Finding the Right PCB Transformer Manufacturer: A Comprehensive Guide

In today's world, nearly every electronic device relies on printed circuit boards (PCBs), and transformers are often a critical component. Choosing the right PCB transformer manufacturer can significantly impact the performance and reliability of your products. This article will explore the essential aspects of selecting a PCB transformer manufacturer, from identifying your specific needs to understanding the options available.

Understanding PCB Transformer Types and Applications

PCB transformers are essential components in electronic circuits, serving to transfer electrical energy between circuits with varying voltage or current levels. These transformers, designed for direct mounting on printed circuit boards (PCBs), come in diverse types, each tailored for specific applications, encompassing power conversion, signal isolation, and impedance matching.

- Power Transformers

Primarily used in power supply circuits to step up or step down voltage levels. They operate at mains frequencies (e.g., 50Hz, 60Hz) or higher frequencies in switch-mode power supplies. Key characteristics include high power handling capacity and low losses. These are typically larger and heavier than signal or pulse transformers, and their selection is dictated by the power requirements of the circuit. For example, a power transformer could be needed to convert the 120V AC from a wall outlet to a lower voltage DC for circuit operation. - Pulse Transformers

Optimized for transmitting pulsed signals, essential in applications such as gate drivers in power electronics and isolated communication lines. They provide electrical isolation while transferring short-duration high voltage pulses. These transformers must have a very low leakage inductance and high isolation voltage and are selected based on pulse width, amplitude, and repetition rate requirements. For example, pulse transformers are critical for isolated gate driver circuits that switch power transistors on and off to deliver power. - Current Sense Transformers

Used to measure electrical current without directly inserting into the circuit. They provide a current proportional to the current in the main conductor while offering isolation, which is critical for safety and measurement integrity. The transformer's turns ratio determines the current output and they are selected according to required accuracy, current range and burden resistor value. A current transformer could be used in power inverters to measure current output, where its output is used by a control system to regulate power transfer. - Signal Transformers

Typically employed to match impedances, isolate circuits, or balance transmission lines. These transformers work across a range of frequencies and are critical for noise reduction, signal quality, and prevent unwanted ground loops. Signal transformers are usually smaller in size, designed for low signal levels, and they are selected based on the signal frequency band, impedance matching requirements, and isolation voltage. An example would be using a signal transformer to isolate an audio signal for audio equipment, preventing unwanted interference and noise.

When selecting a PCB transformer, it is important to consider voltage and current requirements, isolation needs, frequency of operation, and size constraints. The material used for the core (ferrite, amorphous, etc.) affects efficiency and cost. The physical footprint, and the operating environment of the circuit (temperature, humidity) must also be considered. Each transformer type serves unique needs, which require a detailed understanding of their specifications and capabilities to ensure the right choice is made for the intended application.

Key Factors to Consider When Selecting a PCB Transformer Manufacturer

Selecting the right PCB transformer manufacturer is crucial for ensuring the performance and reliability of your electronic devices. Several key factors should be carefully evaluated, including manufacturing capabilities, production capacity, quality certifications, lead times, and cost. A thorough assessment of these aspects will help you identify a manufacturer that aligns with your project requirements and business goals.

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | Assessing the manufacturer's ability to produce both standard and custom transformers, including their range of design options, core materials, and winding techniques. It is important to understand if they can meet the specific requirements of the desired transformer type (e.g., power, pulse, current sense). | High, ensures the manufacturer can produce transformers that meet specific application needs, whether standard or custom. |

| Production Volume Capacity | Evaluating the manufacturer's capability to handle your project's production volume, from small prototypes to large-scale manufacturing runs. This helps to ensure they can meet your demand. | High, necessary to ensure they can handle current and future needs. The capacity needs to align with project goals. |

| Quality Certifications | Verifying the manufacturer's quality management systems through certifications such as ISO 9001 or IATF 16949. Certifications demonstrate a commitment to consistent product quality and process control. | High, shows that the manufacturer adheres to standards. This certification helps ensure quality control throughout the manufacturing process. |

| Lead Times | Considering the manufacturer's typical lead times for transformer production. This helps in planning the project timeline, particularly if your project has time constraints. | Medium, influences project scheduling. Longer lead times can impact time to market. |

| Cost Considerations | Analyzing the overall cost of the transformers, considering both the initial price and potential long-term costs. Cost analysis should be balanced with quality requirements to ensure the transformers are both effective and economical. | Medium, but significant, cost needs to be balanced with quality to ensure both effectiveness and affordability of the transformers. |

Custom vs. Standard PCB Transformers: Which is Right for You?

