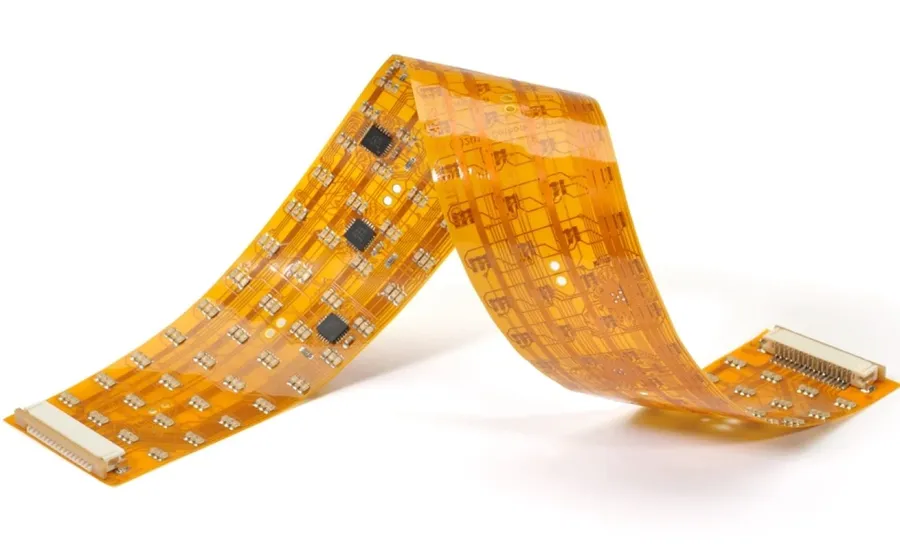

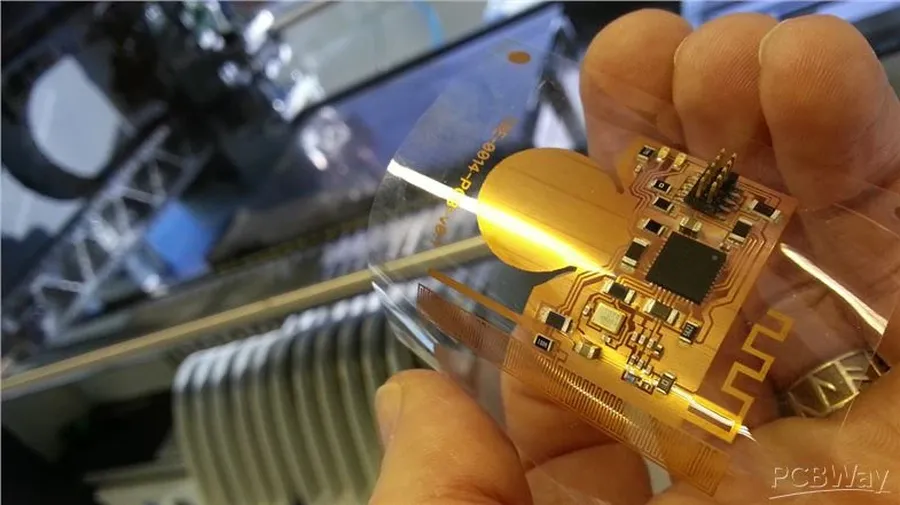

Flex boards, also known as flexible printed circuits (FPCs), are a type of circuit board constructed on a flexible substrate, enabling them to bend and conform to various shapes. This unique characteristic allows for innovative designs and applications across a broad spectrum of industries.

These boards are constructed from thin dielectric materials like polyimide or polyester films, which are then laminated with conductive layers, usually copper. This layering allows for circuit traces, pads, and vias to be etched onto the flexible base, forming complex and compact circuits. The flexibility of these boards offers many advantages, including reduced size and weight of electronic devices, dynamic flexing capabilities, and the ability to create highly integrated assemblies. Common applications span from consumer electronics, such as smartphones and wearables, to automotive, aerospace, and medical devices. In automotive, flex boards facilitate connections in complex harnesses and advanced driver-assistance systems. In medical applications, they are integral to implantable devices and diagnostic equipment because of their low profile and high reliability.

