Finding the Right KiCad PCB Manufacturer: A Comprehensive Guide

In today's fast-paced electronics world, KiCad has emerged as a powerful open-source EDA tool, empowering makers and professionals alike to design innovative PCBs. Choosing the right KiCad PCB manufacturer is crucial for turning your digital designs into physical reality. This article navigates the complex landscape of PCB fabrication, offering insights into how to select the perfect manufacturing partner that understands and supports KiCad project files.

Understanding KiCad and PCB Manufacturing

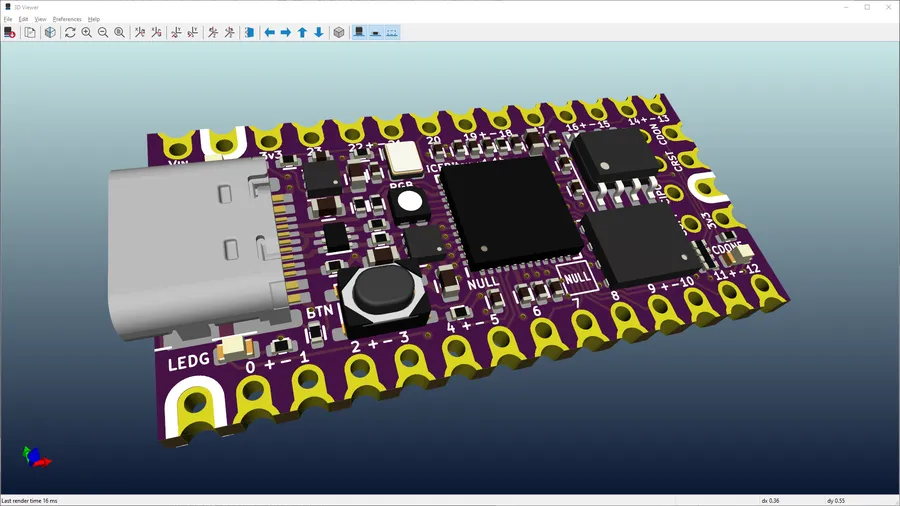

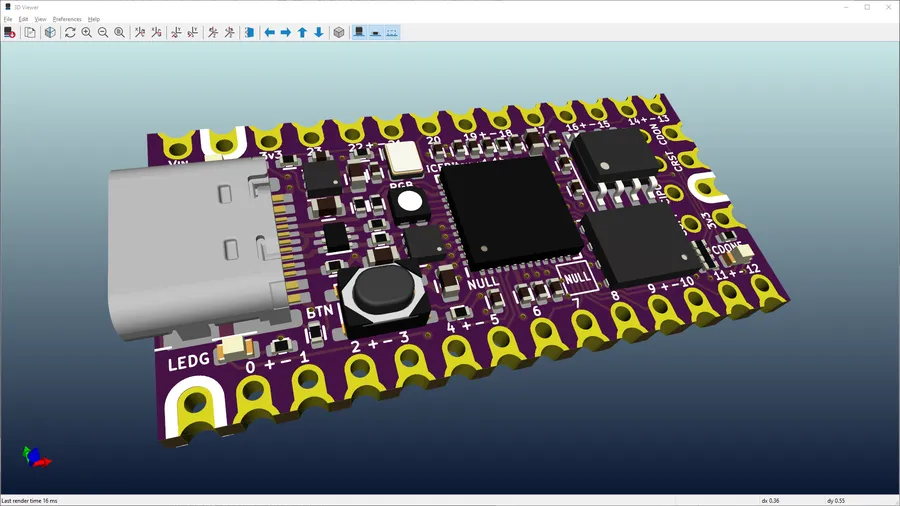

KiCad is a powerful, open-source electronic design automation (EDA) suite, crucial for designing printed circuit boards (PCBs). Its integration with PCB manufacturing involves a series of steps, from schematic capture to board layout, culminating in the generation of manufacturing files. Utilizing a manufacturer that can directly process KiCad files is paramount to avoid potential translation errors, ensuring the final PCB accurately reflects the design. This direct compatibility significantly reduces the risk of manufacturing defects and speeds up the production process. Key file formats in this process include Gerber files for PCB layers, drill files for hole locations, and component placement files that detail the positions of electronic components on the board.