Selecting between custom and standard PCB transformers hinges on a careful evaluation of your project’s specific needs, volume requirements, and budgetary constraints. While standard, off-the-shelf transformers offer cost-effectiveness and readily availability, they might lack the precise characteristics needed for specialized applications. Conversely, custom transformers from a pcb transformer manufacturer, while more expensive and requiring longer lead times, provide optimized performance and tailored fit, making them ideal for projects with demanding requirements.

When considering a custom transformer, several scenarios might justify the added investment. These could include applications with unusual voltage or current requirements, unique isolation needs, or strict size limitations. Custom transformers allow engineers to optimize every aspect of the transformer to ensure the best possible efficiency, performance, and integration with the rest of the PCB.

Evaluating the Technical Capabilities of a PCB Transformer Manufacturer

A thorough evaluation of a PCB transformer manufacturer's technical capabilities is crucial to ensure that they can meet your specific design and performance requirements. This assessment goes beyond simple production capacity and delves into the manufacturer's expertise in design, testing, and problem-solving.

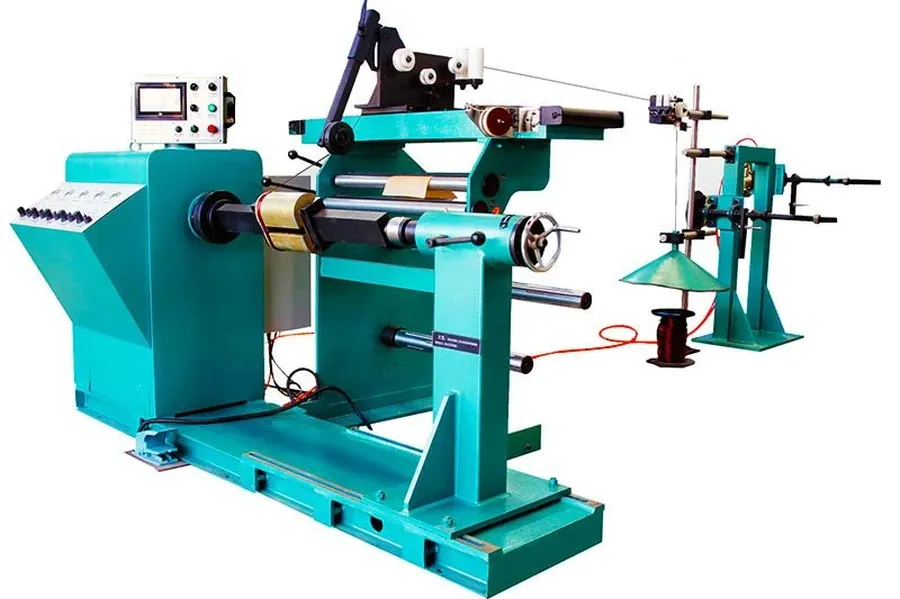

- Design Capabilities

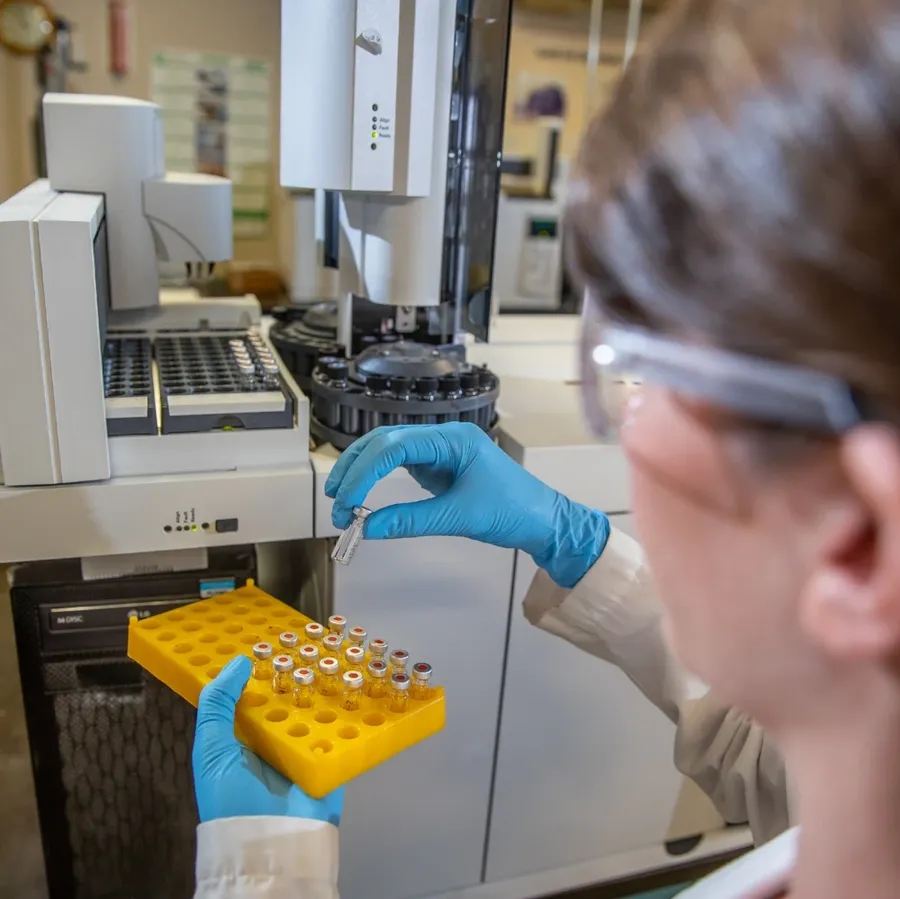

A competent manufacturer should demonstrate strong design proficiency. This includes the ability to perform simulations, optimize designs for performance and manufacturability, and handle complex requirements such as custom turns ratios, specific inductance values, and unique core geometries. Look for evidence of a dedicated team of engineers skilled in magnetics design and material science. - Testing and Validation Facilities

