Finding the Cheapest PCB Manufacturer: A Comprehensive Guide

In today's electronics world, Printed Circuit Boards (PCBs) are the backbone of every device. From simple hobby projects to complex industrial machines, PCBs are indispensable. But cost is always a concern, especially for small businesses and hobbyists. The quest for the cheapest PCB manufacturer is often the first hurdle in many projects. This article will help you navigate this landscape by comparing different manufacturers and highlighting what to look for, ensuring you get the best value for your money, linking cost-effectiveness to societal needs and enabling technological advancements.

Understanding PCB Costs: Factors That Influence Price

Determining the most economical Printed Circuit Board (PCB) manufacturer requires a thorough understanding of the factors that dictate PCB pricing. These factors span from the fundamental materials used in construction to the complexity of the board design itself, all of which significantly affect the final cost.

- Material Choice

The substrate material, such as FR-4, determines the electrical and mechanical properties of the PCB, and varies in cost. High-performance materials are typically more expensive than standard options. - Number of Layers

A board's layer count (single-layer, double-layer, or multilayer) dramatically impacts cost. More layers increase complexity and thus cost, as they involve additional processing and materials. - Board Size

The physical size of the PCB directly correlates with the amount of material used, thereby influencing the price. Larger boards will incur higher manufacturing costs. - Quantity

Volume orders are subject to per-unit price reductions due to economies of scale. Prototypes and small runs are generally more expensive than mass production. - Lead Times

Faster turnaround times typically come at a premium. Standard lead times are more cost-effective, while rush orders will add to the expense. Manufacturers may charge more for expedited services. - Surface Finish

The type of surface finish (e.g., HASL, ENIG, OSP) also impacts costs, with options like ENIG being more expensive due to their superior properties. - Drill Hole Size and Count

More drill holes and smaller hole diameters raise costs because they require more precision and time in manufacturing. - Solder Mask and Silkscreen

Additional features like a solder mask and silkscreen may add to the overall cost. Different colors can also influence the price.

Understanding how these elements interact is fundamental for any engineer or project manager looking to minimize PCB manufacturing expenses. It allows for informed design decisions and strategic vendor selection to balance cost with performance. The subsequent sections will delve into specific manufacturers and tools to assist in finding the most cost-effective solutions, while maintaining necessary quality standards.

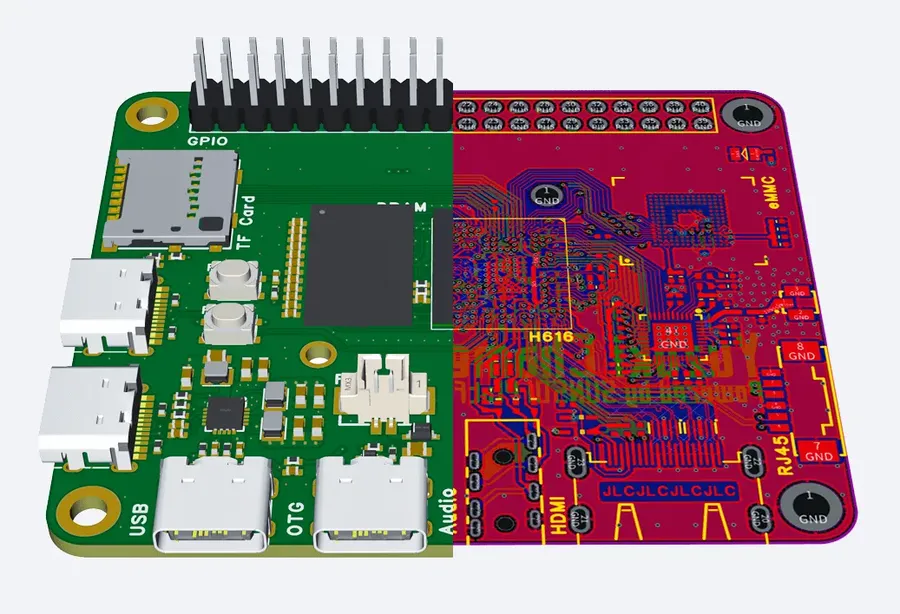

JLCPCB: A Popular Choice for Affordable PCB Manufacturing

JLCPCB has emerged as a leading provider of low-cost printed circuit boards (PCBs), particularly appealing to hobbyists, students, and small businesses seeking economical prototyping and small-batch production runs. Their competitive pricing, coupled with a range of services, makes them a significant player in the budget PCB manufacturing market.