Key Factors to Consider When Choosing a Flex Board Manufacturer

Selecting the right flex board manufacturer is crucial for ensuring the quality and reliability of your electronic products. This decision requires careful consideration of several key factors, moving beyond a simple search for 'flex board manufacturers near me'. The ideal manufacturer will possess the right blend of technical expertise, production capacity, quality certifications, and customer support to meet your specific needs.

- Manufacturing Capabilities

Assess the manufacturer's production capacity and the range of flex PCBs they can produce. Look for manufacturers experienced with the specific type of flex board you need (single-layer, double-layer, multi-layer, or rigid-flex). - Material Expertise

Ensure the manufacturer has a strong understanding of various flexible substrate materials like polyimide, polyester, and liquid crystal polymer. Their material selection process should be aligned with your product’s requirements for flexibility, temperature tolerance, and chemical resistance. - Turnaround Time

Evaluate the manufacturer’s ability to meet your production deadlines. Reliable manufacturers provide realistic estimates for prototyping, production, and delivery, taking into account the complexity of your flex board design. - Quality Certifications

Verify that the manufacturer holds relevant industry certifications such as ISO 9001 for quality management and UL certifications for product safety. These certifications ensure adherence to high manufacturing standards. - Pricing and Cost Structure

Obtain clear, itemized quotes from different manufacturers and carefully compare the costs involved. Understand the cost structure, including material expenses, labor, and any additional services like design support or testing. - Design and Engineering Support

A manufacturer that offers design and engineering support can be invaluable, especially if you need help optimizing your design for manufacturability. This can help avoid costly mistakes. - Communication and Customer Service

Effective communication and reliable customer service are crucial for a successful collaboration. Choose a manufacturer that is responsive, transparent, and willing to address any concerns you may have throughout the project.

How to Search for 'Flex Board Manufacturers Near Me'

Finding local flex board manufacturers requires a strategic approach that combines online searches with targeted industry resources. This section provides practical methods to efficiently locate potential suppliers in your area.

- Leverage Search Engines Effectively

Use specific keywords like 'flex board manufacturers near me', 'flexible PCB supplier [your city/region]', or 'custom flex circuit board manufacturer' in search engines. Utilize quotation marks for exact phrase matching to refine results. Check Google Maps for geographically relevant listings and reviews. - Explore Industry-Specific Platforms

Websites such as Thomasnet, Alibaba, and IndustryNet often list manufacturers categorized by industry and location. These platforms provide detailed company profiles, including certifications and capabilities, allowing you to quickly assess suitability. - Utilize Online Business Directories

Platforms like Yelp, Yellow Pages, and local chamber of commerce websites can offer further options. Filter results by industry and read user reviews to gain insights into customer experiences. - Check Local Business Listings

Many cities and regions have their own online business directories that list local manufacturing companies, this may provide a more focused list of suppliers in your area. - Use Social Media and Professional Networks

Platforms like LinkedIn can be useful for finding manufacturers as well as seeing feedback or recommendations. - Inquire Through Referrals

Ask for referrals from colleagues, other manufacturers, or industry contacts in order to uncover potential suppliers.

Evaluating the Capabilities of Flex Board Manufacturers

A thorough evaluation of a flex board manufacturer's capabilities is crucial to ensure they can meet your specific needs and quality standards. This involves assessing their production capacity, technological proficiency, and specialization in different types of flexible PCBs.

Production capacity determines whether the manufacturer can handle your project's volume, from small prototypes to large-scale production runs. Manufacturers should have adequate facilities and equipment to meet your deadlines without compromising quality.

Technological proficiency is indicated by the manufacturer's investment in advanced manufacturing processes, such as high-precision etching, laser drilling, and automated assembly. This ensures that they can produce intricate and reliable flex circuits.

