Finding Reliable PCB Components Suppliers: A Comprehensive Guide

The intricate dance of modern electronics hinges on the availability of high-quality PCB components. From smartphones to spacecraft, reliable [pcb components suppliers] are the backbone of innovation. This article will be your compass, guiding you through the landscape of PCB component sourcing, providing insights into the options available, helping you choose the right partners, and ensuring your projects are equipped with the best parts the industry has to offer. This guide will help you source with confidence and clarity.

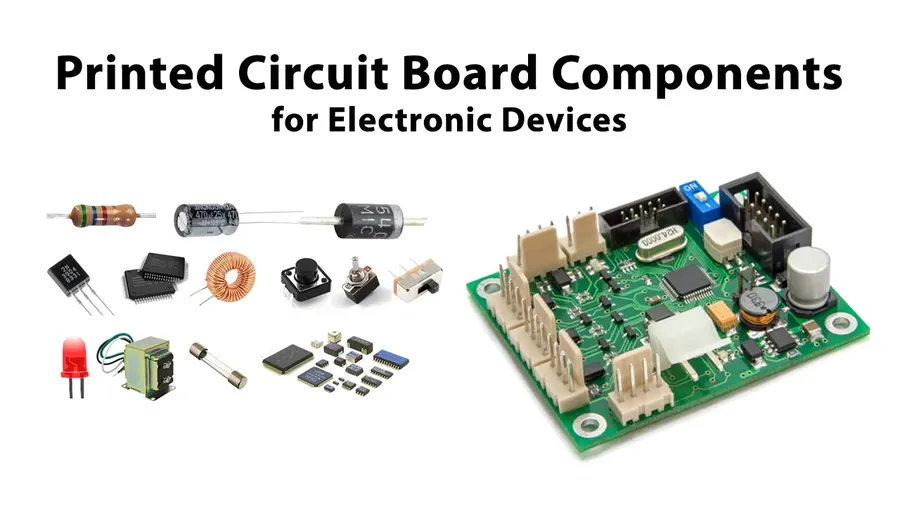

Understanding Your PCB Component Needs

Before engaging with PCB component suppliers, a precise understanding of your project's requirements is paramount. This involves a detailed specification of component types (e.g., resistors, capacitors, integrated circuits), their quantities, acceptable tolerances, and any unique specifications. A thorough Bill of Materials (BOM) serves as the foundation for effective sourcing.

| Parameter | Description | Importance |

|---|---|---|

| Component Type | Specific type of electronic component (e.g., Resistor, Capacitor, IC) | Critical for functionality and compatibility within the circuit. |

| Quantity | The number of each component required for the production run. | Essential for accurate procurement and cost estimation. |

| Tolerance | The acceptable range of variation for component values. Often given as a percentage (e.g., 1%, 5%). | Impacts circuit performance and reliability; tighter tolerances typically increase cost. |

| Special Requirements | Unique specifications such as specific material, package type, or operating conditions | Ensures components meet specific demands and application environments. |

| Bill of Materials (BOM) | A comprehensive list of all components needed for the PCB assembly. | The cornerstone of effective sourcing, it must be accurate and complete. |

Types of PCB Components Suppliers

Navigating the PCB component supply chain requires understanding the diverse types of suppliers available, each offering distinct advantages and disadvantages. Selecting the right type of supplier is critical to balancing cost, quality, and lead times for your project. This section will provide a comprehensive overview of direct manufacturers, authorized distributors, independent distributors, and online marketplaces.

| Supplier Type | Description | Pros | Cons |

|---|---|---|---|

| Direct Manufacturers | Companies that produce the components themselves. | Potential for best pricing for very large quantities, direct technical support, custom components possible. | High minimum order quantities, longer lead times, less flexibility for smaller orders. |

| Authorized Distributors | Distributors who have an official agreement with the component manufacturers. | Guaranteed component authenticity, strong support and traceability, reliable supply chain. | Higher prices compared to other sources, may have limited stock of some parts, may require minimum order amounts. |

| Independent Distributors | Distributors that acquire components from various sources, not directly from the manufacturer. | Potentially lower prices, access to hard-to-find or obsolete components, flexibility in order quantities. | Risk of counterfeit components, less traceability, quality control may vary, uncertain supply chain. |

| Online Marketplaces | Platforms that allow numerous vendors to list their products. | Wide variety of components, price competitiveness, convenient for small orders. | Inconsistent quality, less transparency, potential for long shipping times, potential for counterfeit components. |

