Finding Reliable PCB Manufacturers Near You: A Comprehensive Guide

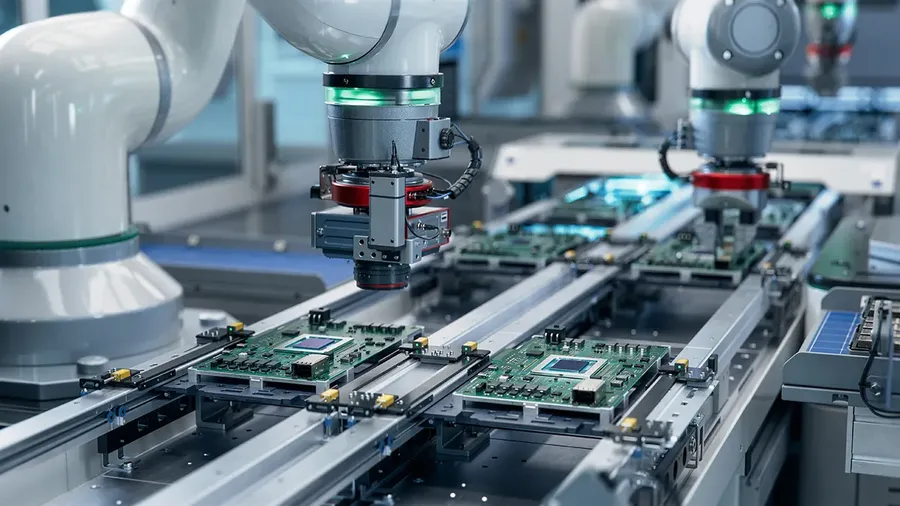

In today's technology-driven world, printed circuit boards (PCBs) are the backbone of almost every electronic device. From smartphones to sophisticated medical equipment, PCBs are essential. But where do you find reliable PCB manufacturers near you? This article explores how to navigate the search and offers a comprehensive guide to finding the best PCB fabrication services, balancing cost, quality, and speed, while also keeping an eye on local [pcb manufacturers near me].

Why Local PCB Manufacturers Matter

Choosing a local PCB manufacturer offers distinct advantages, streamlining the production process and fostering stronger, more responsive partnerships. This approach not only speeds up turnaround times but also significantly reduces logistical complexities and costs, which are critical for projects with tight deadlines or budgets. Local manufacturers are often more attuned to regional requirements and can provide personalized support, crucial for complex or customized PCB designs.

Here is why opting for a local PCB manufacturer can benefit your projects:

- Reduced Lead Times

Local manufacturers can often provide faster turnaround times due to proximity, minimizing shipping delays and enabling quicker prototype development and product launch. - Lower Shipping Costs

Shipping PCBs long distances can be costly, especially for large or heavy orders. Local sourcing reduces these expenses, contributing to an overall lower project budget. - Enhanced Communication and Collaboration

Working with a local manufacturer simplifies communication, allowing for quicker responses to inquiries, clarifications, and design adjustments. This streamlined process reduces misunderstandings and enables quicker problem-solving. - Stronger Business Relationships

Local collaboration fosters stronger, more personal relationships. This can result in enhanced service, better understanding of your needs, and potential long-term partnerships with shared goals and mutual benefits. - Quicker Problem Resolution

In case of issues, having a local partner allows for quicker on-site visits, direct inspections, and expedited troubleshooting, minimizing disruptions and potential costly delays. - Support for Local Economy

Choosing a local PCB manufacturer supports your regional economy and promotes sustainable practices. Investing in local businesses helps to stimulate the growth of your community.

While the benefits of local PCB manufacturing are numerous, it is essential to ensure that your chosen partner can meet your specific technical requirements, quality standards and production volumes. The following sections explore the key factors to consider when evaluating a PCB manufacturer, whether they are local or not.

Online Search Strategies for Finding PCB Manufacturers

Identifying PCB manufacturers in your vicinity requires a strategic approach to online searching. This section details how to effectively leverage search engines and online directories to locate suitable PCB manufacturing partners, specifically expanding on the search term 'PCB manufacturers near me' and guiding you on evaluating the results.

Effective online searches for PCB manufacturers combine targeted keywords with a methodical evaluation process. Begin with broad searches and gradually refine your criteria as you gather information.