Key Factors When Choosing a KiCad PCB Manufacturer

Selecting the right PCB manufacturer is crucial for ensuring that your KiCad design translates into a functional and reliable physical product. Several factors must be carefully evaluated to ensure a successful manufacturing process, encompassing not only cost but also technical capabilities and compatibility with your design specifications.

- File Format Compatibility

The manufacturer should ideally accept KiCad files directly, minimizing the risk of errors during file conversion. If not, they must have a robust system for handling standard Gerber files, drill files (Excellon format), and component placement files, ensuring precise interpretation of your design. - Production Lead Times

Lead times vary significantly depending on the manufacturer's capacity and location. Evaluate both prototype and production lead times against your project timeline, factoring in any potential delays. It's critical to understand the turnaround time they promise. - Pricing and Cost Considerations

Cost is always a factor. Obtain quotes from multiple manufacturers, but do not solely focus on the lowest price. Consider the overall value, which includes quality, lead time, and customer service. Understand the pricing structure for different quantities and board complexity. - Material Options

Verify that the manufacturer offers the necessary materials for your PCB, such as FR4 for standard applications, aluminum for high thermal conductivity requirements, or others that suit the design’s environment and performance specifications. Material selection has significant impact on performance, and costs. - Quality Control Standards

The manufacturer should adhere to recognized quality standards (e.g., IPC standards). Check for certifications and testimonials that guarantee they maintain a certain level of quality, critical for the reliability of your PCBs. - Assembly Services

Determine whether you need PCB assembly services, and if so, whether the manufacturer can handle the complexity of your project. Assembly services often include component sourcing, automated placement, and soldering. Verify their proficiency in surface mount technology (SMT) and thru-hole components. - Design Rule Checks (DRC)

A capable manufacturer will perform thorough design rule checks based on their production capabilities and tolerances. The design rules for your KiCad design should match those of your manufacturer, or you risk manufacturability issues. This step is critical to ensure the design is compatible with their manufacturing process. - Tolerances and Specifications

Understand the manufacturer's tolerances for trace widths, clearances, via sizes, and other parameters that can affect the performance and reliability of your circuit. Ensure your KiCad design adheres to their requirements, and clarify any ambiguities before proceeding.