Choosing the appropriate supplier involves considering factors like project volume, budget, timeline, and the importance of component quality and traceability. For instance, direct manufacturers are ideal for large-scale production with specific requirements, while authorized distributors provide the necessary assurance of quality for critical applications. Independent distributors may be a good option when dealing with parts that have a long lead time or may be obsolete. Online marketplaces offer a wide variety of options, but one must carefully evaluate the quality and reliability.

Key Factors to Consider When Choosing a Supplier

Selecting the right PCB component supplier is paramount to ensuring the quality, reliability, and cost-effectiveness of your electronic products. A thorough evaluation of potential suppliers across several key factors is crucial for making informed decisions that align with your project's requirements and long-term goals.

| Factor | Description | Importance |

|---|---|---|

| Component Quality | The consistency and reliability of the components. Should adhere to industry standards and specifications. | High: Ensures product reliability and longevity. Prevents failures. |

| Pricing | The cost of components. Includes unit price and bulk discounts. Total cost of ownership should be considered (TCO). | Medium: Impacts project budget. Should be balanced against quality and other factors. |

| Lead Times | The time it takes from order placement to delivery of components. Critical for project scheduling. | High: Directly affects project timelines and production schedules. |

| Certifications | The compliance to industry standards (e.g., ISO, RoHS, REACH) and certifications. Ensures adherence to regulations and quality standards. | Medium: Indicates adherence to standards and regulatory compliance. |

| Reliability | The supplier's track record of delivering on time and meeting stated requirements and their ability to deliver consistent quality. | High: Essential for smooth project execution and long-term supply security. |

| Geographical Presence | The supplier's physical location and distribution network. Impacts logistics, shipping costs, and potential delays. | Medium: May impact logistics, shipping costs and delivery times. |

| Customer Service | The responsiveness and support provided by the supplier’s customer service team. Handling queries, resolving issues, and providing technical support. | Medium: Important for effective communication and timely problem resolution. |

| Reputation | The supplier's overall standing in the industry. Based on customer reviews, testimonials, and industry feedback. Check online reviews and forums. | High: Reflects the supplier's credibility and trustworthiness. |

Sourcing Strategies: From Small Batches to High Volume

Effective sourcing strategies for PCB components are highly dependent on the scale of your project, ranging from small prototype runs to high-volume production. A strategic approach ensures cost-effectiveness and timely acquisition of necessary parts, aligning with both budget and production schedules.

- Small Batch/Prototype Sourcing

For prototypes and small runs, focus on flexibility and speed. Online marketplaces or authorized distributors with no minimum order quantities (MOQ) are often ideal. Prioritize quick delivery and easy access to a wide variety of components. Consider using kitted solutions, which bundle the components needed for a specific board. Example: Digikey, Mouser. - Medium-Sized Project Sourcing

As project size increases, establishing relationships with distributors becomes advantageous. They can often offer better pricing and more reliable lead times. Consider using a Bill of Materials (BOM) tool to streamline sourcing. Negotiate pricing and delivery schedules based on projected volumes. Explore options for consigned inventory. - High-Volume Production Sourcing

For mass production, direct relationships with manufacturers or large distributors are crucial. Negotiate volume discounts and explore long-term supply agreements. Focus on supplier reliability, consistency, and robust quality control processes. Explore options for Just-In-Time (JIT) delivery systems. Develop second-source strategies for critical components to mitigate supply risk. Engage with suppliers that can offer complete turnkey solutions.

| Sourcing Strategy | Project Scale | Key Considerations | Suitable Suppliers |

|---|---|---|---|

| Small Batch/Prototype | Prototype runs, low quantities | Flexibility, speed, no MOQ | Online marketplaces, authorized distributors |

| Medium-Sized Project | Moderate production, some cost sensitivity | Reliable lead times, competitive pricing | Distributors, established relationships |

| High-Volume Production | Large-scale manufacturing | Volume discounts, long-term agreements, reliability | Direct manufacturers, large distributors |

Utilizing a Bill of Materials (BOM) tool significantly enhances sourcing efficiency. These tools allow you to upload your BOM, compare pricing across multiple suppliers, and generate purchase orders, saving time and minimizing errors. Many online platforms integrate BOM management features for ease of use.