- Keyword Optimization:

Start with basic keywords like 'PCB manufacturers near me', 'printed circuit board fabrication [your city/region]', or 'PCB assembly [your city/region]'. Experiment with similar phrasing and consider including specific technology requirements (e.g., 'multilayer PCB manufacturer', 'high-frequency PCB supplier', 'flexible PCB manufacturer'). - Online Directories:

Utilize industry-specific directories and platforms (e.g., Thomasnet, IndustryNet, Alibaba) that categorize manufacturers by location and services. These platforms often feature detailed company profiles, including their capabilities, certifications, and contact information. These are useful for making an initial comparison. - Mapping Tools:

Leverage mapping tools (e.g., Google Maps, Bing Maps) by searching for 'PCB manufacturers' in your region. This provides a visual representation of potential providers and can reveal manufacturers not listed in directories.

After your initial search, critically assess the top results. This evaluation process will ensure you select a manufacturer that not only meets your location requirement but also your technical and business needs.

- Website Review:

Check for a professional and informative website. Pay attention to the 'About Us' page, service offerings, manufacturing capabilities, and any documented certifications. A high-quality website is often an indicator of a reputable business. - Geographic Proximity Verification:

While 'near me' is in the search query, verify the physical location of the manufacturer through the address on the website or mapping tools to ensure the provider is truly local. - Initial Contact and Assessment:

Engage with the potential manufacturer via phone or email. Ask for a brief introduction, specific information about their capacity and processes, and request sample boards or a tour of their facilities if possible. This provides a chance to quickly evaluate compatibility. - Check for Customer Reviews:

Look for independent reviews on platforms like Google Reviews, Yelp, or industry forums. These can provide insight into the manufacturer's reliability, communication, and product quality. However, always approach online reviews with caution and note patterns.

Key Factors to Consider When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is crucial for ensuring the success of your electronic projects. This decision should be based on a comprehensive evaluation of several key factors that align with your project's specific requirements and long-term goals. Ignoring these factors can lead to costly delays, substandard products, and ultimately, project failure.

Here are some essential factors to consider when evaluating potential PCB manufacturers:

- Production Capabilities

Assess the manufacturer's ability to produce the types of PCBs you need (single-sided, double-sided, multilayer, flexible, rigid-flex). Consider their capabilities for handling different board sizes, layer counts, and trace widths, ensuring they can meet your technical specifications. - Material Selection

Inquire about the range of materials offered (e.g., FR-4, Rogers, aluminum). The choice of material affects the board's electrical performance, thermal properties, and mechanical strength. Ensure the manufacturer stocks materials compatible with your application’s requirements. - Quality Standards and Certifications

Verify if the manufacturer adheres to relevant industry standards (e.g., IPC standards) and possesses certifications (e.g., ISO 9001, UL). These certifications indicate a commitment to quality management and process control. Confirm compliance through documentation or third-party audits. - Cost Considerations

Obtain detailed quotes, comparing the cost of manufacturing across different manufacturers. However, don't focus solely on the lowest price; evaluate cost alongside quality and other key factors. Understand any additional costs such as tooling, setup, and expedited shipping to get a complete cost picture. - Turnaround Time

Confirm the manufacturer's average lead times and their ability to handle rush orders. Align delivery timelines with your project schedule, especially for time-sensitive projects. A good manufacturer will provide realistic timelines and stick to them. - Customer Reviews and Reputation

Check the manufacturer's reputation by reading online reviews, testimonials, and case studies. Look for patterns of consistent quality, good communication, and adherence to timelines. Contacting previous customers can also give insights into their service and reliability. - Communication and Support

Assess how responsive the manufacturer is during the quote and design review process. Effective communication and good customer support are essential for quick resolution of issues and smooth project execution. Make sure they have engineering staff readily available to answer technical queries.

Carefully considering these factors when choosing a PCB manufacturer significantly reduces the risks associated with PCB manufacturing. A well-informed choice results in higher quality PCBs, reduced costs, and timely project completion.

Understanding PCB Manufacturing Capabilities

Understanding the diverse manufacturing capabilities required for different Printed Circuit Board (PCB) types is critical for any electronics project. This section details various PCB constructions and associated manufacturing processes, ensuring you select a manufacturer that meets your project's specific needs, including surface finishes and plating techniques.

