Find Top Circuit Board Manufacturers Near You: A Comprehensive Guide

From the smartphones we use every day to the complex machinery that powers industries, circuit boards are the invisible backbone of modern electronics. Finding reliable circuit board manufacturers near you can be crucial for projects ranging from hobbyist prototypes to large-scale commercial production. This guide will help you navigate the landscape, understanding key factors and connecting you with the best PCB manufacturers.

Understanding Your PCB Needs

Before initiating a search for 'circuit board manufacturers near me,' a critical first step involves a thorough assessment of your project's unique requirements. This preliminary analysis is crucial for selecting the appropriate manufacturer and ensuring the final product aligns with your specifications. Key considerations include the complexity of the printed circuit board (PCB), the materials required, the production volume, and the desired turnaround time, as each of these factors will influence the choice of manufacturer.

- PCB Complexity

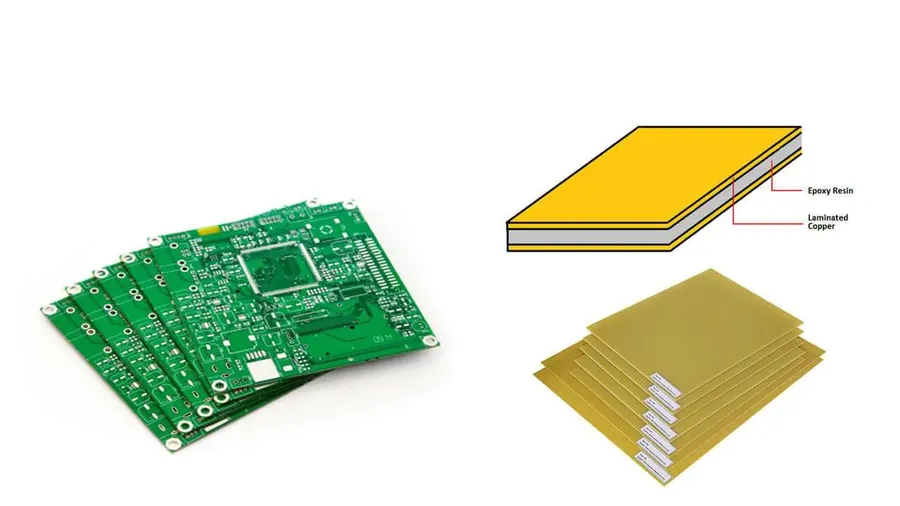

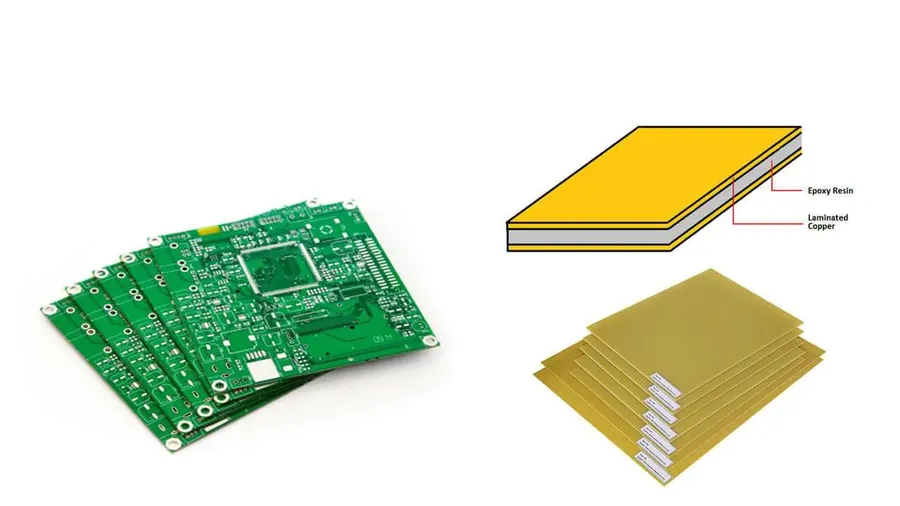

The complexity of a PCB significantly impacts manufacturing processes and costs. It's vital to determine whether your project requires a single-sided, double-sided, or multilayer board. Single-sided PCBs are simplest, with conductive traces on one side, whereas double-sided PCBs have traces on both sides. Multilayer PCBs, with three or more layers, are more complex and are used in sophisticated electronics. - Material Requirements

The choice of material is critical to the PCB's performance and reliability. Common materials include FR-4, known for its balance of cost and performance, aluminum for heat dissipation, and flexible materials for applications requiring bending. Selecting the appropriate material is essential to meet the operational demands of your product. - Production Quantity

The required quantity of PCBs is a key factor. Production volumes can range from prototypes, for initial testing and verification, to small batches for specialized applications, or mass production for large-scale product rollouts. Manufacturers often specialize in particular production volumes, therefore this factor influences the selection process. - Turnaround Time

Turnaround time refers to the period from submitting the design to receiving the finished PCBs. The acceptable lead times are crucial as they directly impact project timelines and deadlines. Manufacturers often offer various turnaround times, with accelerated or rapid options available for time-sensitive projects.