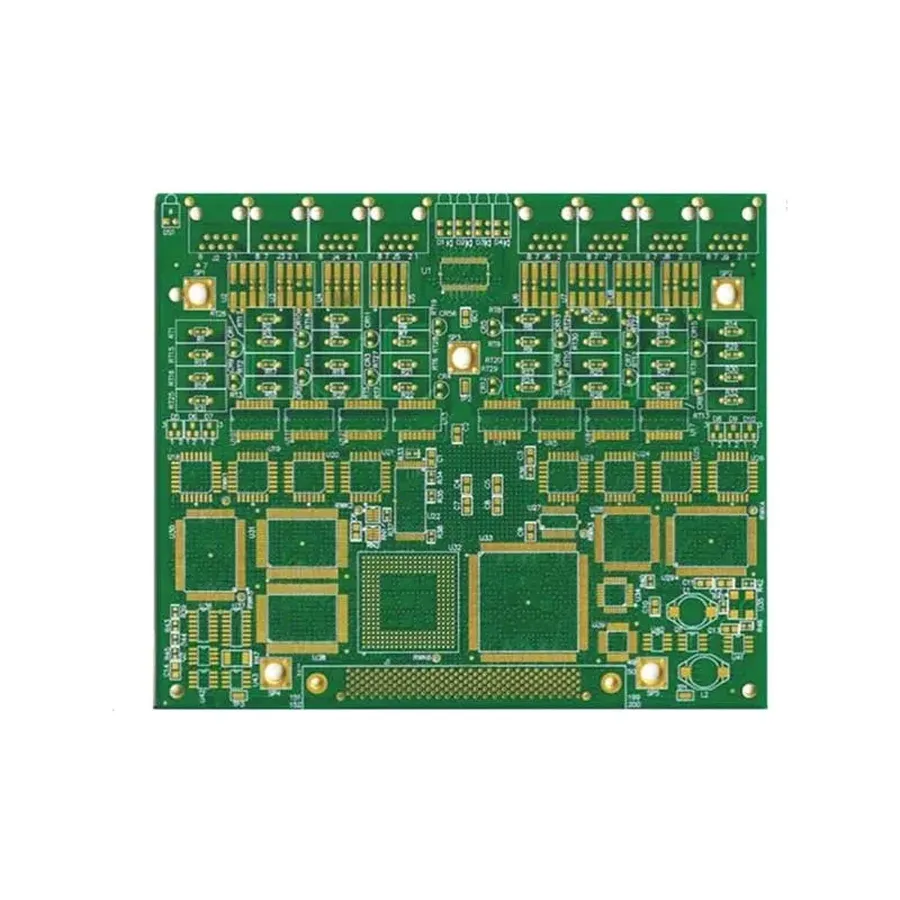

Preparing Your KiCad Design for Manufacturing

Ensuring your KiCad PCB design is production-ready requires careful preparation, primarily involving the generation of manufacturing files and verification against the chosen manufacturer's specifications. This meticulous approach minimizes errors, reduces production delays, and optimizes the final product's quality.

The process hinges on several critical steps, all aimed at translating your design into a format that can be directly interpreted by the manufacturer's equipment. Key among these are the generation of Gerber files for copper layers, solder mask, and silkscreen; Excellon drill files for hole locations; a Bill of Materials (BOM) detailing components; and a component placement file (centroid file) that indicates where parts should be positioned on the board.

- Gerber Files

These files are the cornerstone of PCB fabrication, defining the copper layers, solder mask, and silkscreen. KiCad provides the functionality to export these files in the RS-274X format, which is widely accepted by manufacturers. When generating Gerber files, be sure to select the correct layers and specify parameters like units and coordinate format. - Excellon Drill Files

Excellon files are used to instruct the drill machines in the fabrication process. They specify the locations and sizes of all the holes needed in your PCB. Pay close attention to ensure the correct tool sizes are defined in the drill file generation to meet your manufacturing needs. - Bill of Materials (BOM)

The BOM is a comprehensive list of all the components needed for the board, including their part numbers, manufacturer information, quantities, and reference designators. Ensuring the BOM is accurate and complete is vital for purchasing the necessary components. KiCad can export BOMs, it may require some configuration or use of a plugin. - Component Placement Files (Centroid Files)

The centroid file provides the exact locations and rotations of each component on the PCB. This file is essential for automated assembly, ensuring that components are placed precisely. KiCad can generate centroid files; check the format requirements of your manufacturer. - Design Rule Checks (DRC)

Before exporting files, always run a comprehensive DRC within KiCad. These checks verify your design adheres to specific rules (trace widths, clearances, etc.). Additionally, compare the DRC settings and capabilities of your KiCad setup with that of your manufacturer and make adjustments as required.

The use of plugins or scripts can streamline the export of manufacturing files, automating the process and minimizing errors. For instance, specific scripts may help optimize file formats and ensure all required information is present. Verify with your manufacturer if they have any particular file format or naming convention to ensure compatibility. This prevents unexpected delays or additional work for both you and the manufacturer, as well as preventing any manufacturing errors.

Top KiCad-Friendly PCB Manufacturers

Selecting a PCB manufacturer that is proficient with KiCad files is crucial for a streamlined production process. These manufacturers not only understand the intricacies of KiCad files but also offer services optimized for designs originating from this platform. By working with KiCad-friendly manufacturers, designers can minimize file conversion issues and ensure higher fidelity between their design and the final product. Below we explore several manufacturers known for their support of KiCad.