PCBs are not a one-size-fits-all product; each type presents unique challenges and necessitates specific manufacturing processes. Selecting a manufacturer with the right expertise and equipment for your specific PCB type is essential for a successful project outcome.

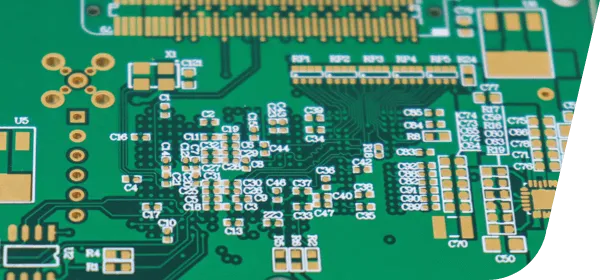

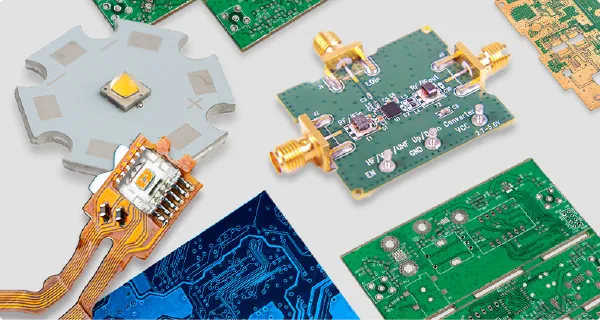

Below are the main types of PCBs and an explanation of their construction and typical uses:

- Single-Sided PCBs

These PCBs have conductive layers only on one side, making them the simplest and most cost-effective option, suitable for basic electronic circuits. - Double-Sided PCBs

With conductive layers on both sides, these allow for more complex circuits and increased component density. They are ideal for intermediate electronic applications. - Multilayer PCBs

Consisting of three or more conductive layers, these are utilized for complex and dense electronic designs. They offer the highest component density and are used in advanced devices. - Flexible PCBs

Constructed using flexible substrates, these PCBs can bend and twist, making them ideal for applications requiring space-saving or dynamic movement, often found in medical devices and wearables. - Rigid-Flex PCBs

These combine rigid and flexible areas within the same PCB, allowing for highly complex designs with mechanical versatility, often utilized in applications requiring robust connections with flexible areas.

Beyond the basic PCB types, the quality and functionality are highly dependent on the materials, surface finish, and plating techniques. These choices directly impact the PCB's performance and long-term reliability.

| Surface Finish | Description | Typical Applications |

|---|---|---|

| HASL (Hot Air Solder Leveling) | Traditional finish using a molten solder coating. Cost-effective, but not as flat as other options. | General purpose electronics, high-volume applications. |

| ENIG (Electroless Nickel Immersion Gold) | Nickel layer followed by a thin gold layer. Excellent solderability and flat surface. | Fine pitch components, wire bonding, high reliability applications. |

| Immersion Tin | Tin layer with good solderability and lower cost than ENIG, however can grow whiskers. | Consumer electronics, cost sensitive applications. |

| OSP (Organic Solderability Preservative) | Organic coating that protects the copper surface during storage and assembly. Cost-effective and good solderability. | Low cost electronics, non-critical applications |

Plating techniques are critical in the PCB manufacturing process. Common methods include electrolytic plating and electroless plating which are used to apply copper to create conductive layers. For connector areas and edge connections, gold or other precious metals are used to improve conductivity and durability.

It's crucial to discuss your specific manufacturing needs with any prospective PCB manufacturer to ensure they possess the equipment and expertise for your specific type of PCB, surface finish, and plating requirements. Matching these capabilities to your design goals is fundamental to a successful product launch.

