Find Reliable PCB Manufacturing Companies Near You

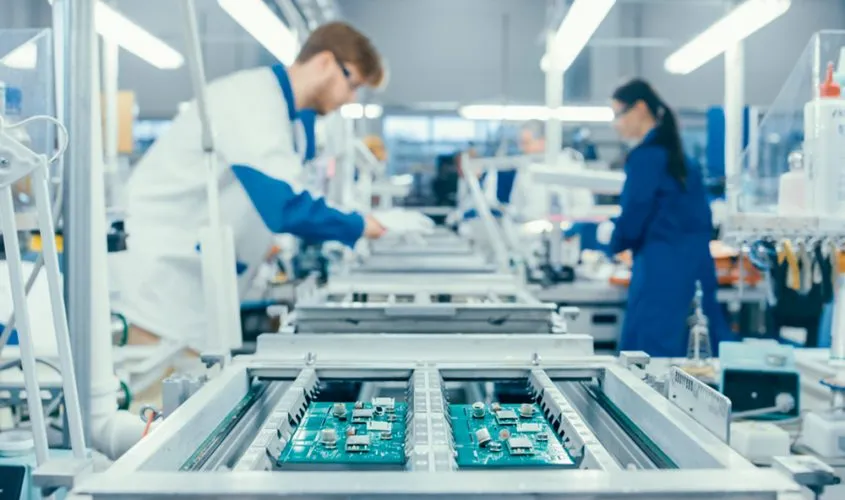

In today's fast-paced world, printed circuit boards (PCBs) are the unsung heroes powering everything from smartphones to medical devices. Finding reliable PCB manufacturing companies near you is crucial for efficient prototyping and production. This article provides a comprehensive guide to help you navigate the world of PCB manufacturing, highlighting key factors, top companies, and crucial considerations for your specific needs.

Understanding Your PCB Needs

Before initiating a search for 'PCB manufacturing companies near me,' a precise understanding of your project's specific requirements is paramount. This crucial pre-selection step ensures you partner with a manufacturer that aligns perfectly with your needs, avoiding costly mismatches and delays. Key considerations include the type of printed circuit board (PCB), materials, the quantity required and desired lead times. These factors are fundamental in determining the most suitable manufacturer for your project.

- Board Type

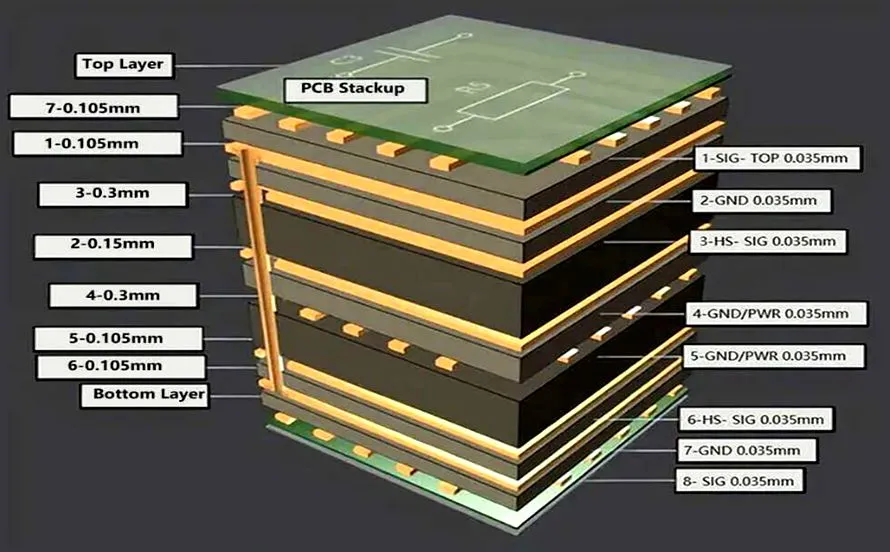

Determine whether you require single-layer, double-layer, or multi-layer PCBs. Each type has unique characteristics impacting complexity and cost. - Material Specifications