Robust testing facilities are paramount. The manufacturer should have access to equipment that can perform thorough testing, including measurements of inductance, leakage inductance, DC resistance, hipot testing for isolation, and temperature rise testing under load. Ensure that the manufacturer can provide testing data and validation reports with each product batch. Testing should adhere to relevant industry standards. - Ability to Meet Specific Technical Requirements

A good manufacturer will not only meet your basic needs but also demonstrate the ability to accommodate specific design challenges. This might include unusual voltage or current handling requirements, strict size and footprint limitations, or operation in harsh environments. Look for manufacturers with a track record of creating solutions for demanding specifications. - Design Assistance and Prototyping Services

The manufacturer should ideally offer design assistance, working with you to create the most effective transformer for your circuit. Furthermore, they should provide rapid prototyping services so you can test and validate a preliminary design before a large-scale production. This collaborative design approach will save time and ensure a smoother manufacturing process.

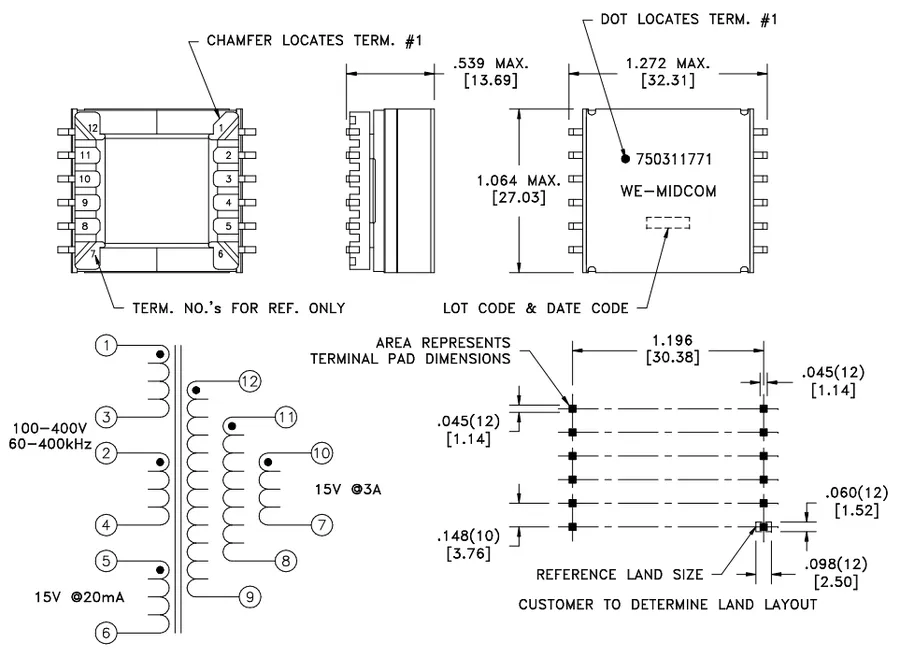

Navigating PCB Transformer Specifications and Data Sheets

Understanding PCB transformer specifications and data sheets is crucial for selecting the correct component for your application. These documents contain vital information regarding the transformer's electrical characteristics, physical dimensions, and performance capabilities, enabling engineers to make informed decisions about compatibility and performance within the overall PCB design.