Navigating Component Shortages and Supply Chain Issues

The electronics industry, including PCB manufacturing, has experienced significant supply chain disruptions in recent years, leading to component shortages and extended lead times. Effective management of these challenges is critical for maintaining production schedules and mitigating project risks. This section outlines strategies to navigate these complex issues.

- Diversify Your Sourcing Options

Relying on a single supplier for critical components increases your vulnerability to disruptions. Establishing relationships with multiple suppliers, including authorized distributors, independent distributors, and even exploring alternative component manufacturers, can help you mitigate risks. Consider different geographical regions to balance global supply challenges. - Implement Robust Stock Planning and Forecasting

Accurate forecasting and inventory management are key to preventing production stoppages. Analyze historical data to predict future needs and maintain sufficient buffer stock. A well-managed stock of frequently used parts helps to cope with fluctuating lead times. - Qualify Alternative Components

In the face of component shortages, having a list of pre-qualified alternative parts can be crucial. Identify substitute components that meet your design requirements and test them thoroughly to ensure compatibility. Having alternative part numbers in your BOM is a good practice. - Prioritize Flexible Suppliers

When choosing [pcb components suppliers], prioritize those with transparent and agile supply chains. Suppliers that can adapt quickly to changing market conditions are better equipped to handle unforeseen disruptions. Establish open communication to understand their challenges and adjust planning accordingly. - Consider Long-Term Agreements

For high-volume projects or critical components, consider establishing long-term agreements with your suppliers. Such agreements can provide price stability, guaranteed supply, and priority in times of shortage. Formal agreements may also have other benefits like payment terms or shipping priorities. - Employ BOM (Bill of Materials) Management Tools

Use digital tools to track components availability, pricing, lead times from different suppliers. This data-driven approach can provide better visibility and enables proactive management of the components needs. This helps in making timely purchasing decisions.

Online Platforms vs. Direct Suppliers for PCB Components

The selection of PCB component suppliers is significantly influenced by the choice between online platforms and direct engagement with manufacturers or authorized distributors. Each avenue offers distinct advantages and disadvantages which can significantly impact cost, quality, and supply chain reliability. Understanding these differences is critical for making informed procurement decisions.

| Feature | Online Platforms | Direct Suppliers |

|---|---|---|

| Pricing | Often competitive, especially for small to medium-sized orders, due to aggregated demand and numerous vendors. | Pricing can be more negotiable, especially for high-volume orders, often resulting in better long-term cost benefits. |

| Component Quality | Quality can vary widely as the platform hosts numerous vendors, some of which may not adhere to strict manufacturing standards. Requires careful vendor selection and verification. | Generally higher and more consistent component quality, as direct suppliers typically adhere to stringent quality control processes. This leads to fewer defective parts and reduced risk. |

| Lead Times | Can be shorter for readily available components due to inventory at multiple vendors, though it can be unpredictable if components are not in stock. | May have longer lead times due to production schedules, but allows for better predictability and project planning. |

| Order Flexibility | Offers high flexibility in terms of small order quantities and numerous component choices, making them ideal for prototypes and small projects. | More rigid in terms of minimum order quantities (MOQs). However, they offer more flexibility in terms of customization and order changes for larger projects. |

| Customer Service | Customer service is often limited and varies between vendors. Issue resolution can sometimes be delayed and complex. | Typically offers more direct and personalized customer service. Building relationships can lead to more dedicated support. |

| Quality Control | Quality control is variable, with no direct control over the manufacturing processes. Risk of counterfeit or substandard parts is higher. | Direct suppliers provide a direct line of sight into the production process, allowing for tighter quality control and reducing the risk of receiving non-conforming parts. |

| Geographical Presence | Often has a wide geographical reach with suppliers located globally, offering a larger selection of parts. | Geographic presence may be more localized to certain production regions, impacting shipping time and costs. |

| Certifications and Compliance | Certifications and compliance may vary from vendor to vendor, requiring diligence on the buyer's part to ensure adherence to industry standards. | Direct suppliers typically provide clear certifications and compliance documents, streamlining the approval process. |

| Logistical Advantages | Online platforms are generally easy to navigate and offer efficient purchasing and order tracking. | Direct suppliers often provide logistical support, particularly for large or complex shipments. |

Frequently Asked Questions About PCB Component Suppliers

This section addresses common questions about PCB component suppliers, providing clear, concise answers to aid in your sourcing process. Understanding these key aspects will ensure you choose the right suppliers for your needs and navigate the complexities of the electronics components market effectively.