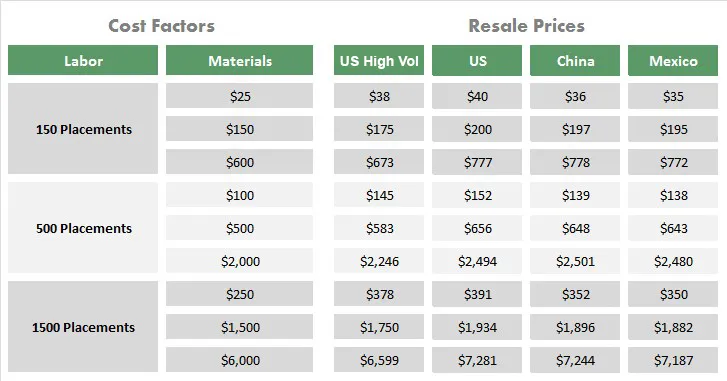

Cost Analysis: Balancing Price and Quality

Understanding the cost drivers in PCB fabrication is crucial for making informed decisions that balance budget constraints with the required quality and performance of your printed circuit boards. This section breaks down these cost factors and offers strategies for optimizing your expenditures without sacrificing quality.

Several factors influence the total cost of PCB fabrication. These can be broadly categorized into design parameters, material choices, manufacturing processes, and order specifics.

- Design Complexity

The number of layers, trace widths, via sizes, and the overall complexity of the circuit design directly impact manufacturing difficulty and cost. High-density designs with fine features usually incur higher expenses due to specialized equipment and more precise manufacturing processes. - Material Selection

The choice of base materials (such as FR-4, Rogers, or polyimide) and surface finishes (e.g., ENIG, HASL, OSP) significantly affects cost. High-performance materials suitable for high-frequency or high-temperature applications are generally more expensive. - Manufacturing Processes

The specific techniques needed for production, such as drilling, plating, and etching, influence costs. For example, blind and buried vias require complex and more expensive techniques. Also, the level of automation used in the fabrication process affects pricing. - Quantity and Order Specifications

Larger production runs generally have lower per-unit costs because manufacturers can amortize their setup costs over a larger volume. The inclusion of special requirements such as impedance control or tight tolerances also impacts cost.

While cutting costs may seem appealing, it's important not to sacrifice the quality of the final product. Here are tips to manage costs without compromising quality.

- Optimize Design

Careful design planning and review can minimize design complexity. Consider design for manufacturing (DFM) guidelines to avoid costly manufacturing processes. For example, maximizing the use of through-hole vias and standard trace widths and spacing can lower costs. - Material Choice Rationalization

Select materials that meet your project requirements without excessive overhead. If high-performance materials are not essential for your application, using standard materials like FR-4 for general purpose applications may offer a cost effective solution. - Negotiate and Compare

Obtain quotes from multiple manufacturers and compare pricing. Also, look for manufacturers that have a good balance of price and quality. Long-term partnerships with manufacturers can often result in better pricing. - Batching and Volume Orders

If possible, consolidate multiple prototypes or production runs to take advantage of volume discounts. Also, planning production well in advance allows for less expensive standard lead times instead of express services. - Panelization

Where possible, work with your manufacturer to panelize your design, to reduce manufacturing costs.

By diligently assessing these cost factors and implementing the outlined strategies, you can achieve a cost-effective PCB fabrication process while ensuring the quality and reliability of your boards. It's a delicate balance that requires a comprehensive understanding of design choices and manufacturing possibilities.

| Cost Factor | Impact on Cost | Cost-Saving Strategy |

|---|---|---|

| Layer Count | Higher cost with more layers | Optimize design; use fewer layers when possible |

| Material Type | Specialized materials increase cost | Choose standard materials when applicable |

| Via Types | Blind/buried vias increase cost | Use standard through-hole vias when possible |

| Order Quantity | Lower cost per unit with larger quantities | Batch multiple orders or increase volume |

| Surface Finish | Special finishes increase cost | Use standard HASL or OSP when applicable |

Turnaround Time: Understanding Lead Times and Rush Services

Turnaround time, or lead time, in PCB manufacturing refers to the period from when a design is submitted to a manufacturer until the finished boards are ready for delivery. Understanding the factors influencing this timeline is crucial for project planning, and choosing between standard and expedited services. This section aims to clarify how various elements impact PCB production lead times and when rush services are most beneficial.

