Finding the Best Cheap PCB Manufacturer: A Comprehensive Guide

In today's fast-paced world of electronics, getting your custom PCBs made shouldn't break the bank. Whether you're a hobbyist, a student, or a seasoned engineer, finding a reliable yet affordable PCB manufacturer is crucial. This article dives deep into the landscape of cheap PCB manufacturing, focusing on the best options and practical advice to ensure your projects are both successful and cost-effective, specifically looking at top providers of cheap PCBs like JLCPCB and PCBWay and how to choose the best one for your specific needs.

Understanding Your PCB Needs and Project Requirements

Selecting the optimal PCB manufacturer hinges on a clear understanding of your project's specific requirements. A thorough analysis of your needs, encompassing factors such as board dimensions, layer count, material specifications, production volume, and desired lead times, will enable a more effective selection process.

- Board Dimensions

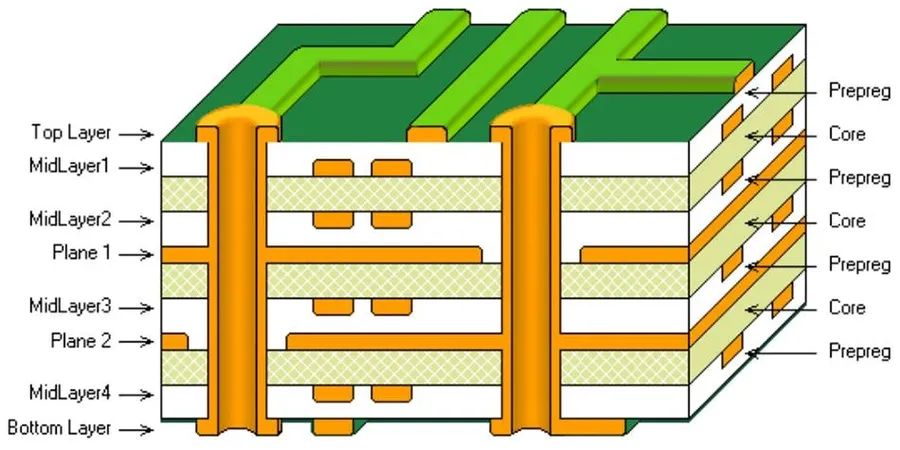

The physical size of your PCB directly impacts cost and manufacturing feasibility. Precise dimensions are crucial for accurate fabrication. - Number of Layers

The complexity of your design dictates the number of layers needed. Single-layer boards are the simplest and cheapest, while multilayer boards offer more routing flexibility but at a higher cost. - Material Specifications

The choice of substrate material (e.g., FR-4, aluminum, polyimide) impacts the PCB's performance, cost, and thermal characteristics. Selecting the correct material is critical for application-specific needs. - Required Quantity

The number of PCBs required will dramatically influence the per-unit cost. Manufacturers offer volume discounts, making large production runs more economical. - Lead Times

Production and shipping times can vary significantly between manufacturers. You must factor in lead times to ensure your project schedule is not compromised. - Special Requirements

Any specific requirements such as impedance control, via type, surface finish, or specific testing needs should also be determined and factored into your selection process.

Top Contenders for Cheap PCB Manufacturing: JLCPCB vs. PCBWay

When seeking cost-effective PCB manufacturing, JLCPCB and PCBWay frequently emerge as industry frontrunners. This section provides an in-depth analysis, comparing their pricing structures, quality benchmarks, service offerings, shipping logistics, and customer support effectiveness to guide your selection process.

| Feature | JLCPCB | PCBWay |

|---|---|---|

| Base Price (Prototype) | Generally lower for small quantities | Slightly higher for small quantities |

| Quality | Consistent, good for general purpose | Consistent, with advanced capabilities |

| Service Range | Broad, with assembly options | Comprehensive, with focus on diverse boards |

| Shipping Time | Variable, generally fast options available | Variable, good express options |

| Customer Support | Responsive, email and online support | Responsive, with more direct contact options |

| Specialization | Strong in prototype and small batch production | Excellent for both prototype and medium/high volume production and complex designs |

Both companies offer a range of services beyond basic PCB fabrication, including PCB assembly (PCBA), stencil production, and design for manufacturing (DFM) checks. JLCPCB excels in rapid prototyping with a user-friendly online platform and competitive pricing for small orders. PCBWay, while often slightly pricier for prototypes, offers a wider array of advanced options and materials, making them suitable for complex projects.