A key aspect is the manufacturer's specialization in specific types of flexible PCBs. Manufacturers may focus on:

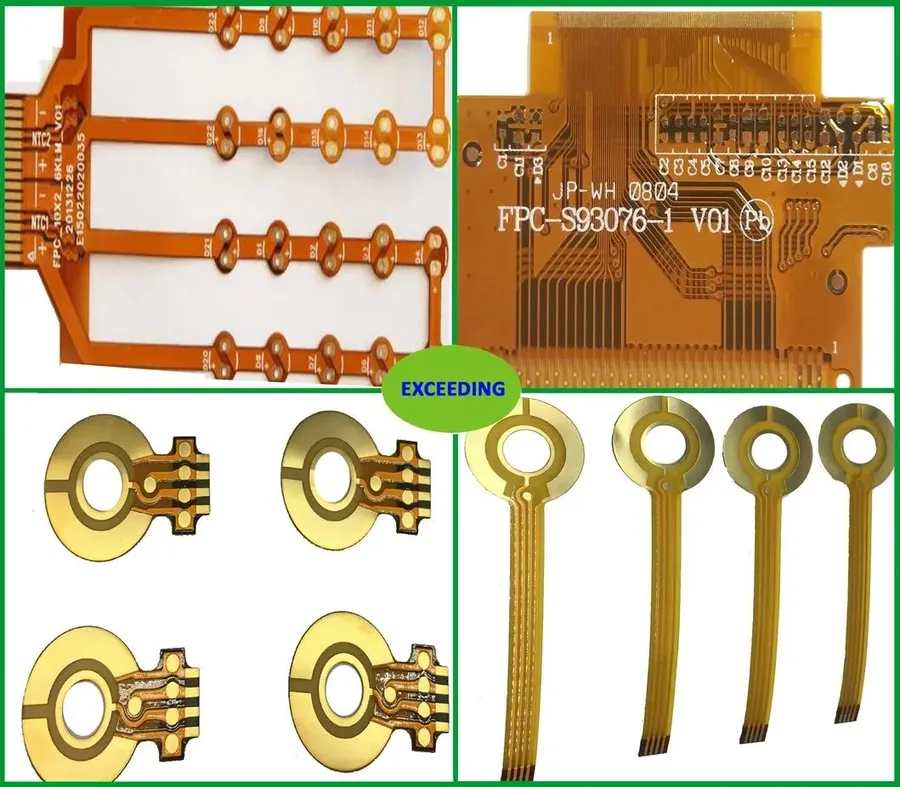

- Single-layer flex boards

These consist of a single layer of conductive material on a flexible substrate, suitable for basic circuitry. - Double-layer flex boards

These have two layers of conductive material, allowing for more complex circuits and higher component density. - Multi-layer flex boards