Effectively comparing datasheets from different PCB transformer manufacturers requires a systematic approach focusing on key parameters that directly influence performance. These parameters typically include voltage ratings (primary and secondary), power handling capacity, operating frequency, isolation voltage, turns ratio, and physical mounting style. Ensuring each parameter aligns with the application’s needs is essential for proper operation and longevity of the final product.

| Specification | Description | Importance |

|---|---|---|

| Primary Voltage (V) | Rated input voltage the transformer is designed for. | Must match the source voltage to avoid damage and ensure proper operation. |

| Secondary Voltage (V) | Output voltage provided by the transformer. | Must meet the voltage requirements of the circuit the transformer is powering. |

| Power Handling Capacity (VA or W) | Maximum power the transformer can handle without overheating or failure. | Must be sufficient to supply the load demands of the circuit. |

| Isolation Voltage (Vrms) | Maximum voltage the transformer can withstand between primary and secondary without breakdown. | Ensures safety and prevents electrical shock or damage to connected devices. |

| Turns Ratio | The ratio of the number of turns in the primary winding to the number of turns in the secondary winding. | Determines the relationship between the input and output voltages and currents. |

| Operating Frequency (Hz) | Frequency range at which the transformer is designed to operate efficiently. | Ensures optimal performance of the transformer within the specified application. |

| Mounting Style | Method used to physically attach the transformer to the PCB, e.g., through-hole, surface mount. | Needs to be compatible with the circuit board layout and assembly process |

| Operating Temperature Range (°C) | Temperature range within which the transformer is designed to function. | Guarantees reliability under various operating environments. |

| Dimensions (mm) | Physical dimensions of the transformer, including height, width, and depth. | Crucial for ensuring the transformer fits within the space constraints of the PCB layout. |

Beyond these standard specifications, look for specific test conditions described in the datasheet. These conditions may include operating temperature, humidity, and load conditions, which are critical for verifying the performance and reliability of a transformer. Always evaluate the test results based on the specified conditions to make sure the PCB transformer is suitable for your specific application environment.

The Importance of Quality and Reliability in PCB Transformers

The reliability of a PCB transformer is paramount for the overall performance and longevity of electronic devices; therefore, the selection of a manufacturer who prioritizes stringent quality control processes is crucial. This involves meticulous material selection, rigorous testing protocols, and adherence to industry standards to ensure consistent performance.

The interplay of material selection, quality control processes, and stringent testing forms a robust foundation for the reliable operation of a PCB transformer. Each of these pillars is essential to minimize the risk of failure and ensure the longevity of the transformer.

- Material Selection

High-quality core materials (ferrite, amorphous metals), insulation materials (enameled wire, tapes), and terminations (solder, pins) are essential for optimal performance and reliability. The materials must be selected to withstand the operating conditions the transformer is intended for, including temperature, humidity, and mechanical stress. A reputable manufacturer will have robust procurement process in place to ensure that only materials that meet strict specifications are utilized. - Quality Control Processes

A manufacturer's commitment to quality should be evident in their QC processes. These processes typically involve in-process checks and final inspections, and must include electrical testing for parameters like inductance, turns ratio, leakage inductance, and isolation voltage. Furthermore, manufacturers should have well documented systems in place that clearly outlines the steps that will be taken in the event of a non-conformity. Statistical process control (SPC) should be utilized to identify and correct issues that would lead to variations in the process. - Testing Protocols

PCB transformers should undergo a battery of tests to evaluate their suitability for various applications. In addition to electrical testing, the manufacturer should perform environmental tests, including temperature cycling, humidity exposure, and vibration testing. These tests mimic the various conditions the transformer will be subjected to during its operational life, and the results provide critical validation data on the design and manufacturing processes. The results of these tests should be readily available to their customers.