Specify the required substrate material (e.g., FR-4, aluminum, polyimide) and its performance characteristics, such as dielectric constant and thermal properties, which are critical for operation in various environments. - Quantity Needs

Indicate if you need a prototype, a small batch, or a large production run. This will affect pricing and manufacturing processes. For prototyping, quick-turn services may be a priority. - Lead Time Requirements

Outline your project deadlines and understand the manufacturer's typical production lead time. Confirm if they offer expedited services if your project has a tight schedule. - Technological Requirements

Assess the complexity of the PCB design. Is there a need for high precision assembly, fine pitch components, or via-in-pad technology? These influence the choice of fabrication technology.

Key Factors to Consider When Choosing a PCB Manufacturer

Selecting the ideal PCB manufacturing partner requires a meticulous evaluation of several critical factors that directly influence the success of your project. These factors include, but are not limited to, the quality of the manufactured boards, the overall cost of production, the lead time required for manufacturing, the range of available manufacturing technologies, the adherence to industry certifications and standards, and the quality of customer support. A comprehensive assessment of these elements is essential to minimize risks and maximize the chances of a successful PCB fabrication and assembly.

| Factor | Description | Impact |

|---|---|---|

| Quality | Refers to the reliability and performance of the manufactured PCBs, influenced by materials, manufacturing processes, and quality control measures. | Directly affects the lifespan and functionality of your final product. Poor quality PCBs can lead to failures and costly recalls. |

| Cost | Encompasses the total expense of manufacturing, including materials, labor, and overhead costs. | Impacts project budget and overall profitability. It's important to find a balance between cost and quality. |

| Turnaround Time | The duration between submitting a design and receiving the finished PCBs. | Crucial for meeting project timelines and launch dates. Delays can be costly. |

| Available Technologies | Includes manufacturing capabilities such as surface mount technology (SMT), through-hole technology, and mixed technology. | The chosen technology must align with the design complexity and specific requirements of the board, thus affecting assembly efficiency and density. |

| Certifications | Demonstrates adherence to industry standards such as ISO 9001, IPC standards, and others. | Provides assurance of quality and reliability, reducing the risk of manufacturing defects. |

| Customer Support | The responsiveness and helpfulness of the manufacturer's support team, from pre-production consultation to post-delivery assistance. | Effective communication and support can significantly expedite the process, resolve issues, and prevent delays. |

Exploring Local PCB Manufacturing Options

Locating PCB manufacturers within your geographic area offers significant advantages, primarily in reduced shipping costs and lead times. Utilizing online directories specifically designed for industrial sourcing can streamline this process, providing access to a variety of potential manufacturing partners.

These platforms often allow filtering by location and specialization, helping users identify companies that align with their specific project requirements. By focusing on local options, you can potentially build stronger relationships, facilitate face-to-face communication, and expedite the overall production cycle.

- PCB Directory

A specialized directory that lists PCB manufacturers globally, with robust search filters to narrow results by location, technology, and certifications. - ThomasNet

A broad industrial sourcing platform that includes a substantial number of PCB manufacturers, providing details on their capabilities, services, and contact information.

| Feature | PCB Directory | ThomasNet |

|---|---|---|

| Focus | Specialized for PCB Manufacturers | Broader Industrial Sourcing |

| Location Filters | Precise Geographic Filtering | Regional and National Filters |

| Technology Details | Extensive Details on Manufacturing Capabilities | General Overview of Technologies |

| Certification Information | Detailed Certification Listings | Certification Details Available, but may vary |

| Search Specificity | High Specificity for PCB Needs | Broader Range of Industrial Needs |

Evaluating PCB Manufacturer Specializations

The PCB manufacturing landscape includes companies with diverse specializations. Understanding these specializations is crucial to finding a partner whose capabilities align perfectly with your project's demands. Some excel in high-precision assembly, others in specialized materials like metal core boards, and yet others in rapid prototyping.

