Finding the Right Custom Circuit Board Manufacturers: A Comprehensive Guide

In our increasingly tech-driven world, custom circuit boards are the backbone of countless innovations, from everyday electronics to cutting-edge technologies. The journey to realizing these innovations often begins with choosing the right custom circuit board manufacturer. This article cuts through the noise to provide a clear path, offering the insights needed to ensure the success of your next project, and how [custom circuit board manufacturers] can bring your designs to life.

Understanding Your PCB Needs

Before engaging with custom circuit board manufacturers, a thorough understanding of your project's specific requirements is paramount. This foundational step ensures that the chosen manufacturer can accurately and efficiently produce the desired PCBs. Defining these needs upfront minimizes costly errors and delays in the production process.

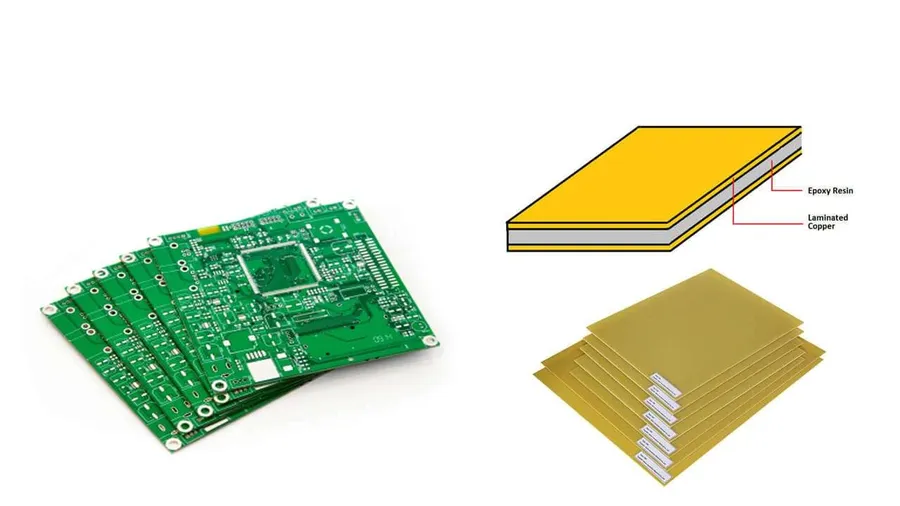

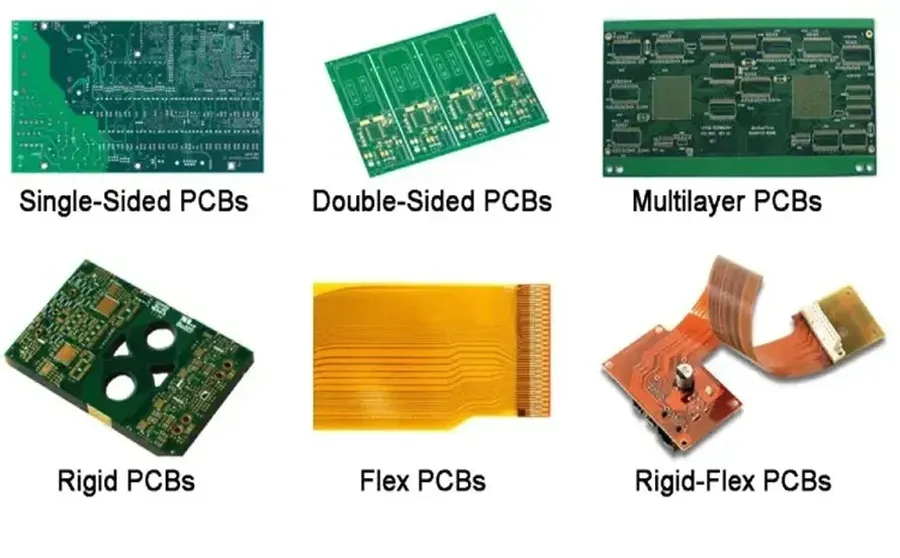

- Board Type

Determine the type of PCB required, such as single-sided, double-sided, or multilayer. Each type has different capabilities and cost implications. - Layer Count

Specify the number of conductive layers needed for your design. Multilayer boards increase complexity and cost but allow for higher circuit density. - Material Selection

Choose the appropriate substrate material, such as FR-4, aluminum, or flexible substrates, based on thermal, mechanical, and electrical requirements. Each material offers different properties suitable for various applications. - Tolerances

Define the acceptable variations in board dimensions, trace widths, and spacing. Precise tolerances are crucial for ensuring proper functionality and reliability. - Copper Weight

Specify the thickness of the copper layers, typically measured in ounces per square foot. This affects the current-carrying capacity of the traces. - Surface Finish

Select the appropriate surface finish for solderability and component placement, such as HASL, ENIG, or immersion tin. - Special Requirements

Identify any special requirements, such as impedance control, blind vias, buried vias, or specific certifications needed for your application.