The suitability of each manufacturer will depend on the specific requirements of the project. For hobbyists or those with simple designs and small production volumes, JLCPCB's cost-effectiveness is attractive. For more complex projects, and larger production runs, PCBWay’s robust capabilities often justify the higher price point.

Alternative PCB Manufacturers: OSH Park, Aisler, and AllPCB

While JLCPCB and PCBWay often dominate discussions about low-cost PCB manufacturing, several other reputable providers offer unique advantages and cater to specific user needs. This section explores alternatives such as OSH Park, Aisler, and AllPCB, analyzing their strengths, weaknesses, and suitability for different types of projects.

| Manufacturer | Focus/Target Audience | Price Range | Typical Lead Time | Strengths | Weaknesses |

|---|---|---|---|---|---|

| OSH Park | Hobbyists, small runs, simple boards | Mid-range, generally more expensive per board for larger quantities than JLCPCB/PCBWay | ~10-15 business days | High-quality purple boards, excellent for small runs, easy online order process, open-source friendly | Higher cost for larger orders, limited customization options, longer lead times |

| Aisler | European market, higher-quality prototypes | Mid to high-range, higher cost per board for small runs but may be competitive for larger runs | ~5-10 business days | Focus on quality and European standards, good for quick turn prototypes, efficient European shipping | Higher base cost, potentially limited global reach |

| AllPCB | Wide range of services, variable complexity | Low to mid range, can be competitive with JLCPCB/PCBWay | ~5-10 business days (depending on complexity) | Offers a wide range of capabilities, can handle complex designs, has more customisation options | Quality can be variable, requires careful design review, may require more communication to obtain accurate orders |

While JLCPCB and PCBWay frequently offer the lowest prices for basic PCBs, these alternative manufacturers have their niche. OSH Park, with its distinct purple PCBs, prioritizes quality and ease of use for smaller, simpler projects. Aisler, serving the European market, is often favored for its quick turnaround on prototypes, adhering to strict European standards. AllPCB offers more customization options and can handle more complex designs, however more careful review is required to obtain an accurate and satisfactory result.

Choosing the right manufacturer depends heavily on project specifics, quantity needed, target standards, and required lead times. While the industry giants like JLCPCB and PCBWay cater to the low-cost high-volume space, OSH Park, Aisler and AllPCB offer valuable alternatives. By carefully evaluating these characteristics, engineers and hobbyists can make informed decisions, balancing cost, quality, and speed to achieve their projects goals.

Price Comparison: Understanding Cost Drivers

Understanding the cost drivers in PCB manufacturing is crucial for optimizing your budget. The final price of a PCB is not just the base cost of the board; it is influenced by several interconnected factors. By carefully analyzing these elements, you can effectively minimize expenses without compromising the quality and performance of your PCB.

| Cost Factor | Description | Impact on Price |

|---|---|---|

| Base PCB Price | The fundamental cost of the board, based on size, layers, and material. | Directly proportional to board complexity and materials. |

| Shipping Costs | Expenses related to delivering the finished boards, including courier fees. | Varies by distance, speed, and carrier; can significantly increase total cost, especially for small orders. |

| Setup Fees | Costs for initial preparation, often including tooling and program setup. | A one-time fee which is relatively high for very small orders, but the per-board impact reduces with higher order volumes. |

| Quantity | The number of PCBs in the order. | The per-board price typically decreases with increasing quantity due to economies of scale. |

| Lead Time | The speed at which the PCBs are manufactured. | Expedited manufacturing will typically increase cost. |

| PCB Complexity | Factors like the number of layers, fine lines and spaces, and use of specific materials. | More complex PCBs with more layers, tighter tolerances and unique material specifications will have higher costs. |

| PCB Finish | The surface finish applied to the copper, such as HASL, ENIG, or OSP. | The selected surface finish will have an impact on overall cost, with more advanced finishes being more expensive. |

Strategies to Lower PCB Manufacturing Costs: Consider these methods to reduce your overall expenses: * **Optimize Board Design:** Simplify your design to reduce board size and layer count. Smaller, less complex boards are less expensive to manufacture. * **Panelization:** If ordering multiple small boards, combine them into a panel. This is more efficient for manufacturers, allowing for volume savings, but can increase upfront cost. * **Choose Standard Materials and Finishes:** Opt for common materials and finishes like FR-4 and HASL (Hot Air Solder Leveling), rather than more exotic options like ENIG (Electroless Nickel Immersion Gold). * **Increase Order Quantity:** The per-board cost will decrease significantly as order quantity increases. * **Plan Ahead:** Avoid rush orders by planning and ordering well in advance. * **Compare Shipping Costs:** Evaluate different shipping options to find the most cost-effective solution. * **Reduce Layers:** Lower the number of layers in your board design when possible.