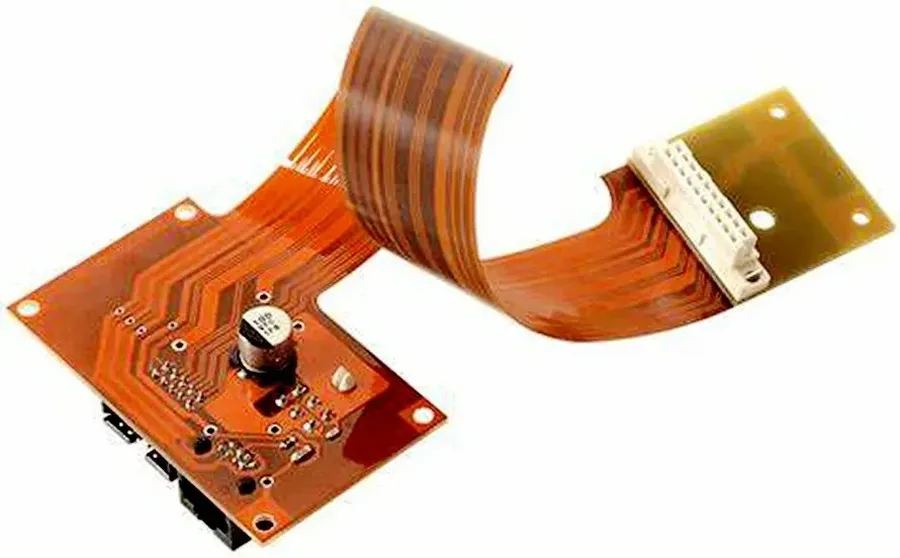

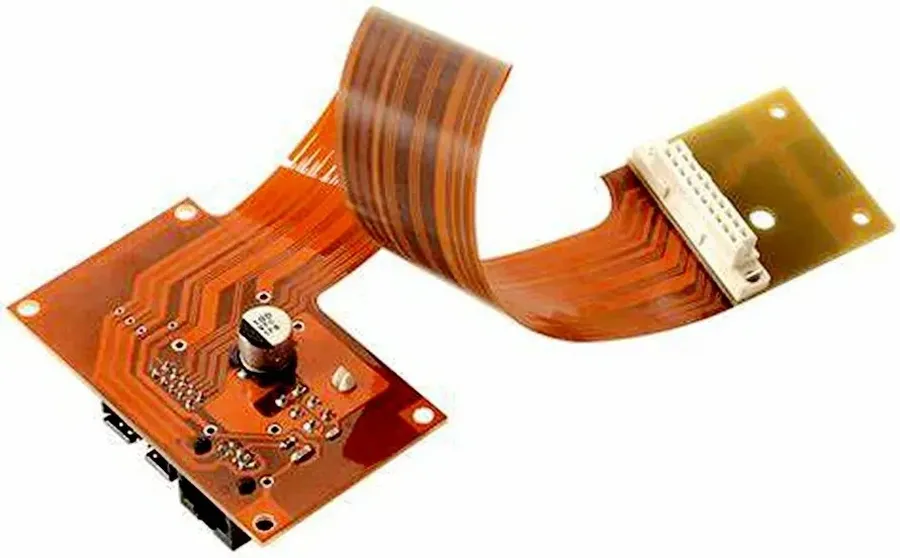

These feature multiple layers of conductors, enabling highly complex and compact designs. - Rigid-flex boards