- High-Precision Assembly:

Manufacturers with this specialization have advanced equipment and expertise to handle very fine pitch components and intricate circuit designs, which is essential for applications requiring high density and accuracy. This includes advanced placement machines, and inspection systems. - Metal Core PCBs:

These boards use a metal substrate, such as aluminum or copper, instead of FR-4. Manufacturers specializing in this can handle the unique processing requirements needed for superior thermal management, robustness, and durability. These boards are ideal for high-power and LED lighting applications. - Quick-Turn Prototyping:

Companies offering quick-turn services specialize in rapid manufacturing of small batches of PCBs for prototyping. These manufacturers prioritize speed, aiming to deliver functional prototypes as rapidly as possible, helping with iterative development. This often involves streamlined processes and flexibility. - Flexible PCBs:

Flexible PCBs, built on flexible substrates, require specialized manufacturing. Manufacturers with this specialization excel in fabricating boards that can bend and conform to various shapes, offering an advantage in compact and dynamic electronic devices. - Rigid-Flex PCBs:

This type of PCB combines rigid and flexible circuits in a single board and is more complex to manufacture. Specialized equipment and experience are critical for ensuring seamless integration of the rigid and flexible sections. These PCBs are frequently used in advanced electronic applications that require both structural integrity and flexibility.

| Specialization | Description | Typical Applications |

|---|---|---|

| High-Precision Assembly | Expertise in handling fine pitch components and intricate designs. | Advanced medical devices, aerospace electronics, and high-density consumer gadgets. |

| Metal Core PCBs | Manufacturing using a metal substrate for enhanced thermal performance and mechanical strength. | High-power LED lighting, automotive electronics, and power supplies |

| Quick-Turn Prototyping | Fast manufacturing of prototypes for rapid design iteration. | Research and development, proof-of-concept projects, and iterative design. |

| Flexible PCBs | Fabrication of boards on flexible substrates that bend and conform to various shapes. | Wearables, flexible displays, and compact consumer electronics. |

| Rigid-Flex PCBs | Integration of rigid and flexible circuits in a single board. | Medical instruments, aerospace equipment, and advanced robotic systems. |

Comparing PCB Manufacturing Technologies

Understanding the nuances of PCB assembly technologies is crucial for selecting a manufacturer that aligns with your project's specifications. Surface Mount Technology (SMT), through-hole technology, and mixed technology each offer distinct advantages and are suitable for different applications.

| Technology | Description | Component Mounting | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Surface Mount Technology (SMT) | Components are mounted directly onto the surface of the PCB. | Surface pads. | High-density electronics, compact devices, consumer electronics. | High component density, cost-effective for mass production, good electrical performance. | Requires specialized equipment, not ideal for large or heavy components, can be more sensitive to handling. |

| Through-Hole Technology | Components have leads that are inserted through holes in the PCB and soldered on the other side. | Through holes. | Robust mechanical connections, prototypes, high-power applications, older designs. | Strong and reliable connection, ideal for larger and heavy components, easier for manual assembly and prototyping. | Lower component density, less suitable for miniaturization, may be more costly for high-volume production. |

| Mixed Technology | A combination of SMT and through-hole technologies on the same PCB. | Surface pads and through holes. | Complex PCBs, combining benefits of both technologies, diverse functionality needs. | Design flexibility, combines strengths of both methods, suitable for a wide range of applications. | More complex assembly process, potentially higher cost and more difficult quality control. |

The selection of the appropriate technology depends on factors including the desired board density, component types and size, mechanical strength needed, as well as budget and production volumes. Therefore it is important to understand the capabilities of manufacturers when comparing them to your requirements.

Frequently Asked Questions About PCB Manufacturing Companies

Understanding the nuances of PCB manufacturing is crucial for project success. This section addresses frequently asked questions to provide clarity on cost factors, geographical manufacturing hubs, and how to select the best partner for your specific needs.

- How much does it cost to get a PCB assembled?

