Finding the Best Prototype PCB Manufacturer: A Comprehensive Guide

In today's fast-paced electronics industry, rapid prototyping is essential. Choosing the best prototype PCB manufacturer can be the key to success, impacting time-to-market, product quality, and cost. Whether you’re a hobbyist or an experienced engineer, understanding the nuances of PCB fabrication is crucial. This article guides you through selecting the best prototype PCB manufacturer, providing insights into what to look for and which manufacturers stand out. By combining industry expertise with user needs, we are able to help you make a perfect choice.

Key Factors in Choosing a Prototype PCB Manufacturer

Selecting the right prototype PCB manufacturer is crucial for the success of any electronic project. This decision hinges on a careful evaluation of several key factors, each impacting the final product's quality, cost, and time-to-market. Balancing these factors according to specific project requirements is essential for optimal outcomes.

The following are key considerations to ensure the chosen manufacturer aligns with your project needs:

- Fabrication Capabilities

Assess the manufacturer's ability to produce PCBs that meet your design specifications, including layer count, minimum trace width and spacing, hole sizes, and supported materials. Advanced designs may require specialized processes or equipment. - Material Quality

The quality of materials used in PCB fabrication directly affects the board's performance and reliability. Ensure the manufacturer uses materials that meet industry standards and your specific application requirements, such as FR-4 for general use, or higher-performance materials for demanding applications. - Turnaround Time

Turnaround time is crucial, especially for prototyping stages. Compare manufacturers' lead times for fabrication and consider if they offer expedited services for rapid prototyping. The ability to quickly iterate designs can significantly shorten the product development cycle. - Cost

Evaluate the total cost of PCB fabrication, including initial setup fees, per-board prices, tooling costs, and any additional charges. Find a manufacturer that offers the best balance of cost and quality that fits your project's budget constraints. - Customer Service

Responsive and knowledgeable customer service can be invaluable, especially when dealing with complex designs or production issues. Assess the manufacturer’s accessibility and readiness to provide technical assistance. - Geographic Location

Geographic location impacts shipping costs, delivery times, and communication convenience. Manufacturers closer to your location may offer faster turnaround times and easier communication. Consider whether domestic or international manufacturing best aligns with your project.

Top PCB Manufacturers for Hobbyists

For hobbyists embarking on electronics projects, selecting the right PCB manufacturer is pivotal for success. This section highlights manufacturers known for their affordability, ease of use, and ability to accommodate smaller orders, making them ideal for the hobbyist community. These manufacturers often provide user-friendly design tools and cater to the needs of low-volume production.

- JLCPCB

JLCPCB is a popular choice among hobbyists due to its low cost and relatively fast turnaround times. They offer a wide range of options, including different board thicknesses and copper weights. Their online platform is user-friendly, and they provide a range of services, from basic PCB fabrication to assembly. The ability to order small quantities makes it attractive for prototyping and hobby projects. - ALLPCB

ALLPCB is another manufacturer that has gained popularity among hobbyists. Similar to JLCPCB, they offer competitive pricing and are geared towards smaller production runs. They provide a streamlined ordering process and various material options, making it easy for hobbyists to translate their designs into physical boards. They also offer assembly services which is useful for more complex projects. - OSH Park

OSH Park is unique in its approach, offering a shared-manufacturing model that pools orders to reduce costs. While turnaround times may be longer than some manufacturers, they are known for their high-quality boards and unique purple solder mask. OSH Park is particularly suitable for hobbyists who value quality over speed and don't mind waiting a bit longer for their boards.

| Manufacturer | Affordability | User-Friendliness | Small Order Support | Specialization |

|---|---|---|---|---|

| JLCPCB | Very Affordable | User-Friendly Online Platform | Excellent | Low-cost prototypes |

| ALLPCB | Affordable | Streamlined Process | Good | Small to Mid-size Projects |

| OSH Park | Moderate | Simple, Collaborative Model | Good | High-Quality Boards |

Leading PCB Manufacturers in the USA

For projects requiring domestic production, several leading PCB manufacturers in the United States offer high-quality fabrication and assembly services. These companies often provide a balance of advanced technologies, reliable lead times, and responsive customer support, catering to both prototyping and large-scale production needs.