- Who are some of the largest PCB component suppliers globally?

Identifying the 'biggest' can be complex as it depends on various factors like revenue, product range and geographical reach. However, some of the largest global PCB component suppliers include companies such as Arrow Electronics, Avnet, and Digi-Key. These companies have extensive inventories and established supply chains. - Which PCB manufacturers are considered to produce the highest quality boards?

Determining the 'best' PCB manufacturer is subjective and varies based on specific needs and requirements, however, some manufacturers are known for high quality and advanced technology, such as: TTM Technologies, and Murrietta Circuits. Quality is often correlated with certifications, material selection, and rigorous testing processes. - Who actually manufactures the raw PCBs (printed circuit boards)?

PCB manufacturing is a multi-step process often completed by specialized factories that focus on board production such as: Kingboard Chemical Holdings, and Unimicron Technology Corp. Some component suppliers offer board assembly, but many rely on these manufacturers for the base circuit boards. - Is there a current shortage of PCB components, and what is the future outlook?

Supply chain issues and component shortages are common in the industry. The situation fluctuates, influenced by global events and market dynamics. Staying informed through industry news and building flexible sourcing strategies can help mitigate risks. While the market can be volatile, current information suggests that component shortages are easing but should be monitored closely. - What are the key factors to consider when comparing different PCB component suppliers?

Key factors include the supplier's component quality, pricing, lead times, certifications, and overall reliability. Additionally, assess their customer service, geographical presence, and reputation within the industry. A supplier's ability to offer consistent quality and on-time delivery is crucial for a successful partnership. - Are there alternatives to using a single primary PCB component supplier?

Yes, diversifying your supply chain can reduce risk. Options include using multiple suppliers, exploring both authorized and independent distributors, and using online marketplaces for certain components. Having alternative sources is important for mitigating supply chain disruptions and shortages. - How can I ensure the quality of components sourced from PCB component suppliers?

Implement a robust quality control process that includes visual checks, functional testing, and adherence to industry standards upon receiving components. Partnering with suppliers who offer certifications such as ISO 9001 can also provide an added layer of quality assurance.

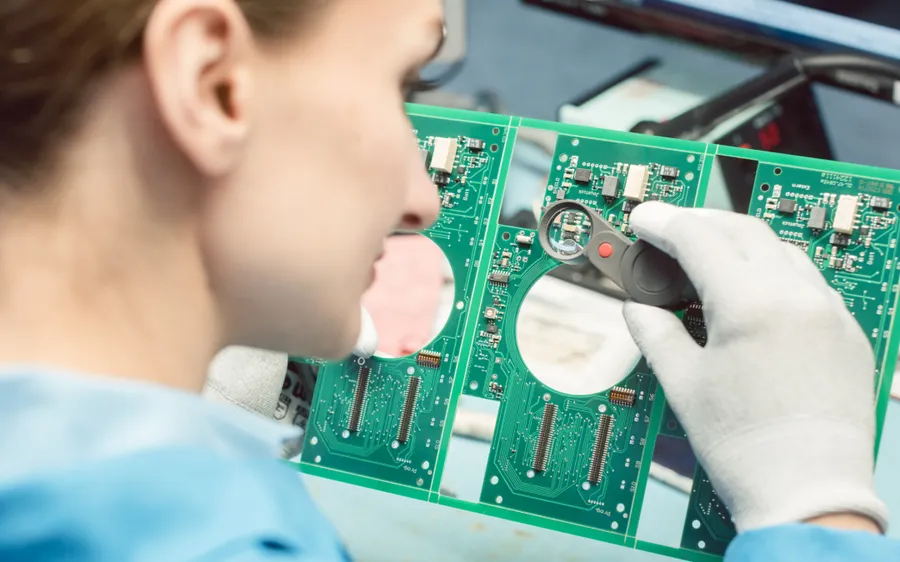

Ensuring Quality Control of Sourced Components

Implementing a robust quality control process for incoming PCB components is paramount to ensuring the reliability and performance of finished printed circuit boards. This process involves a multi-faceted approach encompassing visual inspections, functional testing, and adherence to established industry standards. By rigorously checking components before they are integrated into assemblies, manufacturers can significantly reduce the risk of failures and costly rework.