The cost to assemble a PCB is highly variable, influenced by several key factors. These include the complexity of the board design, the quantity of PCBs required (ranging from prototypes to mass production), the specific materials used in construction, the type of assembly technology needed (SMT, through-hole, mixed), and the chosen manufacturer's pricing structure. A simple single-layer board will cost significantly less than a complex multi-layer board with fine-pitch components. To get an accurate quote, always provide a detailed Bill of Materials (BOM) and Gerber files to potential manufacturers. - Where are most PCBs manufactured?

While PCB manufacturing is a global industry, certain regions have established themselves as major hubs. China is a dominant player due to its large manufacturing capacity and competitive pricing. However, many PCB manufacturers are also located in other parts of Asia, Europe, and North America. The United States, for example, maintains a strong presence in the high-reliability and specialty PCB manufacturing sectors. Choosing a manufacturer will depend on your project's requirements, budget, and any geographic restrictions you may have. - Who is the best PCB manufacturer?

The concept of the 'best' PCB manufacturer is subjective, as it depends entirely on the specific requirements of your project. Factors to consider include the complexity of your board, production volume, budget, turnaround time, quality control standards, and any specialized services needed (e.g., high-frequency boards, impedance control, or flex PCBs). Instead of searching for a single 'best' manufacturer, focus on identifying those that align with your particular project needs and offer a proven track record in your specific industry. - Who is the largest PCB manufacturer in the USA?

The largest PCB manufacturer in the USA depends on the metrics used (e.g., revenue, units produced, or number of employees). Many companies operate in this space, each with different strengths and areas of expertise. Rather than focusing on the single 'largest,' investigate companies that specialize in the type of PCB you need. Some manufacturers excel in high-reliability boards for aerospace or medical, while others focus on high-volume consumer electronics boards. Conduct your due diligence and find the best partner based on a combination of production capability, quality, and price. - What are the typical lead times for PCB manufacturing?

Lead times for PCB manufacturing can vary greatly depending on several factors, including the complexity of the design, order volume, manufacturing location, and the type of technology employed. Simple prototypes can sometimes be turned around in a few days, while more complex or high-volume orders can take several weeks. Express services are available with some manufacturers, often at a premium cost. Always discuss lead times upfront with your potential PCB manufacturer and plan your projects accordingly. Delays in material procurement can also impact lead time. - What are the key quality control measures to look for in a PCB manufacturer?

Key quality control measures include ISO 9001 certification, adherence to IPC standards, thorough inspection procedures, and clear documentation. Reputable manufacturers will also employ in-process testing and final inspections to ensure the quality of the boards. They should also be able to provide you with material certificates, compliance documentation, and testing reports as needed. Be wary of companies that have loose inspection standards or are unable to provide verifiable quality data.

Cost-Effective Strategies for PCB Manufacturing

Optimizing PCB manufacturing costs requires a multi-faceted approach that balances design, material selection, and production processes without compromising quality. By strategically managing these elements, substantial cost reductions can be achieved.