Types of PCB Manufacturers and Their Specializations

The landscape of Printed Circuit Board (PCB) manufacturing is diverse, with various manufacturers specializing in different production scales, board complexities, and material requirements. Understanding these specializations is crucial for selecting the right partner for your specific project, ensuring both quality and cost-effectiveness. This section will explore several key categories of PCB manufacturers to assist in your search.

| Manufacturer Type | Specialization | Typical Use Cases | Advantages | Considerations |

|---|---|---|---|---|

| Prototype PCB Manufacturers | Small quantity runs for testing and design validation. | Early-stage product development, R&D projects. | Fast turnaround times, flexibility in design changes. | May have higher per-unit cost, not suitable for mass production. |

| Rapid Turnaround PCB Manufacturers | Focus on quick production timelines. | Urgent projects, time-sensitive product launches. | Very fast delivery, can accommodate quick revisions. | May have limitations on complexity or board size, often higher cost. |

| High-Volume PCB Manufacturers | Large-scale production runs for mass-market products. | Consumer electronics, industrial products, large-scale deployments. | Economies of scale, lower per-unit cost for large quantities. | Longer lead times, less flexibility for design changes. |

| Rigid-Flex PCB Manufacturers | Specializes in manufacturing boards that combine rigid and flexible sections. | Applications requiring flexible connections and space optimization | Provides unique design possibilities, reduces interconnection complexity. | Specialized manufacturing process, may have higher cost and longer lead times. |

| Specialized Material PCB Manufacturers | Production of boards using specific materials (e.g., aluminum, Rogers, high-Tg FR4) | High-frequency applications, high-temperature environments, unique performance needs. | Offers specific performance characteristics not available with standard materials. | Higher material cost, may require specialized fabrication techniques. |

How to Search for "Circuit Board Manufacturers Near Me"

Effectively locating circuit board manufacturers in your vicinity requires leveraging online resources and strategic search techniques. This section details how to use these resources to find the right PCB manufacturer for your specific needs, focusing on proximity for minimized shipping costs and streamlined communication.

- Utilize Online Directories:

Start your search with specialized online directories such as PCB Directory and ThomasNet. These platforms often list manufacturers based on location, services, and certifications. This can greatly reduce the initial time spent sifting through irrelevant results. - Leverage General Search Engines:

General search engines, like Google, are also valuable tools. By entering specific search phrases, such as 'PCB manufacturers in [Your City]' or 'circuit board assembly near [Your State]', you can retrieve relevant local manufacturers. Google Maps can further assist by visually pinpointing these locations. - Focus on Proximity:

Prioritize manufacturers within a reasonable distance from your location. This helps in reducing shipping times and costs, and also facilitates easier communication, as face-to-face meetings may be possible. Consider this especially for rapid prototyping or projects that require close collaboration with the manufacturer. - Refine Search Terms:

Use specific search terms to target your needs. For example, if you need a flexible PCB, search 'flexible PCB manufacturers near me.' This prevents wasting time evaluating companies not specializing in your specific requirements. This approach can filter through a broad list of manufacturers to ones with the appropriate capabilities

Key Factors to Consider When Selecting a Manufacturer

Selecting the right circuit board manufacturer is crucial for the success of any electronics project. This decision should be based on a thorough evaluation of several key factors, ensuring that the chosen partner aligns with your project's specific needs and quality expectations. These considerations extend beyond just cost, encompassing a range of capabilities and service offerings.