Quality and Manufacturing Standards: What to Expect

Achieving the desired quality in PCB manufacturing hinges on understanding the interplay between various fabrication standards and material choices. Selecting a manufacturer that aligns with your project's specific quality needs is crucial for ensuring functionality and reliability, thereby avoiding costly rework and delays.

| Quality Parameter | Description | Impact |

|---|---|---|

| Dimensional Tolerances | Accuracy of board dimensions and feature placement. | Affects fit into enclosures and component alignment. |

| Layer Alignment | Precision in registration of different board layers. | Critical for multilayer board functionality. |

| Copper Thickness | Specified copper weight and its uniformity. | Impacts current carrying capacity and signal integrity. |

| Solder Mask Accuracy | Precision of solder mask application and registration. | Prevents shorts and ensures proper solder flow. |

| Via Quality | Integrity of plated through holes. | Ensures reliable layer to layer connections. |

| Surface Finish | Type of coating applied to copper pads. | Affects solderability and corrosion resistance. |

| Material Properties | Electrical and mechanical properties of substrate materials (e.g., FR-4, aluminum) | Impacts board performance and durability under different conditions. |

When evaluating PCB manufacturers, consider requesting samples or test boards to verify the quality standards they can achieve. Ensure that the manufacturer is compliant with relevant industry standards such as IPC (Association Connecting Electronics Industries) which outlines standards for acceptable quality in PCB manufacturing. Pay particular attention to their capabilities regarding specific tolerances, materials, and finishes that are crucial for your project, and always ensure you communicate these requirements clearly.

Shipping and Lead Times: Planning for Delivery

Efficient project planning necessitates a clear understanding of shipping options and lead times from your chosen PCB manufacturer. These factors directly impact project timelines, costs, and overall feasibility, requiring a thorough evaluation of the manufacturer's logistics capabilities, shipping speed, and the impact of geographical location and global events on delivery schedules.

| Manufacturer | Typical Shipping Options | Typical Lead Time (Production) | Typical Lead Time (Shipping) | Notes |

|---|---|---|---|---|

| JLCPCB | DHL, FedEx, UPS, Aramex | 2-7 days | 3-10 days | Production time varies by complexity and quantity. Shipping time is dependent on the service chosen and destination. |

| PCBWay | DHL, FedEx, UPS | 3-10 days | 3-10 days | Production time can vary based on board complexity and specifications. Similar shipping times to JLCPCB. |

| OSH Park | USPS | 10-15 days | 2-5 days | Focus on quality over speed with longer production. Primarily ships to US and Canada. |

| Aisler | DHL | 5-10 days | 2-7 days | European focused, may have shorter shipping times for European customers. Production times a little longer. |

| AllPCB | DHL, FedEx, UPS | 3-8 days | 3-10 days | Production and shipping times similar to major competitors. |

- Expediting Orders

Many manufacturers offer expedited shipping options (e.g., express shipping) at an additional cost. If project timelines are tight, this could be a worthwhile investment. Communicate with your manufacturer about your timeframe requirements. - Manufacturer Location Impact

Manufacturers based overseas may offer lower base prices but could entail longer shipping times, potential customs delays, and increased shipping costs compared to domestic providers. Local manufacturers may offer faster shipping with higher per-unit prices. - Global Factors

Global events like holidays, supply chain disruptions, and pandemics can significantly impact production and shipping times. Check for updates and communicate with the PCB manufacturer and be prepared for potential delays by planning ahead and building extra time into the project schedule

Frequently Asked Questions About Cheap PCB Manufacturing

Navigating the world of cheap PCB manufacturing can raise numerous questions for both seasoned engineers and hobbyists. This section addresses common inquiries, providing concise, technically grounded answers to help you make informed decisions.

- What is the absolute cheapest PCB finish available?