When evaluating JLCPCB, several key aspects warrant consideration, including their pricing structure, minimum order quantities, quality standards, and the scope of their manufacturing capabilities.

- Pricing Structure:

JLCPCB is known for its aggressive pricing, often offering very low costs for small quantities of basic PCBs. Their pricing is tiered based on complexity, board size, number of layers, and quantity. They often have special offers for new customers, making initial prototypes very affordable. - Minimum Order Quantities (MOQ):

JLCPCB offers relatively low MOQs, which makes them suitable for both prototyping and small batch production. Typically, the minimum order is 5 pieces for standard PCBs. This flexibility is essential for users who need to test designs or produce only small quantities. - Quality Standards:

Despite the low cost, JLCPCB maintains a reasonable quality standard. They generally comply with industry standards for PCB fabrication. While quality control might not be as rigorous as that of high-end manufacturers, it's often adequate for many prototyping and hobbyist applications. They provide a quality assurance service that includes electrical testing to identify any potential board faults. - Service Offerings:

JLCPCB provides a wide range of services, including PCB manufacturing, SMT assembly, and stencil production. Their SMT assembly services are particularly popular among their customers, allowing for quick and convenient board production that includes component mounting. They also offer PCB design software compatibility, including formats such as gerber files and Eagle CAD files. - Special Deals:

JLCPCB frequently offers discounts and special deals, especially for first orders and prototype runs. These deals can provide substantial cost savings for those testing new designs or needing quick PCB turnaround times.

| Feature | Description |

|---|---|

| Base Material | FR-4 is the most commonly used, however they also offer other material options |

| Layers | From 1 layer up to 24 layers |

| Board Thickness | Varies from 0.4mm to 2.0mm |

| Copper Thickness | 1oz or 2oz standard thickness |

| Minimum Trace/Space | 0.1mm |

| Lead Time | Typically 2-7 days for production, plus shipping time |

| Shipping Options | DHL, FedEx, UPS, etc. |

JLCPCB's online platform is user-friendly, allowing customers to easily upload design files, select board parameters, and place orders. Their strong customer support helps address any issues and facilitate a smooth production process.

PCBWay: Another Strong Contender for Budget-Friendly PCBs

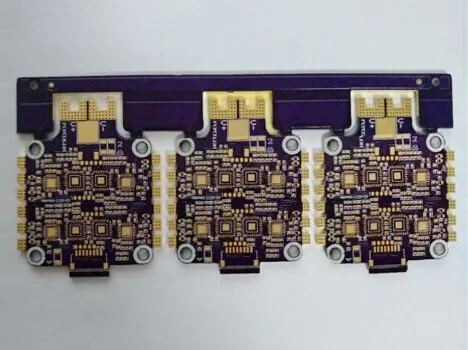

PCBWay stands out as a significant player in the budget-friendly PCB manufacturing arena, offering a wide array of services and competitive pricing. This section delves into PCBWay's pricing structure, customer feedback, service capabilities, and specific advantages to help you assess if they meet your needs.

PCBWay's approach to PCB manufacturing focuses on providing a balance between cost and quality, making it suitable for both hobbyists and professional engineers. They offer a range of PCB types and finishes, ensuring they can handle diverse project requirements.