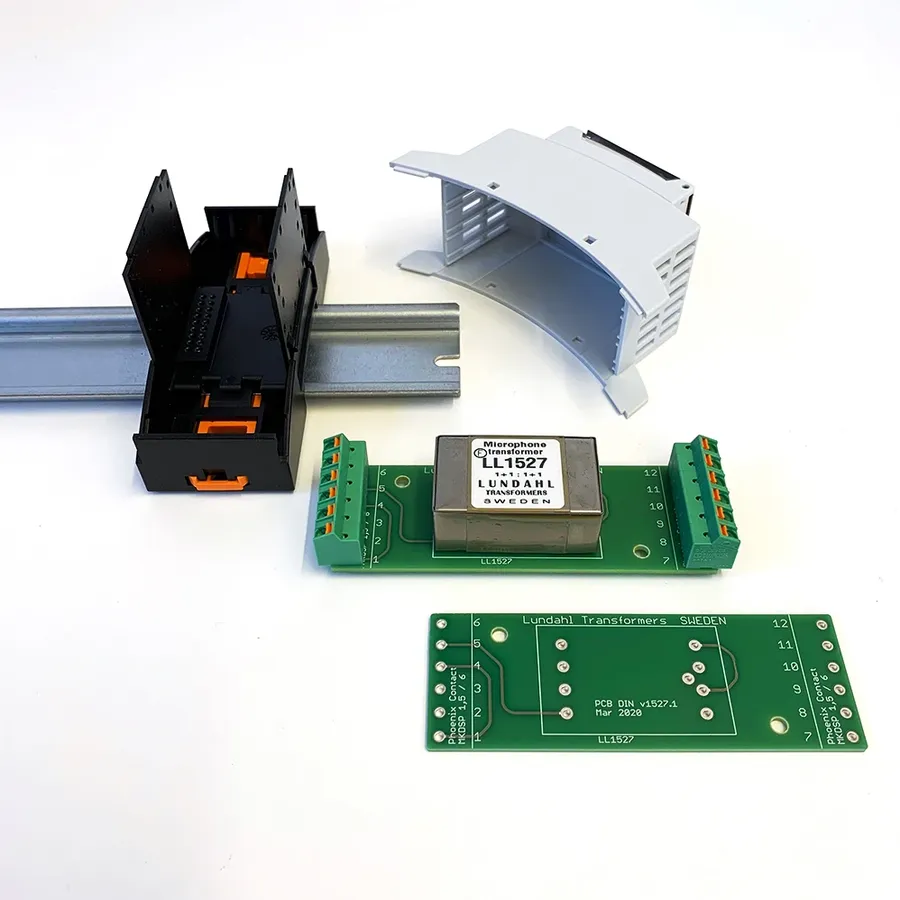

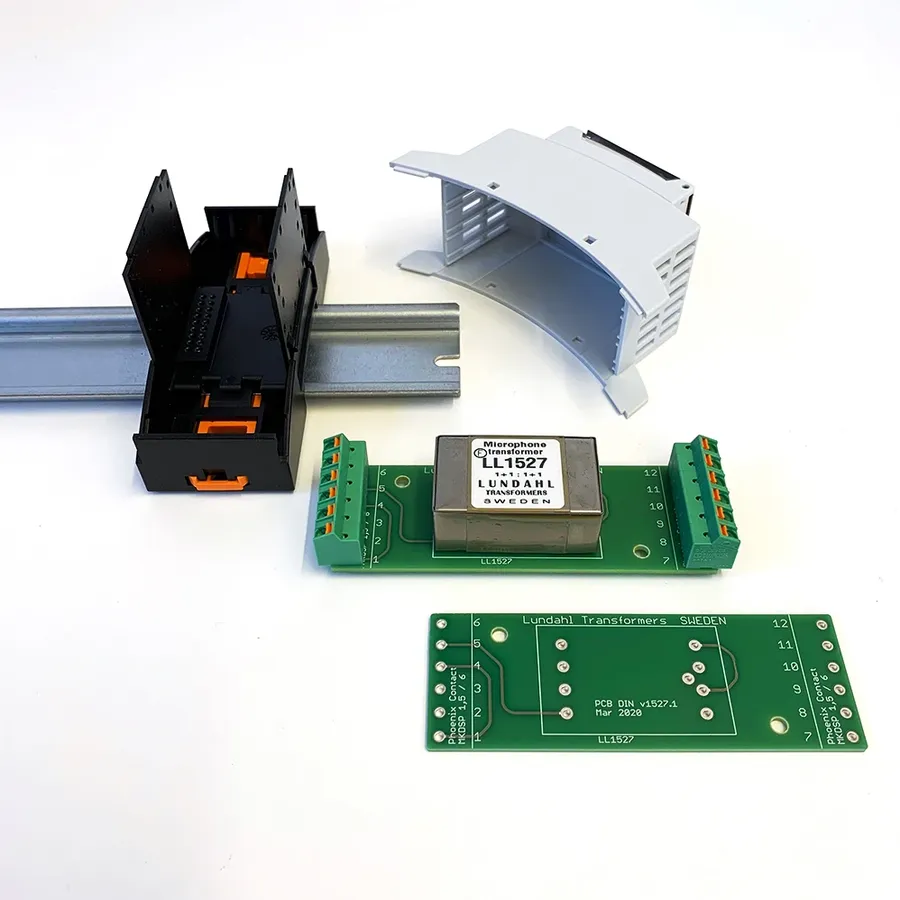

PCB Transformer Mounting Options: Surface Mount (SMD) vs. Through-Hole

Selecting the appropriate mounting technique for PCB transformers—Surface Mount (SMD) or Through-Hole (TH)—is a crucial design consideration that impacts both manufacturing processes and the final product's performance. The choice between these two methods hinges on factors such as component size, assembly costs, and the required mechanical stability.

| Feature | Surface Mount (SMD) | Through-Hole (TH) |

|---|---|---|

| Component Size | Typically smaller, allowing for higher component density | Larger components, requiring more board space |

| Assembly Process | Automated assembly using pick-and-place machines and reflow soldering | May require manual placement and wave soldering or selective soldering |

| Cost | Generally lower assembly cost, especially for high-volume production | Higher assembly costs due to more complex and manual assembly steps |

| Mechanical Strength | Lower mechanical strength compared to through-hole, more susceptible to stress | Higher mechanical strength due to pins inserted through the PCB, better suited to harsh environments. |

| Thermal Performance | Can have challenges with heat dissipation due to smaller contact area | Better heat dissipation due to larger pin contacts |

| Design Flexibility | Less flexible for prototyping and manual rework | More flexible for prototyping and manual rework and suitable for quick testing or modifications |

| PCB Layers | Compatible with multi-layer PCBs and fine-pitch components | May be limited by PCB layer count and the need for plated through-holes |

| Applications | Ideal for mass-produced, compact electronic devices | Often used in applications requiring higher power and mechanical reliability |