The cheapest PCB finish is typically HASL (Hot Air Solder Leveling), which uses a lead-based or lead-free solder to coat exposed copper. While effective for solderability and cost, it has the disadvantage of uneven surface thickness, which can be an issue for fine-pitch components and surface mount technologies (SMT) especially below 0.5mm pitch. - How can I effectively reduce my PCB manufacturing costs?

To reduce PCB manufacturing costs, consider these key factors: minimize board layers (stick to 1 or 2 layers if possible), use standard materials like FR-4, avoid complex geometries and tight tolerances, utilize readily available components, and design for manufacturability (DFM) rules, and, most importantly, consolidate your projects for batch manufacturing when feasible. Increasing your order quantity usually reduces the per-unit cost. Also, consider panelizing your designs to maximize fabrication panel utilization. - Which PCB manufacturer offers the best overall value?

The 'best' manufacturer depends on project needs. JLCPCB and PCBWay are often cited for excellent price and services for small to medium sized projects. However, for very specialized needs or extremely quick turnaround, other manufacturers such as OSH Park might offer better solutions despite higher prices. Consider comparing your exact requirements against their capabilities to make an educated choice. There is no single 'best' manufacturer. Consider also delivery time, services offered, and quality requirements. - Are there any reliable PCB manufacturers offering free samples?

While some manufacturers might offer promotional discounts or limited-time deals, finding completely free PCB samples is rare due to the material and labor costs involved. However, some manufacturers offer initial discount coupons to first-time users and might have student programs that provide reduced costs. Keep a close eye on special promotions, also review manufacturers' website FAQ page to look for special offers. - What are the key factors that influence PCB pricing?

Several factors affect PCB costs, including the number of board layers, the complexity of the design (e.g., the number of vias, track width, and spacing), materials used (e.g., FR-4 vs. high Tg materials), surface finish, the chosen solder mask color, copper thickness, panel size, quantity of boards ordered, and the manufacturer's base pricing. All of these should be considered when optimizing for price. - What is the standard material used for low-cost PCBs and what are its limitations?

The most common and standard material used for cost effective PCB fabrication is FR-4, a glass-reinforced epoxy laminate. While FR-4 offers an excellent balance of cost, mechanical strength, electrical insulation, and resistance to environmental degradation, it does have limitations. Its thermal performance is typically not suitable for high-temperature applications, having a typical maximum operational temperature between 130-170 degrees Celsius, and it's dielectric constant varies with frequency. For high-frequency applications, such as RF circuits, high-performance materials with more stable dielectric properties should be used. For higher temperature applications, higher Tg (glass transition temperature) FR-4 variants should be considered. - How can I avoid common mistakes when ordering cheap PCBs?

Common errors when ordering PCBs include: incorrect Gerber file generation, not adhering to Design For Manufacturing rules and design specifications of the manufacturer, not double checking your bill of materials (BOM) before ordering assembly, choosing the wrong surface finish or solder mask for your needs, and failing to specify the required tolerances. Thoroughly verify all of these before placing your order to prevent delays and additional costs. Always communicate with the manufacturer if in doubt.

Tips for Getting the Most Out of Your PCB Order

Maximizing the value of your PCB order involves careful preparation, a clear understanding of the manufacturing process, and proactive measures to prevent errors and control costs. By optimizing your design, adhering to manufacturer guidelines, and employing smart ordering strategies, you can achieve high-quality boards while staying within budget.

- Prepare Your Design Files Meticulously

Ensure all Gerber files, drill files, and any other required documentation are accurate and complete. Double-check layer alignments, clearances, and pad sizes. Use the manufacturer's design rule check (DRC) tools to identify potential issues before submitting your order. - Optimize Your PCB Design for Manufacturing

Design your PCB with manufacturability in mind. Consider panelization to reduce costs on larger production runs. Use standard component footprints, adhere to recommended via sizes, and space components to facilitate automated assembly. - Choose the Right Materials and Specifications

Select materials and specifications based on the application and environment. Understand the implications of different PCB thicknesses, copper weights, solder mask colors, and surface finishes on your design’s performance and cost. - Understand the Manufacturer's Capabilities and Limitations

Each manufacturer has specific capabilities and limitations. Before placing an order, review their specifications for minimum trace widths, via sizes, and other parameters. Design within these guidelines to avoid production delays or errors. - Review the Order Details Thoroughly

Before finalizing your order, meticulously review all specifications, quantity, delivery options, and costs. Correct any discrepancies or omissions to avoid surprises after the boards are manufactured. - Consider Panelization for Cost Efficiency

For multiple identical boards, request panelization from the manufacturer or design your own. This can lead to significant reductions in costs during the manufacturing process, particularly for larger production runs. - Use Standard Components and Footprints

Employ standard component footprints whenever possible. Custom footprints require additional work and could lead to delays, increased costs, or misalignments. Maintain a consistent and accurate component library.