- Quality Certifications (ISO, UL)

Look for manufacturers with ISO 9001 certification, demonstrating a commitment to quality management systems, and UL certifications, which ensure product safety standards are met. These certifications provide a level of assurance in the manufacturer's processes and the reliability of their products. Verification of these certifications is a good starting point. - Turnaround Times

Evaluate the manufacturer's ability to meet your project deadlines, considering lead times for prototype and production runs. Verify their typical turnaround times for the specific type of PCBs you need. Short turnaround times are vital, particularly for prototyping and fast-paced projects. - Pricing Structures

Analyze the pricing models offered by different manufacturers. Consider not only the per-board cost but also setup fees, tooling charges, and potential discounts for higher volume orders. Obtain detailed quotes to compare different suppliers accurately. - Material Capabilities

Confirm that the manufacturer can handle the specific materials required for your PCB design (e.g., FR-4, aluminum, flexible substrates). Their proficiency with different material types directly impacts the functional performance and reliability of your boards. - Minimum Order Quantities (MOQ)

Be aware of minimum order quantity requirements, particularly for prototypes or small batch production. Choose manufacturers whose MOQs align with your project’s needs to avoid excessive costs or unwanted surplus. - Design Support

Assess the availability of design support services, including Design for Manufacturing (DFM) checks and technical assistance. Design support is often crucial for optimizing your design for mass production and avoiding manufacturing errors. - Customer Reviews and References

Read customer reviews and request references to gain insights into the manufacturer's reputation for quality, reliability, and customer service. Real-world feedback can provide valuable information about a manufacturer's suitability. - In-House Assembly and Testing

Determine if the manufacturer offers in-house assembly and testing services, which can streamline the manufacturing process and ensure higher quality control. Integrated services reduce the risk of incompatibilities and delays.

Comparing Circuit Board Manufacturers: A Practical Guide

Selecting the right circuit board manufacturer requires a systematic comparison of several key factors. Creating a structured comparison allows for an objective evaluation, ensuring that the chosen manufacturer aligns with your project's specific needs and constraints. This process minimizes risks and optimizes outcomes by helping you navigate the complexities of PCB manufacturing.

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C | Notes |

|---|---|---|---|---|

| Price per Board | $X.XX | $Y.YY | $Z.ZZ | Consider volume discounts; compare prices at your projected order quantity. |

| Lead Time | A weeks | B weeks | C weeks | Evaluate for prototyping, rapid turn, and standard lead times. |

| Manufacturing Capabilities | Specific Capabilities A | Specific Capabilities B | Specific Capabilities C | Check for materials, layers, tolerances, and special processes. |

| Customer Support | Support type A | Support type B | Support type C | Assess responsiveness, technical assistance, and communication. |

| Material Availability | Material Availability A | Material Availability B | Material Availability C | Confirm access to preferred materials or alternatives with comparable performance. |

| Quality Certifications | Certifications A | Certifications B | Certifications C | ISO 9001, UL, and other relevant standards are recommended. |

| Minimum Order Quantity (MOQ) | MOQ A | MOQ B | MOQ C | Ensure the MOQ aligns with your production needs, especially for prototyping. |

| Design Support | Design support type A | Design support type B | Design support type C | Availability of DFM feedback, assistance and expertise is beneficial. |

| In-house Assembly and Testing | Yes/No | Yes/No | Yes/No | If needed, verify in-house assembly and comprehensive testing procedures. |

This table provides a framework to help analyze several PCB manufacturer options; remember to fill in the specific data for your project's individual requirements. A practical approach is to assign a score for each criteria that best fits your projects needs or demands. For example: price per board (lowest best), lead time (fastest best), manufacturing capabilities (most complete best), customer support (most responsive best), material availability (materials with superior characteristics or performance). This will allow you to quickly assess and compare each manufacturer.

Circuit Board Manufacturing Cost Factors

Understanding the cost drivers in circuit board manufacturing is crucial for effective budgeting and project planning. PCB costs are not fixed; they vary significantly based on several key factors, necessitating a comprehensive analysis to optimize expenses.

| Cost Factor | Description | Impact on Cost |

|---|---|---|

| Board Complexity | Number of layers, trace density, and component count. | Higher complexity increases manufacturing time and precision requirements, leading to higher costs. |

| Board Size | Physical dimensions of the circuit board. | Larger boards require more material and handling, thus increasing costs. |

| Material Type | Choice of substrate (e.g., FR-4, aluminum, flex). | Specialized materials like aluminum or flex PCBs are more costly than standard FR-4. |

| Quantity Ordered | Number of PCBs required for the project. | Unit costs generally decrease with larger production volumes, due to economies of scale. |

| Turnaround Time | The time required to complete PCB fabrication and assembly. | Rush orders or expedited production usually incur premium costs. |

| Surface Finish | Type of plating on the PCB pads and traces. | Certain finishes (e.g., ENIG, immersion silver) are more expensive than HASL. |

| Drilling | Number and size of vias and holes. | Complex drilling patterns and smaller drills increase manufacturing time and thus cost. |

| Testing Requirements | Type and extent of testing, e.g., flying probe, AOI, ICT. | More rigorous testing leads to increased costs. |

| Design Complexity | Fine pitch components, intricate routing, special impedance requirements. | Complex designs require more precise manufacturing capabilities leading to higher costs. |

To gain a clear understanding of project-specific pricing, request detailed quotations from multiple manufacturers. These quotations should itemize the costs associated with the above factors, enabling a detailed cost-benefit analysis.