- JLCPCB

Known for its cost-effectiveness and rapid turnaround, JLCPCB supports KiCad files directly, offers a wide range of manufacturing options and assembly services, is an excellent choice for both prototypes and production runs, and is a popular choice for hobbyists and small businesses. - PCBWay

PCBWay provides a wide array of PCB manufacturing capabilities, including advanced materials and multilayer PCBs, they also offer assembly services. This makes them suitable for both simple and complex designs, with a great customer service, they stand out for their comprehensive support for KiCad users. - ALLPCB

ALLPCB is a Chinese manufacturer that has a good balance of cost and quality, with a wide range of PCB options from simple to advanced requirements. They can handle large volume orders, they also support KiCad files directly and provides assembly service. It is a solid option for those looking for large production. - Eurocircuits

Eurocircuits specializes in high-quality PCB manufacturing and assembly, they offer comprehensive support for KiCad users, and they have excellent customer support. However, their pricing is a bit higher. This manufacturer is good for high-reliability applications, and they are based in Europe, ensuring compliance with European standards. - Seeed Studio Fusion PCB

Seeed Studio Fusion PCB is another popular choice with the maker community, offering a range of services for prototyping and small production runs. They have a streamlined online platform for uploading KiCad design files, with a good balance of cost and quality. They also have a good support platform for users with all levels of expertise.

Comparing KiCad PCB Manufacturers

Selecting the right PCB manufacturer is crucial for the success of any electronics project. A side-by-side comparison of key parameters can greatly aid in decision-making, helping to align the manufacturer's capabilities with your project's specific needs. This section provides a structured comparison of several manufacturers based on their minimum order quantity (MOQ), lead times for both prototypes and mass production, available surface finishes, and advanced manufacturing options.

| Manufacturer | MOQ | Prototype Lead Time | Production Lead Time | Surface Finishes | Advanced Options |

|---|---|---|---|---|---|

| Manufacturer A | 5 | 3-5 days | 1-2 weeks | HASL, ENIG | Blind Vias |

| Manufacturer B | 10 | 5-7 days | 2-3 weeks | HASL, ENIG, Immersion Silver | Impedance Control |

| Manufacturer C | 1 | 2-3 days | 1 week | HASL, ENIG | None |

| Manufacturer D | 5 | 4-6 days | 1-2 weeks | HASL, ENIG | Impedance Control |

This table provides a snapshot of the capabilities of several example PCB manufacturers. 'MOQ' refers to the Minimum Order Quantity, indicating the smallest number of boards you need to order. 'Prototype Lead Time' shows how long it will typically take to receive a prototype board and 'Production Lead Time' indicates the timeframe for larger orders. 'Surface Finishes' details the types of coatings applied to the board for protection and solderability, and 'Advanced Options' list specific manufacturing capabilities offered by each manufacturer. When choosing a manufacturer, it is paramount to consider all of these factors together to find the optimal balance for your project.

KiCad PCB Assembly Services

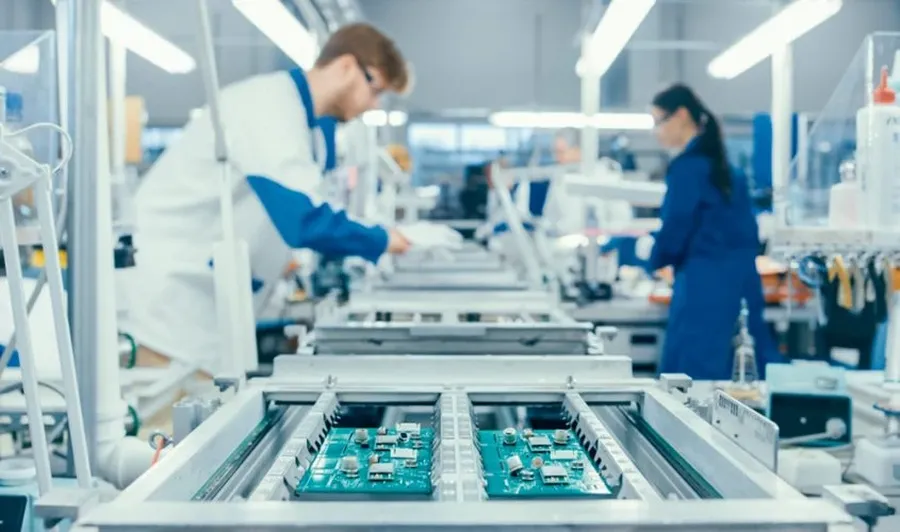

Many KiCad-friendly PCB manufacturers extend their services beyond fabrication to include PCB assembly, offering a streamlined solution for bringing electronic designs to life. These assembly services range from basic component placement to comprehensive turnkey solutions, catering to various project needs and complexities. Utilizing these services can significantly reduce the time and effort required for production, but it is crucial to select a provider that aligns with your specific design requirements and assembly needs, especially for designs incorporating surface mount components.