Types of Custom Circuit Board Manufacturers

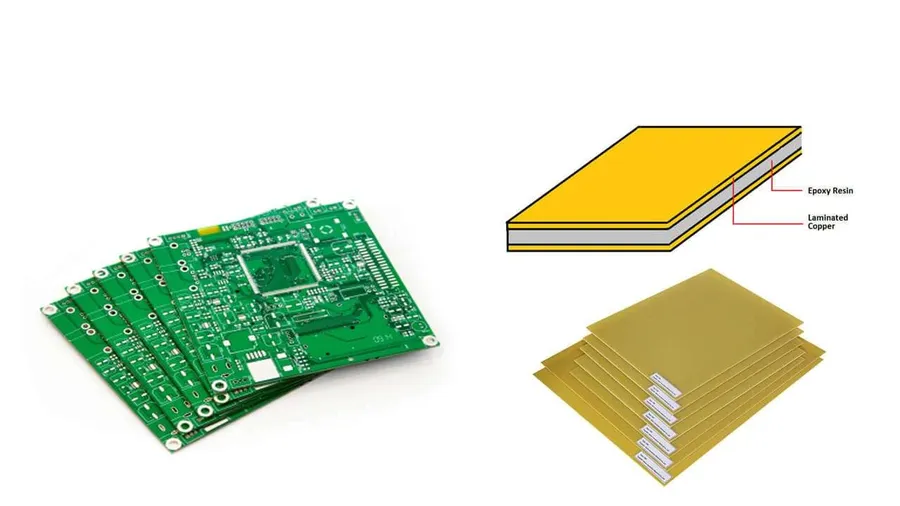

Custom circuit board manufacturers cater to a diverse range of production needs, primarily categorized by the volume and complexity of the order. Understanding these distinctions is crucial for selecting the right partner for your project, ensuring both cost-effectiveness and timely delivery. Manufacturers typically specialize in prototype runs, small-batch production, or high-volume manufacturing. Each type of manufacturer possesses distinct capabilities, equipment, and pricing structures tailored to specific production scales.

| Manufacturer Type | Typical Order Volume | Primary Focus | Ideal For | Cost per Board |

|---|---|---|---|---|

| Prototype Manufacturers | 1-10 Boards | Fast turn times, design validation | Initial design testing, rapid iteration | Highest |

| Small-Batch Manufacturers | 10-500 Boards | Medium-sized production runs, moderate flexibility | Pilot production, market testing | Medium |

| High-Volume Manufacturers | 500+ Boards | Large-scale, cost-optimized production | Mass production, established products | Lowest |

Prototype manufacturers focus on producing small quantities of boards, often with rapid turnaround times, to validate the design. Small-batch manufacturers bridge the gap between prototypes and mass production, offering greater flexibility in terms of materials and specifications, while High-volume manufacturers focus on efficiency to minimize the cost per unit for established products.

Key Factors to Consider When Choosing a Manufacturer

Selecting the right custom circuit board manufacturer is crucial for project success. This involves assessing their experience, technical capabilities, adherence to quality standards, and the responsiveness of their customer support. A thorough evaluation ensures that the manufacturer can meet your project's specific requirements and deliver high-quality PCBs.

- Experience and Expertise

Evaluate the manufacturer's track record. Look for experience in producing boards similar to yours in terms of complexity, materials, and technology. A long history and a portfolio of successful projects are indicators of a reliable partner. - Technical Capabilities

Confirm that the manufacturer possesses the necessary equipment and processes for your design, including specific layer counts, materials (FR-4, Rogers, etc.), impedance control, and surface finishes. Cutting-edge equipment is essential for meeting precise tolerances and ensuring consistent quality. - Quality Certifications and Standards

Verify that the manufacturer adheres to industry quality standards, such as ISO 9001, IPC standards, and other relevant certifications. These certifications guarantee consistent processes and a focus on quality control. - Customer Support and Communication

Assess the responsiveness and helpfulness of the manufacturer's customer service. Clear and prompt communication is essential, especially when addressing design queries or production issues. Look for manufacturers that are accessible and offer support throughout the entire manufacturing process. - Turnaround Time and Lead Times

Consider the manufacturer's production lead times for your volume requirements. While rapid prototyping is valuable, ensure the manufacturer can scale up to meet larger production needs without significant delays. Balance cost savings with necessary project timelines. - Design for Manufacturability (DFM) Feedback

A manufacturer that provides DFM checks and feedback is invaluable, as early identification and correction of design flaws can save costs and time. Look for [custom circuit board manufacturers] that offer these services. - Material Sourcing and Traceability

Enquire about the manufacturer’s sourcing practices for PCB materials. Knowing material origin and ensuring traceability can be crucial for projects with specific quality requirements. Transparency is key to maintaining high quality throughout the process.