- Visual Inspection:

Conduct thorough visual checks of components upon receipt. This involves verifying the correct part number, identifying any physical defects like bent leads, cracks, or corrosion, and ensuring that packaging is intact and undamaged. A detailed visual examination at this stage can prevent integration of flawed parts. Use magnifying equipment and consider automated optical inspection(AOI) systems for high-volume and very small components. - Dimensional Verification:

Verify the dimensions of critical components, particularly surface-mount devices (SMDs), using calipers or optical measurement systems. This step ensures that components are within the specified tolerances and will fit correctly on the PCB, preventing assembly issues and malfunctions caused by incorrect sizes. - Functional Testing:

Perform functional testing of components, which includes electrical tests using multimeters, component testers, and more specialized equipment. This confirms that parts meet specifications and perform as intended. For instance, resistors should have the correct resistance, capacitors the correct capacitance, and integrated circuits the correct logic and performance. Conduct sample testing on incoming lots to ensure compliance. - Adherence to Industry Standards:

Ensure that all sourced components comply with relevant industry standards, such as those set by IPC, JEDEC, and IEC. This may include material certifications, lead-free compliances, and other requirements. Following standards ensures the reliability and compatibility of the components with the fabrication process and finished products. Maintain detailed records of these standards. - Material Verification:

For critical components or when sourcing from new suppliers, verify material composition using techniques like X-ray fluorescence (XRF) or other material analysis methods. This confirms that the materials used match the specifications and avoids the use of counterfeit or inferior parts which can cause major failures in the future. Maintain complete chain of custody of your materials. - Documentation and Traceability:

Maintain detailed documentation and traceability for all sourced components. This includes recording the supplier information, date codes, lot numbers, and inspection results. Detailed records will be essential for quality audits, investigations and future root cause analysis. Traceability can also be essential in the case of recalls or other supply chain issues.

By incorporating these quality control measures, manufacturers can significantly reduce the occurrence of component-related failures, minimize rework and increase the overall reliability of their products. A proactive approach to component quality ensures long-term product performance and customer satisfaction.

Building Long-Term Relationships with PCB Component Suppliers

Cultivating robust, long-term relationships with PCB component suppliers is essential for securing favorable terms, ensuring consistent component quality, and establishing a reliable supply chain. These strategic partnerships are pivotal for sustained sourcing success and predictable project timelines, moving beyond transactional interactions towards collaborative alliances.

- Key Benefits of Long-Term Supplier Relationships

Consistent quality, reduced risk, preferential pricing, priority access to stock, and enhanced collaboration opportunities are the main advantages of nurturing robust partnerships with suppliers. - Establishing Mutual Trust and Understanding

Transparency, open communication, and reciprocal understanding are the foundational elements for successful long-term partnerships, moving beyond the typical buyer-seller dynamic. - Strategies for Strengthening Supplier Relationships

Consistent communication, clear performance expectations, collaborative problem-solving, and demonstrating loyalty are vital to building lasting and productive alliances with your suppliers. - Proactive Communication and Feedback

Maintain regular contact with your suppliers through meetings, feedback sessions, and site visits. Sharing production forecasts and being transparent about your needs builds trust and strengthens the relationship. - Collaborative Forecasting and Planning

Work with suppliers to forecast demand accurately and avoid supply chain disruptions. Shared inventory planning can result in lower costs, less waste, and higher supply chain flexibility.

Selecting the right [pcb components suppliers] is crucial for any successful electronics project. By understanding your needs, exploring your options, and employing effective sourcing strategies, you will be empowered to achieve consistent, quality results. This will ensure your projects have the components necessary to function well and help you deliver innovative electronic devices to the market.

AnyPCBA

AnyPCBA