A pcb transformer manufacturer must facilitate both mounting techniques to cater to diverse customer needs. This includes providing transformers designed for either SMD or TH mounting, and offering support with design considerations for each. SMD transformers are often favored for their high density and suitability for automated production, while TH transformers offer enhanced mechanical robustness and may be preferred for specific applications that demand extra structural integrity, such as in harsh environments or high power applications where the device will be subject to mechanical stress. The choice between them will depend on the specific needs of your application and the manufacturing processes you have in place.

Frequently Asked Questions About PCB Transformers: A Guide for Buyers

This section addresses common questions about PCB transformers, providing clarity on selection criteria, certification requirements, lifespan expectations, and typical failure modes. Understanding these aspects is crucial for making informed decisions when selecting a PCB transformer manufacturer.

- What are the primary factors to consider when selecting a PCB transformer?

Key considerations include voltage and current ratings, isolation requirements, size constraints, operating frequency, and the specific application. Additionally, the transformer's environmental operating conditions should be factored in. Selecting a transformer that meets or exceeds these requirements ensures optimal performance and safety of your PCB design. - What certifications are typically required for PCB transformers?

Certifications vary depending on the application and region. Common certifications include UL (Underwriters Laboratories), CE (Conformité Européenne), and CSA (Canadian Standards Association). These certifications indicate compliance with safety standards and provide assurance of product quality. It is essential to verify which certifications are required for your specific end-product and geographical location. When choosing a PCB transformer manufacturer, ensure they can provide all necessary certification documentation. - What is the expected lifespan of a PCB transformer?