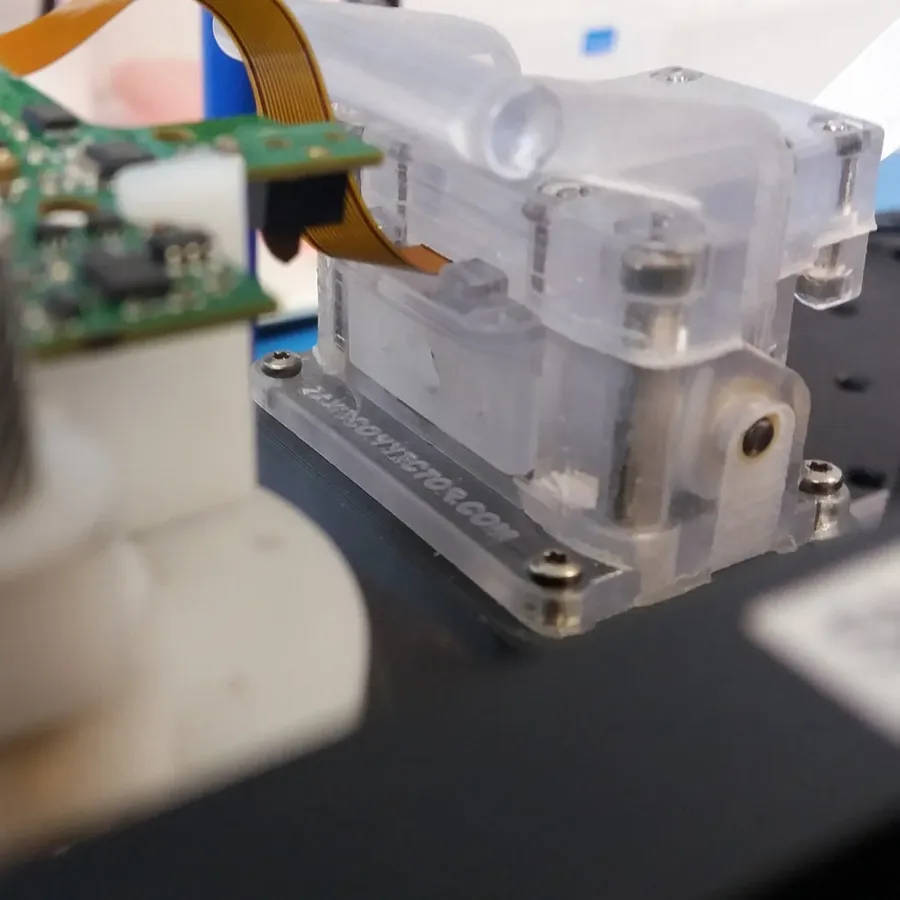

These combine rigid and flexible sections, providing a solution for designs requiring both rigidity and flexibility, commonly used in applications that need stability and the ability to bend or fold.

Understanding the specific type of flexible PCB that the manufacturer specializes in is important to ensure they can effectively produce the board that will meet your design requirements.

| Factor | Description | Importance |

|---|---|---|

| Production Capacity | Ability to handle project volume | Ensures timely completion and scalability. |

| Technological Proficiency | Use of advanced manufacturing techniques | Guarantees high-precision and reliability. |

| Specialization | Expertise in specific flex board types | Ensures suitability for project needs. |

The Importance of Quality Assurance and Certifications

Quality assurance and relevant certifications are paramount in the flex board manufacturing process, directly influencing the reliability and performance of the final product. These measures ensure that the boards meet stringent industry standards, leading to consistent quality, reduced defects, and increased longevity, which are crucial for applications in demanding industries such as aerospace, medical devices, and automotive.

The pursuit of the 'flex board manufacturers near me' should not overshadow the importance of quality. While proximity can offer convenience, ensuring the manufacturer adheres to strict quality control and has the necessary certifications is non-negotiable for product performance. A manufacturer with robust quality control measures minimizes the risk of product failure, reduces potential downtime and associated costs, and enhances the overall reliability of electronic products.

Key certifications, such as ISO 9001 and UL recognition, indicate a manufacturer's commitment to maintaining high standards and consistent processes. ISO 9001 certification signifies a robust quality management system, encompassing aspects like design, manufacturing, and supply chain management, while UL certifications validate the safety and performance of the product.

Furthermore, it's crucial to understand the different levels of quality control that may be applied in manufacturing. These typically include material inspection upon arrival, in-process inspection, and final product inspection using advanced testing equipment. These rigorous checks are crucial for identifying any deviations or defects, preventing the distribution of sub-par components, and maintaining a consistently high standard for the end product.

In summary, when searching for 'flex board manufacturers near me', verify the manufacturer’s quality control processes and certifications. This ensures the chosen supplier is committed to producing high quality, reliable flex boards suitable for your intended applications. Don't sacrifice quality for the convenience of proximity; diligent evaluation of a manufacturer's quality protocols is essential for a successful partnership.

Frequently Asked Questions About Flex Boards

This section addresses common inquiries regarding flex boards, providing precise and informative answers to enhance your understanding of these flexible circuit solutions. We will explore typical questions about their material composition, design parameters, and variations.

- What is the typical thickness of a flex board?

Flex board thickness varies depending on the application, but typical thicknesses range from 0.1 mm to 0.3 mm. Thinner boards are more flexible, while thicker boards offer greater mechanical support. The copper layer thickness also contributes to the overall board thickness. Specific project requirements often dictate the exact thickness. - What are the best materials used in flex board construction?

Polyimide (PI) is the most common material for flex circuits because of its excellent flexibility, temperature resistance, and dielectric properties. Polyester (PET) is another alternative, offering lower cost, but with lower temperature resistance than PI. Adhesives, typically acrylic or epoxy, are used to bond the copper layers to the substrate, and need to be compatible with the base material. - What materials are flex boards typically made of?