- Optimize PCB Design

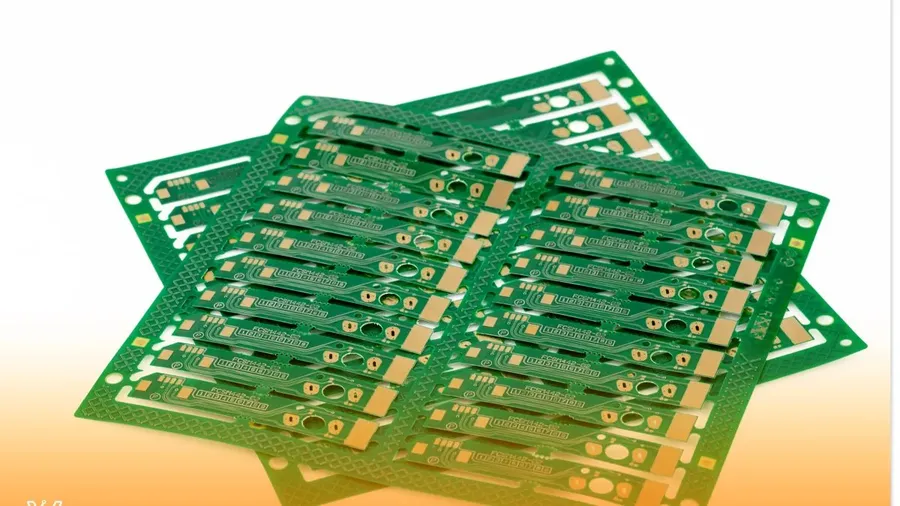

Simplify the design by reducing the number of layers, minimizing board size, and using standard components. A streamlined design reduces manufacturing complexity and cost. - Panelization

Utilize panelization, where multiple PCBs are manufactured on a single panel, to maximize material usage and production efficiency. This reduces the per-unit cost. - Negotiate Volume Discounts

Obtain quotes for different production volumes. Manufacturers often offer discounts for larger orders due to economies of scale. - Choose Cost-Effective Materials

Select materials that meet your application requirements without being overly expensive. Standard FR-4 laminate is often a cost-effective option for many applications, but alternatives exist for specialized needs. - Standard Component Selection

Opt for standard, readily available components to avoid premium pricing and long lead times. Consider open-source component libraries that can reduce design cost and complexity. - Early Involvement of the Manufacturer

Consult with the manufacturer during the design phase to identify potential cost-saving opportunities and design optimizations. Early collaboration can prevent costly errors and rework. - Consolidate Orders

If you have multiple PCB projects, consider combining them into a single order to achieve greater volume discounts.

| Strategy | Description | Potential Cost Savings |

|---|---|---|

| Design Optimization | Simplify design, reduce layers, use standard components. | 10-30% |

| Panelization | Manufacturing multiple boards on a single panel | 5-15% |

| Volume Discounts | Larger production runs | 5-20% |

| Material Selection | Use standard or cheaper alternatives where appropriate | 5-10% |

Quality Control and Certifications

Rigorous quality control and adherence to industry certifications are paramount when selecting a PCB manufacturer. These measures ensure the reliability and performance of your printed circuit boards, ultimately reducing the risk of defects and project delays. A manufacturer's commitment to quality directly reflects the final product's dependability and longevity.

- ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems. A PCB manufacturer holding this certification demonstrates a commitment to consistent processes, continuous improvement, and customer satisfaction. It indicates that the manufacturer has established a robust framework for managing all aspects of production, from design review to final inspection. - IPC Standards

IPC (Association Connecting Electronics Industries) standards are industry-specific guidelines for PCB design, fabrication, and assembly. Compliance with these standards ensures that the manufactured boards meet internationally recognized requirements for performance, reliability, and quality. Look for manufacturers that adhere to relevant IPC classes and specifications for your project requirements. - UL Certification

UL (Underwriters Laboratories) certification signifies that a manufacturer has met stringent safety standards, particularly important when PCB operate within specific power parameters or in hazardous environments. UL certified manufacturers use materials that are evaluated to meet safety requirements, ensuring the final product reduces safety risks. - RoHS Compliance

Restriction of Hazardous Substances (RoHS) compliance restricts the use of specific hazardous materials in electronic products. It is essential to choose a manufacturer that complies with RoHS directives to ensure environmental safety and meet regulatory demands in many markets. This indicates responsible sourcing and manufacturing practices.

| Certification/Standard | Focus | Benefits |

|---|---|---|

| ISO 9001 | Quality Management System | Consistent Processes, Continuous Improvement, Customer Satisfaction |

| IPC Standards | Industry-Specific Design, Fabrication, and Assembly | Internationally Recognized Performance and Reliability |

| UL Certification | Safety Standards | Reduced Safety Risks |

| RoHS Compliance | Restriction of Hazardous Substances | Environmental Safety, Regulatory Compliance |

Practical Tips for a Successful PCB Manufacturing Project

To maximize the success of your PCB manufacturing project, meticulous planning and clear communication are crucial. A well-defined design, proactive interaction with the manufacturer, and a rigorous testing strategy can significantly reduce errors and ensure a high-quality final product. The following tips will guide you through each stage.