The lifespan of a PCB transformer depends on several factors, including its operating conditions (temperature, load, humidity), the quality of materials used in its construction, and the manufacturing processes employed. High-quality transformers, when used within their specified ratings, can last for many years (typically 10-20 years). However, operating the transformer outside of its specified ratings, or exposure to extreme environmental conditions can drastically reduce its lifespan. - What are the most common failure modes in PCB transformers?

Common failure modes include insulation breakdown due to overvoltage or thermal stress, open or shorted windings, core saturation from excessive current, and mechanical damage due to vibration or mishandling. It is crucial for a pcb transformer manufacturer to address each of these possible failure modes during the design and testing phases of transformer development. - What are the advantages of using custom PCB transformers?

Custom PCB transformers allow for optimization of performance, size, and cost for a specific application. When off-the-shelf solutions cannot meet your needs due to space constraints, unique voltage or current requirements, or when high efficiency and specific regulatory criteria need to be met, a custom solution from a PCB transformer manufacturer can be invaluable. Custom designs allow for exact component optimization, which is not feasible with standard transformers. - How do I choose the correct mounting method for a PCB transformer? (SMD vs. Through-Hole)

The choice between Surface Mount (SMD) and Through-Hole (THT) mounting depends on the design requirements and manufacturing processes. SMD components are typically used for high-density, automated assembly where weight and size are critical. THT components are generally more robust and easier to handle manually, making them suitable for high-power applications. The PCB transformer manufacturer will often guide you on the best mounting method depending on component size, power requirements, and production capabilities. - How do I find the right PCB transformer manufacturer?

Finding the right manufacturer involves several steps: first, determine your specific requirements, then research manufacturers with a suitable product range and manufacturing capabilities. Look for manufacturers with relevant certifications, good customer reviews, and proven reliability. Request samples, evaluate their design assistance, and assess their lead times before selecting a manufacturer for your PCB transformer needs.

Comparative Analysis of Top PCB Transformer Manufacturers

Selecting the right PCB transformer manufacturer is crucial for ensuring the performance and reliability of electronic products. This section provides a comparative analysis of several leading manufacturers, offering a structured overview to aid in the shortlisting process. This analysis considers product range, certifications, and customer reviews, providing a concise yet comprehensive view.

| Manufacturer | Product Range | Certifications | Customer Reviews | Customization Options | Lead Times |

|---|---|---|---|---|---|

| Manufacturer A | Wide range of standard and custom transformers, including low-profile and high-frequency designs. | ISO 9001, UL, RoHS | Generally positive feedback regarding product quality and reliability. Some comments on lead times. | Offers extensive customization for core materials, winding specifications, and packaging. | Standard products are readily available, while custom orders vary, usually 4-8 weeks. |

| Manufacturer B | Specializes in high-power transformers and custom solutions for industrial and automotive applications. | ISO 14001, IATF 16949, VDE | Known for strong technical support and ability to meet demanding specifications. Some users find them expensive. | Provides complete customization from design to final product, often assisting with prototyping. | Custom solutions require 8-12 weeks. Production volume dependent. |

| Manufacturer C | Offers a broad range of surface mount (SMD) and through-hole PCB transformers. Competitive pricing. | ISO 9001, CE, Reach | Good value for money. Occasionally mixed feedback on response time for complex technical support. | Offers some customization options within standard product lines. | Readily available for most standard products. Customization requires discussion. |

| Manufacturer D | Focuses on high-frequency and pulse transformers with good performance in compact designs. | ISO 9001, RoHS Compliant, various industry specific certifications. | Positive reviews for high quality and good performance. Some complaints regarding MOQ. | Limited customization options for standard product line, but capable for large volume orders. | Lead time for standard products is good but minimum order quantities may apply. Large volume orders have negotiable timelines. |

| Manufacturer E | Specializes in custom designed transformers, with extensive experience in multiple industries. | ISO 9001, 14001 and others dependant on the industry. | Known for expertise and collaborative approach with customers. Some reviews mention high cost associated with smaller orders. | Full design and customization from small quantity to large volume. | Custom designed and built transformers have a lead time of 6-10 weeks, based on volume. |

Choosing the right PCB transformer manufacturer is crucial for the performance and reliability of your electronic products. By carefully considering your specific requirements, the technical capabilities of the manufacturer, and the various transformer options available, you can ensure you find a partner who provides high-quality solutions tailored to your needs. Remember to prioritize reliability, quality, and cost-effectiveness when making your selection, and always consider a pcb transformer manufacturer that can meet your long-term needs.

AnyPCBA

AnyPCBA