Several variables affect the turnaround time of PCB production:

- Design Complexity

Intricate designs with multiple layers, fine traces, or unique features demand more time for processing and fabrication. - Material Availability

Specific or non-standard materials can lead to delays if they are not readily available in stock. - Manufacturing Capacity

The manufacturer's current workload and capacity to handle new orders affect production timelines. - Order Quantity

Larger orders typically require more time for production than smaller batch sizes. - Surface Finish and Plating

Different surface finish and plating requirements add additional processing steps and potentially extend lead times. - Post-processing

If specific post-processing steps like special testing, or custom packaging are requested, this may add additional time.

Standard lead times can vary significantly across different manufacturers and project specifications. Quick-turn and express services are designed for situations when a fast turnaround is a priority. However, these options usually come with a premium price and may have limitations.

| Service Type | Typical Lead Time | Cost | When to Use | Limitations |

|---|---|---|---|---|

| Standard Service | 1-4 weeks | Standard | Most regular projects with flexible timelines | Longer lead times, may not meet tight deadlines |

| Quick-Turn Service | 3-10 business days | Higher than Standard | Projects with urgent needs, prototype verification | Potential limitations on complex designs, higher cost |

| Express Service | 1-3 business days | Highest | Critical projects requiring the shortest turnaround time possible | Limited design complexity, smallest batch sizes, highest cost |

Choosing between standard, quick-turn, and express services depends largely on the project requirements, budget, and time constraints. Projects with relaxed timelines can benefit from the cost-effectiveness of standard services, while time-sensitive applications, especially in prototype verification phases, may require express services despite the increased cost. Understanding these trade-offs is essential for efficient project management.

Frequently Asked Questions About PCB Manufacturing and Local Sourcing

This section addresses common queries regarding PCB manufacturing, with a focus on local sourcing advantages and cost considerations. We aim to provide clear and concise answers to assist in your PCB procurement process.

- Where are most PCBs manufactured?

While PCBs are manufactured globally, a significant portion of production occurs in Asia, particularly in China and Taiwan. However, there are many reputable PCB manufacturers in North America and Europe that offer advantages like faster turnaround and localized support. - How much do PCBs cost to make?

PCB costs vary widely depending on complexity, materials, quantity, and manufacturing location. Factors such as layer count, board size, surface finish, and the use of special materials impact pricing. A simple, single-sided board produced in high volume is significantly less expensive than a complex, multi-layer board. - What is a typical PCB pricing structure?

PCB pricing usually includes non-recurring engineering (NRE) costs for setup and tooling, and then a per-unit cost that reduces with volume. Quotes usually consider factors such as panel size, materials, number of layers, complexity, testing requirements, and lead time. Volume discounts are typical. - Who is the best PCB manufacturer near me?

The 'best' PCB manufacturer depends greatly on specific project needs. Consider the manufacturer's capabilities (single-layer, multi-layer, flex), certifications, experience, quality, reviews, turnaround time, and price in relation to your individual requirements. Comparing several manufacturers is advised. - Why is there a PCB shortage?

Global PCB shortages are often due to a confluence of factors including increased demand, supply chain disruptions (such as raw material availability), and geopolitical issues. These factors can impact lead times and pricing, highlighting the benefits of establishing relationships with multiple manufacturers, particularly local options, to mitigate risk. - What are the benefits of using a local PCB manufacturer?

Local PCB manufacturers offer advantages like reduced shipping costs, faster lead times, easier communication, and the ability to build strong relationships. They may also be more responsive to custom requests, and potentially subject to fewer supply chain interruptions. Local presence also allows for more direct quality control oversight. - How do I evaluate a PCB manufacturer's quality?

Assess a PCB manufacturer's quality through several methods: certifications (ISO, IPC), independent quality audits, examining sample boards for build quality, and by reviewing customer testimonials. Look for clear quality management systems and traceability processes in their manufacturing process.

Beyond Price: Evaluating Quality and Reliability

While cost is a significant factor in selecting a PCB manufacturer, the quality and reliability of the boards are paramount for product success. This section explores methods for assessing these crucial aspects, ensuring you partner with a manufacturer capable of delivering dependable PCBs.

Evaluating the quality and reliability of PCB manufacturing extends beyond simple cost comparisons. It requires a detailed look at various factors, from certifications and sample testing to customer feedback and supply chain traceability.