Frequently Asked Questions About Circuit Board Manufacturing

This section addresses common questions regarding circuit board manufacturing, providing clear and concise answers to assist you in navigating the process effectively. We aim to clarify typical confusions and provide substantial information.

- What is the average cost of a circuit board?

The average cost of a circuit board varies significantly based on several factors, including board complexity (number of layers), size, materials used, quantity ordered, and turnaround time. Simple, single-layer boards for prototypes can cost a few dollars each, while complex, multi-layer boards with high-density interconnects for mass production can range from tens to hundreds of dollars per unit. Obtaining quotes from multiple manufacturers is essential for an accurate cost estimate. It's important to note that material costs, particularly for specialized substrates or high copper weights, can substantially influence final pricing. - Who is the best PCB manufacturer for my project?

The 'best' PCB manufacturer depends heavily on your specific project requirements. There isn't a single universal 'best' manufacturer. For prototyping, you might prioritize quick turnaround times and lower costs. For mass production, you might prioritize cost per unit and manufacturing capacity. For specialized applications, like high-frequency or high-temperature PCBs, you'll need a manufacturer with specific capabilities in materials and process control. Key considerations include the manufacturer's certifications (ISO, UL), experience, technology, and customer support. It's prudent to solicit quotes from multiple manufacturers and evaluate samples to determine the best fit. - How can I avoid PCB shortages?

To mitigate the impact of PCB shortages, several strategies can be employed. Planning ahead by anticipating demand and placing orders in advance is crucial. Also, diversifying your supply chain by having more than one manufacturer approved can provide redundancy and buffer against shortages. Consider using more readily available materials and components, if possible, and engaging in frequent communication with your manufacturer to stay informed of any potential supply chain issues. Early design freeze and flexibility in specifications can also improve lead times. - Who builds circuit boards from my design?

Typically, your design, which is often in Gerber files and related documentation, will be sent to a PCB manufacturer. These manufacturers have the facilities and processes to fabricate boards based on your specifications. Some manufacturers may also offer PCB design services; however, in general, the design should be finalized before submitting it to the manufacturer for production. They convert your electronic design into a physical product using various techniques such as etching, drilling, and plating. - Is PCB assembly included in the manufacturing services?

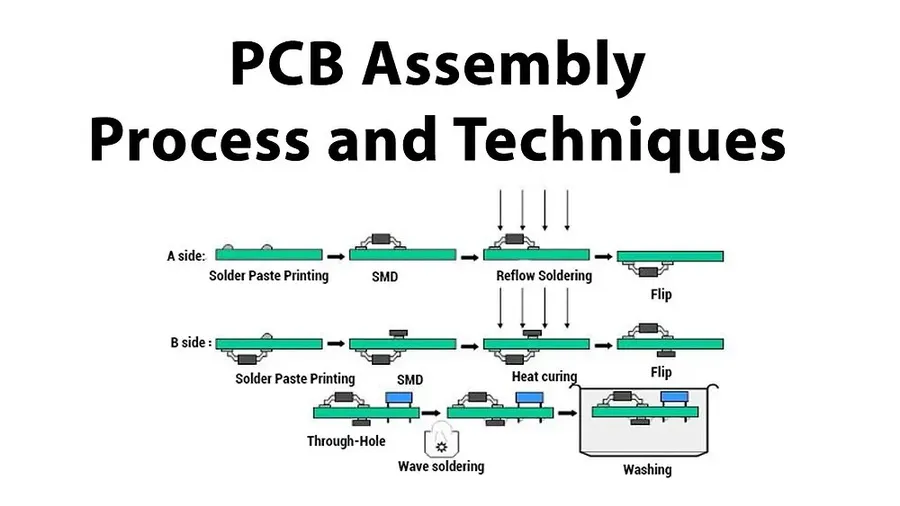

Not all PCB manufacturers offer assembly services, but many do. PCB assembly is a separate step that involves placing electronic components onto the manufactured board and soldering them into place. If assembly is required, ascertain whether the manufacturer can provide a turnkey solution, which encompasses both PCB fabrication and assembly, or if you will have to source this service separately. Turnkey solutions can simplify the process and often result in time and cost savings. Confirm that the manufacturer has the necessary equipment and skilled staff to perform assembly to required standards. - What are the key factors to evaluate when selecting a PCB manufacturer?