Cost Considerations for Custom PCB Fabrication

Understanding the cost structure of custom PCB fabrication is crucial for effective project budgeting. It's not just about the per-unit price; several factors contribute to the overall cost, requiring a detailed analysis of pricing models to avoid unexpected expenses.

| Cost Factor | Description | Impact on Overall Cost |

|---|---|---|

| Tooling Costs | Initial expenses for setting up the manufacturing process, including creating the necessary templates and machinery adjustments. | Significant for prototypes and small batches; less impactful for high-volume production. |

| Per-Unit Pricing | The cost to produce each individual circuit board, based on material usage, complexity of the design, and layer count. | Directly proportional to the number of PCBs manufactured. |

| Material Costs | The price of raw materials, such as FR-4, metal cladding (copper), solder mask, and silkscreen inks. | Can vary significantly based on the selected material and its performance characteristics. |

| Design Complexity | Features like fine pitch components, multiple layers, impedance control, and specialized vias affect production time and processing costs. | Increases the cost per unit and may increase setup time. |

| Assembly Services | The cost of assembling components on the manufactured PCBs, if provided by the manufacturer. | May include component sourcing, labor for placement, and testing costs. |

| Testing and Inspection | The cost associated with testing and inspecting the manufactured PCBs to ensure that they meet the project specifications. | Essential for quality control, this can influence the total cost and reduce yield. |

| Shipping Costs | Expenses for transporting the fabricated boards from the manufacturing facility to the desired location. | Varies based on the distance, speed, and method of delivery; higher for international shipping and express delivery. |

| Potential Hidden Charges | Unexpected costs that might arise due to errors in design files, rush orders, or extra rework. Clarify these with your manufacturer beforehand. | Can significantly impact overall budget, so clarify terms and conditions upfront. |

It is essential to request a detailed quote that breaks down each of these cost elements to accurately evaluate offers from different custom circuit board manufacturers. Furthermore, exploring options for cost-effective design practices can significantly reduce the overall expenditure without compromising performance. These may include standardizing components where possible, optimizing the board layers, and using standard materials.

Geographical Considerations: USA vs. International Manufacturers

Selecting a custom circuit board manufacturer involves a crucial decision: whether to partner with a domestic (USA) or an international provider. This choice significantly impacts various aspects of your project, including lead times, costs, communication, and quality control. While international manufacturers may offer cost advantages, domestic options often provide benefits in terms of speed and ease of communication.

| Factor | USA Manufacturers | International Manufacturers |

|---|---|---|

| Lead Time | Generally shorter, faster turnaround times due to proximity. | Longer lead times, affected by shipping and customs. |

| Shipping Costs | Lower shipping costs due to shorter distances and domestic shipping rates. | Higher shipping costs, including potential import duties and taxes. |

| Communication | Easier communication due to language and time zone compatibility; potential for better responsiveness. | Potential for communication barriers due to language differences and time zone variations. |

| Quality Control | Often easier to audit and manage quality due to proximity and domestic regulations. | Quality control can be more challenging due to geographical distance and different standards. |

| Cost | Generally higher per-unit cost, higher labor cost and material cost. | Generally lower per-unit cost, lower labor cost and material cost. |

| Intellectual Property Protection | Stronger protection due to US law. | Potentially weaker protection depending on country and local laws. |

Many custom circuit board manufacturers located in the USA offer a good balance of competitive pricing, high quality, and fast turnaround, making them a viable choice for many projects. They often possess a deeper understanding of US standards and regulations, which can be particularly important for sensitive applications or industries.