Flex boards primarily consist of three key materials: a flexible dielectric substrate like polyimide or polyester, conductive layers usually of copper, and adhesives to bind the layers together. The dielectric provides insulation, while the copper acts as the conducting pathways. The adhesive material must maintain its bonding at operational temperatures. Coverlays, typically polyimide based, can provide environmental protection for the completed board. - What are the key differences between single-layer, double-layer, and multi-layer flex boards?

Single-layer flex boards feature one conductive copper layer on one side of the dielectric, suitable for simple circuits. Double-layer flex boards have conductive layers on both sides, interconnected with vias, to allow for increased circuit complexity. Multi-layer flex boards contain three or more copper layers, separated by dielectric layers, for complex routing needs. Each variation provides increasing circuit density and capability. - What is a rigid-flex board and what are its advantages?

Rigid-flex boards combine flexible and rigid sections into one integrated circuit. This approach combines the advantages of both technologies, and allows for enhanced design flexibility and compactness. Rigid sections provide structural support for components while flexible sections allow for 3D interconnects and can reduce the number of connectors needed. Rigiflex boards also improve overall reliability compared to using discrete interconnects. - How does temperature affect the performance of flex boards?

The materials used in flex boards, particularly the dielectric and adhesives, have temperature limitations. High operating temperatures can affect the electrical and mechanical properties of these materials, potentially leading to circuit failures. It's crucial to choose materials suitable for the required operating temperature range. The glass transition temperature (Tg) of materials is an important factor in high-temperature applications. - Can flex boards be repaired?

Repairing flex boards can be challenging due to their delicate construction and thin materials. Minor damages like broken solder joints may be repairable, however, it usually requires specialized equipment and expertise. Major damages that compromise the substrate or conductive layers are often irreparable, and replacement is recommended for high-reliability systems.

Comparing Flex Board Manufacturing Options

Selecting the appropriate type of flexible printed circuit board (flex board) is crucial for optimal performance and cost-effectiveness in your application. This section provides a detailed comparison of various flex board types, including single-layer, double-layer, multi-layer, and rigid-flex configurations, outlining their distinct characteristics, benefits, and typical uses.

| Feature | Single-Layer Flex | Double-Layer Flex | Multi-Layer Flex | Rigid-Flex |

|---|---|---|---|---|

| Structure | Single conductive layer on a flexible substrate | Two conductive layers on a flexible substrate | Three or more conductive layers separated by insulating layers | Combination of rigid and flexible layers |

| Flexibility | Highly flexible; bends easily in one direction | Good flexibility; bends in multiple directions | Moderate flexibility; less bending than single or double layer | Flexible in certain areas, rigid in others. |

| Complexity | Simplest design, easiest to manufacture | More complex than single-layer; moderate design complexity | Most complex design; highest manufacturing complexity | Complex integration of rigid and flexible elements. |

| Cost | Least expensive | Moderate cost | Most expensive | Higher cost due to complexity. |

| Applications | Simple circuits, low-density connections, basic sensors | Moderate density circuits, slightly more complex sensors and displays | High density interconnects, complex electronics, compact designs | Aerospace, medical devices, automotive applications requiring both flexible and rigid elements. |

| Advantages | Low cost, light weight, highly flexible | Good balance of flexibility and circuit density | Highest circuit density, complex designs | Combines advantages of rigid and flex boards |

| Disadvantages | Limited circuit density, only one conductive layer | More expensive than single-layer flex | Higher cost, less flexible | Complex design and manufacturing; higher cost |

Negotiating Prices and Terms with Flex Board Manufacturers

Successfully negotiating prices and terms with flex board manufacturers requires a strategic approach, focusing on understanding cost drivers, securing transparent quotes, and establishing mutually beneficial agreements. This section outlines practical steps to navigate these negotiations effectively, particularly in the context of 'flex board manufacturers near me' searches where local market factors may influence pricing.