Choosing the right PCB assembly service involves understanding the different service models. Full turnkey assembly services handle all aspects of production, from bare board fabrication to component sourcing and final assembly, while partial assembly services allow designers to provide some of the components, offering flexibility and potentially reducing costs. Understanding the implications of each option is essential for effective project planning and execution.

- Full Turnkey Assembly

The manufacturer handles everything: PCB fabrication, component procurement, and assembly. This minimizes your workload and simplifies logistics. - Partial Assembly

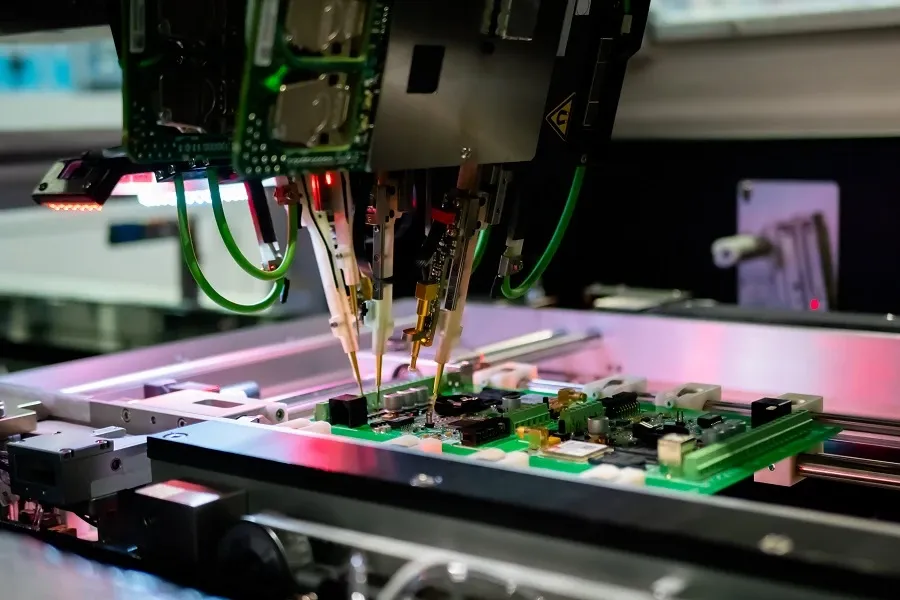

You provide some or all of the components, while the manufacturer handles the assembly. This offers cost savings and flexibility. - Surface Mount Technology (SMT) Assembly

Most modern PCBs use surface mount components. SMT assembly is a precise process requiring specialized equipment and skill, and most assembly services offer this type of assembly. Manufacturers vary in terms of what size components, such as fine pitch QFN and BGA components, they are capable of handling.

Frequently Asked Questions About KiCad PCB Manufacturing

Navigating the PCB manufacturing process with KiCad can raise several questions. This section addresses common queries regarding KiCad, PCB fabrication, and assembly, providing clarity and practical information for users at all levels.

- Who developed KiCad?

KiCad is an open-source project maintained by a global community of developers and contributors. It is not owned or developed by a single company, ensuring its free and accessible nature for everyone. - Which PCB manufacturer is the largest?

The largest PCB manufacturers vary depending on the criteria (revenue, production volume, etc.) and are subject to change. However, some of the biggest players globally include companies like Unimicron, Zhen Ding Technology, and TTM Technologies. These companies typically handle large-scale production. - Which companies manufacture PCBs?

Numerous companies worldwide manufacture PCBs, ranging from small shops focusing on prototypes to large corporations handling mass production. Examples include JLCPCB, PCBWay, and Seeed Studio, as well as larger, more specialized manufacturers depending on your project's needs. - Which companies are using KiCad?