- Detailed and Accurate PCB Design

Begin with a comprehensive and accurate PCB design using professional CAD software. This design should include all necessary details, such as component placement, trace widths, and layer stack-up. A meticulous design will minimize the potential for manufacturing errors and reduce rework costs. - Clear Communication with the Manufacturer

Establish clear and consistent communication with your chosen PCB manufacturer. Discuss your design specifications, project requirements, and any specific concerns. Maintain open dialogue throughout the manufacturing process to address any unforeseen issues or adjustments. - Comprehensive Testing Plan

Develop a detailed testing plan that includes both electrical and functional tests. This plan should specify the procedures for component verification, circuit integrity checks, and performance evaluation. Thorough testing ensures that the manufactured boards meet your specifications and operate as expected. - Design for Manufacturing (DFM)

Adopt a design for manufacturing (DFM) approach early in the PCB design process. Consider manufacturing constraints, component availability, and assembly techniques to optimize the board's producibility and minimize potential complications during manufacturing. - Prepare a Complete Bill of Materials (BOM)

Provide the manufacturer with a detailed and accurate BOM that includes all necessary components and specifications. This will help in component procurement and prevent mismatches. - Review and Approve Manufacturing Data

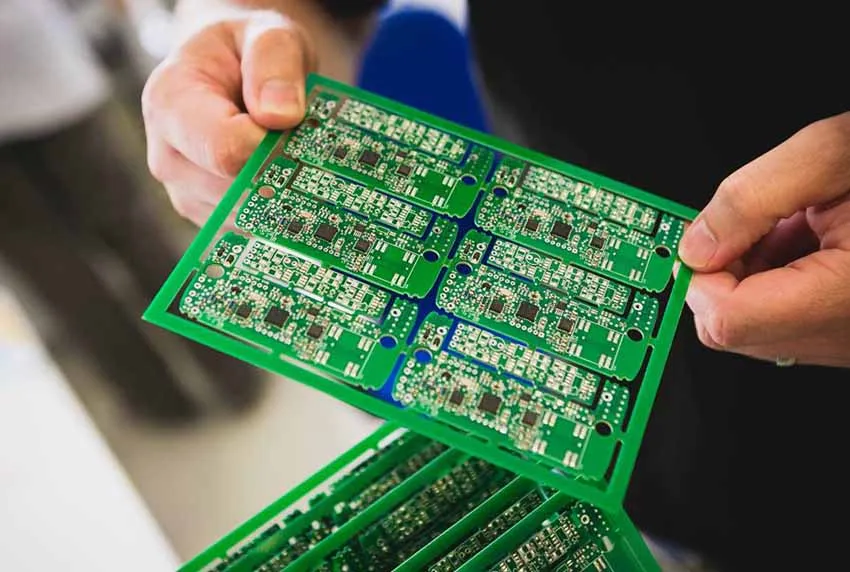

Before initiating the mass production, thoroughly review all manufacturing data including Gerber files and other production documents. Clear your doubts and confirm that everything is correct before moving forward. - Plan for Prototypes First

Start with prototypes for testing purposes, rather than direct mass production. This allows you to test the designs and make necessary changes before committing to larger orders, thus saving costs and time in the long run.

Finding reliable 'PCB manufacturing companies near me' is a critical step in bringing your electronic projects to life. By carefully considering your needs, understanding key factors, and conducting thorough research, you can partner with a company that offers quality, cost-effectiveness, and expertise. Whether for a quick prototype or a large production run, the right manufacturer can make all the difference. Local companies offer numerous advantages, from reduced shipping costs to easier communication. Explore the resources mentioned above and take the time to make the correct decision when choosing your 'pcb manufacturing companies near me'. Ultimately, thorough research and careful partner selection will lead to project success.

AnyPCBA

AnyPCBA