Key aspects to consider when evaluating PCBWay include:

- Pricing:

PCBWay employs a tiered pricing model, often with discounts for higher order volumes. Their prices are generally competitive with other budget manufacturers, but they vary based on board complexity, size, layer count, material, and required lead times. It is essential to get a quote specific to your design to accurately assess the cost. - Customer Reviews:

Customer feedback is mixed but generally positive, with many citing good quality for the price. Some users report occasional issues with tolerances or communication, highlighting the need to carefully inspect finished boards and maintain clear communication with PCBWay about project specifics. - Service Scope:

Beyond basic PCB manufacturing, PCBWay offers services like PCB assembly, stencil production, and SMT component sourcing, which can be advantageous for projects needing a complete solution. Their platform is also user-friendly, offering design checks and online tracking for orders. - Advantages over competitors:

PCBWay's strength lies in its diverse service offering, user-friendly platform, and quick turnaround times. While they may not consistently be the absolute cheapest option, they offer a comprehensive ecosystem that can streamline PCB fabrication and assembly process.

| Feature | Description |

|---|---|

| Minimum Order Quantity | Typically starts from 5 PCBs, which is competitive for small runs. |

| Material Options | Standard FR-4, aluminum, and flexible PCB materials are available. |

| Layer Count | Supports up to 12 layers, accommodating complex designs. |

| Surface Finish | HAL, ENIG, OSP and other surface finishes are available |

| Assembly Services | Offers full or partial assembly with a good selection of common SMT components. |

| Lead Times | Vary based on complexity, generally between 2 to 7 days for manufacturing with additional time for assembly. |

Comparing PCB Manufacturers: JLCPCB vs. PCBWay

Choosing between JLCPCB and PCBWay, two dominant players in the affordable PCB manufacturing space, requires a detailed comparison across several key parameters. This section provides a head-to-head analysis of their pricing, quality, service speed, and other relevant factors, empowering you to make an informed decision based on your specific project requirements.

| Feature | JLCPCB | PCBWay |

|---|---|---|

| Base Price (for small quantity, e.g., 5-10 boards) | Generally lower for standard specifications | Slightly higher for basic boards, but can be competitive for more complex specs |

| Quality (Standard PCB) | Consistent and good quality for standard FR4 PCBs, meets industry standards. | Generally considered very good, especially for more complex PCB constructions. |

| Service Speed (Standard Production) | Fast turnaround time, often within 24-72 hours for standard orders. | Similar turnaround time as JLCPCB, but may vary depending on complexity and current order volume. |

| Minimum Order Quantity | Low MOQ, suitable for prototyping and small-batch production. | Offers flexible order quantities, starting from small prototypes |

| Assembly Services | Offers a comprehensive range of assembly services, but less automated compare to PCBWay. | Very strong and automated SMT Assembly service, both Prototype and mass production. |

| Online Ordering System | Easy-to-use, direct online ordering platform. | User-friendly platform with a strong project management interface. |

| Material Options | Offers standard FR4, aluminum, and some flexible material options. | A wider range of materials is available including advanced substrates and finishes. |

| Customer Support | Responsive customer support, mostly through email and online chat. | Strong customer service with more personalized support options. |

| Shipping | Offers various shipping options, including DHL and FedEx. | Similar shipping options, may have slightly different costs based on location. |

| Special Offers and Coupons | Frequent promotional offers and coupons. | Also provides various discounts and promotions. |

| Strengths | Lower initial price point for basic PCBs, strong on rapid prototyping. | Excellent quality and a wider range of fabrication capabilities, excellent for more complex projects. Automated Assembly services. |

| Weaknesses | May have limited options on some advanced materials or assembly services compare to PCBWay. | Can be slightly more expensive for basic PCBs than JLCPCB. |

Both companies offer robust online ordering systems, and while both provide assembly services, PCBWay tends to have more automated systems for SMT assembly. The choice between the two often hinges on the specific nature of your project; JLCPCB shines for basic, cost-sensitive prototyping and small runs, while PCBWay is suitable for more complex, high-quality builds with comprehensive assembly requirements. Consider your budget, material needs, and desired turnaround time when selecting the right manufacturer.