A Comparison of Popular Custom Circuit Board Manufacturers

Selecting the right custom circuit board manufacturer is pivotal for the success of any electronics project. This section provides a comparative analysis of several popular manufacturers, highlighting their strengths and weaknesses to aid in your decision-making process. The evaluation encompasses critical factors such as turn times, pricing structures, and the range of features available, giving you a detailed overview to align with your specific project needs.

| Manufacturer | Strengths | Weaknesses | Typical Turn Time | Price Point | Special Features |

|---|---|---|---|---|---|

| JLCPCB | Cost-effective, good for prototypes, fast turnaround for basic PCBs. | Limited advanced technology options, may have longer lead times for complex designs or large volumes. | 2-7 days | Very competitive | PCB Assembly, Stencil Service, online ordering platform. |

| PCBWay | Good range of PCB options, including advanced materials and technologies, good customer support, diverse assembly options. | Slightly higher cost compared to JLCPCB, possible longer lead times for complex assembly. | 3-10 days | Moderate | PCB Assembly, Flexible PCBs, SMT Stencils |

| AllPCB | Comprehensive manufacturing capabilities including a wide array of advanced boards, offers a variety of assembly options, and online instant quotes. | Not as popular as JLCPCB and PCBWay, may have higher prices for some complex boards. | 3-10 days | Moderate to High | Multi-layer boards, Rigid-flex boards, Custom assembly services |

| Elecrow | Good for small to medium sized businesses, offers a one-stop service for prototyping and manufacturing. | Not as popular as some other manufacturers, may not have as many advanced options. | 5-12 days | Moderate | Component sourcing, PCB Assembly, and 3D printing services |

| Advanced Circuits | High quality, robust capabilities, excellent for complex designs, strong customer support. Excellent reputation with many years in the industry. | Higher cost, not ideal for very basic projects. | 1-5 days | High | Rapid prototyping, advanced materials, ITAR compliant. |

| Sierra Circuits | Specializes in high-speed and RF PCBs, excellent for advanced applications, offers design and engineering support. High-quality boards and excellent customer service | Very high cost, longer lead time for very complex boards. | 5-15 days | Very High | Controlled impedance PCBs, embedded capacitance, design services. |

Frequently Asked Questions About Custom Circuit Board Manufacturers

This section addresses frequently asked questions regarding custom circuit board manufacturing, providing clarity on selecting the best manufacturer, assessing DIY feasibility, understanding lead times and costs, and determining typical project requirements for successful fabrication.

- Who is the best PCB manufacturer?

The 'best' PCB manufacturer depends heavily on your specific needs, such as production volume, complexity, and budget. Manufacturers like JLCPCB and PCBWay are popular for prototypes and small batches due to their cost-effectiveness, while others may excel in high-volume or specialized PCBs. Researching specific capabilities and customer reviews is crucial to determine the optimal fit. - Can I make my own circuit board?

Yes, it is possible to make your own circuit boards, especially for simple designs. Methods include etching, using pre-sensitized boards, or employing a CNC machine for milling. However, achieving the precision, quality, and reliability of professional manufacturers, especially for complex multi-layer boards, is challenging and time-consuming for most individuals. - Who is the largest PCB manufacturer in the USA?

Identifying the absolute 'largest' PCB manufacturer in the USA can be challenging due to fluctuating market positions and the private nature of many companies. However, several large and reputable companies dominate the American market with substantial manufacturing capacity, including those specializing in high reliability, military and aerospace applications. These companies are often preferred for large scale or high-stakes projects. - How much does it cost to build a circuit board?

The cost of building a circuit board varies widely based on several factors. These include the complexity of the design, the number of layers, the board size, the materials used, the required quantities, and the manufacturer's pricing policies. Prototypes and small batches generally cost more per unit compared to high-volume orders due to setup and tooling costs. It is best to obtain quotations from several manufactures based on detailed design specifications. - What are the typical requirements for successful PCB fabrication?

Successful PCB fabrication requires detailed and accurate design files, typically in Gerber format, a complete Bill of Materials (BOM) specifying all components, clear specifications regarding materials, tolerances, and special requirements. Additionally, proper consideration of design for manufacturability (DFM) guidelines to minimize fabrication errors and delays is crucial. Good communication between the designer and the manufacturer is key to resolving any issues. - What is the typical lead time for custom PCB manufacturing?

Lead times for custom PCB manufacturing vary significantly depending on the manufacturer, the complexity of the board, and the order volume. Standard lead times can range from a few days for simple prototypes to several weeks for complex, high-volume production. Expedited services are available at an additional cost. The choice between domestic and international manufacturer also influences lead time. - What are the key considerations when choosing a PCB material?

Choosing a PCB material depends on the intended application of the circuit board. Factors like operating temperature, mechanical stress, signal frequency, and impedance requirements determine the best option. Common materials include FR-4 (suitable for general use), high-Tg FR-4 (for higher temperatures), and Rogers materials (for high-frequency applications). Selecting the right material is essential to functionality and reliability.

The Importance of PCB Design Files

Accurate and complete design files are paramount for a seamless transition from design to manufacturing when working with custom circuit board manufacturers. These files serve as the blueprint for your PCB, guiding the fabrication process and ensuring the final product meets your specifications. Neglecting the details of these files can result in delays, errors, and costly rework.