Key aspects to consider include the following:

- Understanding Cost Factors

Gaining insight into the cost structure of flex board manufacturing is crucial. Factors influencing price include material costs (e.g., polyimide, copper), the complexity of the design (number of layers, trace widths), production volume, tolerances, surface finishes, and any additional features (e.g., stiffeners, shielding). A thorough understanding of these cost components will position you to negotiate more effectively. - Obtaining Detailed and Transparent Quotes

Always request a detailed breakdown of costs within a quote, instead of just an overall price. This should include costs for materials, tooling, fabrication, testing, and any other associated expenses. Transparency will help you assess the fairness of the quote and identify areas where costs might be reduced or negotiated. Be wary of manufacturers who are unwilling to break down costs or who offer vague quotes. - Leveraging Volume and Long-Term Commitments

If your requirements are for high-volume production or if you can commit to a long-term supply relationship, you may be able to negotiate more favorable pricing. Manufacturers often offer discounts for bulk orders or consistent business, which can significantly reduce your overall costs. Long-term relationships also open doors to improved service and partnership. - Negotiating Payment Terms

Payment terms are another key aspect of negotiation. Be sure to clearly define the down payment schedule, payment milestones, and final payment terms and understand the impact of these terms on your cash flow. Also, it is crucial to discuss penalties for late payments and the possibility of discounts for prompt payments. - Specifying Delivery Schedules and Lead Times

Agree on realistic and detailed delivery schedules with the manufacturer. Lead times can impact the overall project schedule, so it's vital to clarify any delays or delivery constraints in the negotiation phase. Negotiating flexible delivery times might offer options for both cost savings and optimal project flow management. - Incorporating Quality Guarantees and Warranty Clauses

Ensure that the contract includes clear terms for quality assurance, returns, and warranty. This protects your investment in the event that the supplied flex boards do not meet the quality standards agreed upon. Negotiate a clear and concise warranty and dispute resolution clause before proceeding. - Addressing the 'Flex Board Manufacturers Near Me' Factor

When searching for 'flex board manufacturers near me,' local proximity can impact costs due to transportation and logistics. Highlight your need for local sourcing and negotiate favorable terms that take location into account. Localized manufacturers might offer expedited service and lower shipping costs but may not have the same capacity as larger manufacturers located further afield.

Building Long-Term Relationships with Flex Board Suppliers

Establishing a robust and lasting partnership with your flex board supplier is paramount for consistent quality, reliable delivery, and potentially more favorable pricing in the long run. This involves more than just transactional exchanges; it necessitates a strategic approach focused on mutual benefit and clear communication.

- Clear Contract Negotiation

A well-defined contract is the cornerstone of a strong supplier relationship. It should explicitly outline quality standards, delivery timelines, payment terms, and dispute resolution mechanisms, ensuring both parties understand their obligations. - Open and Consistent Communication

Maintaining open communication channels is crucial for addressing concerns promptly and sharing relevant information regarding changes in designs, delivery schedules or material requirements. Regular communication helps prevent misunderstandings and fosters trust. - Quality Assurance Processes

Implement a robust quality assurance process that includes regular audits and feedback mechanisms to monitor the supplier's performance. This ensures that the flex boards consistently meet the required specifications and prevents quality issues before they occur. - Regular Performance Evaluation

Conduct periodic performance reviews with your supplier to identify areas for improvement and acknowledge successes. This collaborative approach helps optimize performance and strengthen the relationship. - Mutual Investment in Improvement

Explore opportunities for mutual investment in process improvements, technology upgrades, or training programs that can enhance efficiency, reduce costs, and improve the quality of flex board manufacturing. This signifies a shared commitment to long-term success. - Flexibility and Adaptability

A strong supplier relationship is characterized by flexibility and adaptability. The ability to respond to unforeseen issues, changing needs or emerging opportunities are a sign of a strong partnership.

Finding the right flex board manufacturers near you is key to your project's success. By focusing on crucial aspects like capabilities, quality control, certifications, and building solid relationships, you will be well-equipped to choose the right manufacturer for your flex board needs and stay ahead in the competitive market. Remember that reliable 'flex board manufacturers near me' are out there – use this knowledge to make informed decisions.

AnyPCBA

AnyPCBA