Other Budget PCB Manufacturers to Consider

While JLCPCB and PCBWay are prominent in the budget PCB manufacturing landscape, several other manufacturers offer competitive pricing and services. This section explores alternative options, evaluating their cost-effectiveness, quality, and reliability to provide a broader perspective for PCB sourcing.

Below is a comparison of some budget PCB manufacturers beyond the two most commonly discussed:

| Manufacturer | Cost-Effectiveness | Quality | Reliability | Specializations |

|---|---|---|---|---|

| AllPCB | Generally competitive, often has good deals on specific board types. | Good, especially for standard FR-4 boards. May vary with complexity. | Fairly reliable with a decent turnaround time. Known to communicate well with their customers. | Offers a wide range of services, including assembly, also specializes in flex PCBs. |

| Elecrow | Known for low prices on small quantities. May have higher prices for larger or complex boards. | Acceptable for hobbyist and prototype projects. Quality can be variable so careful checks are essential. | Generally dependable, though some users report occasional delays or quality discrepancies. | Strong in the educational market and small batch production. Offers both PCB fabrication and component sourcing. |

| Seeed Studio Fusion | Prices are competitive for small quantity orders. Good options for rapid prototyping. | Good quality for most standard requirements, but like most fabs, more complex designs require special attention. | Generally dependable, good for fast turnaround and good customer support. | Popular for rapid prototypes, with a range of assembly services and component sourcing. |

| Aisler | Competitive in Europe with different tiers of production. | Good quality, focusing on precision and standards, especially within the European market. | Highly reliable, and are known for their customer services and consistent output. | Offers a streamlined production system, and is geared towards a smooth production process with minimal hassles. |

When choosing a manufacturer it's essential to evaluate not just the initial quoted price but also factors like shipping costs, lead times, and the overall customer service. Some manufacturers may excel in specific areas, such as quick turnaround for prototypes or specialized materials, while others may offer more competitive pricing for large-scale productions.

It is also crucial to note, that when evaluating cost-effectiveness, quality and reliability, you should compare specific parameters (board complexity, number of layers, quantity, board size, and lead times etc) for each manufacturer as a fair basis for comparison.

Non-Chinese PCB Manufacturer Options

While Chinese PCB manufacturers often lead in terms of cost, sourcing PCBs from non-Chinese manufacturers can be advantageous for various reasons, including geographic proximity, potentially faster lead times for certain locations, and alignment with specific quality or ethical standards. Although these options may come with a higher price tag, they offer unique benefits that may justify the increased expenditure.

This section explores some notable non-Chinese PCB manufacturers, examining their strengths and weaknesses.

- Eurocircuits

A European manufacturer known for its high-quality PCBs and comprehensive online tools for design analysis and ordering. They are a strong option if you need more stringent quality control and are willing to pay a premium. - Advanced Circuits

A US-based manufacturer that offers a range of PCB fabrication services, with a focus on fast turnaround times and prototype manufacturing. Their pricing is generally higher than that of Chinese manufacturers, but their speed and domestic location can be crucial for some projects. - Sierra Circuits

Another US-based PCB manufacturer specializing in complex PCB designs and advanced materials. They cater to clients with high-performance requirements and are often the choice for specialized applications. - Other Local Manufacturers

Many countries have local PCB manufacturers that may not be as globally known but offer specific regional advantages such as faster shipping, better alignment with local regulations, and more personalized customer support. These manufacturers can be ideal for small to medium businesses that need reliable PCB production.

| Feature | Chinese Manufacturers (e.g., JLCPCB, PCBWay) | Non-Chinese Manufacturers (e.g., Eurocircuits, Advanced Circuits) |

|---|---|---|

| Price | Lower | Higher |

| Lead Time | Varies, generally longer due to shipping | Potentially shorter for nearby locations |

| Shipping | International shipping required | Domestic or closer shipping options |

| Quality | Good, but may vary; requires careful vendor selection | Typically higher quality standards |

| Customer Support | Potentially delayed due to time differences and language barriers | More responsive with better local support |

| Ethical Considerations | May raise ethical sourcing concerns for some clients | Potentially better alignment with ethical labor and material practices |