Here's a closer look at some of the key players:

- Advanced Circuits/4pcb.com

Known for its extensive capabilities and quick-turn services, Advanced Circuits is a popular choice for prototypes and small to medium production runs. They offer a wide range of materials and surface finishes, and are particularly noted for their easy-to-use online quoting and ordering system. Their strength lies in their ability to handle complex designs with tight tolerances. Typical lead times can range from a few days for expedited services to a couple of weeks for standard production. - Sunstone Circuits

Sunstone Circuits offers a comprehensive suite of PCB services, including design software, prototyping, and full-scale production. They are recognized for their commitment to quality and excellent customer support. Sunstone offers a variety of specialty services such as extended material and stack up options and has a strong focus on delivering reliable PCBs within tight deadlines. Typical lead times can be 1-2 weeks for standard PCBs. - Bay Area Circuits

Bay Area Circuits is a versatile PCB manufacturer specializing in high-quality prototypes and small to medium production runs. They are well-regarded for their engineering expertise and ability to handle challenging designs with a quick turnaround. They also provide in-house assembly services. Their expertise extends to rigid, flexible, and rigid-flex PCB production. Typical lead times are typically between 5-10 business days, depending on complexity and quantity.

When selecting a U.S.-based manufacturer, consider the specific needs of your project, including the complexity of the design, required materials, quantity, and turnaround time. While U.S. manufacturers may have slightly higher costs compared to their overseas counterparts, they often provide advantages in terms of communication, quality control, and shorter lead times, which can be critical for certain projects.

Global PCB Manufacturing Powerhouses

Several PCB manufacturers have established a significant global presence, providing cost-effective and rapid prototyping services. These companies leverage large-scale production facilities and efficient supply chains to deliver PCBs quickly and affordably to customers worldwide. Key players in this sector include JLCPCB, PCBWay, and AllPCB, each with unique strengths in terms of manufacturing capabilities and service offerings.

These manufacturers often excel in handling high-volume orders while also catering to smaller prototype runs, making them attractive options for both large enterprises and smaller-scale projects. Their global footprint allows them to offer competitive pricing, and their streamlined processes typically result in faster turnaround times compared to more localized manufacturers. The following sections detail a breakdown of each company.

- JLCPCB

JLCPCB stands out for its highly automated manufacturing process, which enables very competitive pricing and fast turnaround times, often within 24 hours for certain services. They are particularly popular for their extensive range of fabrication options and low-cost entry point for prototypes. JLCPCB's user-friendly online platform and support for various file formats make them accessible to a broad user base. They offer PCB assembly services as well, allowing for a streamlined turnkey solution. Their capabilities extend from simple single-layer boards to more complex multi-layer designs. - PCBWay

PCBWay has gained recognition for its comprehensive services, including not just PCB manufacturing but also PCB assembly, SMT stencils, and CNC machining. They provide a robust platform that allows customers to manage their orders, track progress, and access technical support. PCBWay’s production facilities are equipped to handle a variety of materials and specifications, which gives them a competitive edge in the market. PCBWay tends to have slightly higher costs compared to JLCPCB but they often provide more manufacturing flexibility and additional engineering services such as design rule checking and quality control. - AllPCB

AllPCB is another major global player that leverages its manufacturing capabilities to deliver fast turnaround times and cost-effective PCB production. They have a customer-focused approach and offer real-time tracking of orders. AllPCB supports a wide array of PCB types, including single-layer, double-layer, and multilayer boards, catering to diverse project requirements. They emphasize reliable delivery and a commitment to customer satisfaction. While AllPCB is often compared to JLCPCB and PCBWay, they sometimes offer different specializations in materials and rapid prototyping services.