- Certifications and Standards

Look for manufacturers that hold relevant certifications such as ISO 9001, ISO 13485 (for medical devices), or IPC standards. These certifications demonstrate a commitment to quality management and adherence to industry best practices. For instance, IPC-A-600 is a widely used standard that specifies acceptance criteria for printed boards. - Sample Testing and Inspection

Request sample PCBs for testing before committing to a large production run. This enables you to assess the board's adherence to specifications, solderability, and overall build quality. Manufacturers should have robust inspection processes, including automated optical inspection (AOI), to catch potential defects. - Customer Feedback and Reviews

Examine online reviews, testimonials, and case studies related to the PCB manufacturer's services. While no company is immune to occasional negative feedback, look for patterns suggesting consistent issues or positive experiences. Reputable manufacturers often openly display customer feedback and references. - Traceability in the Supply Chain

Understanding the manufacturer's supply chain is essential. Ensure they source high-quality materials from trusted suppliers, maintain records of material batches, and can trace components used in your PCBs. This transparency minimizes the risk of counterfeit parts and potential quality issues. Traceability is usually associated with serial numbers for the raw materials and process steps that are recorded throughout the manufacturing process.

| Evaluation Method | Focus | Benefits | Considerations |

|---|---|---|---|

| Certifications | Adherence to Industry Standards | Demonstrates a commitment to quality practices and process control. | Validate the certifications by checking the issuing body and standard's validity. |

| Sample Testing | Conformance to specifications | Allows a practical evaluation of product quality, performance and physical characteristics before a large order is placed. | Ensure sample size is statistically relevant and testing encompasses the necessary performance criteria. |

| Customer Feedback | Reputation and Reliability | Offers insights into customer experiences and identifies any patterns of issues and inconsistencies. | Consider the sample size of reviews. A single very negative or positive review should not solely determine your assessment. |

| Traceability | Supply Chain Transparency | Provides evidence that the manufacturer has control over the quality of raw materials and the overall supply chain, mitigating risks of counterfeit materials. | Verify if they adhere to regulations (e.g., REACH for materials) and ensure their records are detailed and readily available. |

By thoroughly evaluating these factors, you can significantly mitigate the risks of poor PCB quality and ensure your products are built on a solid foundation of reliable, high-quality components. Do not be hesitant to ask probing questions from a manufacturer about these aspects before making your choice.

Comparative Table of PCB Manufacturers

To facilitate informed decision-making when selecting a PCB manufacturer, this section provides a comparative table. This table highlights key differentiators among various PCB manufacturers, including price, lead time, quality certifications, customer reviews, services offered, and minimum order quantities. The data presented is intended to assist in quickly assessing and comparing potential partners.

| Manufacturer | Price (USD per board) | Lead Time (Days) | Certifications | Customer Reviews (Avg. Rating) | Services Offered | Min. Order Quantity |

|---|---|---|---|---|---|---|

| Manufacturer A | $5.00 - $15.00 | 3-7 | ISO 9001, UL | 4.5/5 | Single-sided, double-sided | 10 |

| Manufacturer B | $8.00 - $20.00 | 5-10 | ISO 9001, ISO 13485 | 4.2/5 | Multilayer, flexible | 1 |

| Manufacturer C | $3.00 - $12.00 | 7-14 | ISO 9001 | 4.0/5 | Single-sided, double-sided, rigid-flex | 50 |

| Manufacturer D | $10.00 - $30.00 | 1-5 | ISO 9001, AS9100 | 4.8/5 | Multilayer, high-density | 1 |

| Manufacturer E | $6.00 - $18.00 | 5-12 | ISO 9001, IPC | 4.3/5 | Multilayer, HDI | 5 |

*Note: This table provides a general overview and data is for illustrative purposes only. Actual prices and lead times may vary based on specific project requirements and order volumes. Customer reviews are based on averages and may vary.*

Finding the right PCB manufacturers near you is crucial for successful electronic projects. By using the strategies and information outlined in this guide, you can confidently navigate the search for reliable and high-quality PCB fabrication services. Whether you are in need of rapid prototyping or mass production, understanding the nuances of PCB manufacturing, especially from providers of [pcb manufacturers near me], will ensure that your project’s foundation is strong and your final product is top-notch. Consider the information shared in this article when making your next selection and feel free to revisit as the market evolves.

AnyPCBA

AnyPCBA