Choosing between Chinese and non-Chinese PCB manufacturers depends heavily on the specific requirements of your project. If cost is the primary driver, Chinese manufacturers like JLCPCB and PCBWay often provide the most economical solutions. However, for projects requiring higher quality, faster lead times, localized customer support, or adherence to strict ethical guidelines, non-Chinese manufacturers present a compelling alternative despite their higher price point. Consider the trade-offs carefully based on your specific application and constraints.

Using PCB Shopper for Price Comparison

PCB Shopper is a valuable tool designed to streamline the process of comparing real-time quotes from numerous PCB manufacturers, enabling users to quickly identify the most cost-effective options for their projects.

This platform aggregates pricing data from various manufacturers, allowing users to input their specific PCB requirements and receive a comprehensive list of quotes. This eliminates the need to manually visit each manufacturer's website, saving time and effort.

- Key Features of PCB Shopper:

- Real-time quotes:

Provides up-to-date pricing information, ensuring you get the most accurate estimates. - Multiple manufacturer comparisons:

Aggregates quotes from a wide range of PCB manufacturers, including popular ones like JLCPCB and PCBWay, as well as lesser-known options, giving a broader view of the market. - Customizable parameters:

Allows users to specify various PCB parameters like board dimensions, layer count, material, solder mask color, and quantity, making sure the quotes are specific to project needs. - User-friendly interface:

Designed to be easy to use, even for users new to PCB manufacturing. - Time-saving:

Reduces the time spent on manual price comparisons.

By using PCB Shopper, users can get a better understanding of the pricing landscape for their specific PCB requirements. This aids in making informed decisions based on the data presented. It's an essential tool for anyone aiming to secure the best possible deals on PCB manufacturing, balancing price with quality and lead time.

Frequently Asked Questions About Selecting a Cheap PCB Manufacturer

Navigating the world of PCB manufacturing can be complex, especially when budget is a primary concern. This section addresses common questions regarding cost-effective PCB production, helping you make informed decisions without sacrificing quality. It's important to understand that 'cheapest' does not automatically equate to 'inferior'; often, it's about finding the right balance of price, lead time, and quality for your project's specific needs.

- What are the primary factors that influence PCB manufacturing costs?

Several factors affect PCB pricing, including material type (FR-4, aluminum, etc.), board complexity (number of layers), order quantity, board size, and lead times. Tighter tolerances and specific design requirements can also increase costs. Understanding these elements will help you optimize your design and procurement strategy. - Are the cheapest PCB manufacturers always located in China?

While many of the most cost-effective PCB manufacturers are based in China due to their large-scale operations and established supply chains, there are budget-friendly options in other regions, including Europe and North America. However, these options might come with a higher price tag in some cases. - How do lead times affect PCB prices?

Faster lead times typically mean higher manufacturing costs. Rush orders require manufacturers to re-prioritize production, which comes at a premium. Planning ahead and avoiding last-minute requests can significantly reduce expenses. - Is it possible to get high-quality PCBs from budget-friendly manufacturers?

Yes, many budget PCB manufacturers, particularly those with established reputations, provide excellent quality control. It's essential to assess customer reviews, consider their inspection processes, and look for certifications to ensure quality standards are met. - What are the typical shipping costs from overseas PCB manufacturers?

Shipping costs from overseas PCB manufacturers can vary significantly depending on the shipping method (standard, express), the weight of the order, and the destination. It's important to factor in shipping costs when comparing quotes from different manufacturers. - What minimum order quantity (MOQ) should I expect from cheap PCB manufacturers?

MOQs vary widely between manufacturers. Some may cater to small prototype runs with very low or no minimums, while others are designed for larger scale production and have larger MOQs. Choose a manufacturer that is suitable for your production volume. - How can I ensure the cheapest option doesn’t compromise on quality?