KiCad's open-source nature and powerful capabilities have led to its adoption by a wide range of companies, from small startups and hobbyist groups to large corporations across various industries. While specific usage details are not always public, its flexibility makes it appealing to diverse user profiles. - Can PCB manufacturers use KiCad files directly?

Most PCB manufacturers do not directly use KiCad project files (.kicad_pcb). Instead, they rely on industry-standard formats such as Gerber files, Excellon drill files, and component placement (centroid) files. These formats are generated from your KiCad design and provide the necessary data for fabrication and assembly. Some manufacturers offer tools or plugins to import KiCad files for easier use, but ultimately, manufacturing data is translated into the industry standard formats mentioned. Some may provide a direct import to make it easier for the user to upload their files, but it will be translated into the formats they need, so it is always best practice to generate the gerber and other output files. - Is it possible to get instant quotes based on KiCad files?

While it's not typical for manufacturers to provide instant quotes directly from KiCad project files, many offer online quote calculators where you can upload Gerber and other required files to get an immediate or near-instant price estimate. This usually requires the generation of the standard manufacturing output files. Some manufacturers might provide online tools that allow the user to upload the .kicad_pcb or .zip file and extract the required data, so the user won't need to spend time generating the files, but always double check to ensure that the user will get the best results from the manufacturer. - What is the typical timeframe for prototype fabrication and assembly?

Prototype fabrication times can vary significantly depending on the manufacturer, complexity of the design, and whether assembly services are included. Generally, prototype fabrication can range from 2-3 days for standard bare boards to 1-2 weeks with assembly. Factors such as rush service availability and the manufacturer's current workload can influence lead times. Always verify these details with your selected manufacturer.

Tips for Smooth PCB Manufacturing with KiCad

Ensuring a smooth PCB manufacturing process with KiCad involves meticulous planning, adherence to design rules, and clear communication with your chosen manufacturer. This section provides actionable tips to minimize errors and delays, resulting in high-quality PCBs.

- Design for Manufacturability (DFM) Best Practices

Incorporate DFM principles early in your design process. This includes adequate spacing between traces and pads, appropriate via sizes, and avoiding sharp angles in traces. Review your design against the manufacturer's capabilities to proactively resolve potential issues before fabrication. - Thorough Design Rule Checks (DRC)

Utilize KiCad's built-in DRC tool and double-check your design against the specific design rules provided by your manufacturer. Pay close attention to minimum trace widths, clearances, hole sizes, and annular ring dimensions to avoid fabrication errors. - Effective Communication with Your Manufacturer

Maintain clear and consistent communication with your manufacturer from the beginning of the project. Ask clarifying questions about their capabilities, tolerances, and preferred file formats, or about any unclear aspects of their design specifications. A clear exchange of information can drastically reduce errors and turnaround times. - Precise Component Footprints and Libraries

Verify all component footprints and library information to ensure accuracy. Incorrect footprints or part specifications can cause significant rework or result in defective PCBs. Use a reliable library and always double check it against the datasheet. - Proper Packaging of Your KiCad Project

Organize all necessary files such as Gerber, Excellon drill files, centroid data, and Bill of Materials (BOM) in a structured and labeled manner to avoid errors. If applicable include a schematic in pdf and any fabrication notes or important information. Make sure that the file names are easy to understand and follow the manufacturer's requirements, which will facilitate the manufacturer review. - Understanding Manufacturer's Design Specifications

Have a comprehensive understanding of your chosen manufacturer’s design rules, specifications, and requirements. Pay close attention to layer stackup, material properties, and manufacturing tolerances to ensure your design can be manufactured as intended. This includes specific limitations such as via types, impedance control requirements and surface finish options

Selecting the appropriate KiCad PCB manufacturer is a pivotal step in the journey from design to tangible product. With the right approach, you can transform your designs into reality with speed and efficiency. Choosing the right [kicad pcb manufacturer] can improve time to market, reduce development costs, and ensure the final product is of the highest quality. As technology continues to evolve, the integration between design software like KiCad and manufacturing processes will become even more seamless, enabling more creators to bring their innovations to life.

AnyPCBA

AnyPCBA