The core files typically include Gerber files, a Bill of Materials (BOM), and potentially pick-and-place files for assembly.

- Gerber Files

Gerber files are the industry-standard format for PCB fabrication. They are essentially a set of vector-based files describing each layer of your board (copper traces, solder mask, silkscreen, drill holes, etc.). Ensure they are generated correctly from your design software and are compatible with your chosen manufacturer's requirements. Any inaccuracies in these files will lead to manufacturing defects. - Bill of Materials (BOM)

The BOM is a comprehensive list of all the components required for your PCB assembly. It should include detailed information for each component, such as manufacturer part numbers, package types, and quantities. A precise BOM ensures that all necessary parts are sourced correctly, preventing delays and ensuring the accurate assembly of your board. It also helps with cost estimation and procurement. - Pick-and-Place Files

Pick-and-place files are needed for automated assembly processes. These files include the location and rotation information of each component on the board. Correct pick-and-place files ensure proper component placement during automated assembly, significantly reducing assembly time and potential errors. - Other Critical Design Files

Depending on your specific project, other files may be required, including fabrication drawings, stack-up details, and special instructions. These supplementary files provide additional context and guidance to the manufacturer, ensuring they understand any special requirements for your project. Providing comprehensive documentation up front can avoid misunderstandings and potential delays. For instance, fabrication drawings could include critical dimensions or via types that are not obvious from the gerber files.

Tips for Successful PCB Manufacturing

Successful PCB manufacturing hinges on a combination of meticulous planning, informed decision-making, and adherence to best practices, especially when working with custom circuit board manufacturers. The following tips offer a roadmap to ensure your PCB project progresses smoothly, yielding high-quality results.

- Material Selection

Choosing the right PCB material is crucial for performance and reliability. Consider factors like the dielectric constant, thermal conductivity, and operating environment of your application. FR-4 is a common choice for many applications, but for high-frequency or high-temperature environments, you may need to explore materials like polyimide or PTFE. Ensure your chosen material is supported by your selected manufacturer and meets industry standards. - Design for Manufacturability (DFM)

DFM is a critical step in the PCB design process, optimizing your layout for efficient and cost-effective manufacturing. Key considerations include trace width and spacing, via sizes, pad dimensions, and component placement. Utilize the DFM guidelines provided by your custom circuit board manufacturer to avoid potential issues, such as fabrication defects or assembly challenges, which can result in costly rework and delays. Many manufacturers offer DFM checking tools that can flag potential issues before fabrication, so take full advantage of these resources. - Gerber File Verification

Gerber files serve as the blueprint for PCB fabrication. Always meticulously verify the files before submitting them to the manufacturer. Use a Gerber viewer to check for proper layer alignment, correct pad sizes, accurate trace routing, and the absence of errors. Incorrect Gerber files can lead to production errors and non-functional boards, requiring costly respin and delays. Double-checking this will prevent errors. - Accurate Bill of Materials (BOM)

A complete and accurate BOM is essential for both fabrication and assembly. Your BOM should include all component information such as the manufacturer part number, reference designator, package type, and quantity. A mistake in the BOM can cause delay and cost overruns when it is discovered late in the process. Consistent review of the BOM is critical before the design is sent for fabrication. - Communication with Manufacturer

Maintain clear communication with your custom circuit board manufacturer throughout the process. Discuss any specific requirements, tolerances, or assembly details upfront. Address potential questions or concerns promptly, to prevent any misunderstandings or fabrication issues, which could be costly and time consuming. This ensures that the fabricated boards meet your specific design requirements. - Prototyping and Testing

If possible, create a small batch of prototypes before committing to large-scale production. Thoroughly test the prototypes to verify their functionality and performance. This step is critical to identify and address any design flaws before the bulk production and avoids costly reworks. The prototype stage can also highlight any issues that need to be resolved before large-scale manufacturing. - Assembly Considerations

If your project includes PCB assembly, ensure that your design supports the assembly process. Consider component placement, pad design, and reflow profiles. Communicate your assembly requirements to your manufacturer early in the process to prevent potential issues.

Selecting the right custom circuit board manufacturer is crucial for bringing your electronic designs to life. By carefully evaluating your project needs, understanding various manufacturing options, and focusing on factors such as cost and lead time, you can find a reliable partner. Remember that good preparation, clear communication, and a focus on quality with [custom circuit board manufacturers] can help you avoid common pitfalls, and this guide serves as a reference point for future PCB projects, ensuring success in a dynamic industry.

AnyPCBA

AnyPCBA