Evaluating PCB manufacturers requires consideration of several key factors. These include: manufacturing capabilities (minimum trace/space, layer count, vias), quality certifications (ISO 9001, UL), material options, turnaround times, minimum order quantities (MOQ), pricing structures, design support, and customer service reviews. A manufacturer’s communication proficiency and responsiveness are also vital. It's advisable to request sample PCBs and to assess their adherence to your specifications before committing to large production runs.

Latest Trends in the PCB Manufacturing Industry

The PCB manufacturing industry is continuously evolving, driven by the demand for smaller, faster, and more efficient electronic devices. This section highlights some of the most significant trends shaping the future of PCB fabrication, offering insights into the advancements that will impact the next generation of electronic products.

- Environmentally Friendly PCBs

With increasing environmental concerns, there is a strong push towards sustainable manufacturing practices in the PCB industry. This includes the use of halogen-free materials, lead-free solders, and recycled materials. The focus is on reducing waste and using processes with a smaller environmental footprint, promoting a circular economy approach. - Embedded Technology

Embedding components directly within the PCB substrate is gaining traction. This technique allows for more compact designs, improved thermal management, and better signal integrity. It also offers increased protection for components and a higher density of circuit elements within a small area. This trend is crucial for advanced electronics where space is a premium. - Improved Surface Finish Options

Advanced surface finish technologies are being developed to enhance the performance and reliability of PCBs. These finishes are critical for improving solderability, providing corrosion resistance, and ensuring long-term durability, while ensuring the fine pitch requirements for modern, high density assemblies can be achieved. Options such as electroless nickel immersion gold (ENIG), immersion silver (ImAg) and electroless palladium immersion gold (ENEPIG) are becoming increasingly common. - Advanced Materials

The use of new materials with enhanced electrical, thermal, and mechanical properties is a key trend. These include high-performance laminates, ceramics, and flexible substrates. The development of materials to support high frequency applications, like 5G and beyond, are a focal point of research and development efforts. These innovative materials enable higher performance in smaller and more complex form factors. - Miniaturization and High-Density Interconnect (HDI)

The continuous demand for smaller and more powerful devices leads to miniaturization trends in PCB manufacturing. HDI technologies, featuring microvias, fine lines and spaces, are used to accommodate a higher density of connections and components on smaller PCBs. This allows for more intricate circuits within a smaller footprint, crucial for applications in portable electronics and wearable technology. - Smart Manufacturing and Automation

The integration of smart manufacturing techniques and automation is improving PCB production efficiency. The use of robotics, AI-driven inspection and process monitoring are enhancing production yields, reducing errors, and leading to faster and more cost-effective manufacturing. These advancements allow for better quality control and reduce human errors.

Tips for Streamlining Your PCB Manufacturing Process

Efficient PCB manufacturing relies on a well-organized and proactive approach. Streamlining the process involves clear communication, accurate design files, and anticipating potential challenges, significantly reducing delays and errors.

- Maintain Clear Communication with Manufacturers

Establish open and consistent dialogue with your chosen PCB manufacturer. Clearly articulate your project requirements, specifications, and any concerns. Regular communication can help identify and address issues early on. - Prepare Comprehensive and Accurate Design Files

Submit well-organized and meticulously checked design files (Gerber, CAD). Adherence to industry standards is crucial. Use clear naming conventions, and include all relevant information, such as layer stack-up, drill files, and assembly drawings. Verify design files with software before submitting, ensuring accuracy and compliance. - Anticipate Common Manufacturing Errors

Be aware of common issues that can arise during manufacturing, such as misaligned layers, incorrect drill sizes, and solder mask defects. Design with manufacturability in mind and specify tolerances where necessary. Proactive consideration of potential manufacturing errors and specifying critical design parameters will minimize potential complications. - Verify Design Files with Manufacturers

Where possible request a design for manufacturability (DFM) review from the manufacturer before finalizing your order. A DFM check can identify potential problems in the design that would make manufacturing difficult or expensive and can suggest improvements. This service is often free and provided by most manufacturers, and is essential for ensuring the smooth execution of your project. - Plan for Necessary Testing and Inspection

Prior to production, establish clear testing procedures and metrics to ensure the quality and functionality of the final boards. This is particularly important for critical applications. Specify the types of inspections that need to be done, and ensure that these inspections occur throughout the process.

Finding the right 'circuit board manufacturers near me' involves careful research and an understanding of your project's needs. By considering factors like manufacturer specializations, pricing, and customer reviews, you can ensure a successful PCB fabrication process and potentially partner with circuit board manufacturers near you to build your vision to life. Remember to prioritize clear communication and thorough research to secure the best possible outcome.

AnyPCBA

AnyPCBA