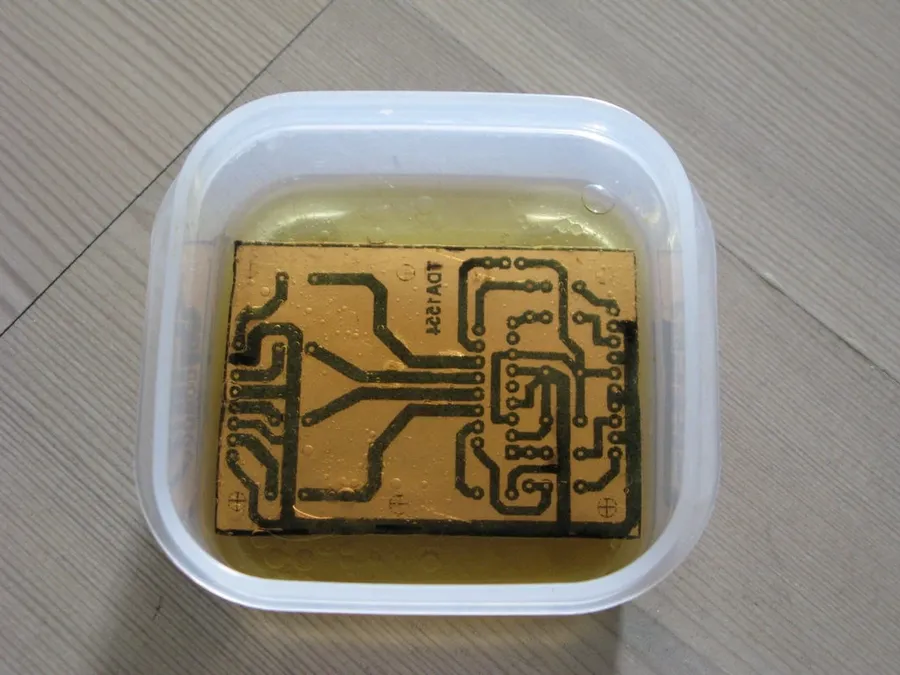

Turnaround Time and Rapid Prototyping for PCBs

Rapid prototyping is crucial for accelerating product development cycles, and the turnaround time offered by PCB manufacturers is a key factor in achieving this. Quick turnaround allows for faster design iterations, enabling engineers and designers to test and refine their products more efficiently, and getting to market faster.

Different manufacturers offer various expedited services, but understanding the implications of each is important. These services can dramatically reduce the time from design submission to having a physical board in hand. However, the level of expedition that the manufacturer is capable of, may impact other key factors such as cost.

This section delves into how manufacturers handle the different demands of rapid prototyping.

- Standard Turnaround Times

Most manufacturers provide a standard lead time, which can range from a few days to a couple of weeks, depending on the complexity of the PCB and the manufacturer's workload. This option is typically the most cost-effective, but is not ideal for rapid iterations. - Expedited Services

Many manufacturers offer expedited services to significantly reduce lead times. This is usually achieved through prioritised production, and may come with an additional cost. Some manufacturers, such as JLCPCB and PCBWay, are well-known for their ability to offer fast turnaround options. - 24-Hour Options

Certain manufacturers, like those focused on rapid prototyping, offer 24-hour turnaround options. These are typically limited to less complex designs and materials, and carry a premium cost. These services are useful for quickly testing a single iteration in a quick and efficient manner. - Impact of Complexity

The complexity of a PCB design can significantly affect turnaround times, irrespective of whether it is a standard or expedited service. Factors like layer count, special materials, and fine pitch components can add time to the manufacturing process. - Considerations

When selecting a manufacturer and service, consider both cost and turnaround times that are necessary for project development cycles.

Cost Considerations and Budgeting

Understanding the cost implications is crucial when selecting a prototype PCB manufacturer. This involves evaluating various factors beyond just the per-board price, such as initial setup fees, tooling costs, and potential expenses for expedited services. Proper budgeting ensures project feasibility and prevents unexpected financial burdens.

- Initial Setup Fees

Many manufacturers charge a one-time setup fee to prepare for the fabrication process. This fee covers the costs associated with file processing and tooling setup. It's usually a flat rate but can vary based on the complexity of the design and the specific manufacturing process. - Per-Board Prices

This is the cost for each individual PCB. It varies widely based on the board's size, layer count, material used, and manufacturing volume. Larger orders often result in lower per-board prices due to economies of scale. - Tooling Costs

Tooling costs, especially for more complex designs or specialized fabrication requirements, may add significantly to the overall expense. Consider if there are costs for custom stencils or specific routing requirements. - Expedited Service Fees

If your project requires a quick turnaround, expedited services are an option, but they often come with premium fees. These fees increase with faster fabrication and shipping times. - Shipping Costs

Shipping costs vary depending on the manufacturer's location and the shipping method chosen. For international manufacturers, anticipate higher shipping fees, including possible import duties and taxes. - Hidden Costs

Be aware of potential hidden costs, such as charges for design rule checks, re-spins due to errors, or additional charges for specific finishing processes. It's best to confirm all costs upfront before placing the order.