To avoid sacrificing quality for cost, always request sample boards before large-scale production, and carefully review the manufacturer's quality assurance process. Look for certifications (e.g., ISO) and review customer feedback. Providing clear design specifications and adhering to standard manufacturing guidelines can also minimize errors and quality issues. Do not compromise on materials or specifications that will result in a performance issue with your product.

Tips for Reducing PCB Manufacturing Costs

Optimizing PCB design and manufacturing processes is crucial for reducing costs. By implementing strategic choices in material selection, design practices, and order management, significant savings can be achieved without compromising the quality or functionality of the printed circuit board.

- Optimize Board Design

Efficient design practices can reduce material usage and manufacturing complexity, thereby lowering costs. Consider the following: Minimize board size to reduce material cost; Utilize standard component sizes where possible to avoid custom fees; Optimize component placement to reduce the number of layers and manufacturing steps. Simple designs with fewer vias and through-hole components can significantly lower expenses. - Panelization

Panelizing multiple boards into a single panel can often result in reduced per-board costs, as manufacturers can process more boards at once. Consider how your design can be panelized while ensuring easy separation post-manufacturing. - Material Selection

The choice of substrate material can greatly affect cost. While FR-4 is a common and cost-effective choice, other materials such as CEM-1 can be even more cost-effective if they meet your project requirements. Consider the trade-offs between cost and performance based on your project's need for specific performance characteristics such as high frequency signal transmission or temperature requirements. - Avoid Rush Orders

Expedited services come at a premium. Plan ahead and allow for standard lead times to avoid paying extra for rush orders. Proper planning ensures that the project timelines are met while minimizing manufacturing costs. - Component Selection and Sourcing

Choose commonly available components to avoid extra costs associated with specialized or hard to source components. Buy components in bulk and from reliable suppliers, which can lead to reduced component costs and reduced shipping fees. Verify component availability prior to finalizing design to avoid delays and redesigns. - Layer Reduction

Reducing the number of layers in a PCB can dramatically reduce manufacturing costs, because each additional layer increases material and processing costs. Optimize routing and component placement to minimize the number of layers needed to achieve your required functionality. Single and double-layer boards are typically the most cost effective. If multilayer boards are needed, careful design can minimize the overall layer count. - Gerber File Optimization

Ensure your Gerber files are clean and well-organized. Inconsistent or complex files can cause delays, manufacturing errors, and increase costs. Ensure that your design files and design rules are set correctly with appropriate clearance values that are acceptable to the manufacturer to reduce the chances of errors and added costs during production. Consult with your manufacturer to verify their file requirements. - Choose Appropriate Finish

Surface finishes like HASL (Hot Air Solder Leveling) are generally cheaper than options like ENIG (Electroless Nickel Immersion Gold). Choose a finish that meets your application needs without incurring unnecessary costs. Be aware of cost trade-offs with different finishes. - Proper Documentation

Providing clear, accurate, and complete manufacturing documentation helps avoid errors and extra costs due to miscommunication. Include a comprehensive Bill of Materials (BOM), detailed assembly instructions, and any specific requirements to ensure smooth and cost-effective production.

By carefully considering these points, engineers and designers can significantly reduce PCB manufacturing costs without sacrificing quality or performance. Implementing these recommendations ensures that projects remain cost effective, meet specifications and reduce unwanted expenses.

Finding the cheapest PCB manufacturer doesn't have to be a daunting task. By understanding the factors that influence PCB costs and carefully comparing manufacturers like JLCPCB and PCBWay, and using tools like PCB Shopper, you can find the best balance of price and quality. Whether it is for simple home projects or large business deployments, understanding your options can significantly reduce costs and increase the reach of your work and your technology. Keep an eye on new, cheaper alternatives, as competition tends to drive prices down, enabling more innovation and better solutions.

AnyPCBA

AnyPCBA