Future Trends in Affordable PCB Manufacturing

The landscape of affordable PCB manufacturing is continuously evolving, driven by technological advancements and market demands. Anticipating these trends is crucial for both manufacturers and consumers to optimize cost-effectiveness and leverage new capabilities.

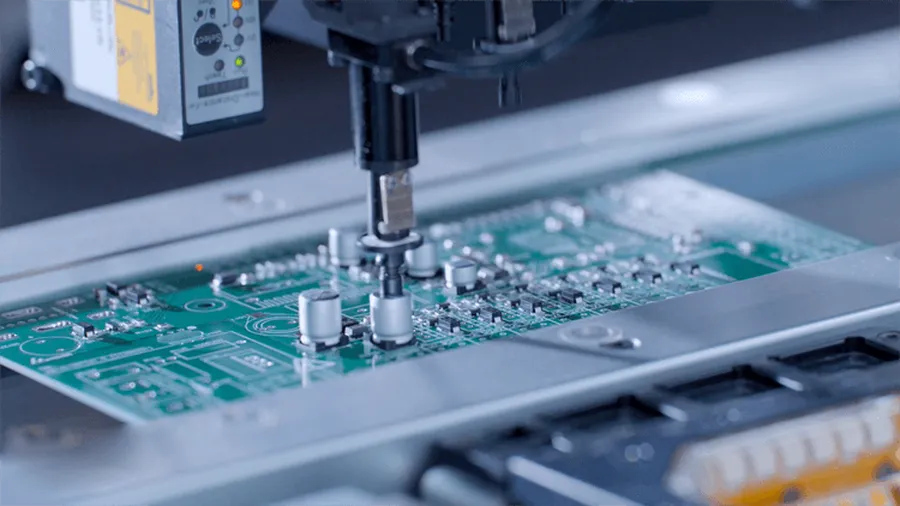

- Automation and Artificial Intelligence (AI)

Increased automation through robotics and AI is streamlining PCB production, leading to reduced labor costs and higher manufacturing speeds. AI-driven systems can also optimize layout, reduce material wastage, and improve quality control. - Advanced Materials

Research into novel PCB materials is opening new possibilities for higher performance and cost savings. This includes alternatives to traditional FR-4, such as flexible substrates, eco-friendly materials, and composites with better electrical and thermal properties. - 3D Printing of PCBs

Additive manufacturing, or 3D printing, is emerging as a promising technology for rapid prototyping and small-batch PCB production. This method offers significant flexibility in design and faster turnaround times, especially for complex designs and customized boards. - Cloud-Based Design and Collaboration Platforms

The integration of cloud-based tools is facilitating seamless design, manufacturing, and collaboration. These platforms offer real-time design review, access to standardized component libraries, and efficient order management, leading to better communication and reduced errors. - Increased Focus on Sustainability

Environmental consciousness is driving the development of more sustainable manufacturing processes and materials, including recycling programs and the use of non-toxic chemicals. This reduces the environmental impact of PCB production and potentially provides cost benefits through better resource management. - Global Supply Chain Optimization

Manufacturers are optimizing supply chains to improve logistics and minimize the impact of global trade fluctuations. This is done through diverse supplier networks and strategic warehousing, allowing for reduced lead times and more predictable costs. - Standardization of Processes and Data

The adoption of universal standards for PCB design, manufacturing data, and communication is improving compatibility between design tools, fabrication processes, and suppliers. This can result in smoother and faster order processing with fewer discrepancies and costs.

Finding the best cheap PCB manufacturer involves balancing cost, quality, and delivery time. While JLCPCB and PCBWay stand out for their competitive pricing and comprehensive services, exploring other options can also be advantageous. Remember, careful planning and understanding your project's specific requirements are crucial for making informed decisions. Choosing the right partner like JLCPCB or PCBWay will enable you to bring your innovative ideas to life without breaking the bank. Keeping an eye on the future of PCB manufacturing will further enable you to be at the leading edge of electronic prototyping and mass manufacturing.

AnyPCBA

AnyPCBA