To effectively manage your budget, it is important to request quotations from multiple manufacturers and compare not only the per-board price but also the total cost, including all the additional fees and shipping. Manufacturers like JLCPCB and PCBWay are known for offering cost-effective solutions, while manufacturers in the US may have higher costs, but potentially shorter lead times and better customer support. Carefully consider your project’s needs and resources to identify the best value within your budget constraints.

PCB Assembly Services and Turnkey Solutions

Integrating PCB assembly services with fabrication offers significant advantages, streamlining the manufacturing process and reducing overall project timelines. Turnkey solutions, in particular, provide a comprehensive approach, where a single manufacturer handles both the fabrication and assembly, often including component sourcing, significantly simplifying logistics and reducing risks associated with coordinating multiple vendors.

This integrated approach not only saves time but also enhances quality control. By using a single provider for both PCB fabrication and assembly, potential issues related to component fit, solderability, and overall board performance can be more effectively addressed, leading to higher yields and more reliable end products.

Several PCB manufacturers offer these integrated services. Companies like JLCPCB, PCBWay and ALLPCB have expanded from mere fabrication to providing complete turnkey solutions. These manufacturers leverage their fabrication expertise to ensure that assembly is seamlessly performed. Turnkey services are especially beneficial for projects that require meticulous precision and reliability or for organizations with limited internal manufacturing capabilities.

Opting for turnkey solutions from a reputable manufacturer allows clients to focus on design and functionality rather than the complexities of coordinating multiple suppliers. This approach minimizes the risks of mismatched components and delayed delivery schedules, and the responsibility of sourcing components is shifted to the manufacturing partner, which generally has established relationships with reliable suppliers, translating into cost savings and efficiency. Furthermore, having a single point of contact for both fabrication and assembly greatly simplifies communication and streamlines project management.

Frequently Asked Questions About Prototype PCB Manufacturing

Comparative Analysis of Top Prototype PCB Manufacturers

Selecting the right prototype PCB manufacturer involves weighing several crucial factors. This comparative analysis provides a side-by-side look at some of the leading manufacturers discussed, highlighting their strengths and trade-offs to facilitate a more informed decision.

| Manufacturer | Price | Turnaround Time | Quality | Supported File Formats | Specializations |

|---|---|---|---|---|---|

| JLCPCB | Very competitive, generally low cost | Fast, often within 24-48 hours for expedited service | Good for the price, may vary for advanced features | Gerber, Eagle, KiCad | High volume, rapid prototyping, standard PCBs |

| ALLPCB | Competitive, with volume discounts available | Variable, typically 3-5 days, faster options available | Good quality, offers various finish options | Gerber, Altium, Eagle | Wide range of PCB types, fast turnaround |

| OSH Park | Moderate, typically more expensive for smaller orders | Slower, typically 10-12 days | High quality, known for reliability | Gerber, Eagle | Small batch, hobbyist-focused, high quality |

| Advanced Circuits | Higher, suitable for complex prototypes | Fast for standard services, 24h options available | Very high, meets stringent industry standards | Gerber, ODB++ | Complex PCBs, high-reliability applications |

Choosing the best prototype PCB manufacturer is essential for both hobbyists and professionals. By carefully evaluating crucial factors such as production capabilities, turnaround times, and costs, and comparing options like JLCPCB, ALLPCB, and local US manufacturers, you can ensure that your project aligns with the highest quality standards and your budget. The right manufacturer will be a partner in bringing your innovative designs to life. Always remember to choose the best prototype PCB manufacturer to ensure a seamless and efficient path from design to reality.

AnyPCBA

AnyPCBA